Patents

Literature

52results about How to "Reduce the amount of quasi-engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

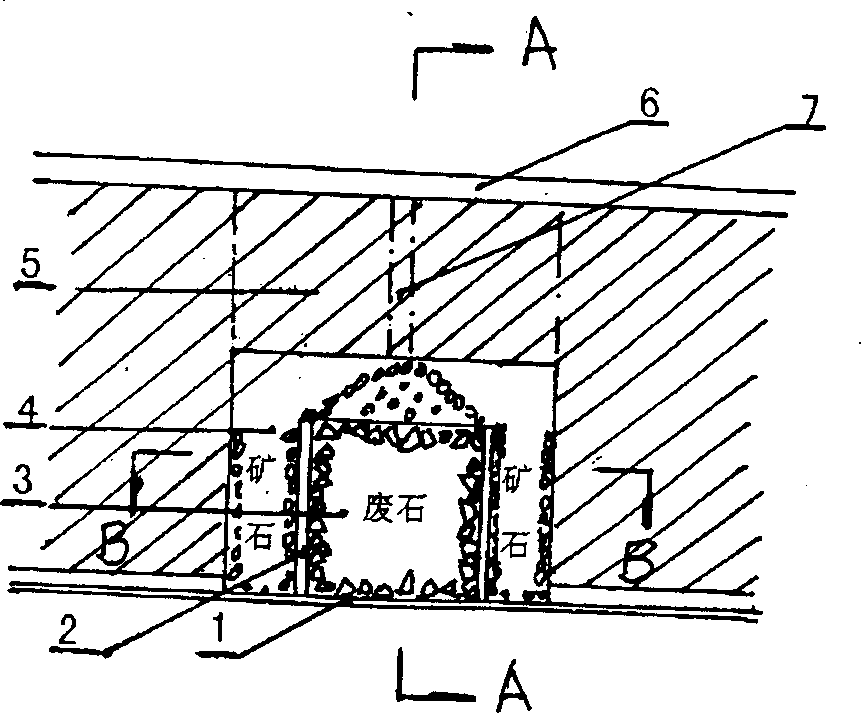

Room-and-pillar major-diameter longhole inverted-step-like segmented lateral caving subsequent filling mining method

InactiveCN102953732AImprove mining safetyGood for stope stabilityUnderground miningSurface miningRoom and pillar miningSingle stage

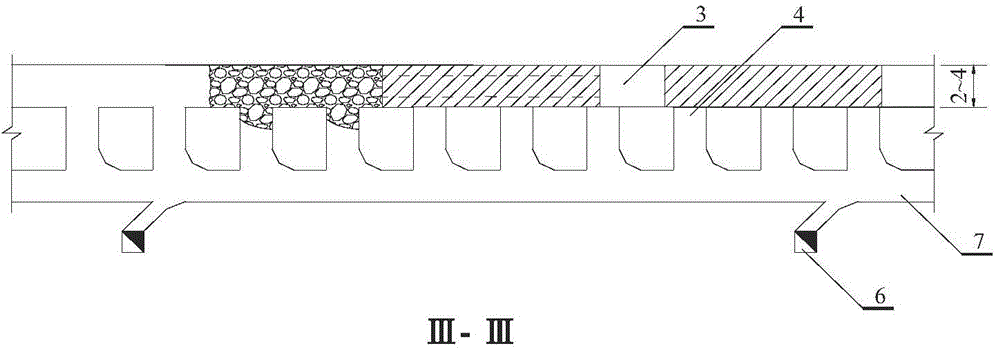

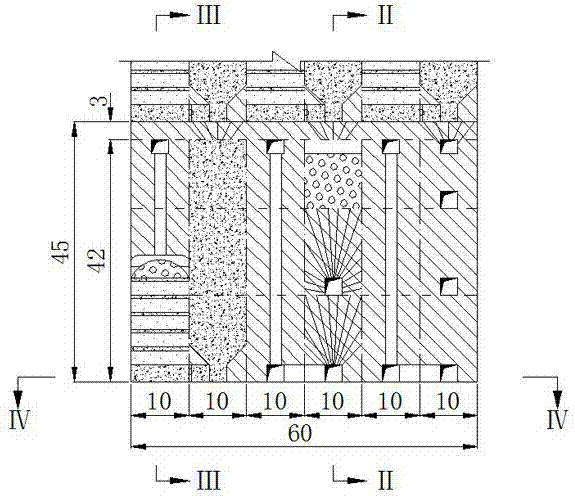

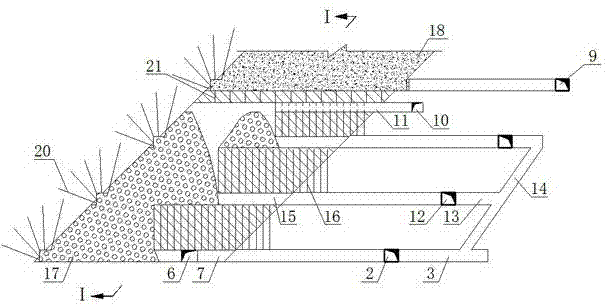

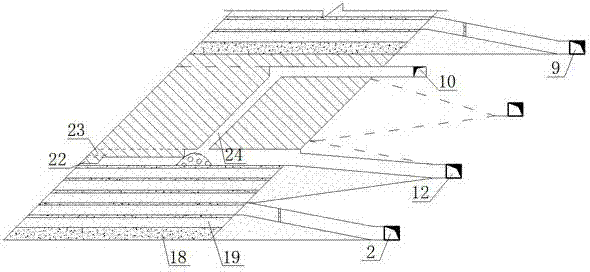

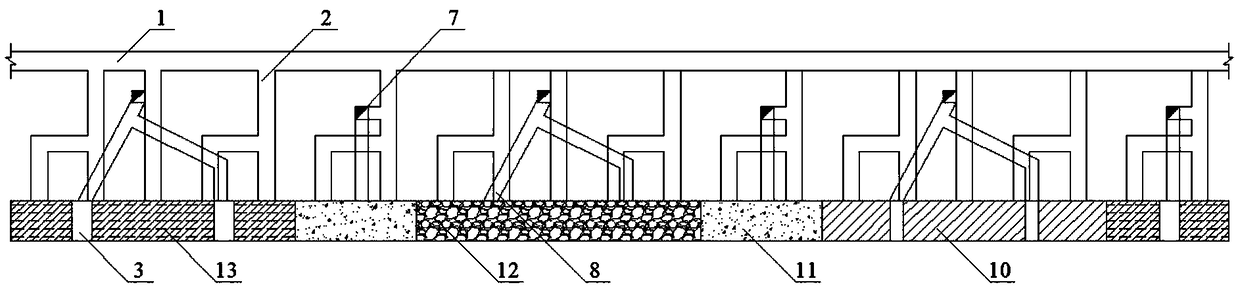

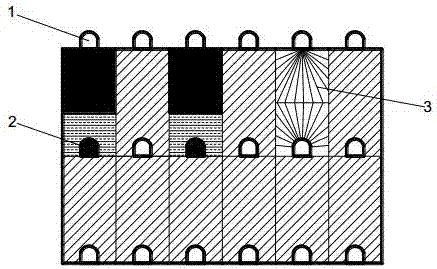

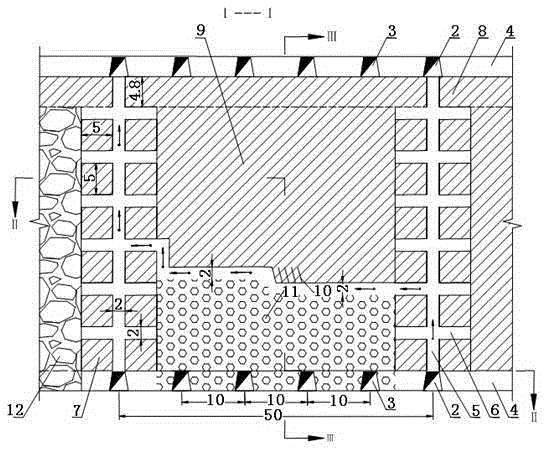

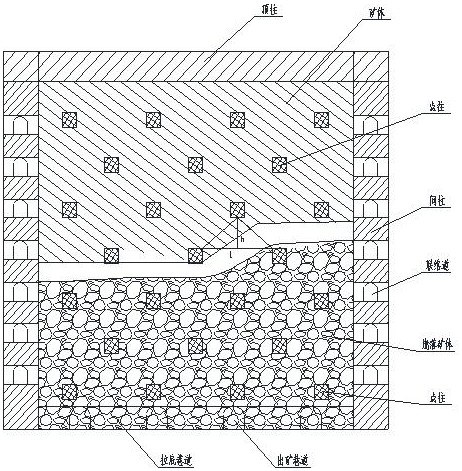

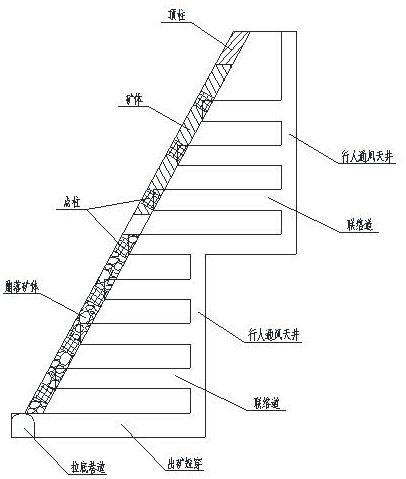

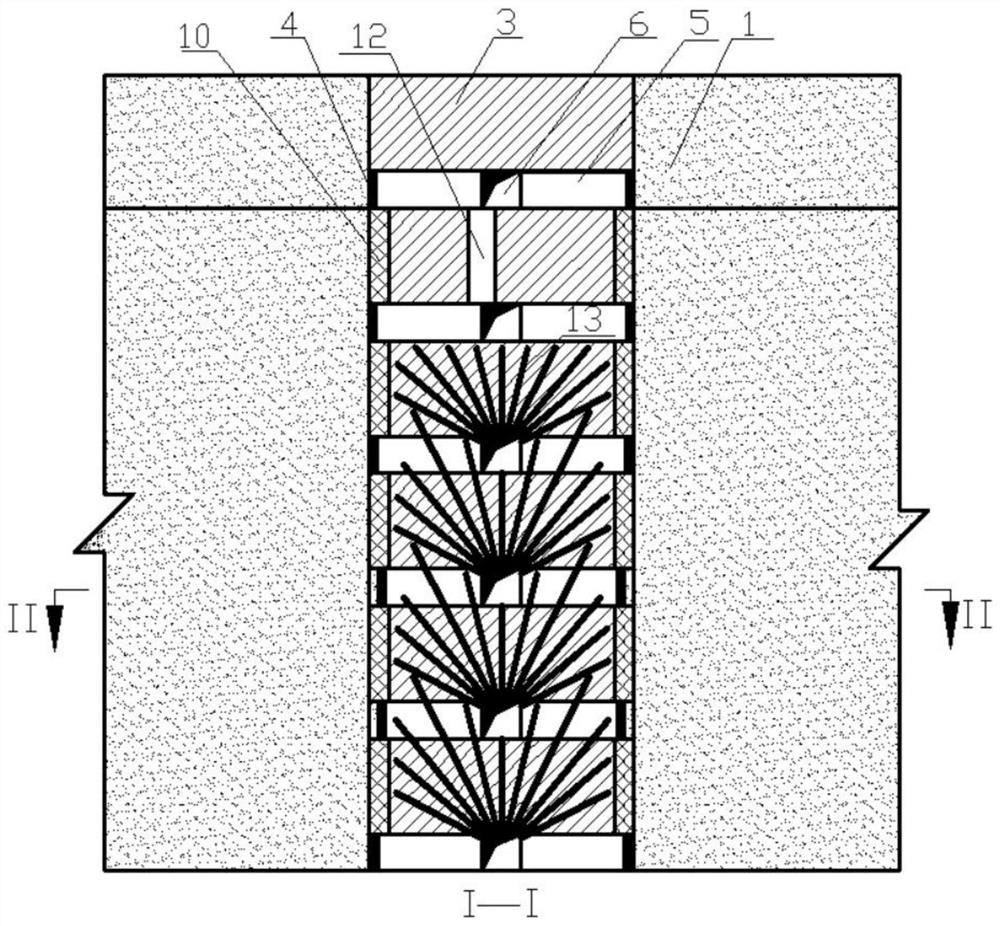

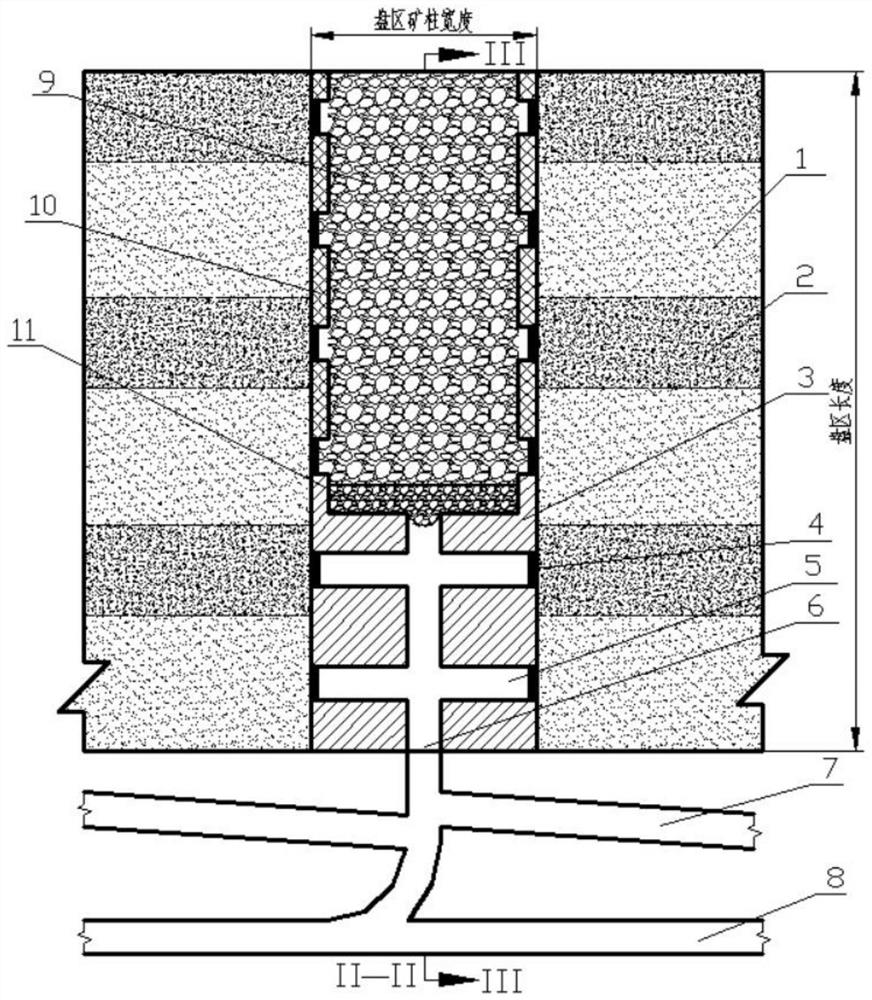

The invention discloses a room-and-pillar major-diameter longhole inverted-step-like segmented lateral caving subsequent filling mining method for a steeply-inclined medium-thick orebody and gently-inclined and inclined extremely-thick orebodies with steady surrounding rocks at upper and lower panels. The method is characterized in that: an orebody is divided into panels, then the panels are divided into continuous single-stage stoping units, and mining is carried out by using a stoping sequence of stoping one unit every other unit, i.e., mining a room at first and a pillar next; when mining a room, a V-shaped trench bottom structure is employed, a longhole drilling chamber is arranged at the upper part of stope, bar-shaped pillars are left to support the top plate of the chamber, a down-the-hole drill is used for drilling rocks, an explosion mode of light section VCR method underholing inverted-step-like lateral caving with a common emulsion explosive is employed, access roads towards the room for ore removal are arranged in the pillars, and cemented roof-contact filling is employed; and during stoping of the pillars, access roads for ore removal are dug towards the pillars in cemented bodies in the room, a stoping manner for the pillars is identical to that for the room, and non-cemented filling with tailings and waste is employed. The method provided by the invention has the advantages of high security, a low production cutting ratio, great production capacity, low operation cost and small loss and dilution of resources.

