Vertical-shaft sand making machine

A sand making machine and vertical shaft technology, which is applied in the field of mining machinery and equipment, can solve the problems of low rotor speed, different performance of the whole machine, wear and tear of the machine body, etc., achieve the effect of increasing the rotor speed, facilitating maintenance and replacement, and solving the locking effect of the main shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

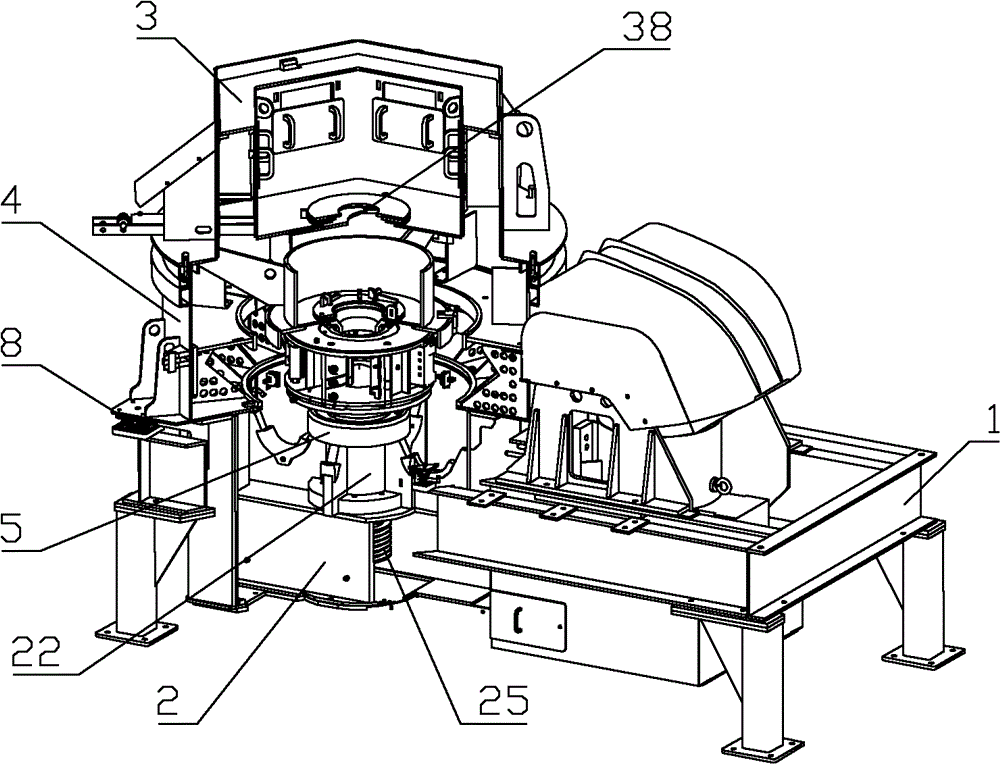

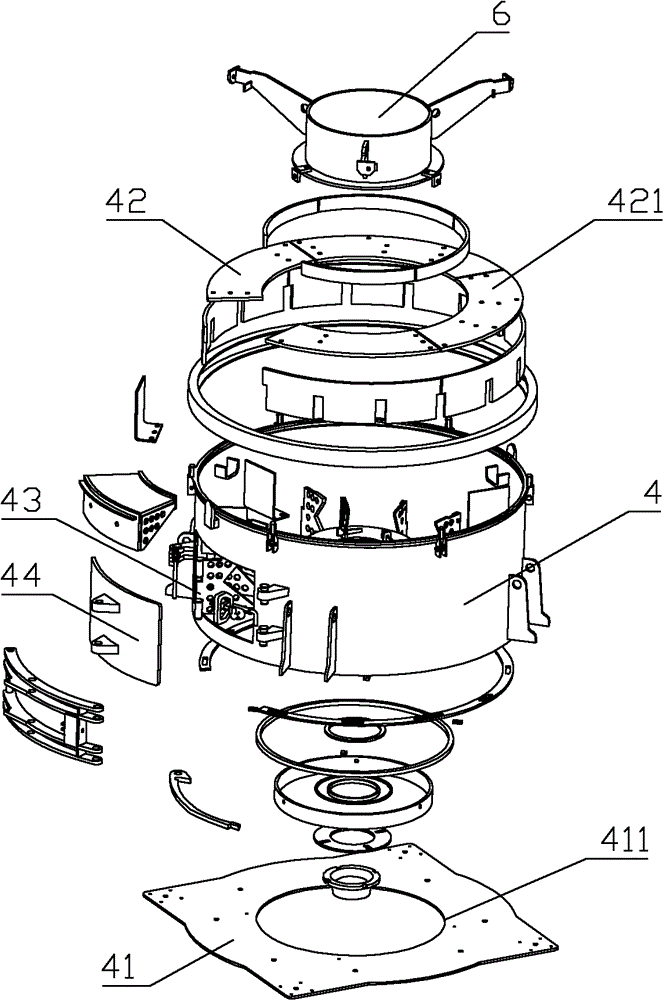

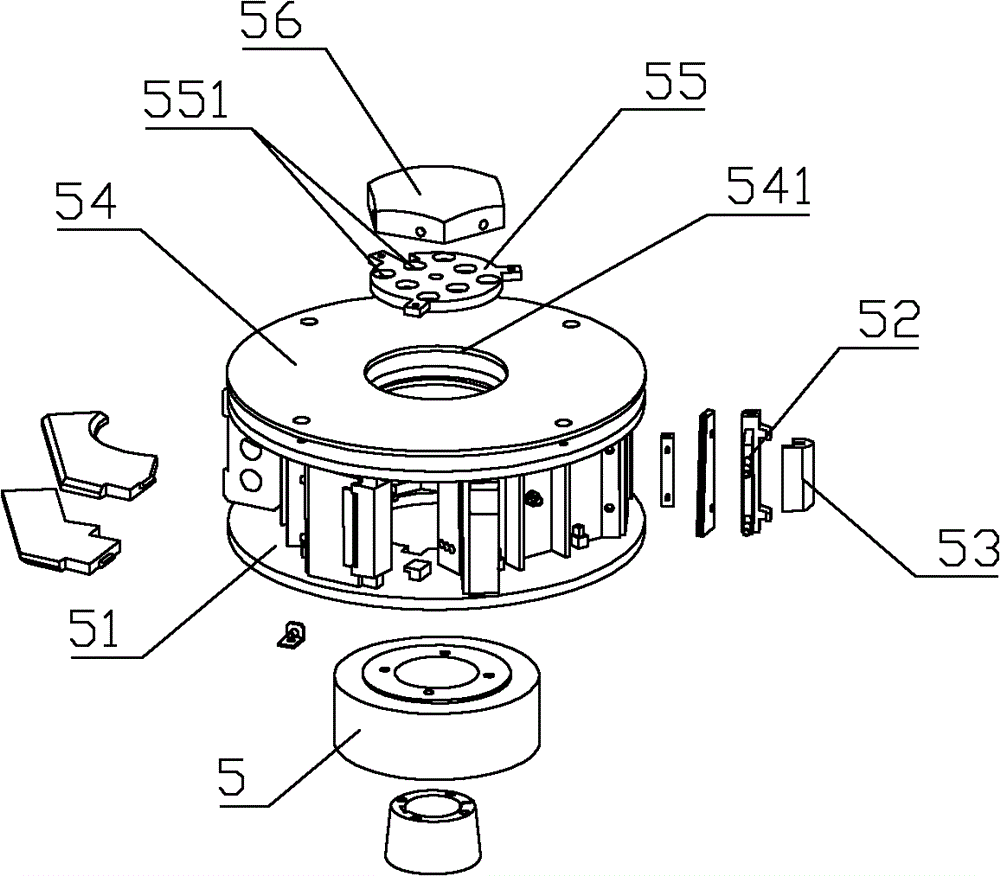

[0025] Such as Figures 1 to 9 A schematic structural view of an embodiment of the present invention is shown, a vertical shaft sand making machine, including a frame 1, a vertical shaft box seat 2 is arranged on the frame, and a vertical shaft assembly driven by a motor is arranged in the vertical shaft box seat. A crushing assembly for crushing stones is provided above the vertical shaft assembly, and a feed hopper 3 is provided above the crushing assembly. The crushing assembly includes a crushing chamber assembly fixed on the frame and a The components are connected to the rotor component that crushes the stone. There is a feeding channel between the feeding hopper and the crushing cavity component to communicate with each other, and a lubrication system is provided in the vertical shaft component.

[0026] The crushing chamber assembly includes a crushing chamber cylinder 4 fixed on the frame, a lower cylinder cover 41 arranged at the lower end of the crushing chamber cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com