Mechanical fault judgment system and method based on noise test

A technology for mechanical failure and noise testing, applied in vibration testing, testing of mechanical components, testing of machine/structural components, etc. It can solve problems such as complex, difficult, and signal pollution by noise, and achieve simple system settings and reduced economic costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In the fully enclosed, precision-level semi-free sound field anechoic test room, at a position 10cm away from the front of the first cylinder, the noise signal of the 4135 unit was collected with a high-frequency microphone. According to the characteristics of the diesel engine noise signal, the sampling frequency is set at 22.05kHz, and different valve clearance fault acquisition signals are set at different speeds, and the sampling time length is 2s.

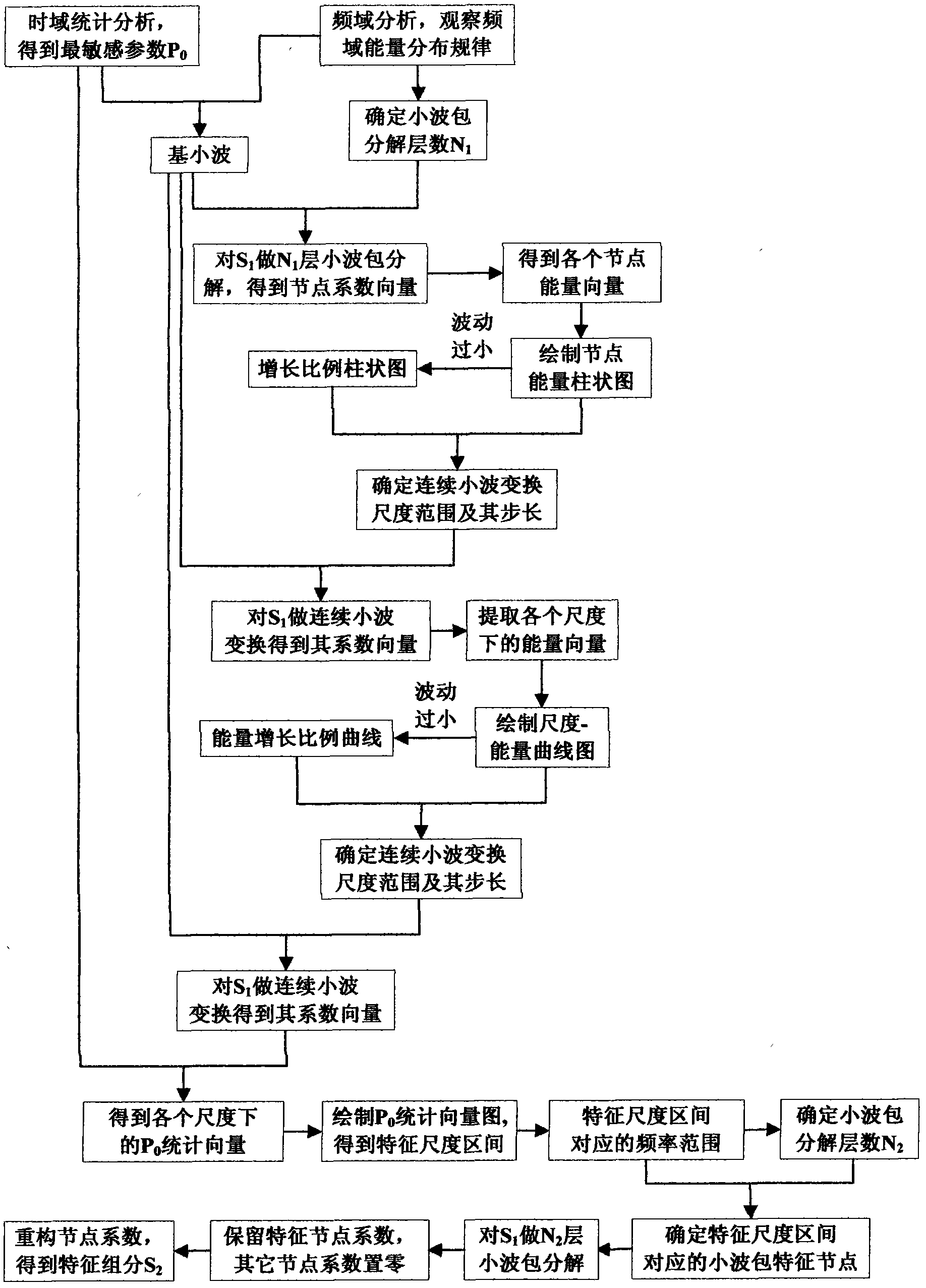

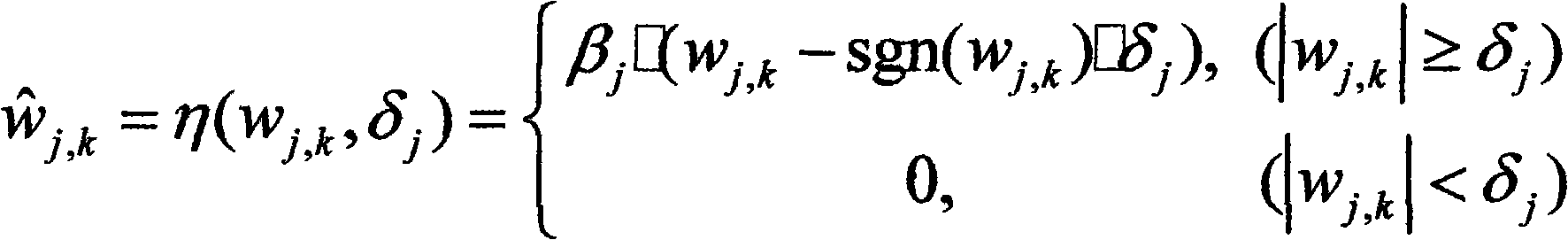

[0054] According to the parameter optimization method, Morlet wavelet parameters are optimized, and the threshold value is obtained by the threshold function, and the signal is decomposed into four layers of wavelet packets, and the coefficients are reconstructed after quantization processing to obtain the noise reduction signal S 1 .

[0055] In the time domain, the denoised signal S 1 Statistical analysis shows that the most sensitive parameter is the kurtosis parameter. Again to S 1 Do FFT and PSD analysis to obse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com