Owner:彭康

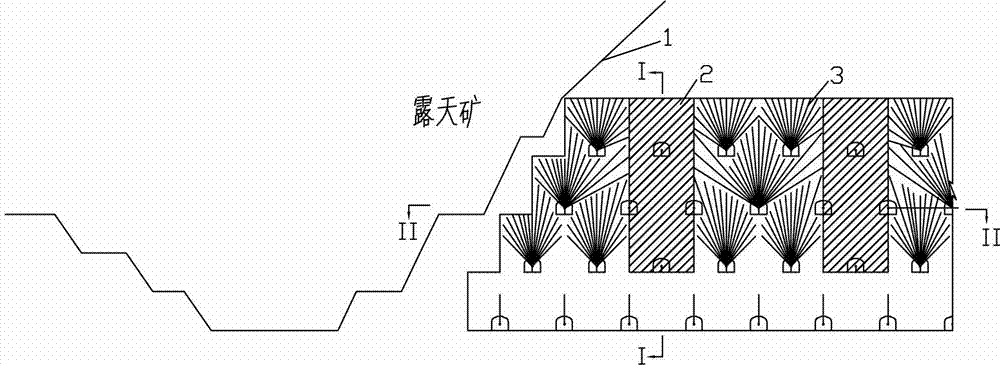

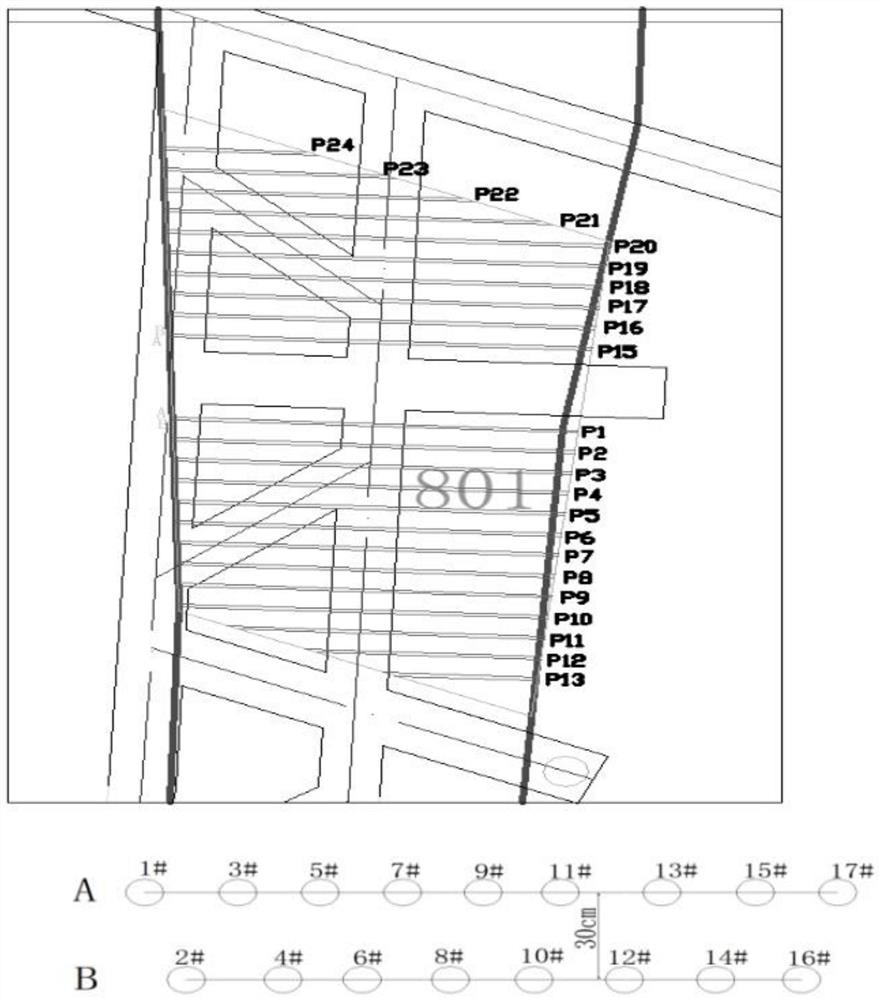

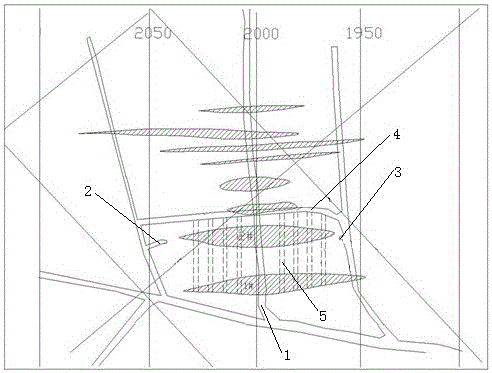

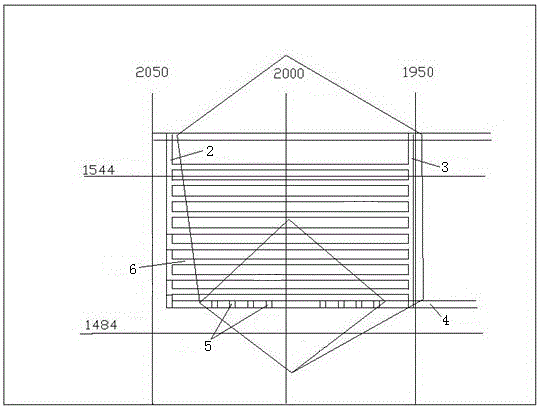

Drift-pillar-free sublevel barnyard caving mining method of open pit transferred underground transitional period

ActiveCN103089266ADecrease the sampling factorReduce the amount of quasi-engineeringUnderground miningBlastingOpen-pit miningRock cutting

The invention relates to a drift-pillar-free sublevel barnyard caving mining method of an open pit transferred underground transitional period. The drift-pillar-free sublevel caving mining method comprises the following steps of: carrying out sublevel recovering; and finishing rock drilling, blasting and ore removing in a feeding path. The drift-pillar-free sublevel caving mining method is characterized in that at an open pit transferred underground recovering transitional period, open pit mining and underground hanging wall ore recovering are carried out at the same time; a barnyard method and a drift-pillar-free sublevel caving method are combined to recover hanging wall ore; when open pit ore is mined, a drift-pillar-free sublevel barnyard method is used for recovering a hanging wall ore sublevel feeding path; and after the open pit mining is finished, a drift-pillar-free sublevel caving method is used for carrying out large-scale blasting and ore removing on safety pillars, other sublevel ores and barnyard-method residual ores. The drift-pillar-free sublevel barnyard caving mining method disclosed by the invention has the advantages of effectively reducing accurate mining coefficient and saving economic cost. The accurate mining engineering amount is greatly reduced and the accurate mining invest is reduced at the same time; and the extracted ore amount and the production capability of unit accurate mining engineering are increased and the economic benefit is effectively improved.

Owner:ANSTEEL GRP MINING CO LTD

Diagonal ore-break-down medium-length hole mining method for steeply-inclined thin vein ore body

ActiveCN104989404AReduce depletionReduce lossesUnderground miningSurface miningRoom and pillar miningStart stop

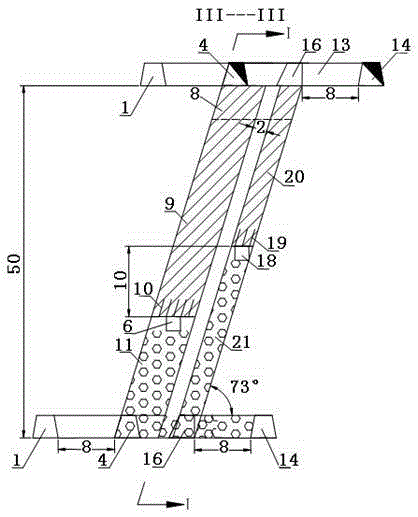

The invention discloses a diagonal ore-break-down medium-length hole mining method for a steeply-inclined thin vein ore body. The method comprises the following steps: arranging a stope according to the strike of the ore body, dividing rooms, pillars and sections according to the inclination direction of the ore body and arranging a level haulage roadway along the vein of the ore body from the footwall of the ore body; driving ore-drawing crosscuts into the ore body from where the level haulage roadway is located; horizontally arranging an undercutting roadway along the vein and parallely driving rock-drilling prospecting rises along slant height; arranging ore drop shafts to abut against the haulage roadway; starting stoping from one side of the stope, stopping stoping when the undercutting roadway is driven to the position of the first rock-drilling prospecting rise and then driving the rock-drilling prospecting rise; allowing a medium-length hole drilling machine to gradually travels from undercutting roadway to rock-drilling prospecting rise, drilling medium-length upward blast hole, carrying out denotation and drawing ore out from the bottom ore-drawing crosscuts; and after the first rock-drilling prospecting rise reaches a certain position, continuing driving the undercutting roadway until the position of the second rock-drilling prospecting rise is arrived at, carrying out medium-length hole mining, and repeating the above-mentioned operations until stoping of the stope is completed. The diagonal ore-break-down medium-length hole mining method has the advantages of high production efficiency, great production capacity and good operation security.

Owner:CENT SOUTH UNIV

Chamber and overhand cut combined cut-and-filling stoping method in pre-roof-protecting stage

InactiveCN104847352AImprove mining safetyImprove stope production capacityUnderground miningSurface miningEngineeringCut and fill

The invention relates to a chamber and overhand cut combined cut-and-filling stoping method in a pre-roof-protecting stage. The method comprises the following steps: dividing a middle ore body into panels along the trend of the ore body, further dividing the middle section into a plurality of sections in the vertical direction, and mainly adopting a footwall out-out-pulse traceless accurate mining mode; arranging chambers and pillars in the panels at intervals; recovering the chambers first, and adopting a sublevel open stoping method with subsequent backfilling; after recovering the chambers, recovering the pillars and adopting an overhand horizontal cut-and fill method for the pillars, and before recovering the chamber in stages, pre-supporting a long cable in advance for an upper panel in a sublevel upper panel supporting lane; pre-supporting the fore-set by using an anchor rod and a metal net in an air return cross gateway below the fore-set; when the pillars are recovered in layers, stopping mining when the pillar is 3m close to the main crack of the upper panel F1 in horizontal distance and reserving the panel as an upper panel roof-protecting ore of the sub layer, and when the lower layer is recovered, fully recovering the upper panel roof-protecting ore reserved in the previous layer, and meanwhile, reserving the upper panel roof-protecting ore in the lower sub layer; and sequentially circularly recovering and reserving the upper panel roof-protecting ore. By virtue of the method provided by the invention, safe, efficient and low-cost mining can be implemented for thick and large ores which are relatively broken.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

Two-step upward high-layering bagging cut-and-filling stoping method

InactiveCN104373125AReduce construction costsReduce complexityUnderground miningSurface miningSlurryCut and fill

The invention relates to a two-step upward high-layering bagging cut-and-filling stoping method. A fragmented haulage way is constructed from a slope opening; a stope connection way is drilled from the fragmented haulage way to an ore body footwall; an intra-vein haulage way is constructed in a vein of the ore body footwall for communicating ore chambers with jamb stopes; after the stoping of the ore chamber stopes is finished, a bagging tailing stop wall is built in an outlet position for stope filling; when the stop wall is built, the intra-vein haulage way of the footwall is remained as a stoping channel of the jamb stopes; after the stoping of the jamb stopes is finished, multiple jamb stopes are taken as one district; filling stop walls are built at the two ends of the intra-vein haulage way of the footwall and in an outlet of the stope connection way; and the multiple jamb stopes are filled once through the mobility of filling slurry. The method is low in stope preparation work amount, is low in production cost of the filling stop walls, can realize synchronous filling of the multiple two-step stopes, and reduces the complexity of the filling process.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Artificial roof room-and-pillar shrinkage subsequent filling mining method

ActiveCN108661646AImprove securityAvoid constructionUnderground miningSurface miningRoom and pillar miningBlock structure

The invention provides an artificial roof room-and-pillar shrinkage subsequent filling mining method. The method comprises the steps that mine block structures are divided, specifically, an ore body is divided into multiple stages, ore chambers and ore pillars are divided in the stages in an ore body trend, and the ore chambers and the ore pillars are divided into multiple subsections; mining preparation and out seam mining preparation are conducted, specifically, a stage transportation haulage, a stage ore removal crosscut, a service ventilating raise, a subsection connection roadway, a filling inclined roadway and a drilling chamber are arranged; cutting is conducted; exploding is conducted, specifically, sector-shaped blast holes are drilled in the stage drilling chamber to cave down ores; stopping and ore removal are conducted, specifically, exploding is conducted from bottom to top in each stage, after each time of exploding, part of ores are transported from the stage ore removalcrosscut, remaining ores are shoveled out collectively on the stage ore removal crosscut after the ores are circulated to the topmost subsection ores are exploded and caved down, if the way of working to the dip is adopted during the stages, before upper stage stoping, an artificial roof is constructed on the top of the upper stage, and an artificial bottom is constructed on the bottom of the upper stage, and the artificial bottom of the upper stage is the stoping artificial roof of the next stage; and if the way of working from bottom up is adopted, the artificial roof of the next stage serves as the stoping artificial bottom of the upper stage.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

