Novel hydraulic breaker oil way with function of preventing piston from being stuck

A technology of hydraulic crushing and hydraulic oil, which is used in mechanically driven excavators/dredgers, earthmoving machines/shovels, construction, etc. Body hole and piston hydraulic clamping force and friction force, etc., to reduce hydraulic clamping force and friction force, improve production efficiency, and solve the effect of locking and straining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

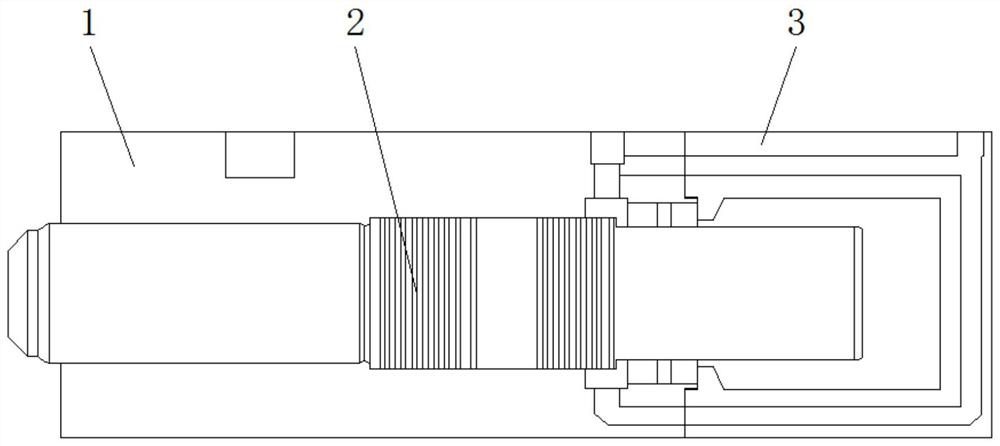

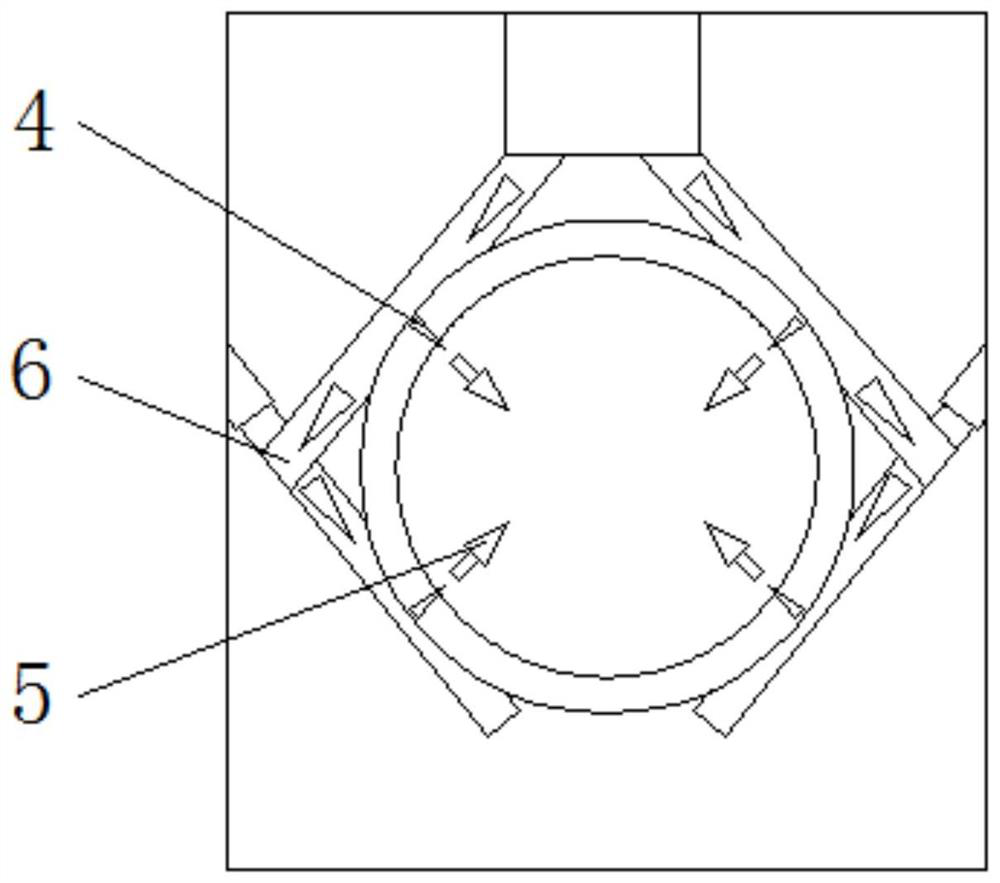

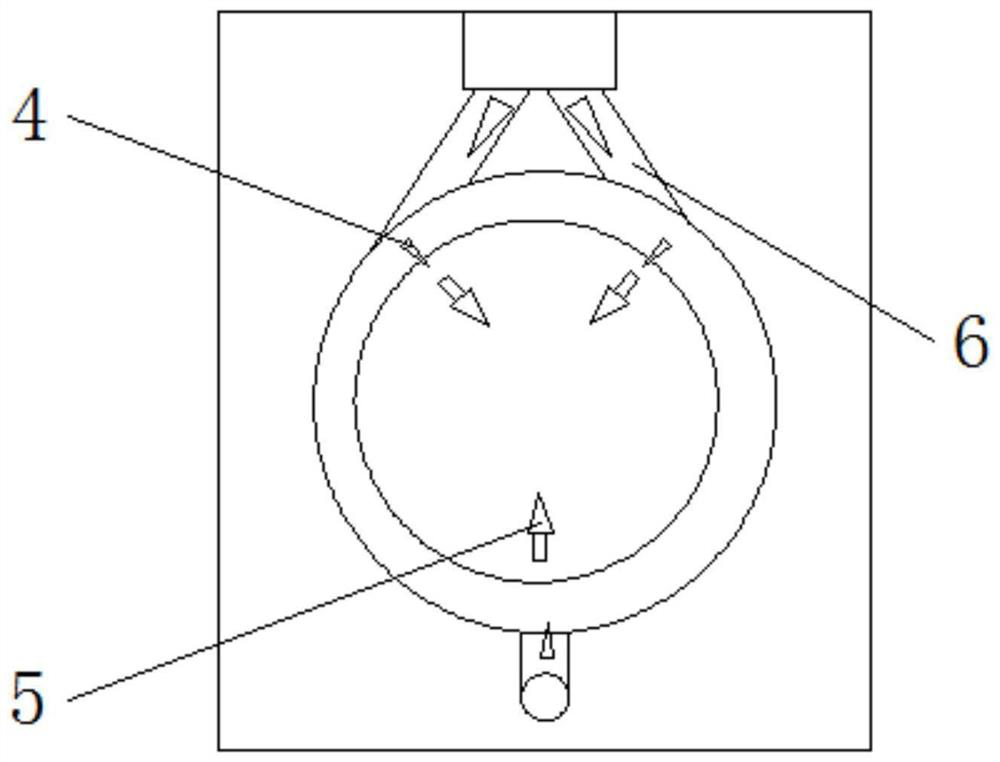

[0016] refer to Figure 1 to Figure 3 A further description will be given to an embodiment of the oil circuit of a novel hydraulic breaker with anti-piston stuck in the present invention.

[0017] A new hydraulic breaker oil circuit with anti-piston stuck, see figure 1 and 2 , comprising a middle cylinder 1 and a rear cylinder 3, the middle cylinder 1 and the rear cylinder 3 are fixedly connected, and the inside of the middle cylinder 1 is provided with a piston 2, the piston 2 passes through the rear cylinder 3, and the inside of the middle cylinder 1 All are provided with an oil passage 6, and the hydraulic oil in the internal oil passage 6 of the middle cylinder 1 flows into the inside of the middle cylinder 1 from the middle cylinder hole provided on the middle cylinder 1 along a plurality of symmetrical directions. The hydraulic oil in the oil circuit 6 is input or output from multiple symmetrical directions, so that the force on the periphery of the piston 2 is uniform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com