Cement grinding aid and preparation method thereof

A technology of cement grinding aid and silane coupling agent, which is applied in the field of cement additives, can solve the problems of urgent improvement of fineness and specific surface area, no obvious improvement of cement grinding energy consumption, and no obvious improvement of strength, etc., to achieve Both grinding aid and strengthening effect are excellent, improving grinding efficiency and enhancing effect are good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

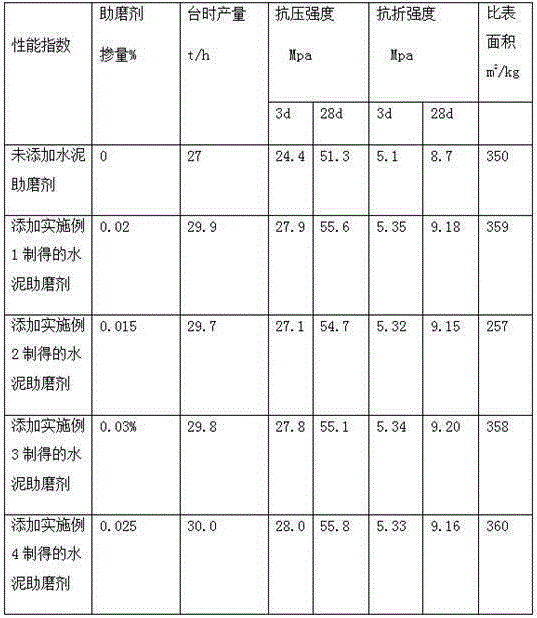

Examples

Embodiment 1

[0027] A cement grinding aid is made from the following raw materials in parts by weight:

[0028] Polymerized polyol 13 parts; Triisopropanolamine 12 parts; Polyol ether 13 parts; Ethylene glycol 18 parts; Triethanolamine 25 parts; Molasses 17 parts; Lignin 13 parts; Sodium chloride 0.03 parts; Alkenyl silicon 0.5 parts of oxane; 40 parts of water.

[0029] The lignin is extracted from papermaking black liquor, and the extraction method is as follows: adding a mass fraction of 25% sulfuric acid solution to papermaking black liquor until the pH value of papermaking black liquor is 4, and adjusting the temperature of the black liquor to 50 ℃, there is a precipitate, and after standing for 2 hours, the precipitate is filtered, washed, and dried to obtain lignin.

[0030] The alkenyl siloxane is vinyltrichlorosilane, vinyltrimethoxysilane, vinyltriethoxysilane, vinyltris(β-methoxyethoxy)silane, vinyltriacetic acid butylsilane, tri-tert-butoxyvinylsilane, vinyltri-tert-butylpero...

Embodiment 2

[0035] A cement grinding aid is made from the following raw materials in parts by weight:

[0036] Polymerized polyol 15 parts; Triisopropanolamine 8 parts; Polyol ether 15 parts; Ethylene glycol 15 parts; Triethanolamine 28 parts; Molasses 18 parts; Lignin 14 parts; Sodium chloride 0.04 parts; Aminosiloxane 0.6 parts; 43 parts of water.

[0037] The lignin is extracted from the papermaking black liquor. The extraction method is as follows: add a sulfuric acid solution with a mass fraction of 30% in the papermaking black liquor until the pH value of the papermaking black liquor is 3, and adjust the temperature of the black liquor to 55 ℃, there is a precipitate, and after standing for 1 hour, the precipitate is filtered, washed, and dried to obtain lignin.

[0038] The aminosiloxane is anilinomethyltrimethoxysilane, anilinomethyltriethoxysilane, N-(4-aminobutyl)aminomethyltriethoxysilane, γ-aminopropyltrimethoxysilane ylsilane, (3-aminopropyl)triethoxysilane, N-methyl-3-amin...

Embodiment 3

[0043] A cement grinding aid is made from the following raw materials in parts by weight:

[0044] Polymerized polyol 18 parts; Triisopropanolamine 10 parts; Polyol ether 12 parts; Ethylene glycol 20 parts; Triethanolamine 30 parts; Molasses 15 parts; Lignin 15 parts; Sodium chloride 0.05 parts; Vinyl trichloride 0.3 parts of silane, 0.5 parts of anilinomethyltriethoxysilane; 45 parts of water.

[0045] The lignin is extracted from the papermaking black liquor, and the extraction method is as follows: adding a sulfuric acid solution with a mass fraction of 25% in the papermaking black liquor until the pH value of the papermaking black liquor is 4, and adjusting the temperature of the black liquor to 53 ℃, there is precipitation, and after standing for 1.5 hours, the precipitate is filtered, washed, and dried to obtain lignin.

[0046] Described cement grinding aid, its preparation method, the steps are as follows:

[0047] (1) Take parts by weight of water in a reactor, heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com