Hydraulic device for miniature numerical control machine tool

A technology for CNC machine tools and hydraulic devices, applied in the field of hydraulic devices, can solve the problems of easy locking of cylinders, easy corrosion of machine tools and water generation, etc., and achieves the effect of simple structure and improved work stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

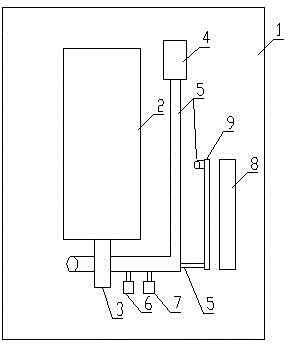

[0011] Depend on figure 1 A hydraulic device for a small numerically controlled machine tool is composed of an oil tank 1, an oil supply device and an oil circuit cooling device; the oil supply device and the oil circuit cooling device are arranged in the middle and right parts of the oil tank 1; The oil supply device includes a drive motor 2, an oil pump 3, a single-head solenoid valve 4, an oil pipe 5, a pressure regulating valve 6 and a pressure gauge 7; the oil circuit cooling device includes an oil pipe 5, a cooling fan 8 and a heat sink 9 .

[0012] When working, the drive motor 2 drives the oil pump 3 to extract the hydraulic oil from the oil tank 1 and divide it into two paths, one path passes through the oil pipe 5 and delivers it to the single-head solenoid valve 4 through the pressure regulating valve 6 and pressure gauge 7 in turn. 7 to adjust the pressure regulating valve 6 to control the oil pressure in the oil pipe 5 within the working requirements. The single-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com