Grinding process applied to high-precision and easy-to-assemble hub unit

A hub unit and easy-to-assemble technology, which is applied in the field of high-precision and easy-to-assemble hub unit grinding technology, can solve the problems of poor coaxiality, poor running stability, and short service life in channel processing, and achieve high precision and long service life. Long, wear-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

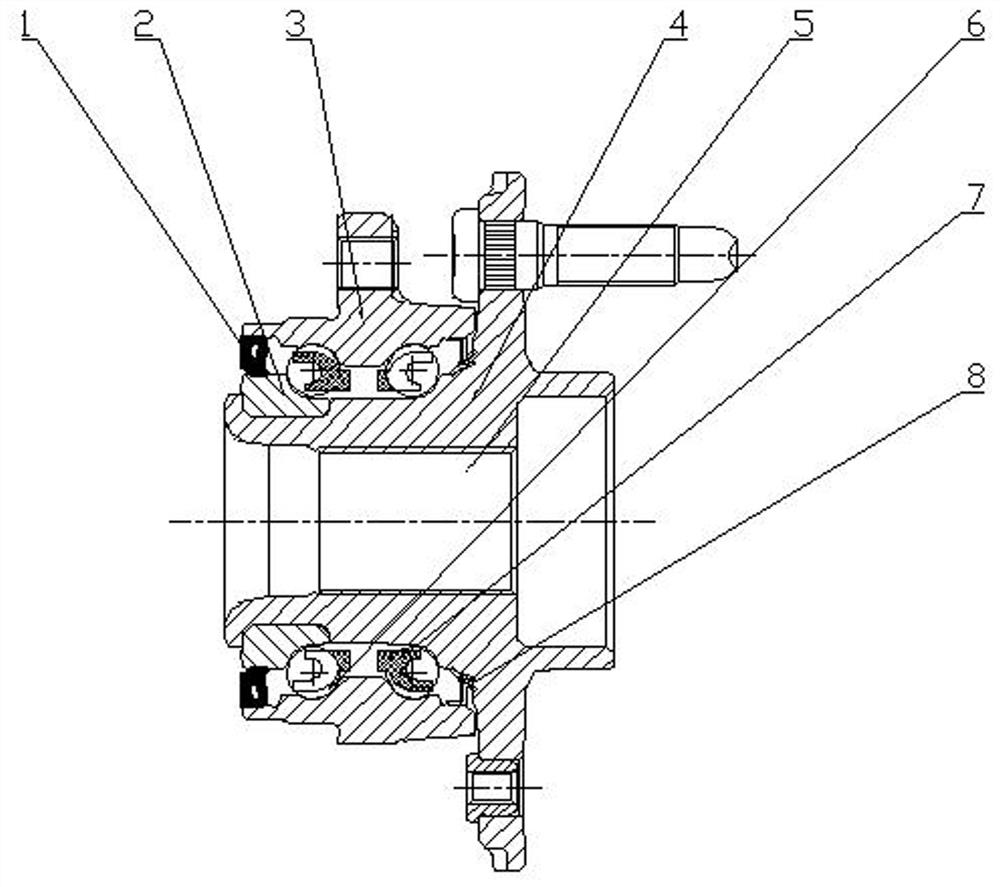

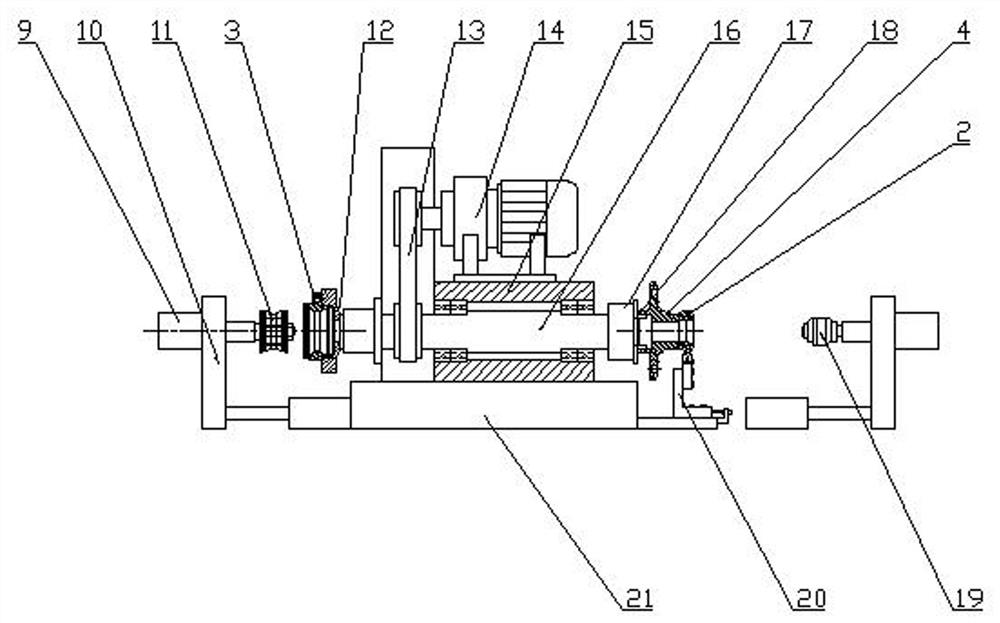

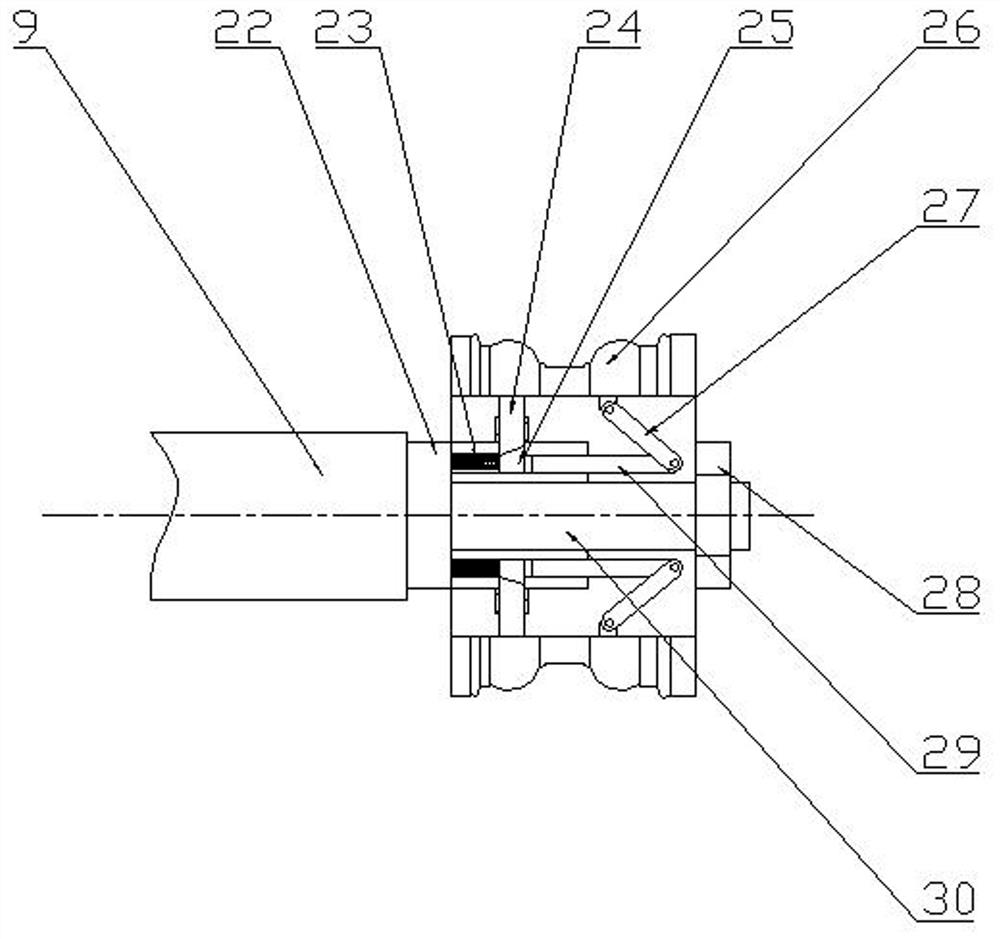

[0030] Example: such as Figure 1-5 As shown, a hub unit includes a hub flange 4, the hub flange 4 is provided with a spline hole 5 that is integrated with the hub flange 4, and the hub flange 4 is provided with a nested hub flange 4 The inner ring 2 is connected. The inner ring 2 is provided with an outer ring flange 3 that is sleeved with the hub flange 4 at intervals. The outer ring flange 3 and the inner ring 2, and the outer ring flange 3 and the hub flange 4 are both A cage 7 is provided. The cage 7 is provided with 8 steel balls 6 nested and connected with the cage 7, and the inner ring 2 is provided with a snap-fit socket between one end of the outer ring flange 3 and the inner ring 2 A multi-lip skeleton sealing ring 8 is provided between the magnetic sealing ring 1, the other end of the outer ring flange 3 and the hub flange 4.

[0031] The wheel hub unit grinding process applied to high precision and easy to assemble is characterized by including the following opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com