Gas supply circuit used for controlling low-temperature gas-liquid connector

A connector and gas-liquid technology, applied in the direction of gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve problems such as termination of the launch process, impact on the launch process, failure to achieve target requirements, etc., to improve reliability and improve The effect of job reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

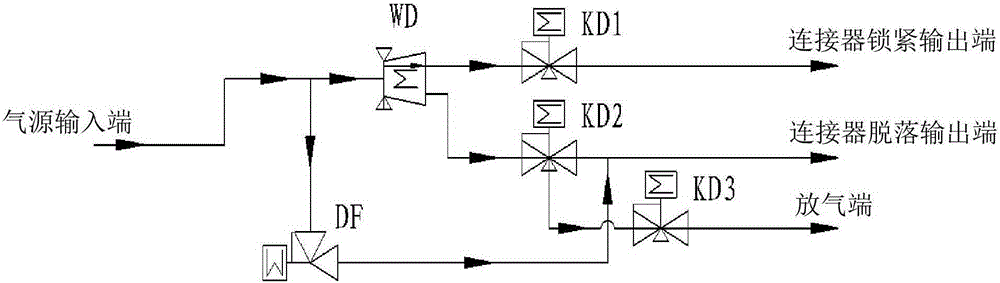

[0019] figure 1 It shows a schematic structural diagram of the gas supply circuit for the control of the low-temperature gas-liquid connector provided by Embodiment 1 of the present invention, see figure 1 , the gas supply circuit for the control of the low-temperature gas-liquid connector provided in Embodiment 1 of the present invention includes:

[0020] air source input;

[0021] Two-position five-way solenoid valve WD, the first end of the two-position five-way solenoid valve WD is connected to the air source input port;

[0022] The first normally open solenoid valve KD1, the first end of the first normally open solenoid valve KD1 is connected to the second end of the two-position five-way solenoid valve WD;

[0023] The second normally open solenoid valve KD2, the first end of the second normally open solenoid valve KD2 is connected to the third end of the two-position five-way solenoid valve WD;

[0024] The connector locking output end is connected to the second en...

Embodiment 2

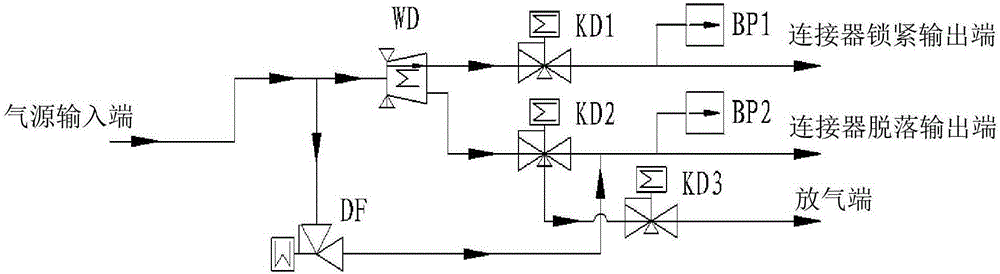

[0037] figure 2 It shows a schematic structural diagram of the gas supply circuit for the control of the low-temperature gas-liquid connector provided by Embodiment 2 of the present invention, see figure 2 In addition to all the components shown in Embodiment 1, the air supply circuit for the control of the low-temperature gas-liquid connector provided by Embodiment 2 of the present invention also includes: a first pressure sensor BP1 and / or a second pressure sensor BP2; in:

[0038] The first pressure sensor BP1 is arranged between the connector locking output end and the second end of the first normally open solenoid valve KD1;

[0039] The second pressure sensor BP2 is arranged between the output end of the connector disconnection and the second end of the second normally open solenoid valve KD2.

[0040] Wherein, the first pressure sensor BP1 and / or the second pressure sensor BP2 can monitor the working conditions of the gas supply circuit, that is, the first pressure ...

Embodiment 3

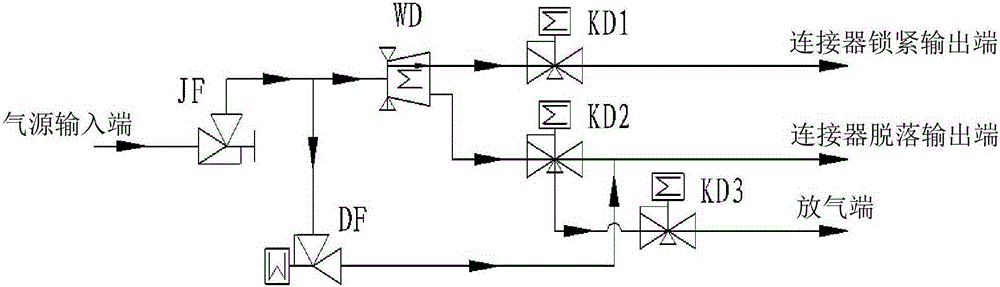

[0044] image 3 It shows a schematic structural diagram of the gas supply circuit for the control of the low-temperature gas-liquid connector provided by Embodiment 3 of the present invention, see image 3 In addition to all the components shown in Embodiment 1, the air supply circuit for the control of the low-temperature gas-liquid connector provided by Embodiment 3 of the present invention also includes: a manual shut-off valve JF;

[0045] The manual cut-off valve JF is arranged between the air source input end and the connection point between the first end of the two-position five-way solenoid valve WD and the first end of the two-position two-way solenoid valve DF.

[0046] Wherein, the manual shut-off valve JF can be an unloading manual shut-off valve, which can be used as an air source on-off valve for controlling the entire air supply circuit; the embodiment of the present invention sets the manual shut-off valve JF at the front end of the air supply circuit, In addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com