High-temperature-resistant minisize adjustable plunger-type lubrication flow pump

An adjustable, plunger-type technology, applied in the direction of pressure lubrication of lubricating pumps, piston pumps, variable-capacity pump components, etc., can solve the problems of non-variable, non-interrupted liquid supply, large flow, etc. Death, improve the effect of high temperature work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

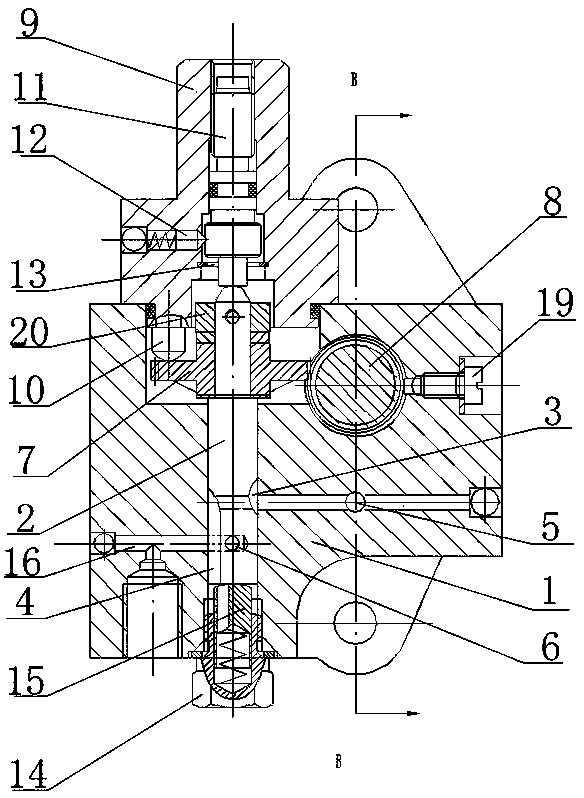

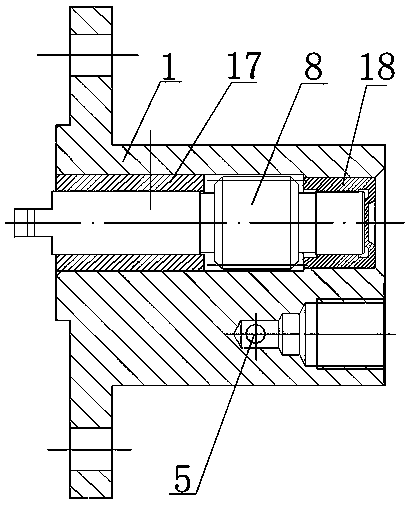

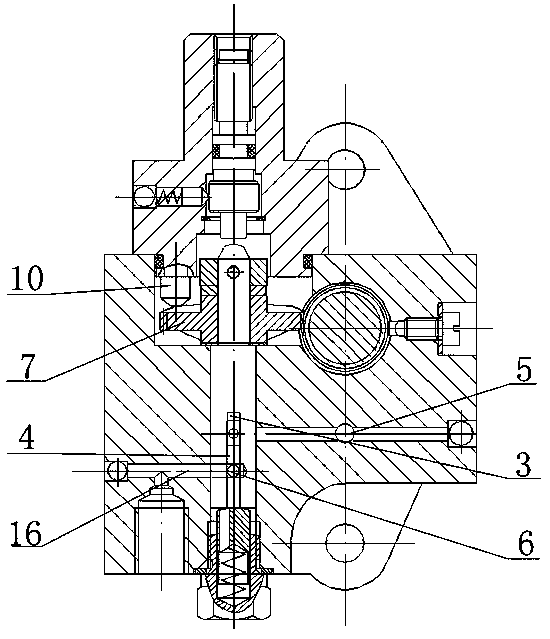

[0022] The high temperature resistant miniature adjustable plunger type lubricating flow pump includes a pump body 1, a counterbore is opened on the top surface of the pump body 1, a piston rod counterbore is opened at the bottom of the counterbore, and a piston rod counterbore is arranged inside the counterbore. There is a piston rod 2 whose outer diameter matches the piston rod counterbore, a spring is supported between the lower end of the piston rod 2 and the bottom of the piston rod counterbore, and the side walls of the piston rod 2 are respectively along the circumferential direction and the generatrix direction of the piston rod 2 There are horizontal oil guide grooves 3 and vertical oil guide grooves 4 oppositely arranged. A through hole is provided between the horizontal oil guide groove 3 and the vertical oil guide groove 4. The horizontal oil guide groove 3 and the vertical oil guide groove 4 are connected. The central angle of the pair is less than or equal to 90 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com