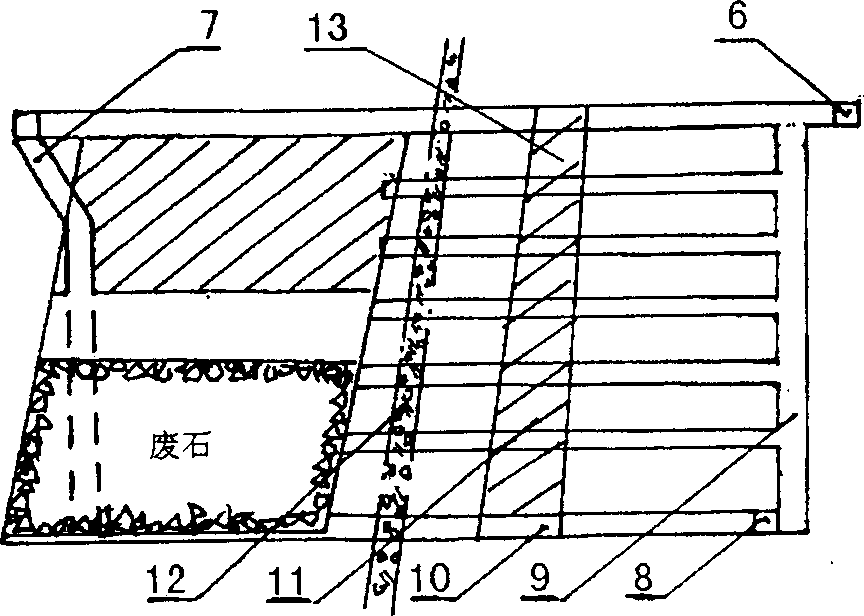

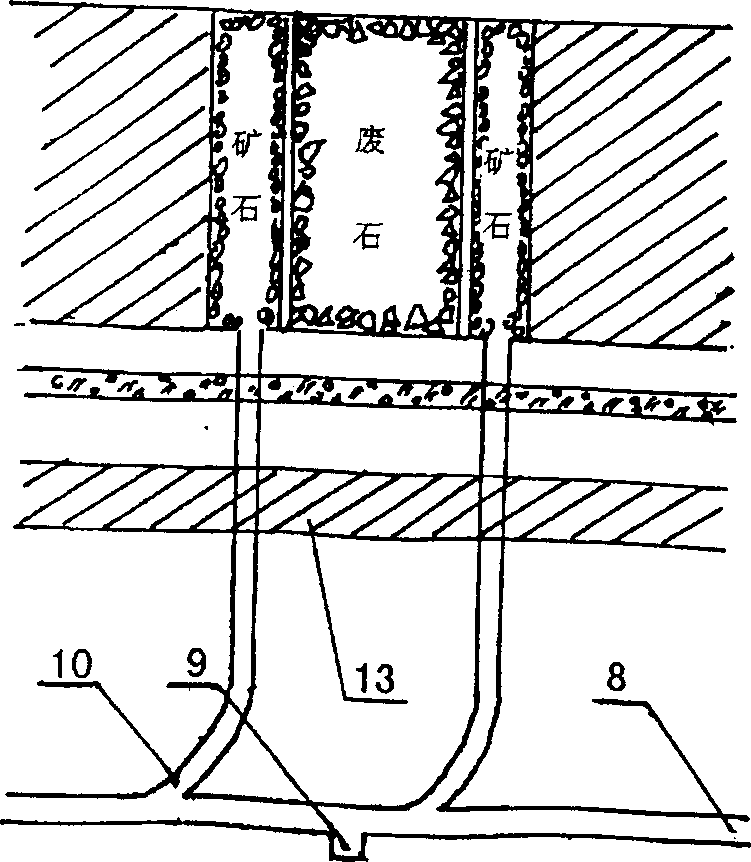

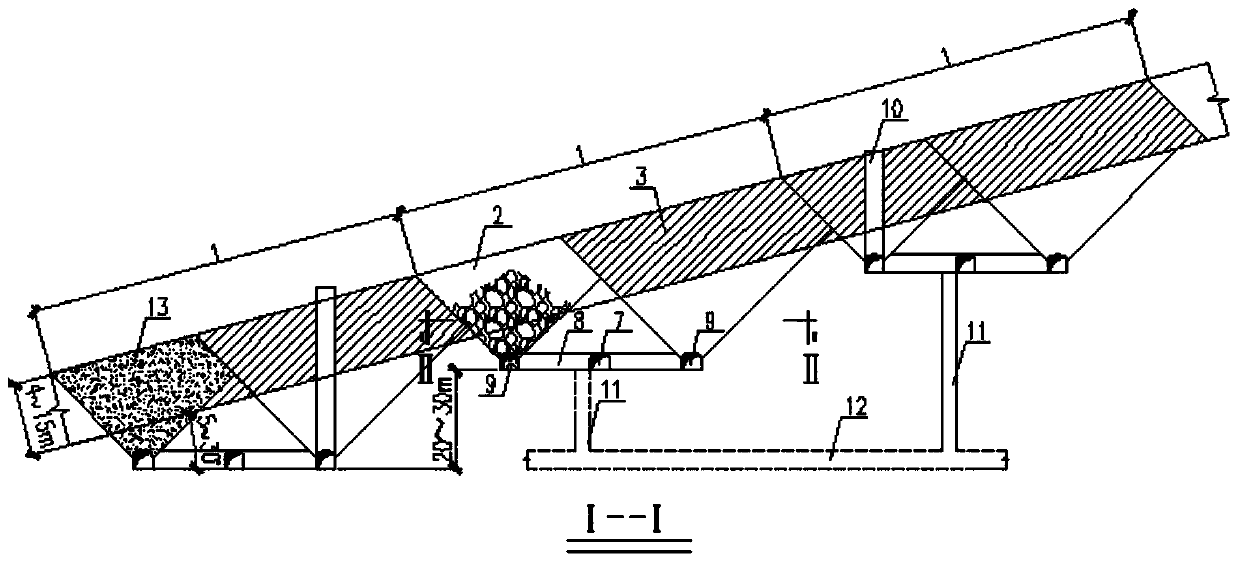

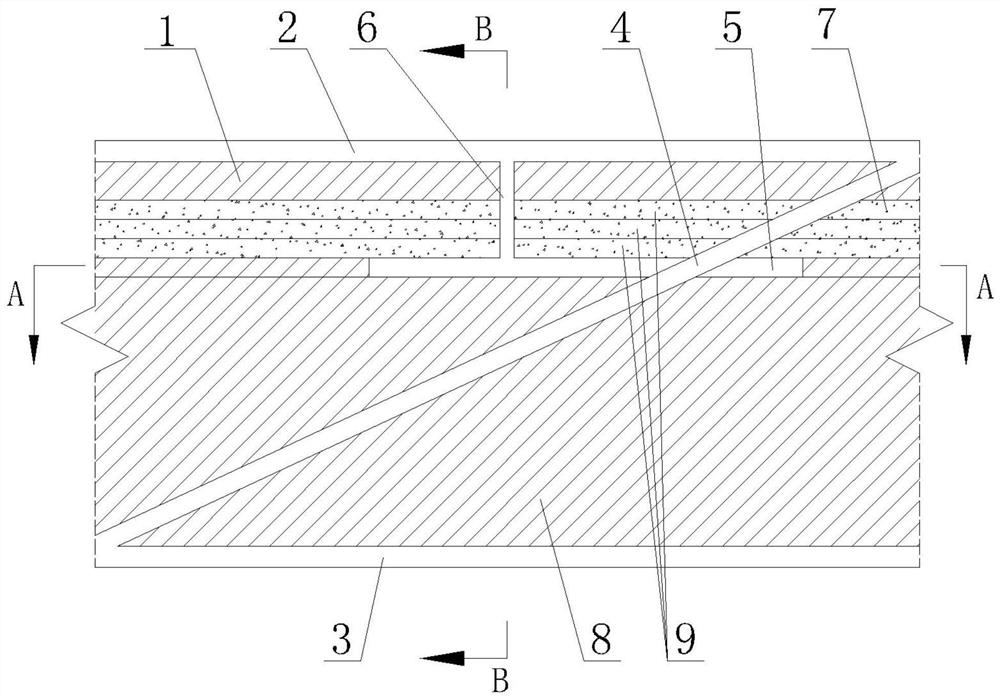

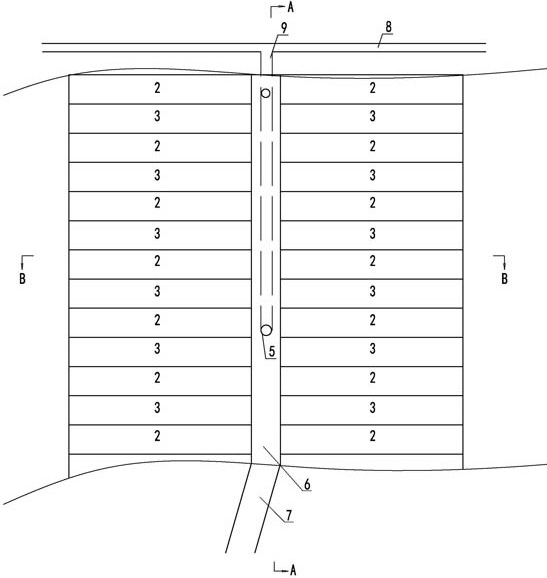

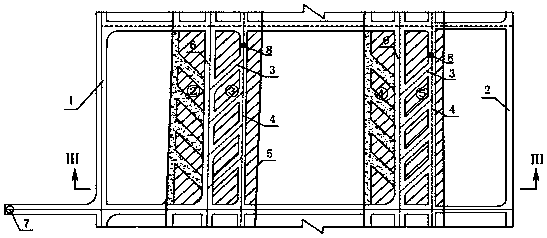

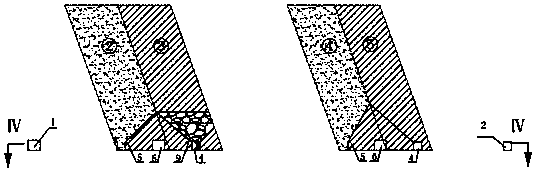

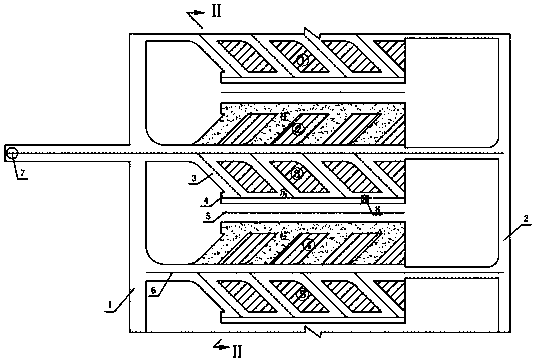

Novel method for collaboratively exploiting underground double stopes of underground mine

ActiveCN105952450AIncrease production capacityImprove mining efficiencyUnderground miningSurface miningEngineeringStoping

