A leak-proof device for the gluing mechanism of an edge banding machine

A technology of anti-leakage device and edge banding machine, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of poor sealing of the gluing mechanism, leakage of glue, and short bearing life, so as to reduce the storage amount of glue. , Reduce the possibility of glue leakage, good leakage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

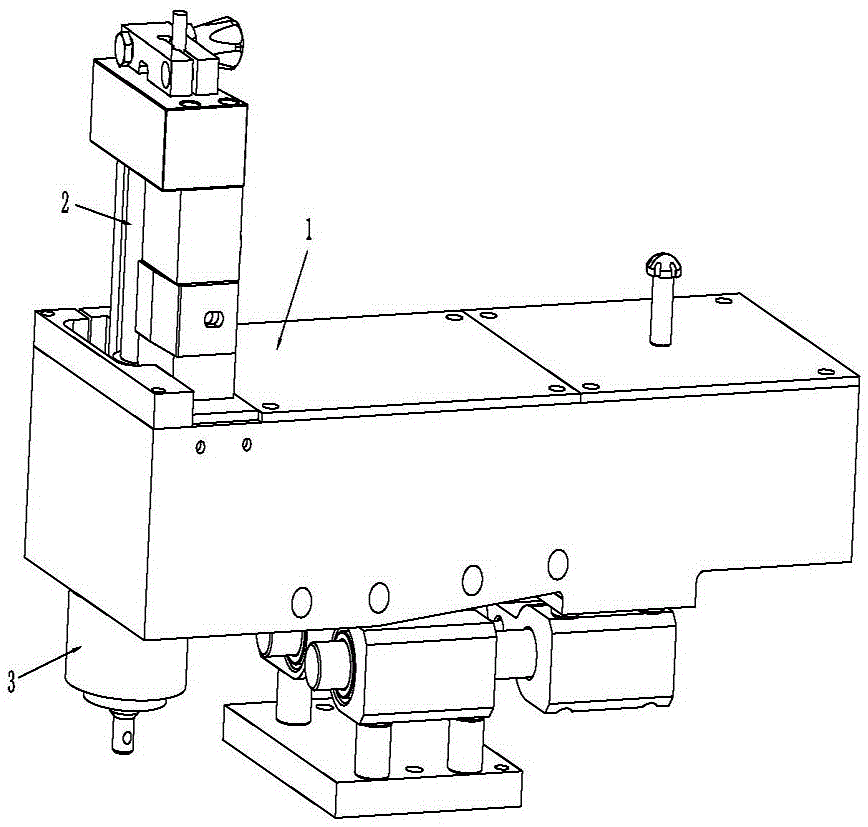

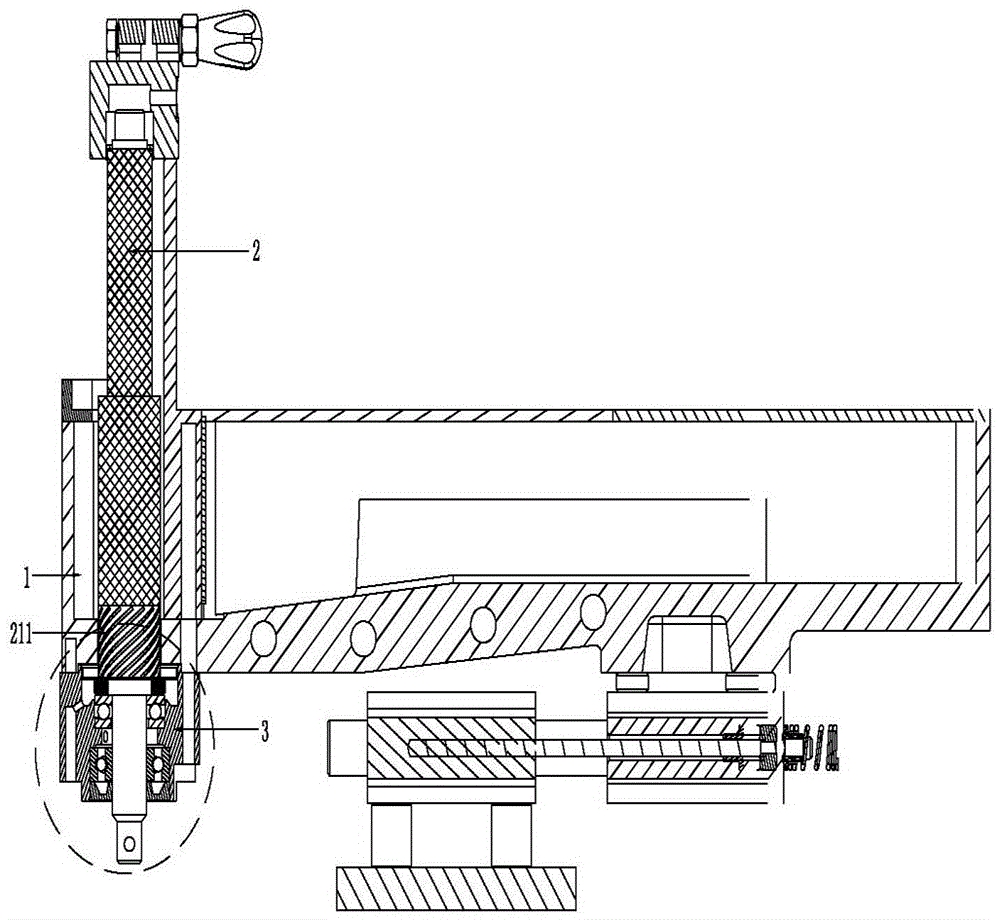

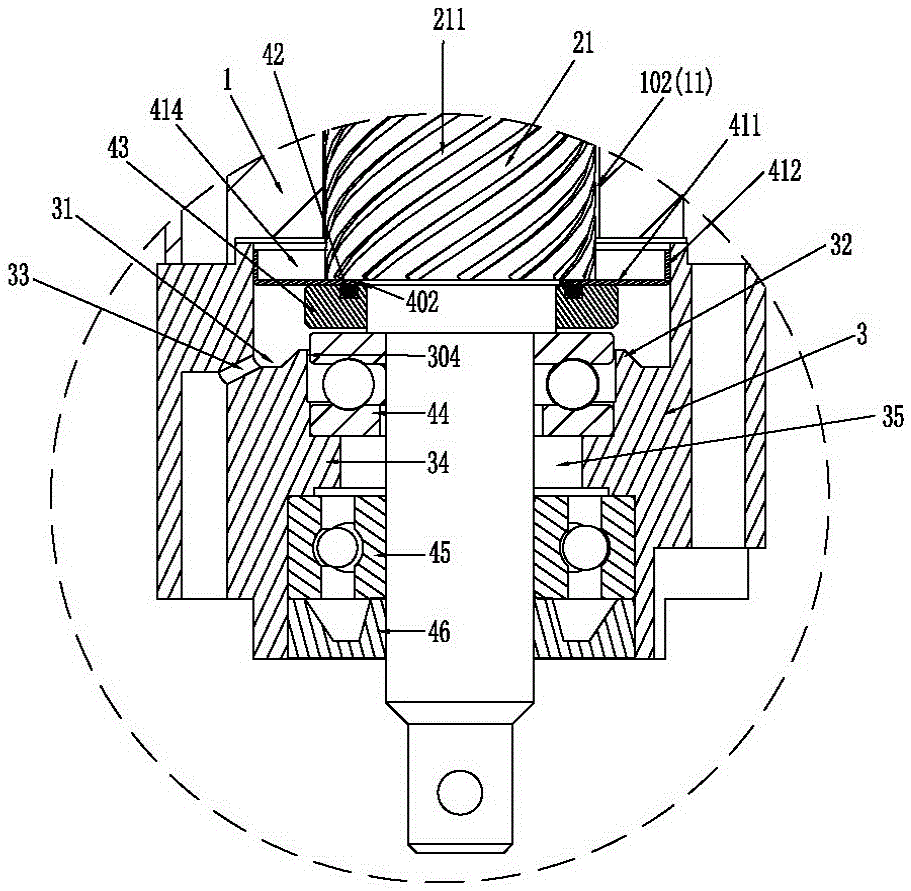

[0047] Please refer to Figure 1 to Figure 5Shown in (b), it has shown the concrete structure of preferred embodiment of the present invention, and it comprises parts such as glue supply box 1, glue-applying shaft 2 and rubber-feeding wheel seat 3, wherein, this glue-applying shaft 2 comprises The gluing shaft working part 21 and the gluing shaft connecting part 22 fixedly connected to each other; the gluing shaft connecting part 22 is rotatably connected in the rubber supply wheel seat 3, and the bottom end of the gluing shaft connecting part 22 passes through The rubber wheel seat 3 extends out of the bottom end of the rubber wheel seat 3, and the glue shaft connection part 22 is responsible for sealing and power transmission; the bottom of the aforementioned glue supply box 1 is provided with a bottom hole 11 for the glue shaft 2 to pass through. The gluing shaft working part 21 vertically penetrates the glue supply box 1 through the bottom hole 11 and protrudes from the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com