Conveying device for wood floor

A transmission device and wooden floor technology, which is applied in the field of wooden floor processing equipment components, can solve the problems of increased economic costs, achieve reduced economic costs, increase service life, and solve the effects of chain and track lockup and severe wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

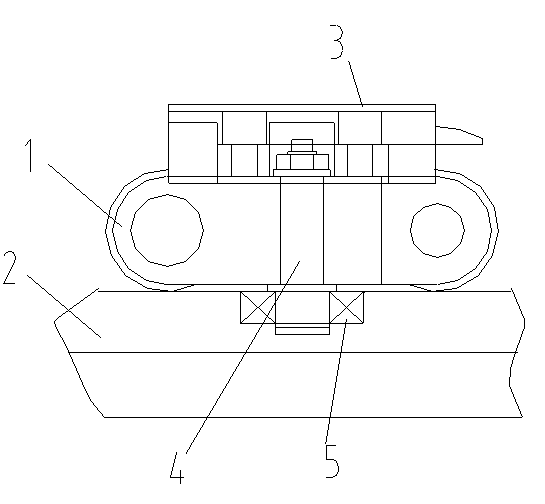

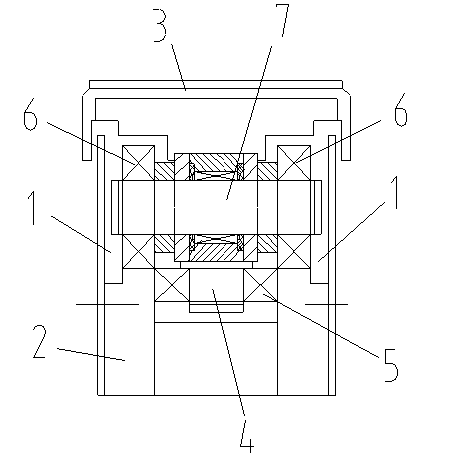

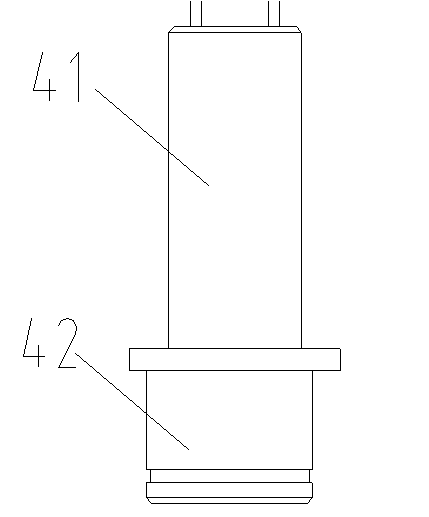

[0012] as attached figure 1 , 2 , 3 shows a wooden floor transmission device according to the present invention, comprising a chain, a guide rail 2, a support panel 3, a guide shaft 4, and a guide wheel 5; the chain moves along the guide rail 2; the support panel 3 is set On the chain; the upper end of the guide shaft 4 is arranged on the chain; the lower end of the guide shaft 4 is arranged in the guide rail 2; the upper end of the guide shaft 4 is fixed with a nut; the lower end of the guide shaft 4 is provided with a guide Wheel 5; the guide shaft 4 includes a main shaft 41 and an eccentric shaft 42; the main shaft 41 and the eccentric shaft 42 are arranged in parallel, and the central axes of the main shaft 41 and the eccentric shaft 42 are not collinear; the chain includes a plurality of A chain link unit; the chain is formed by connecting the chain link units end to end; the chain link unit includes a chain link 1, a bearing 6, and a rotating shaft 7; both ends of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com