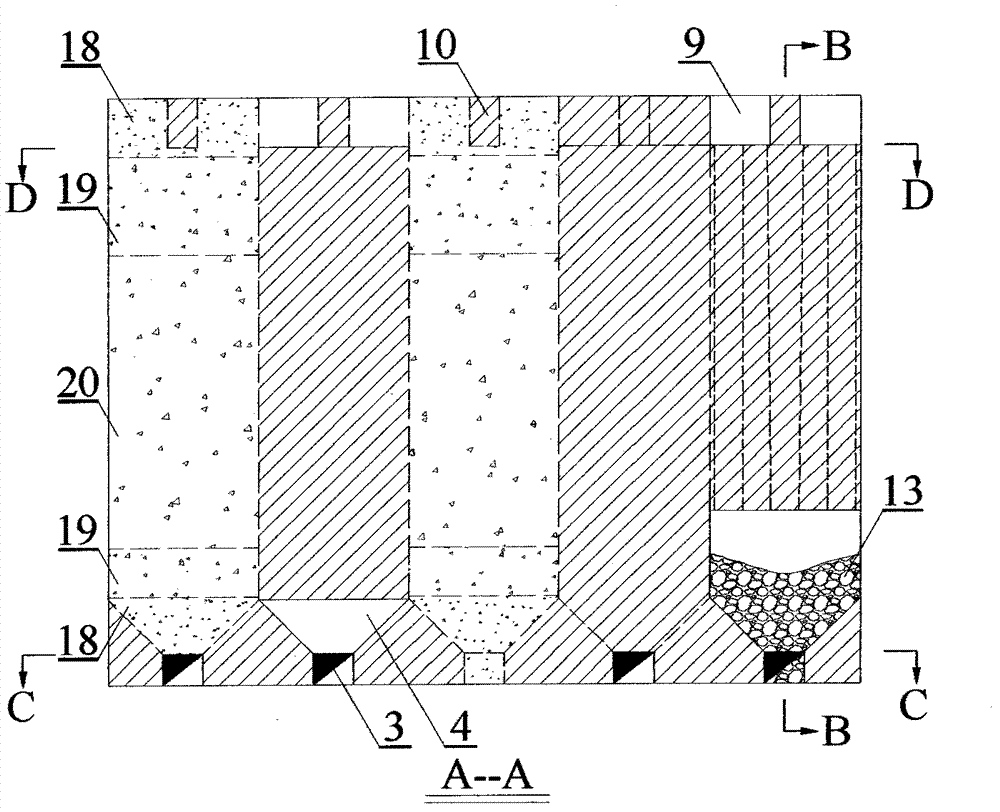

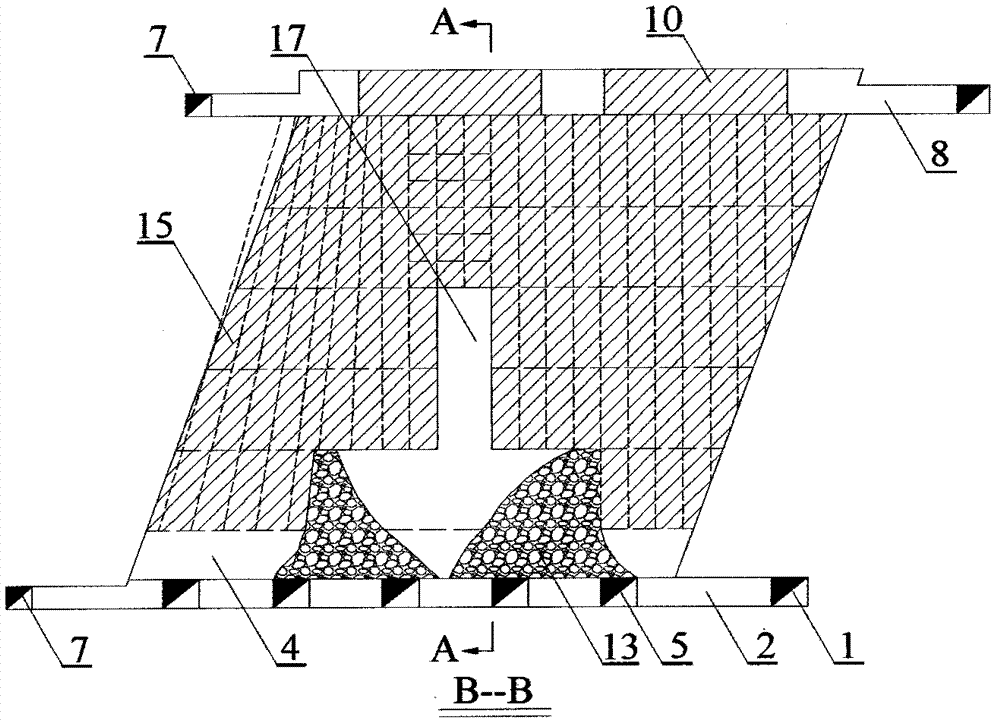

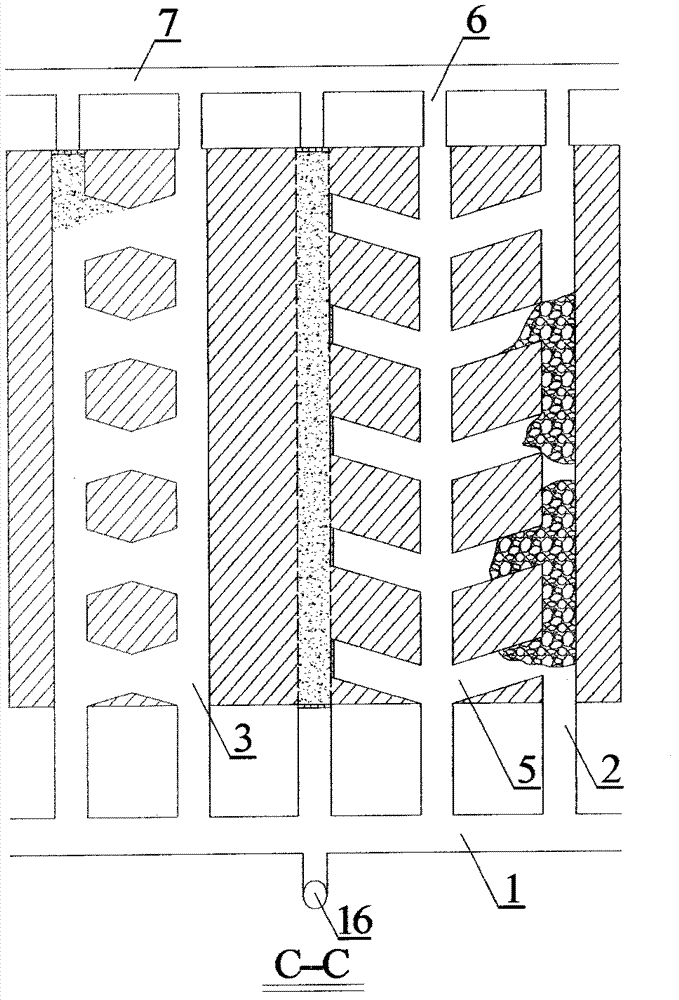

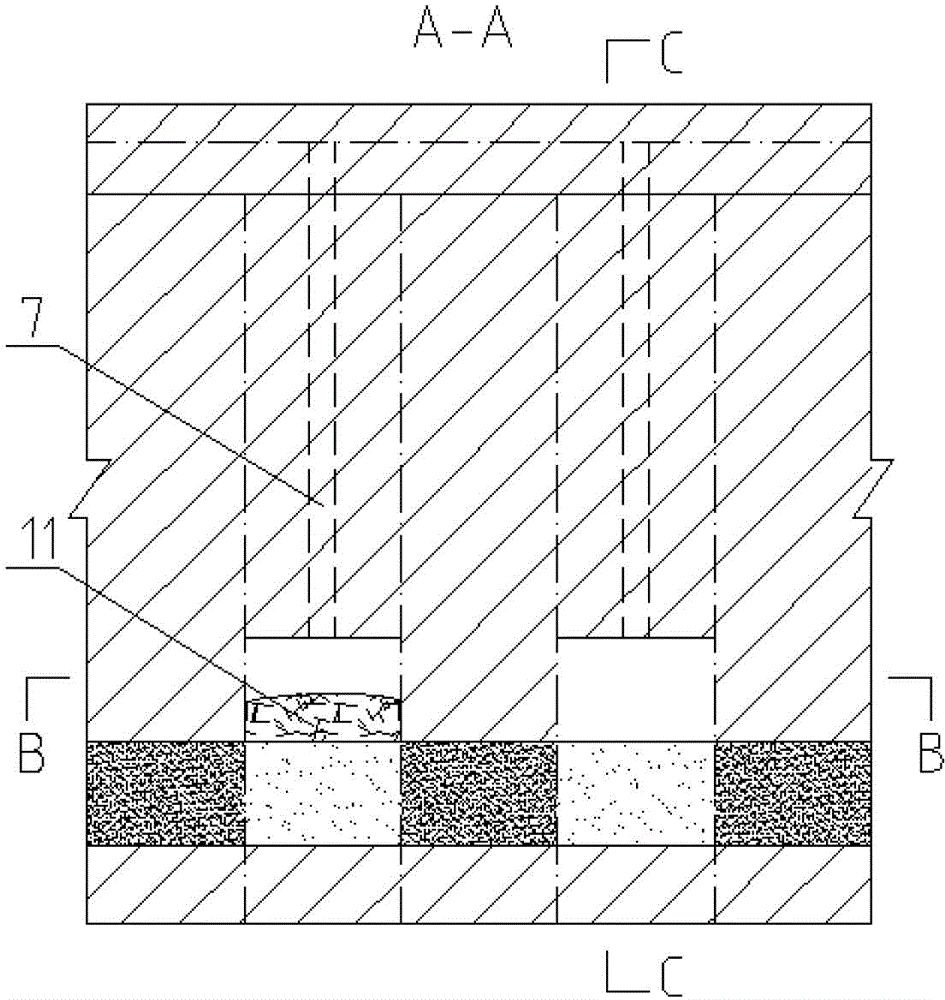

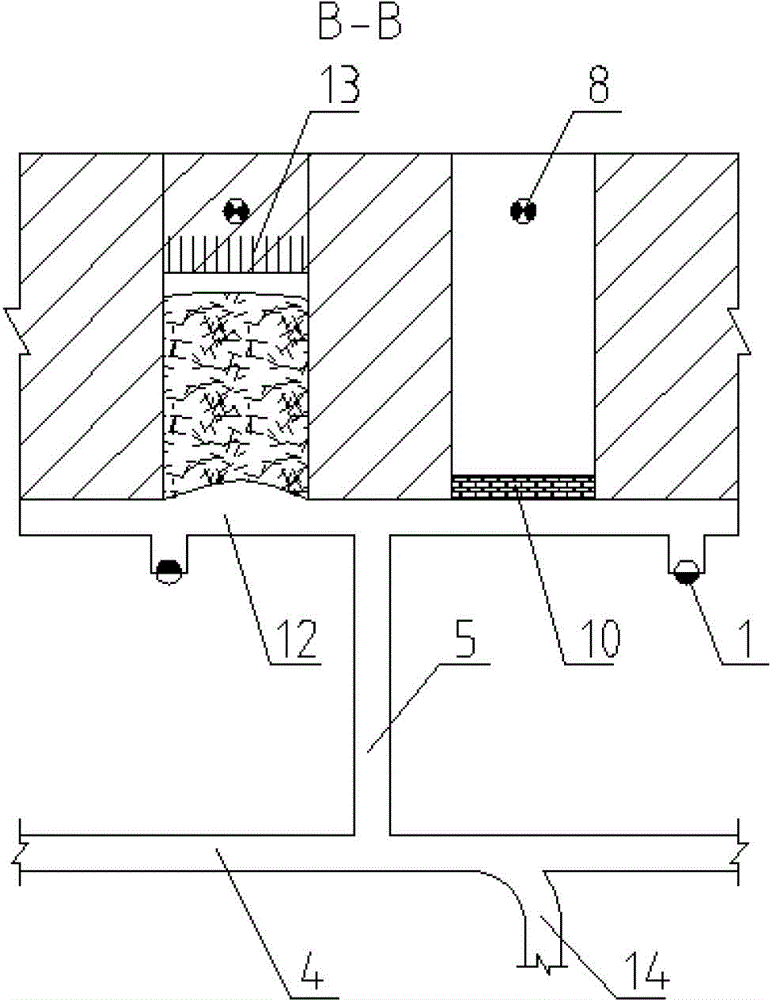

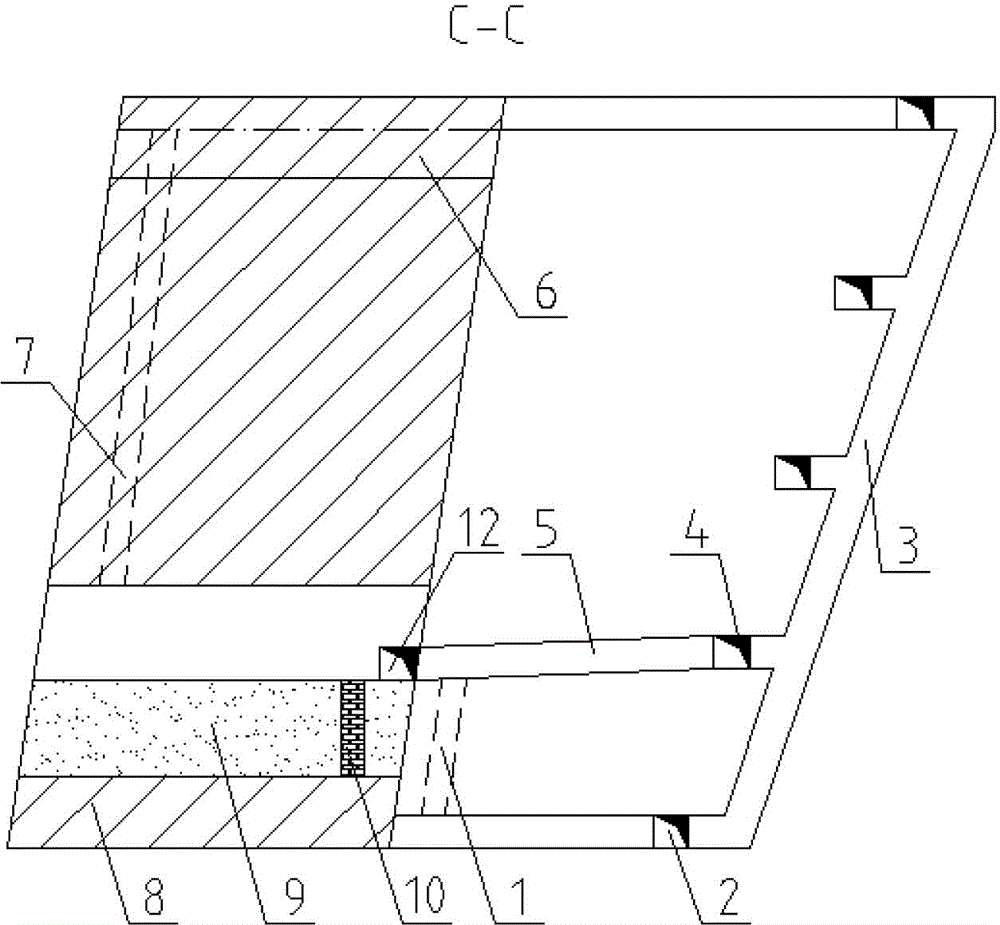

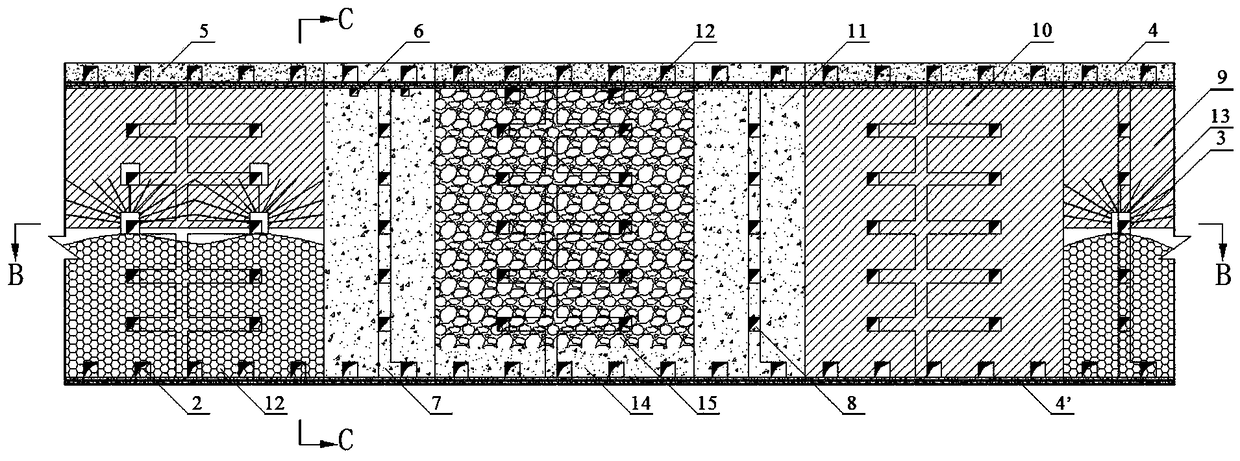

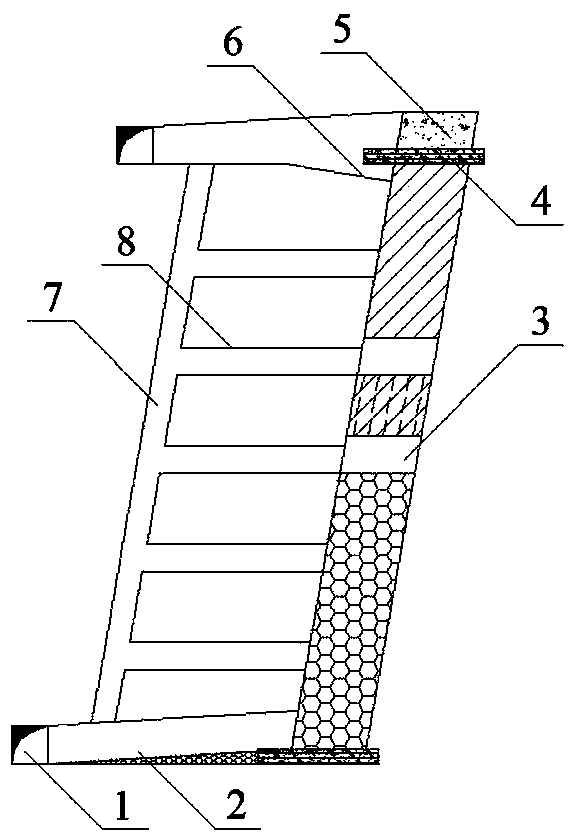

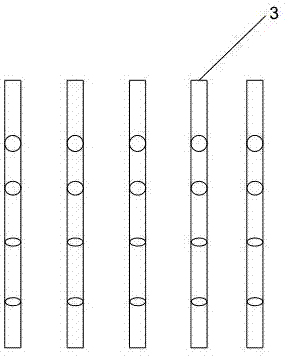

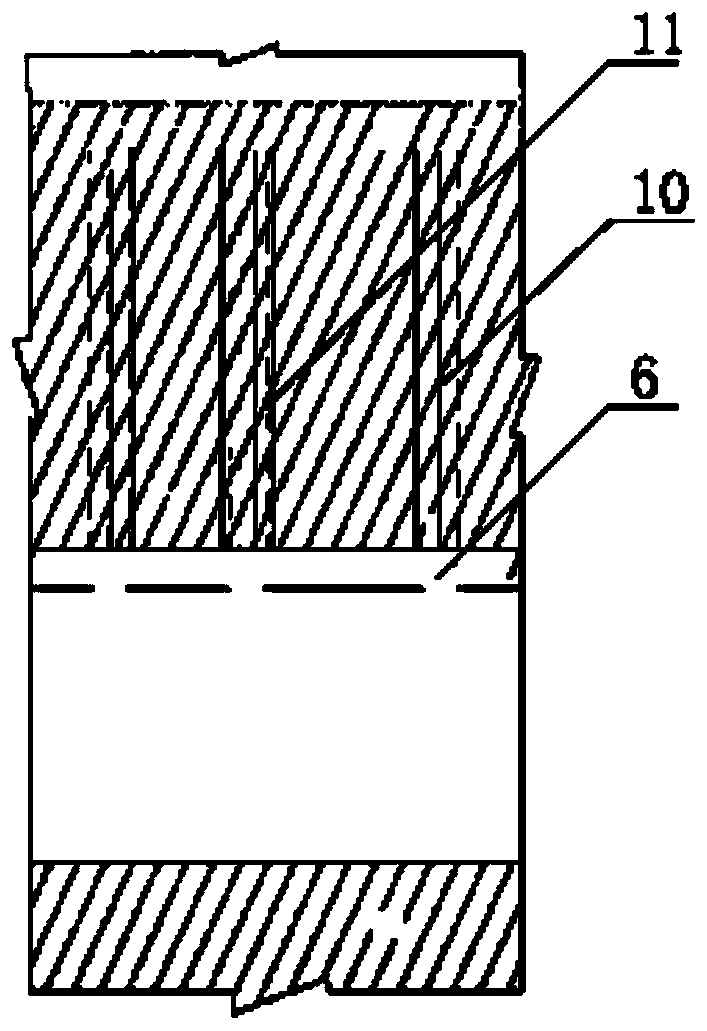

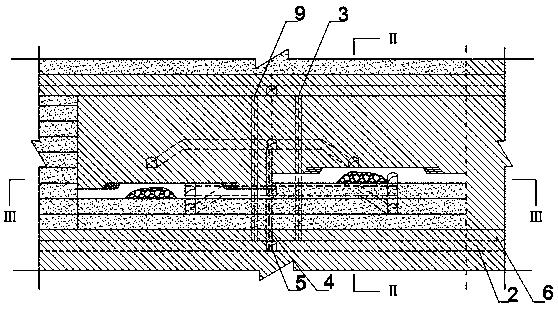

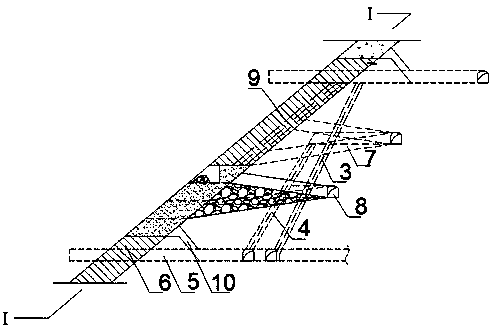

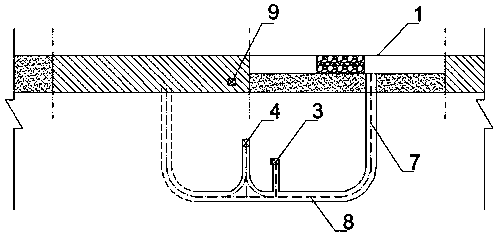

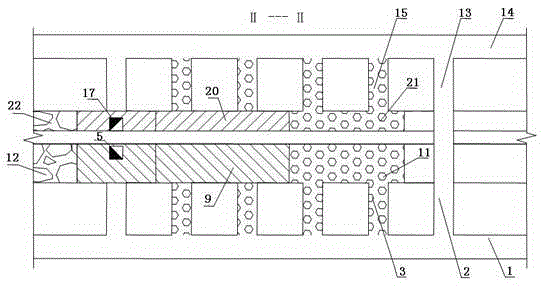

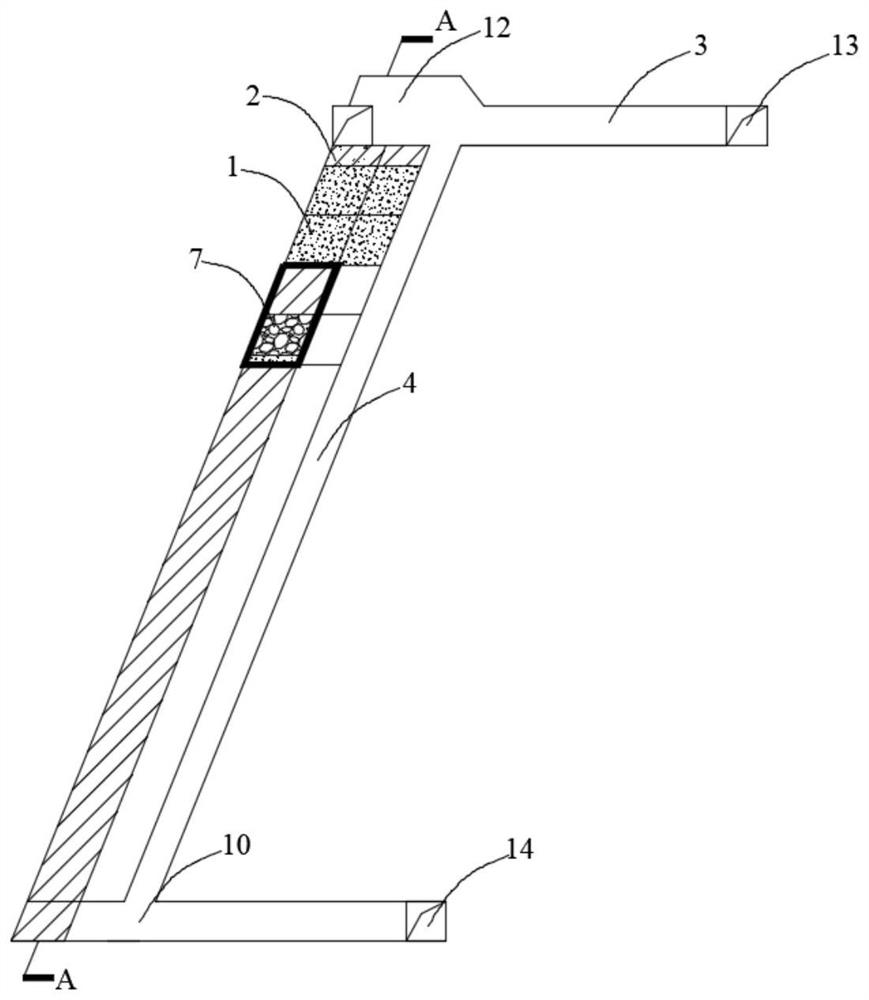

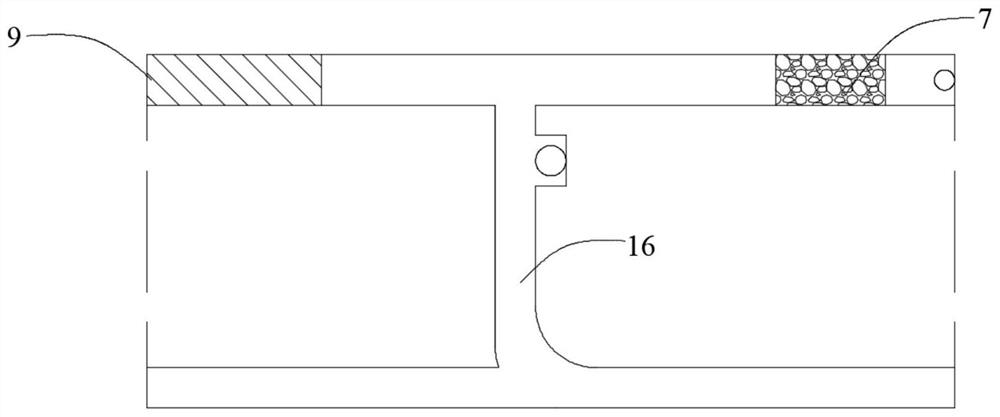

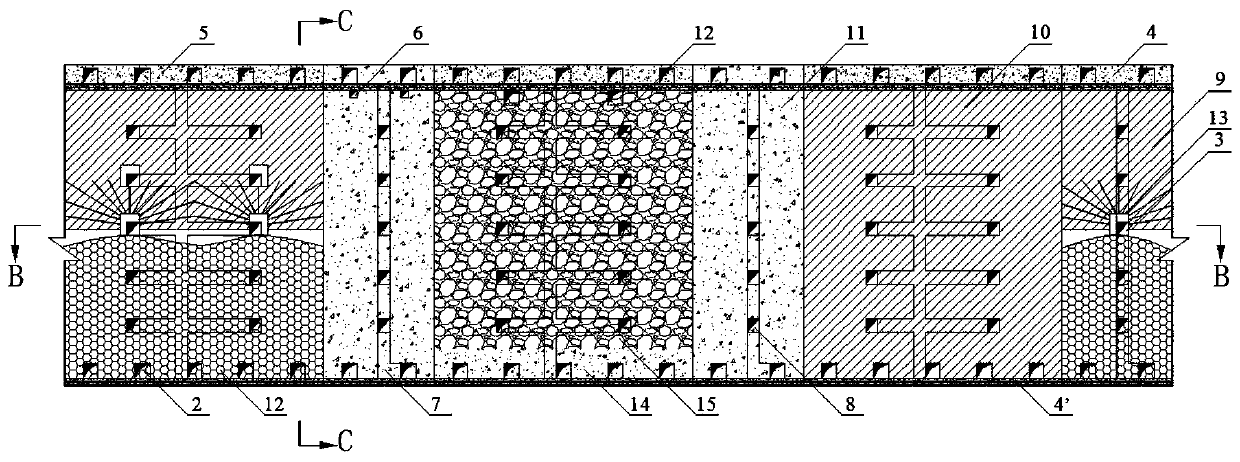

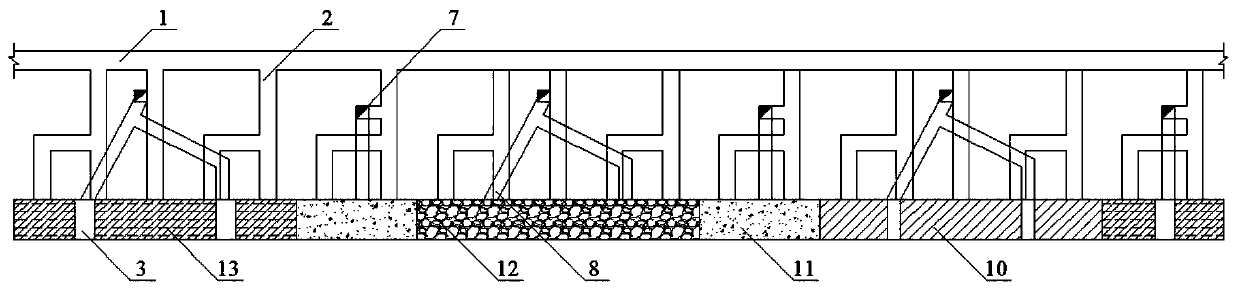

The invention discloses a novel method for collaboratively exploiting underground double stopes of an underground mine. Each ore block is internally divided into two stopes including a left stope room (9) and a right stope room (10), and a jamb (8) is reserved between every two ore blocks. A drilling chamber (1) is formed in the top end of each ore block, a downward blast hole (2) is formed in each drilling chamber (1) through deep hole rock drilling equipment, a controlled blasting technology is adopted, initiation of explosion is conducted segment by segment to achieve one-time explosion, the working face of the left stope room (9) is ahead of the working face of the right stope room (10), advancing is conducted in a ladder form, and caved ores are transported to a winze through an ore removal linked lane; an ore removal lane (5) is arranged on a single side of each ore block, the left stope room (9) and the right stope room (10) share the same ore removal lane (5), after stoping of a whole ore block is stopped, a goaf is subjected to backfill, a filing body (7) is formed, and the filing body (7) supports the jambs (8). By means of the novel method, double-stope synchronous stoping can be achieved for inclined and large and thick ore bodies which are good in rock-ore stability, and production capacity is high; synchronous ore removal of the two stope rooms can be achieved through only one ore removal lane of an ore removal structure at the bottom, and therefore the stope preparation work amount is reduced.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Filled mining method

InactiveCN1424487AShort filling lengthHigh speedUnderground miningSurface miningUltimate tensile strengthMineralogy

Owner:广东金鼎黄金有限公司

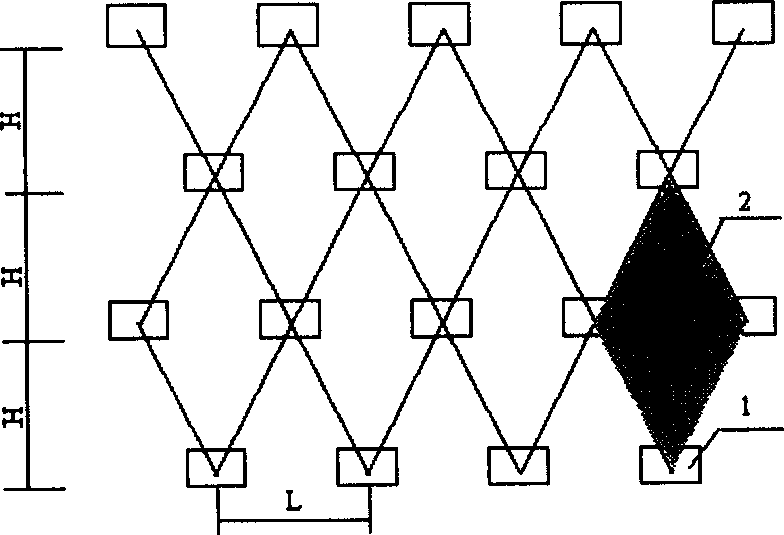

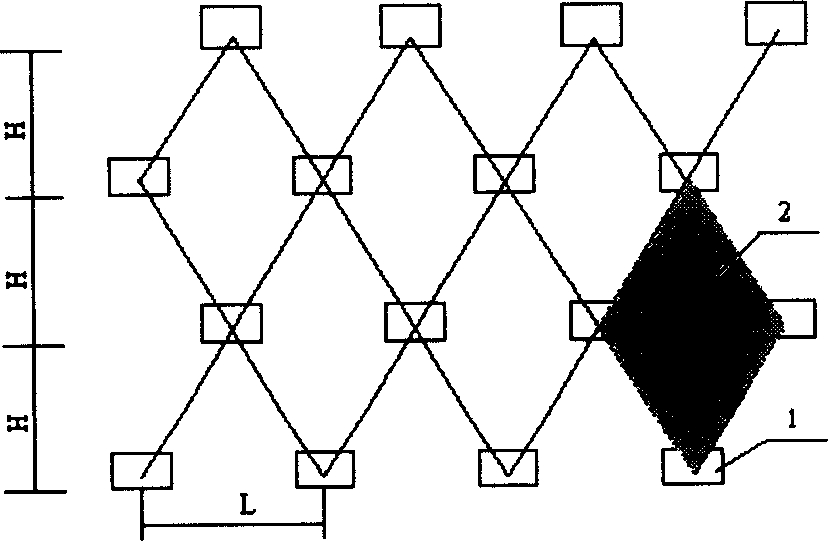

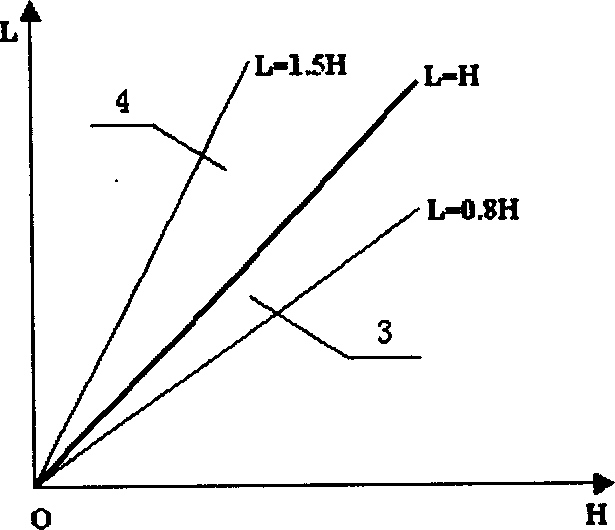

Sill-free sublevel caving method with drift space greater than sublevel height

InactiveCN1734055ALarge range of controlReduce digging ratioUnderground miningSurface miningSpelunkingUltimate tensile strength

This invention relates to an underground mining technology, especially to a sectionalized avalanche mining method without bottom pole whose route space is more than the sectionalized height. The bodily technique method as follows: after choosing the sectionalized height, confirming the route space L according the following methods: the route space L is more the sectionalized height H, the route space L =(1.0-1.5).sectionalized height H. This invention is mainly applied in the underground mining, and this technique method can improve the control range of each route greatly, and save the mining quantity, and reduce the ratio of grubbing and plucking, and improve the mining efficiency.

Owner:宝钢集团上海梅山有限公司

Sublevel open stoping method ground pressure control method of inclined large and thick ore bodies

ActiveCN109162715AReduce exposure timeReduce loading pressureUnderground miningSurface miningEngineeringGround pressure

The invention belongs to the field of mining and relates to a sublevel open stoping method ground pressure control method of inclined large and thick ore bodies. Chamber is divided into three sublevels in the vertical direction, and a roof pillar is reserved above; an along-vein roadway, a rock drilling roadway, a cutting level and a cutting raise are arranged at each sublevel; medium-length holeblasting is adopted to form cutting grooves; during stoping of the chamber, sublevel centralized blasting is adopted, centralized blasting is performed on the whole chamber four times in total. The method has the benefits as follows: a mining preparation arrangement manner combining going along with and penetrating through veins outside of footwalls is adopted, and the mining preparation work amount is reduced; the sublevel centralized blasting technology is adopted, the stoping cycle of a stope is shortened, and the exposure time of a vacant stope is shortened; sublevel centralized ore removal is adopted, and the hanging wall pressure, transferred by falling ore, applied to footwall rock is reduced; a triangular ore pile is reserved on a chamber hanging wall, mixing of hanging wall wastestone during stoping is avoided, and the dilution rate is decreased.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

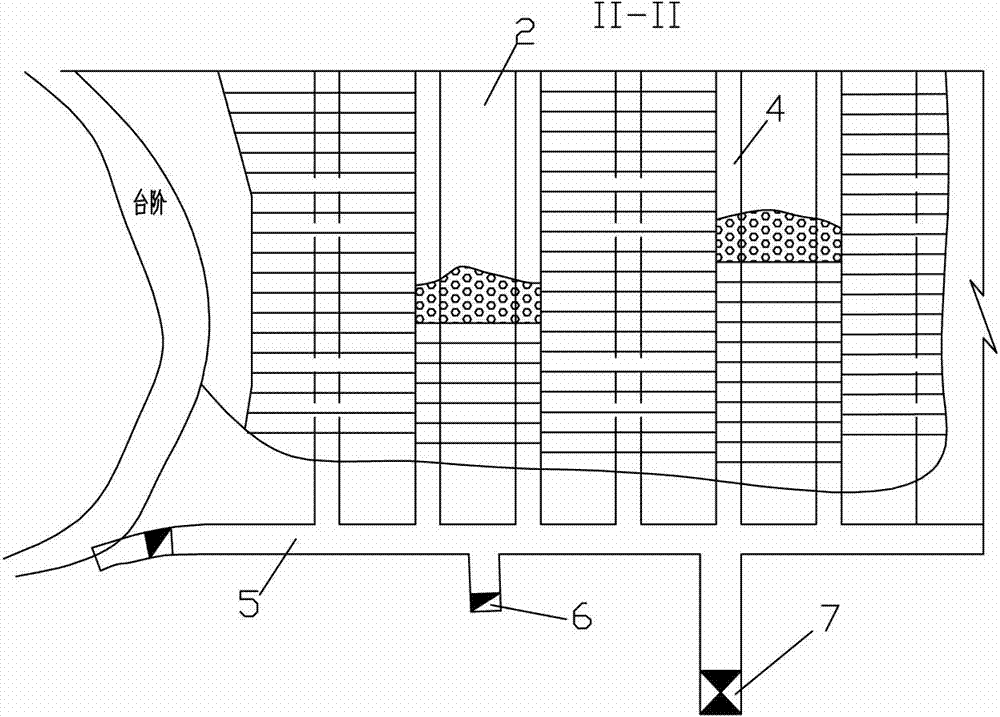

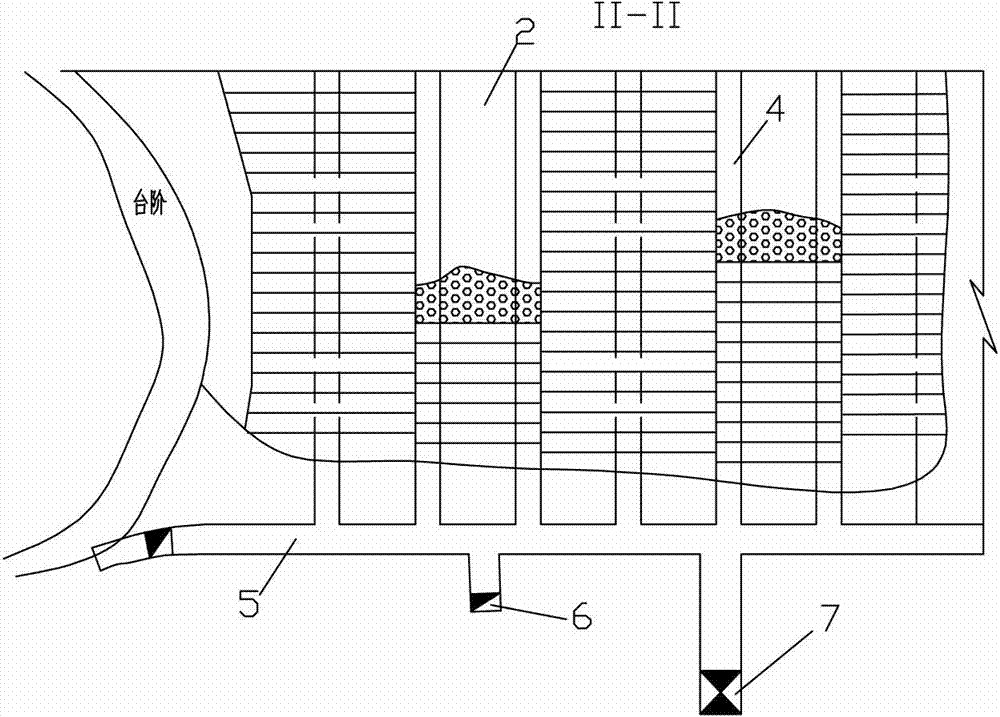

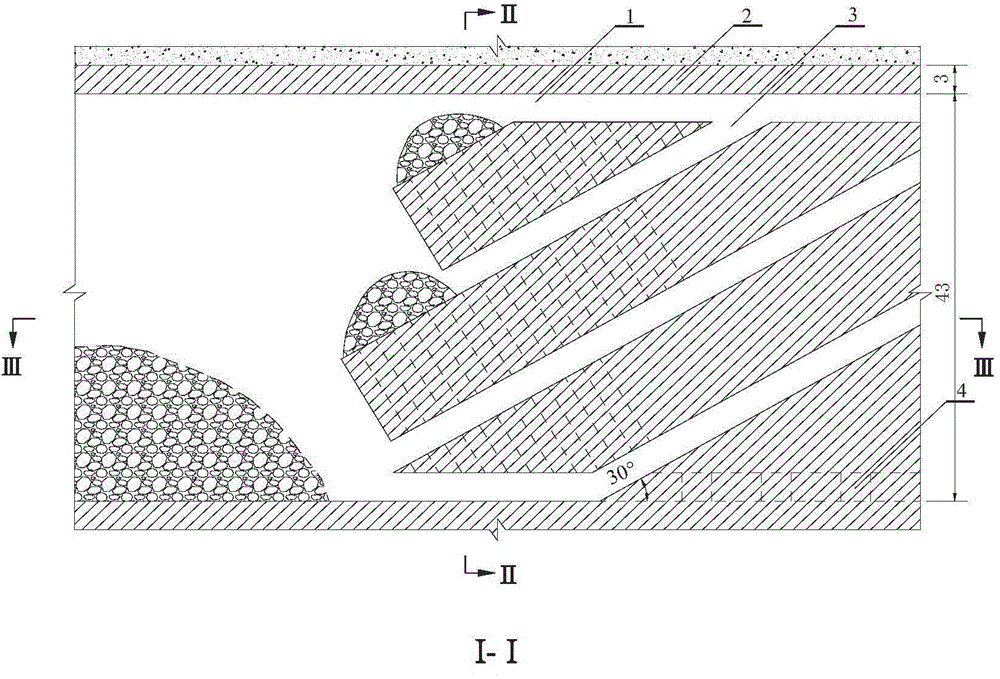

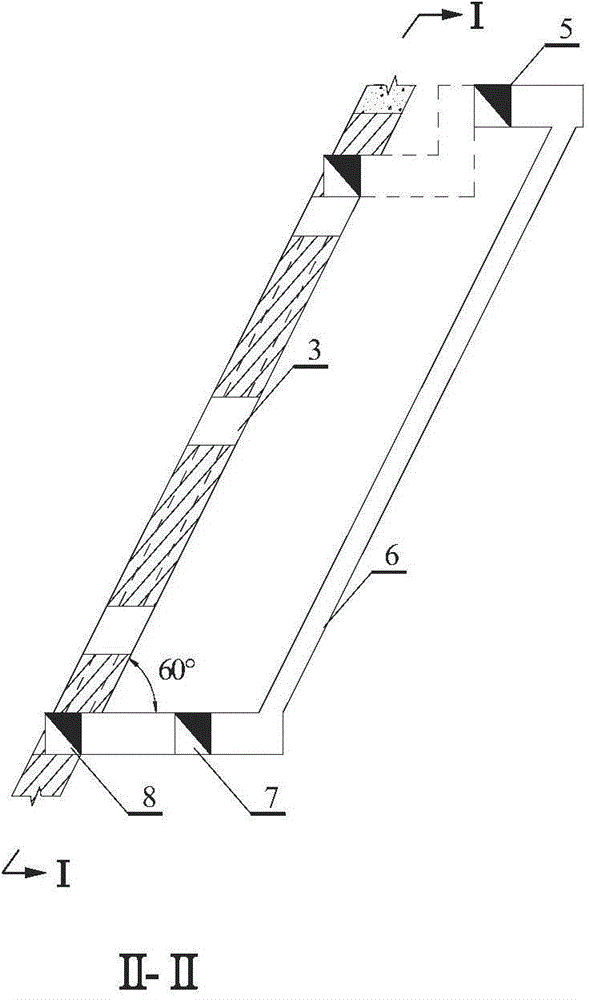

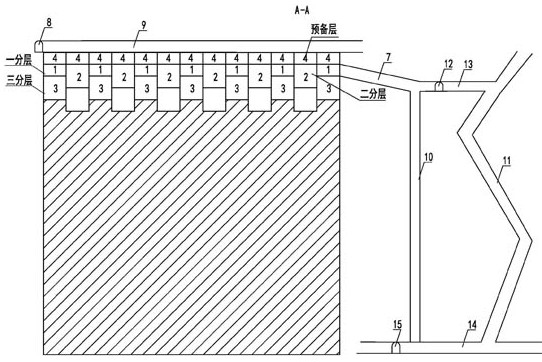

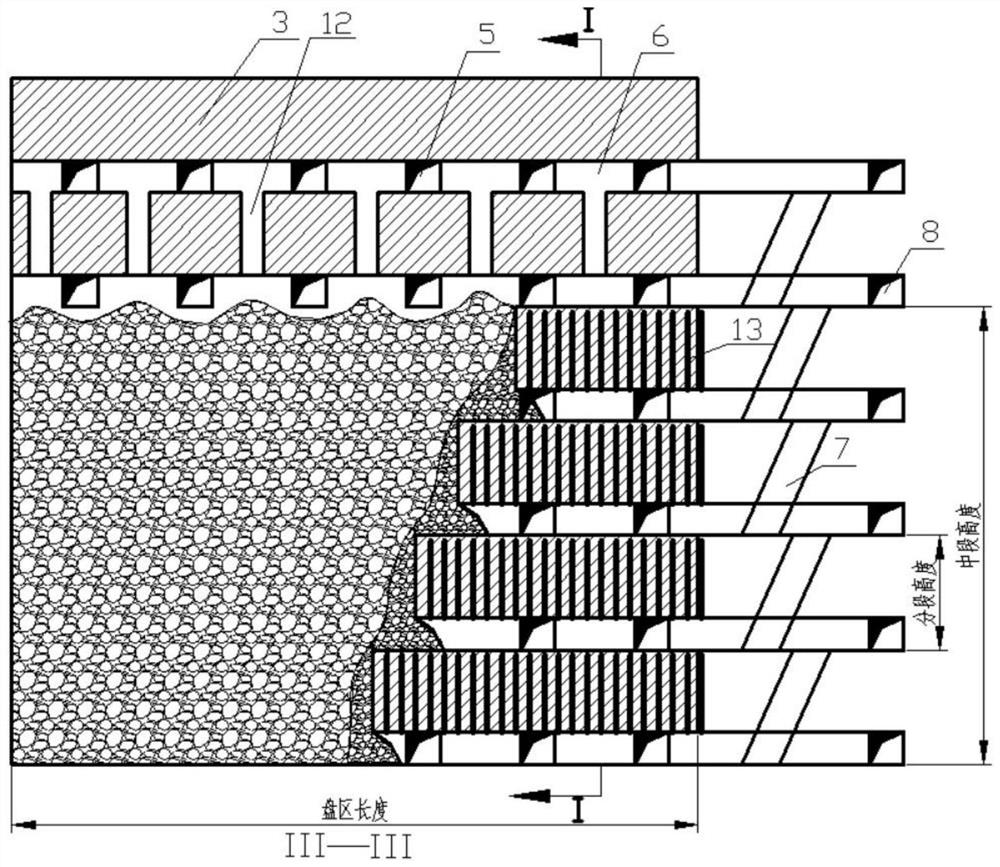

Gentle dip medium-thick ore body safety and low-cost combined segmented mining method

ActiveCN110359914AAvoid direct accessGuarantee job securityUnderground miningSurface miningEngineeringYard

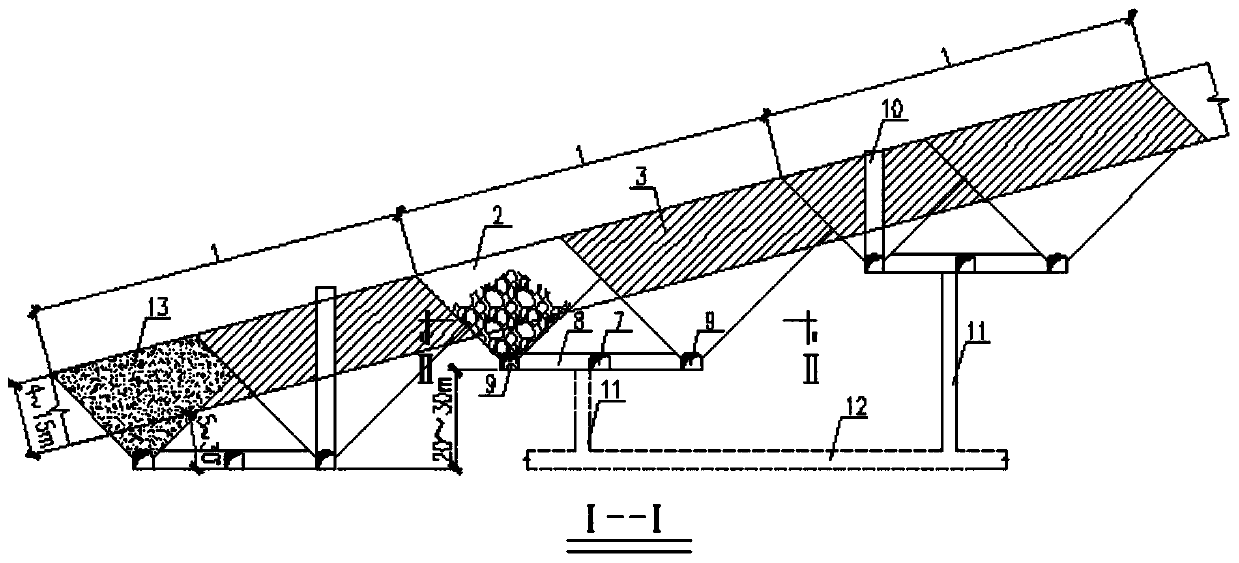

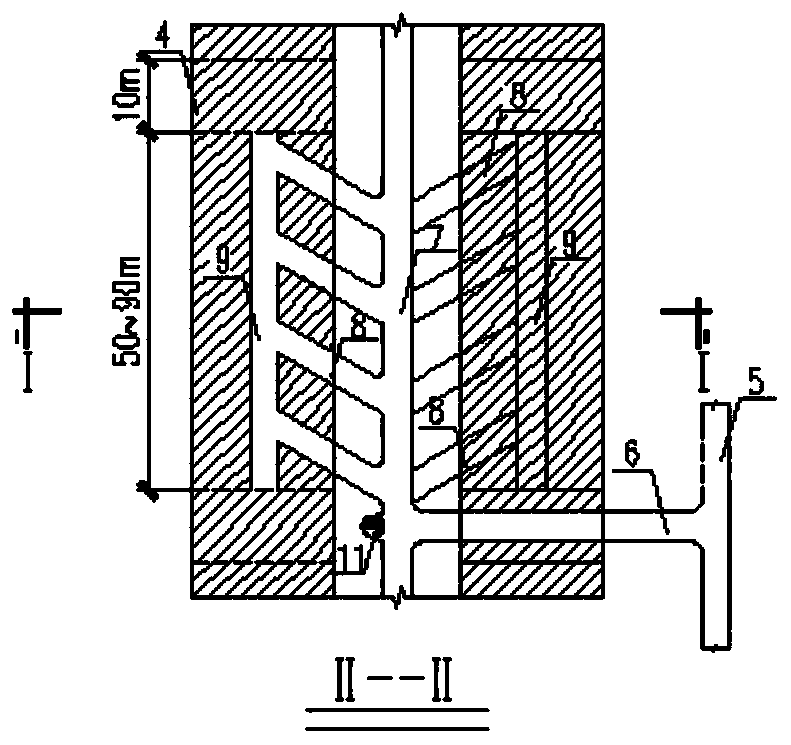

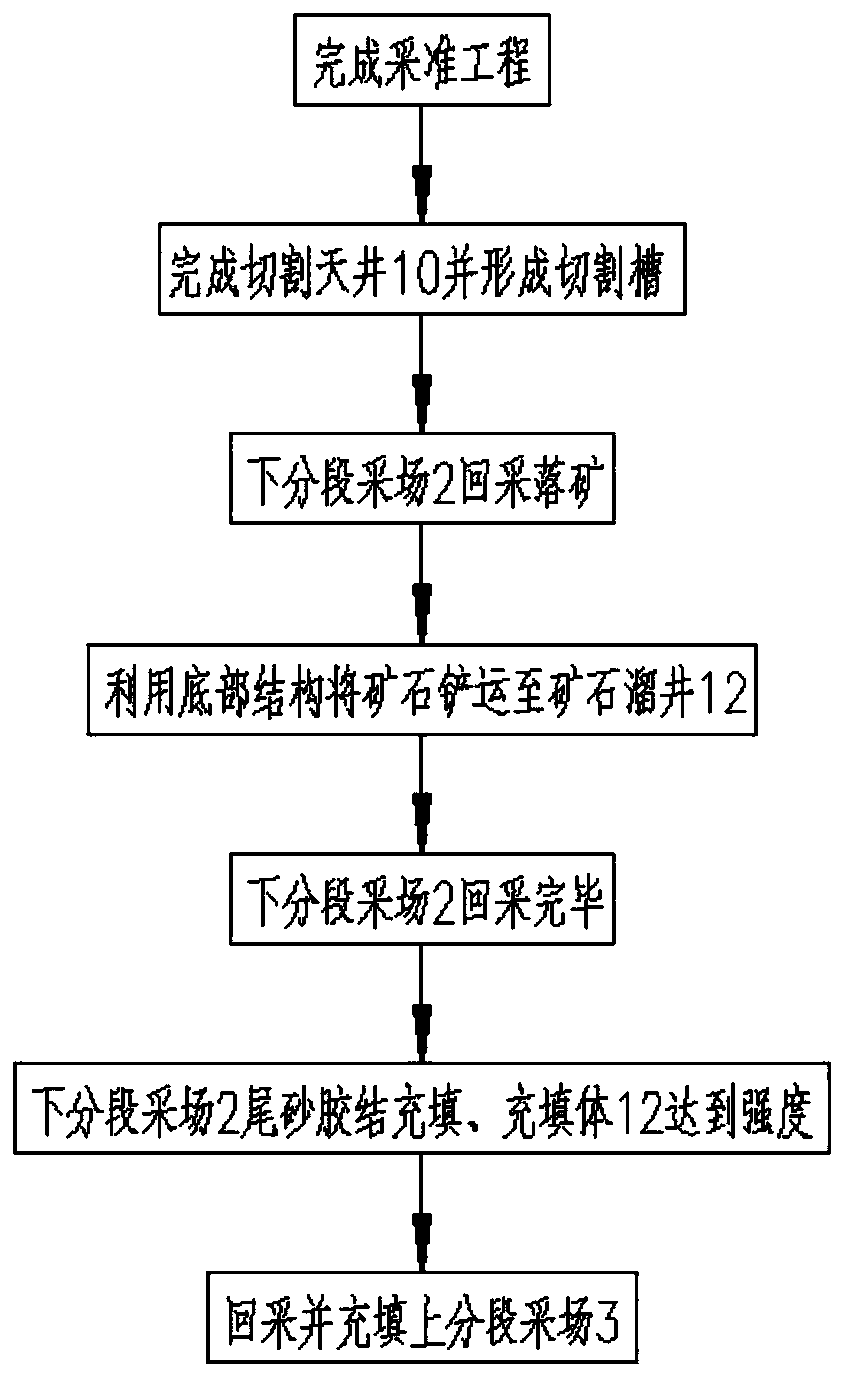

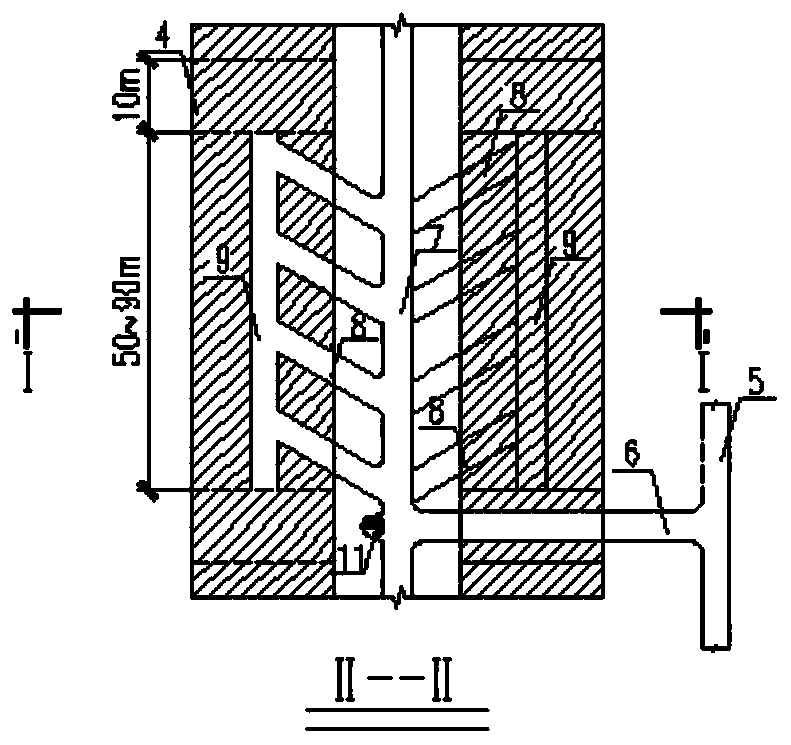

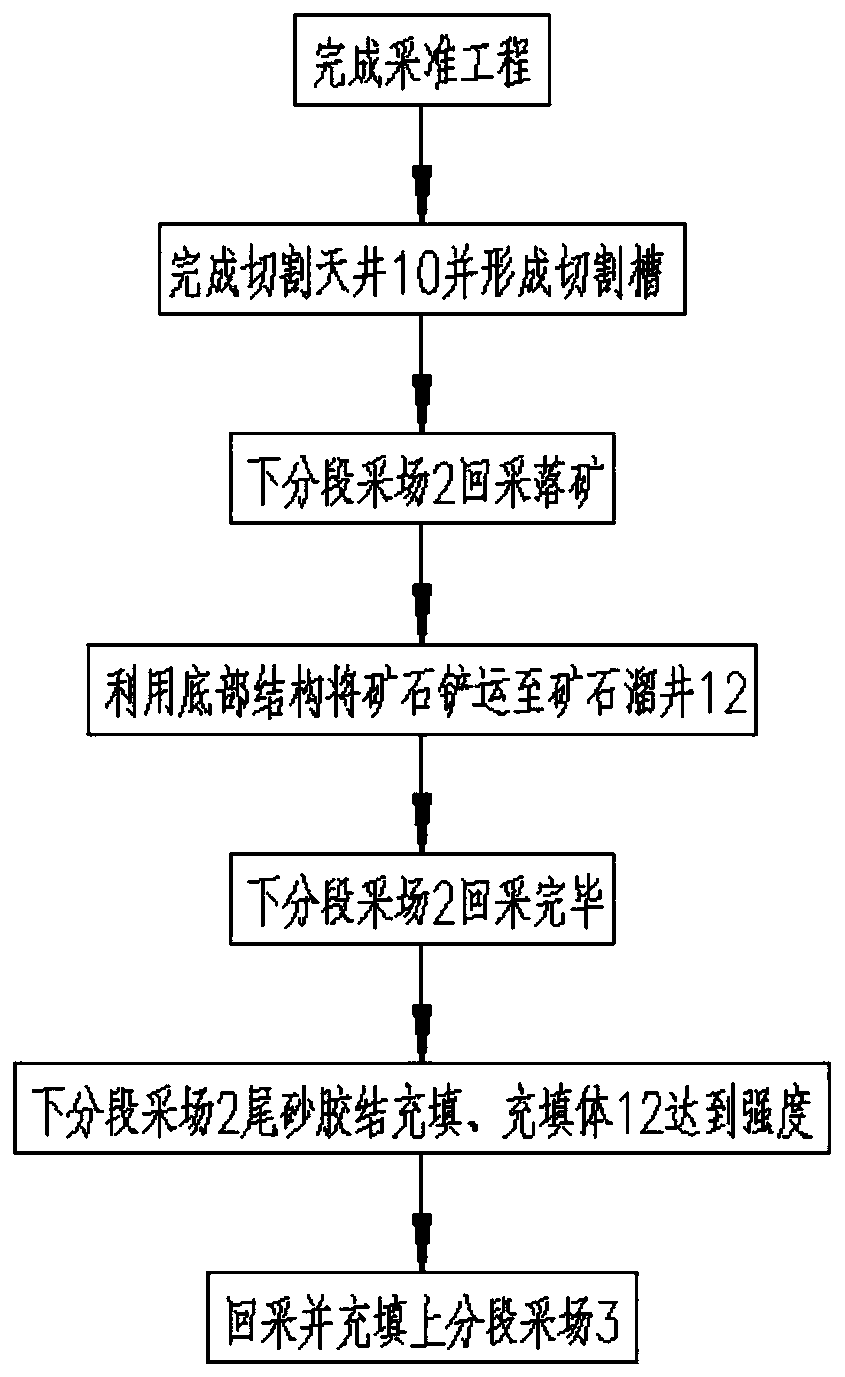

The invention discloses a gentle dip medium-thick ore body safety and low-cost combined segmented mining method. Lower segmented stopes (2) and upper segmented stopes (3) are alternately arranged in the ore body vertical direction at each interval of 10-15 m, one recovery unit (1) is formed through combination of each lower segmented stope (2) and the corresponding upper segmented stope (3), and studs (4) are scratched at the end portions of the recovery units (1). In each lower segmented stope (2), a cutting groove is formed with a cutting open yard (10) as the free face, and ore falls into atrench (9). A shoveling and conveying machine is utilized for conducting ore loading in an ore loading access road (8), carries the ore into an ore drop shaft (11) through an ore discharging roadway(7) and then lowers the ore into a conveying roadway (12) for car loading and conveying-out. According to the gentle dip medium-thick ore body safety and low-cost combined segmented mining method, every two segmented stopes are gathered into one recovery unit for exploitation, the ore discharging roadway, the ore drop shaft, a slope ramp linking way and other projects are commonly used, the stopepreparation cost is reduced, the preparing time for the stope preparation work is saved, and the exploitation efficiency is improved. Exploited waste stone can be machined into building materials to be sold, and the stockpiling space is additionally arranged for tailing filling.

Method for mining thick ore body through segmental ore breaking and subsequent cemented filling

InactiveCN107130962AEnsure safety and stabilityPrevent weatheringUnderground chambersUnderground miningShotcreteMesh reinforcement

The invention discloses a method for mining a thick ore body through segmental ore breaking and subsequent cemented filling. The method comprises the following steps: 1) dividing the ore body into a plurality of segments along the vertical direction of the ore body; 2) dividing the ore body into a plurality of stopes in each segment along the trend of the ore body; 3) arranging rock drilling roadways along a direction perpendicular to the trend of the ore body in each stope, wherein the rock drilling roadways penetrate the ore body and extend to the hanging wall rock of the ore body; 4) supporting the rock drilling roadways formed in the step 3): a, spraying concrete onto the wall surfaces of the roadways; b, knocking anchor poles into the two sides and the tops of the roadways; c, fixedly laying steel mesh reinforcement onto the two sides of the roadways; and d, spraying a 100-mm-thick layer of concrete onto the surfaces of the steel mesh reinforcement; and 5) carrying out mining: a, mining the ore body from hanging segment to footwall segment successively; and b, mining every stope in each segment in such a manner that primary mining is carried out on odd or even stopes at first and then secondary mining is carried out on the rest stopes.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Annular arrangement route mining method

ActiveCN110939443AReduce exposed areaImprove safety production factorUnderground miningClimate change adaptationMining engineeringMechanical engineering

The embodiment of the invention discloses an annular arrangement route mining method which is suitable for medium-thick ore bodies and above. The construction steps are as follows: three stope main connecting roadways are constructed in a delineated ore body, a first-step route is constructed to a left stope connecting roadway and a right stope connecting roadway along the position of the stope main connecting roadways parallel to the trend of the ore body, and a second-step route is constructed to the stope main connecting roadways along the boundaries of a left stope and a right stope; the first-step route is provided with a special cemented filling drainage well, the second-step route is provided with a reserved special ventilation well, and a graded tailings filling process is adopted;the route mining sequence, filling, ventilation and other processes of an upper section and a lower section are exchanged, the workload of stope preparation is reduced until stope coal extraction isfinished, alternate roof-contact filling upward mining of the first-step route and the second-step route of the stope is carried out, and the undercutting work quantity is reduced; and graded tailingsfilling and cemented filling are constructed alternately, and the advantages that the filling cost is reduced, the labor efficiency is high, the stope preparation work amount is relatively small, thestrength of a filling body is high, and the ventilation effect is good are achieved.

Owner:甘肃省合作早子沟金矿有限责任公司

Partition combined cut-and-filling stoping method

ActiveCN110552701AImprove recovery efficiencyIncrease profitUnderground miningBlastingCut and fillEngineering

The invention discloses a partition combined cut-and-filling stoping method, which includes the following steps: step 1, arranging a stope: dividing the stope into a front left stope and a rear rightstope along the trend of the ore body, and dividing the stope into three sections in the vertical height direction and dividing each section into three layers: step 2, constructing a transverse drifting prospecting lane to a bottom column to the vertical ore body, performing construction to a measurement inclined shaft from the stope boundary to the position above the bottom column, constructing undercutting level along the ore body trend at the position above the bottom column and near the measurement inclined shaft, then constructing a filling return air shaft inside the stope near to the lower section, and communicating the two sections at the upper part; step 3, constructing a lode outer slipping shaft and a pedestrian drainage well from the transverse drifting prospecting lane, takingthe undercutting level as a free face, then respectively performing primary lamination and secondary lamination stoping inside the two subsection stope layers, then performing stoping layer by layer;erecting the pedestrian drainage well, laying an artificial false bottom and filling an undercutting layer after the stoping is finished. The method has the advantages that the structure is simple, the construction is reasonable, the stoping efficiency is high, and the two adjacent stopes can be combined for combined stoping.

Owner:锡林郭勒盟山金阿尔哈达矿业有限公司 +1

Synchronous mining shrinkage stoping method for double-layer mine variety inclined ore body

The invention discloses a synchronous mining shrinkage stoping method for a double-layer mine variety inclined ore body. The method comprises the following four steps of 1 accurate mining, wherein a horizontal rock drift and a horizontal ore drift of a bottom plate are tunneled separately along the strike of a lower-layer mine variety, penetrate through an upper-layer mine variety by tunneling a cross drift and then enter a top plate, a horizontal rock drift and a horizontal ore drift of the top plate are tunneled separately along the strike of the lower-layer mine variety, an extracted ore drift is constructed every other a section of distance between the horizontal rock drifts and the horizontal ore drifts, and accurate mining raises are constructed in the horizontal ore drifts in the inclined direction of the ore body; 2 cutting, wherein connection roadways are constructed by being perpendicular to the accurate mining raises in the accurate mining raises every other a section of the distance; 3 stoping, wherein layered ore break by blasting is performed from bottom to top after undercutting of the horizontal ore drifts is finished; 4 ore drawing, wherein a carry-scraper performs ore drawing on a stope through the extracted ore drift. According to the synchronous mining shrinkage stoping method for the double-layer mine variety inclined ore body, synchronous stoping of the two mine varieties is achieved, the mining activity time is shortened, the bottom structure of a traditional shrinkage stoping method is eliminated and changed into a rock access ore drawing, the safety is reliable, and the ore recovery rate is increased.

Owner:GUIYANG AL-MG DESIGN & RES INST

Downward high-layer cemented filling mining method

ActiveCN112177612AIncrease production capacityReduce mining costsUnderground miningSurface miningMining engineeringMechanical engineering

The invention provides a downward high-layer cemented filling mining method. The method comprises the steps of stope arrangement, accurate mining cutting, stoping and filling. In the stoping process,layers of the preset number are divided into stoping subareas in a downward drift and upward layer stoping synergistic effect manner, and stoping is conducted on ore bodies of subarea lower layers ineach stoping subarea through a drift method; and then ore bodies of subarea upper layers are stoped in a retreating manner in an upward picking mining manner. By means of the manner, the overall stoping strength and the mechanization degree can be effectively improved, so that the ore removal efficiency is greatly improved, and the overall production capacity of a stope is improved. Meanwhile, based on the division of the stoping subareas in the method, a plurality of layer connecting roadways required by a plurality of layers originally can be reduced to one, so that the mining preparation work amount is greatly reduced, the mining efficiency is further improved, the ton ore stoping cost is reduced, and the method has the characteristics of simple process, high safety, high production capacity, low ton ore cost and the like.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

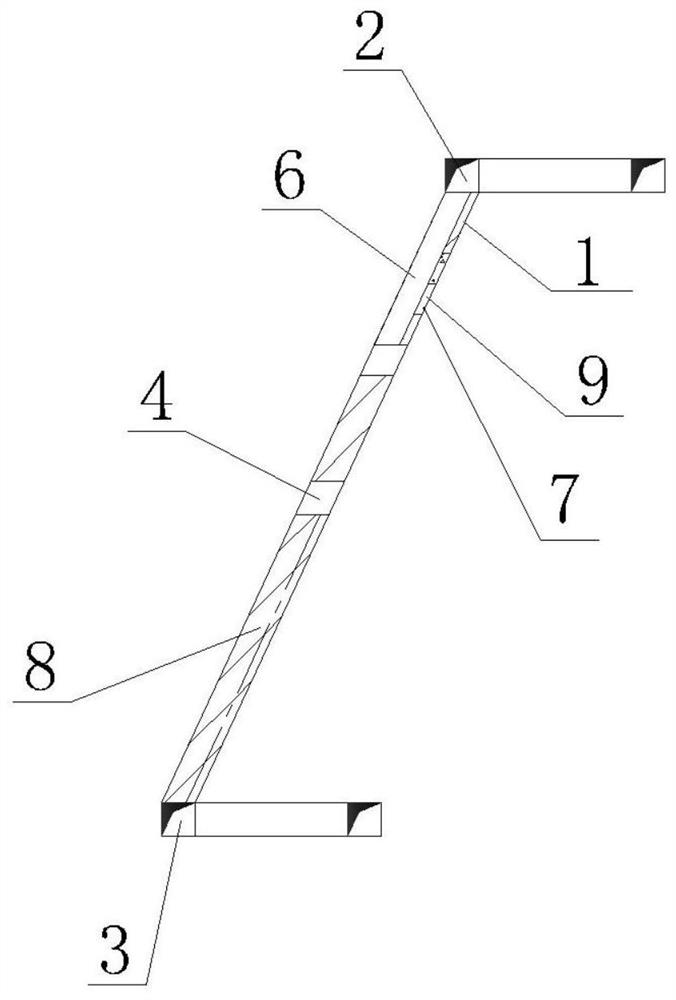

Method for mining inclined and steeply inclined thin ore body

PendingCN114183142AAchieve miningEasy to operateUnderground miningSurface miningMining engineeringRock bolt

The invention discloses a method for mining an inclined and steeply inclined thin ore body, which comprises the following steps of: dividing ore blocks along the trend of the ore body, and upwards digging an outside-vein pedestrian ventilation raise, a connection gateway and an ore removal roadway on a footwall of the ore body; the stoping sequence of advancing from one side of a stope to the other side and from bottom to top is adopted, blast hole drilling and one-time multi-hole multi-row blasting are conducted, point columns are reserved in the stoping process, wall-knocking and top-digging work is strengthened, and anchor rods are adopted for anchoring when necessary; firstly, one third of the ore is transported out by a forklift through an ore removal roadway, the reserved point columns and the caved ore support the hanging wall surrounding rock of the stope together, and after stoping is conducted to the top column position, a large amount of ore drawing is conducted; and blocking a transverse drift roadway, an ore removal roadway and the like of the stope by using grouted rubble. Through theoretical calculation and field practice, mining of the inclined thin ore body is achieved under the conditions that a filling technology is not newly built and the whole mining technology is not changed, and high operability is achieved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Hanging wall crushing gentle-inclined thick and large ore body filling mining method

ActiveCN112682041ASafe working conditionsImprove working environmentUnderground miningClimate change adaptationMining engineeringMechanical engineering

The invention discloses a hanging wall crushing gentle-inclined thick and large ore body filling mining method. The method comprises the steps that 1) a hanging wall area and a mining area are divided in the ore body walking direction, and a stud is arranged; 2) stages and sections are divided, and ore blocks are arranged in the sections in a strip mode; 3) a stope preparation slope ramp is arranged on a lower wall to communicate all the sections, and ore removal connecting channels are arranged in a cross drift in a staggered mode to communicate with ore receiving roadways of all the ore blocks; 4) roof control is conducted on hanging wall crushing surrounding rock in advance, and a stable roof environment is reconstructed; 5) parallel medium-length hole caving is conducted downwards through roof control roadways; 6) retreating type stoping is conducted from the two wings to the middle in the hanging wall area, and ore blocks are transferred to an ore removal draw shaft through trackless equipment; 7) filling operation is conducted after stoping is finished; 8) all the sections are stoped step by step, and ore body mining is completed; and 9) the stud is recovered in the cross drift in a retreating mode. According to the method, the stable roof environment is reconstructed, and the operation condition is safe; good through air flow can be formed, and the operation environment is good; and medium-length hole caving is adopted, the ore removal route is simple and fixed, large-scale operation of the trackless equipment is facilitated, and the production efficiency is high.

Owner:FENY

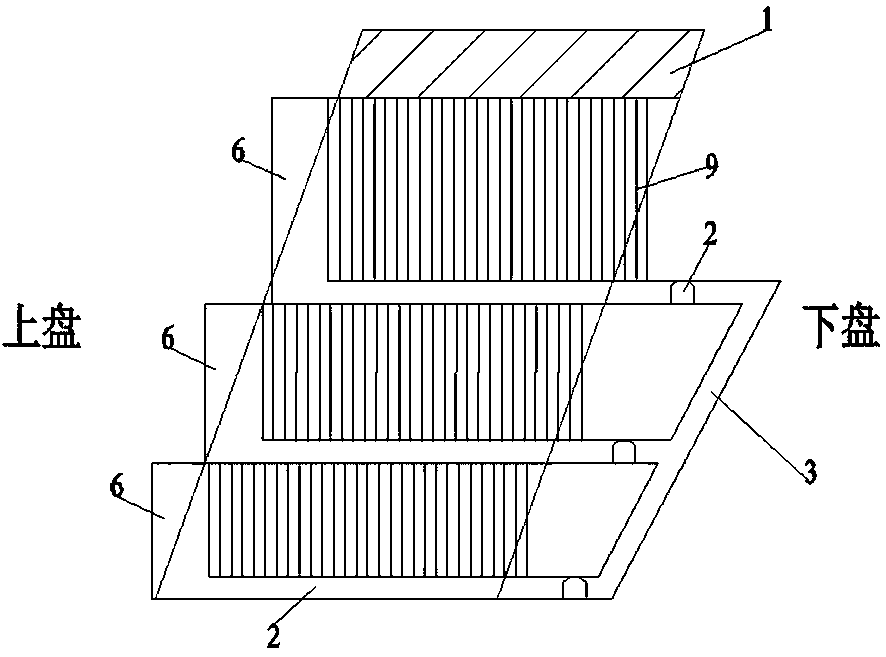

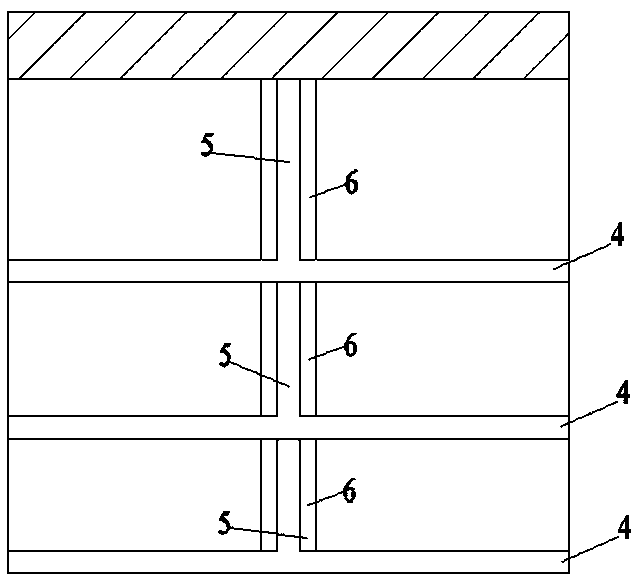

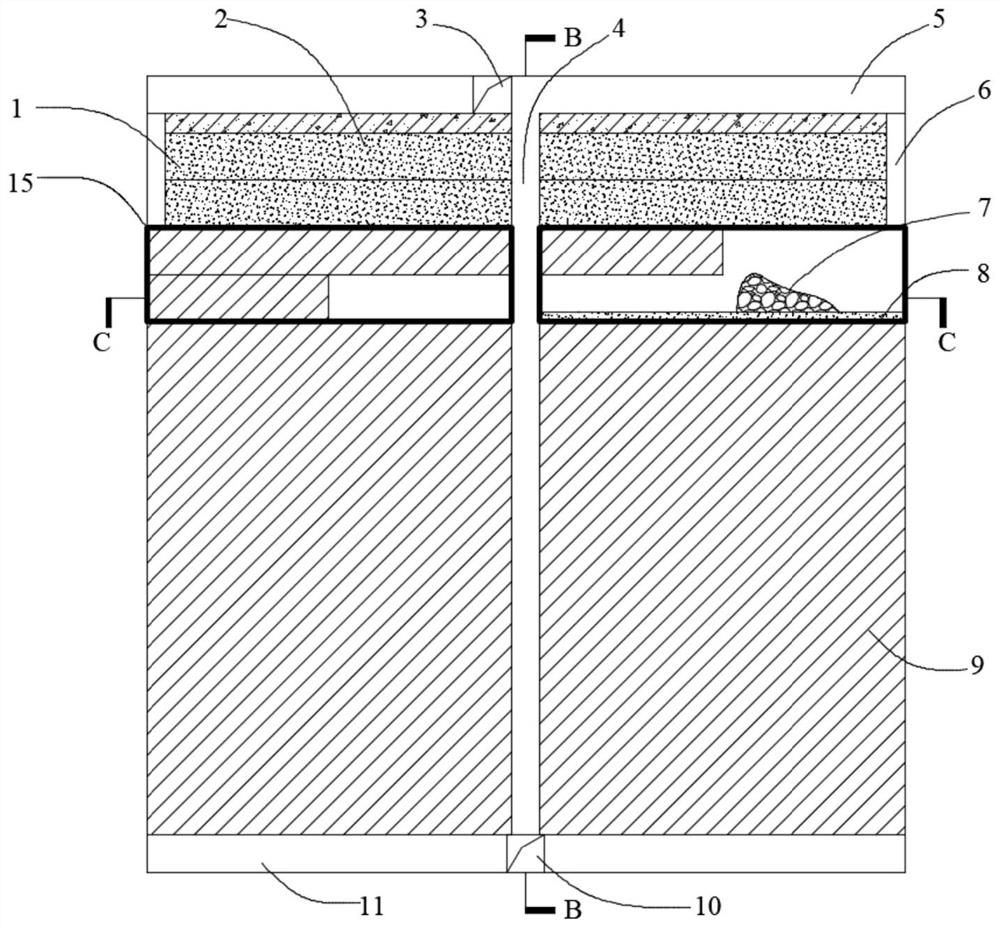

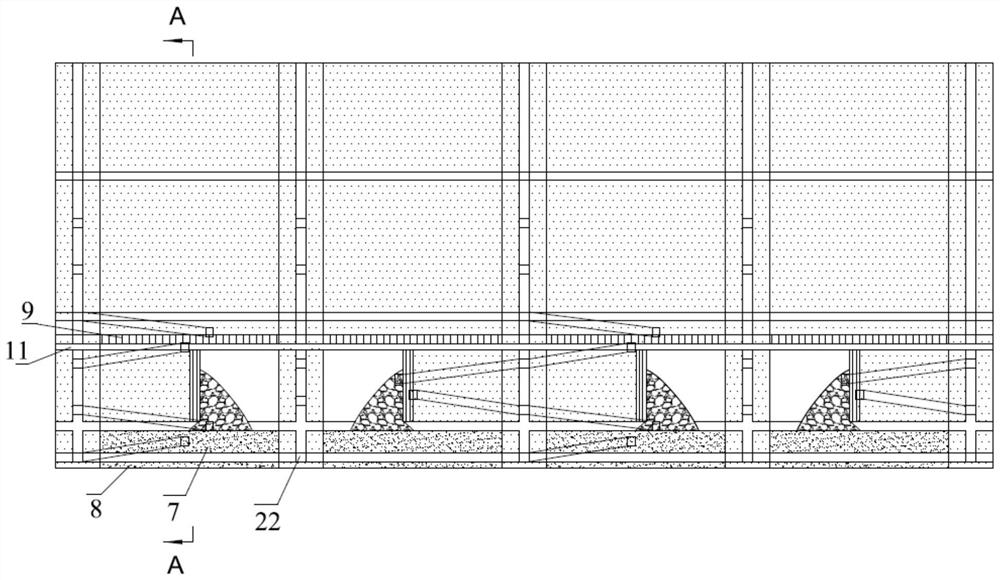

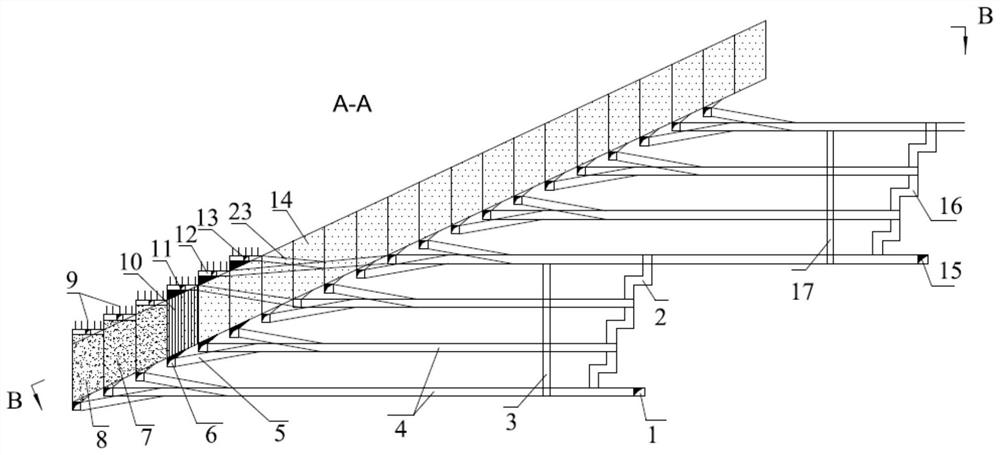

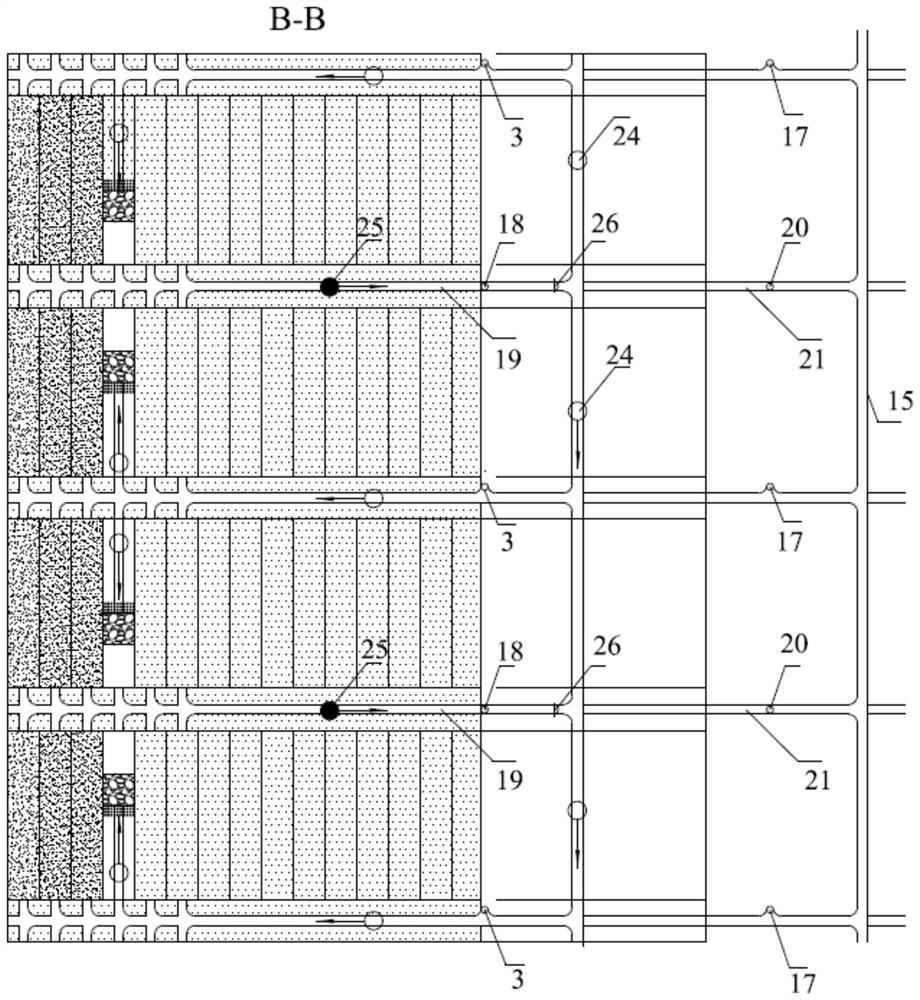

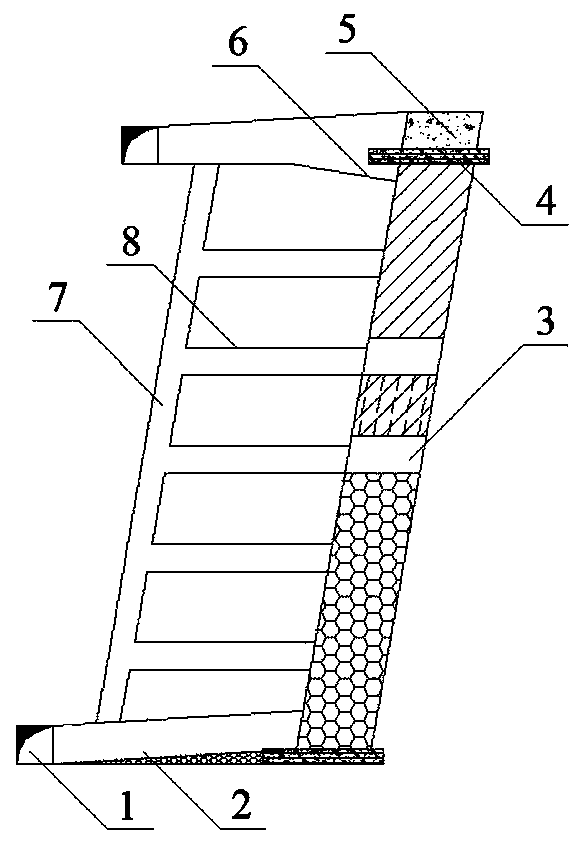

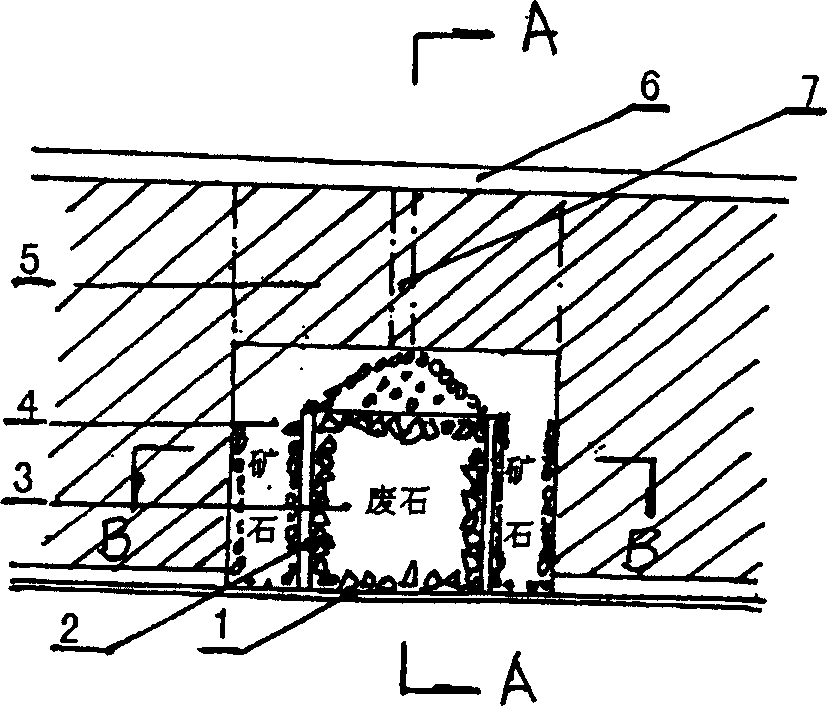

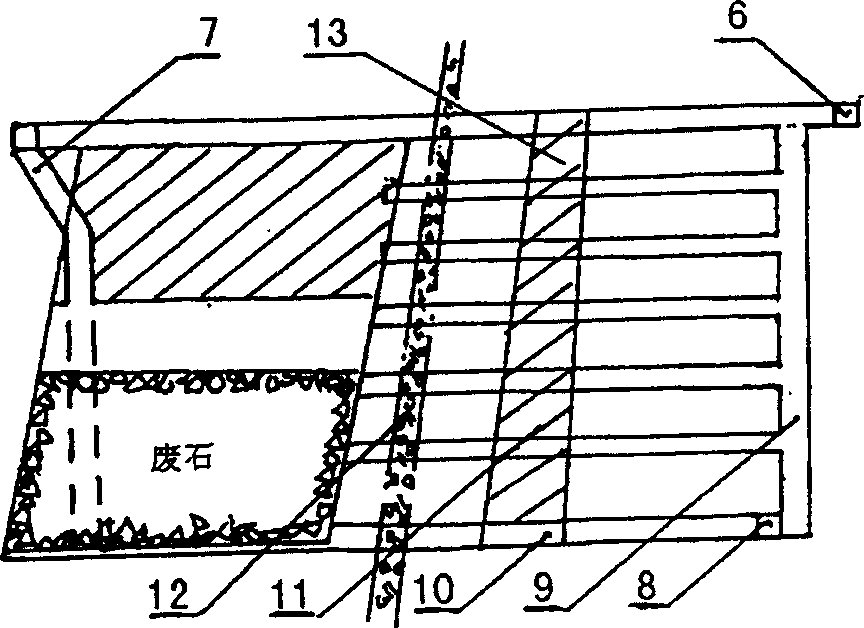

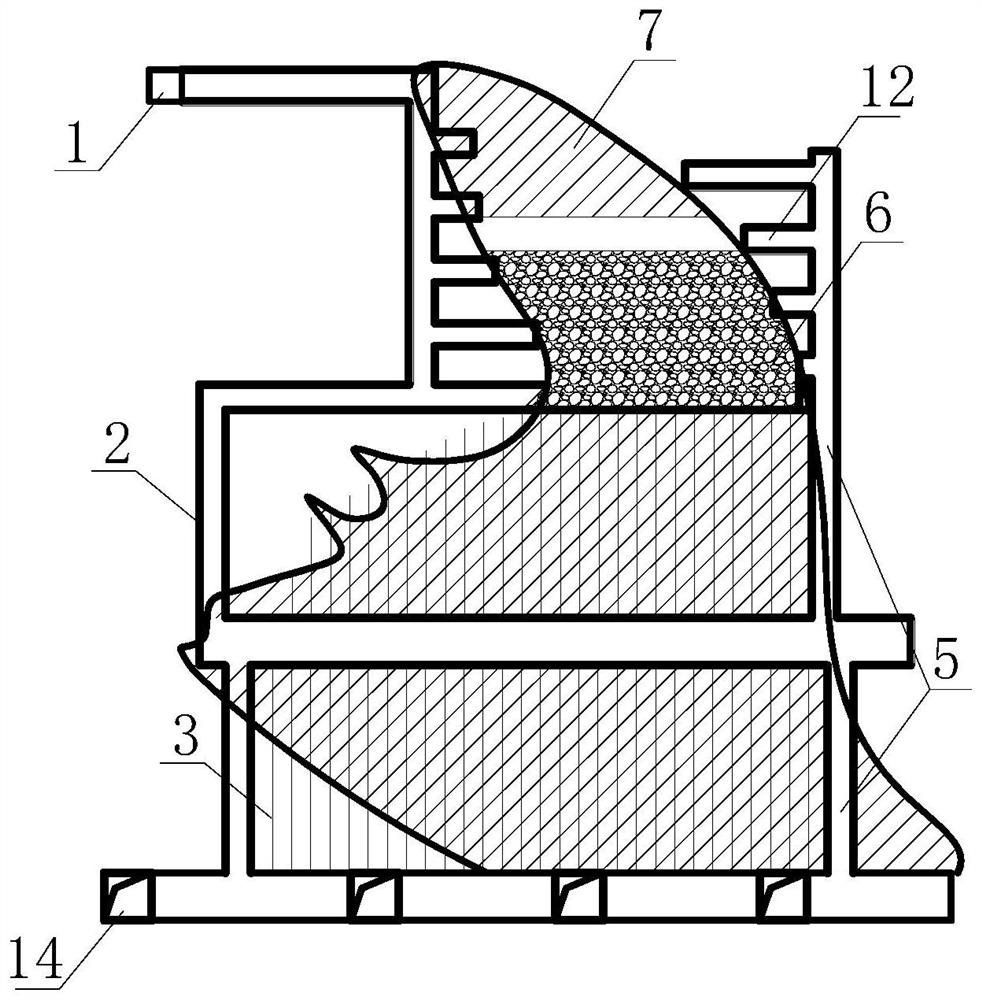

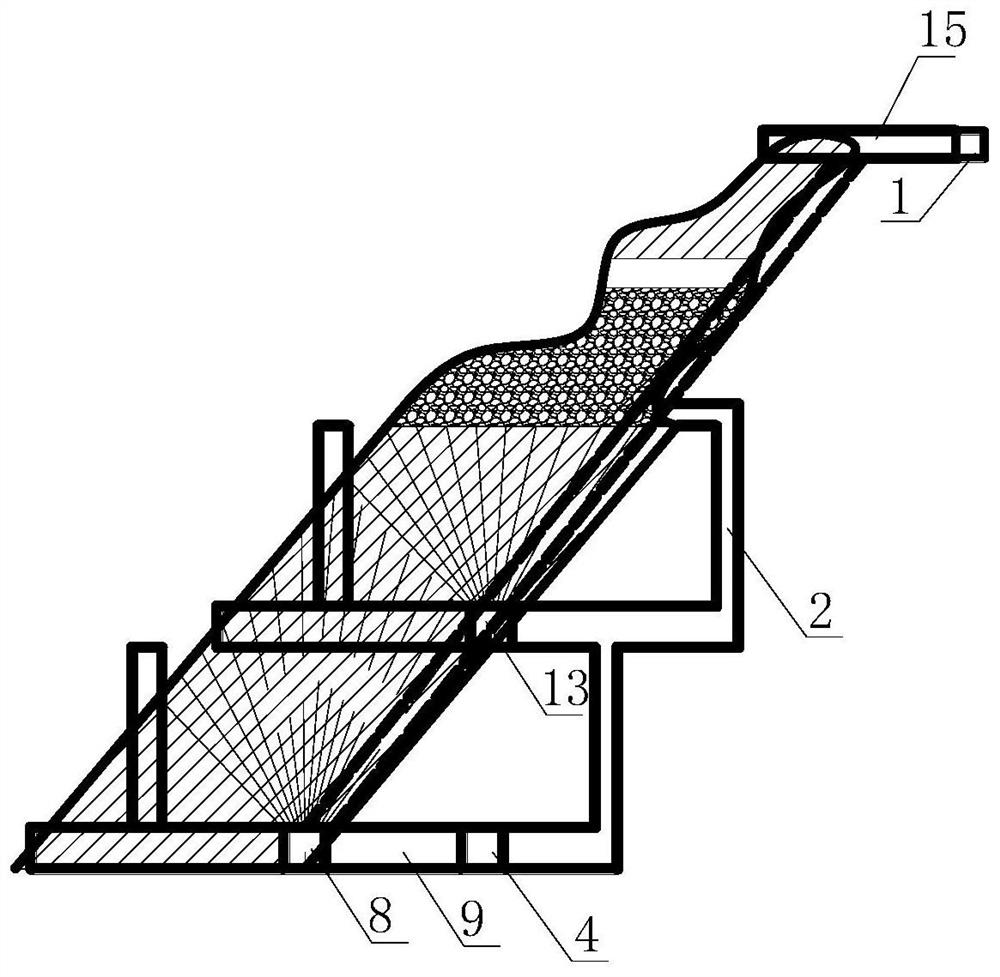

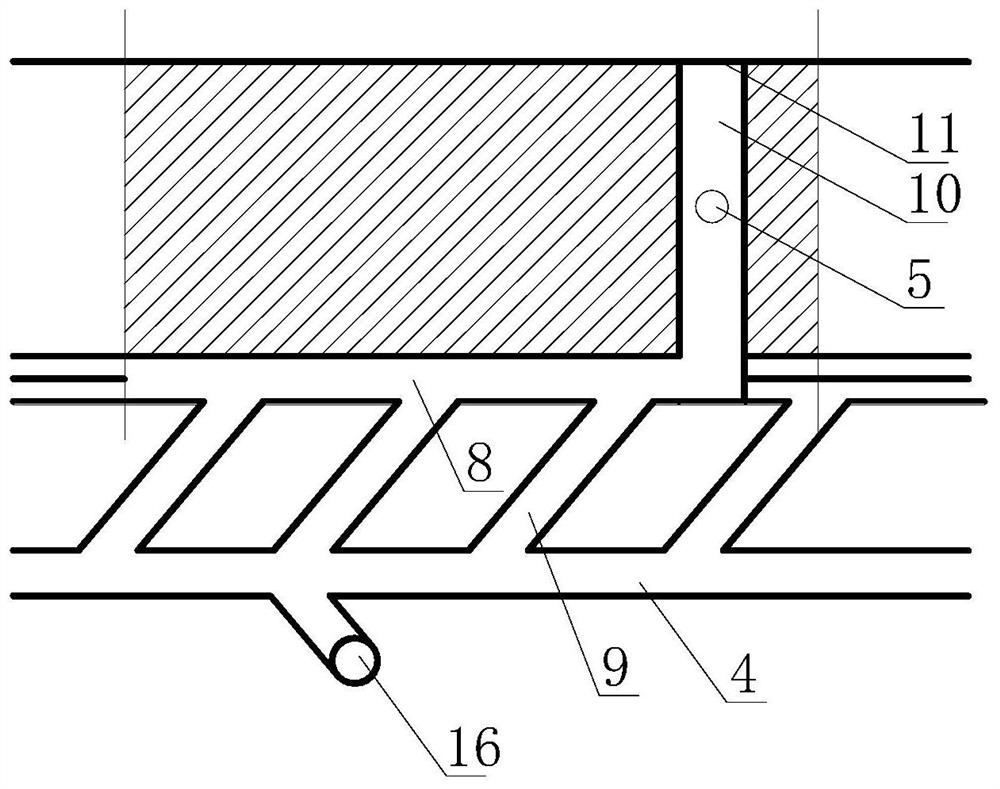

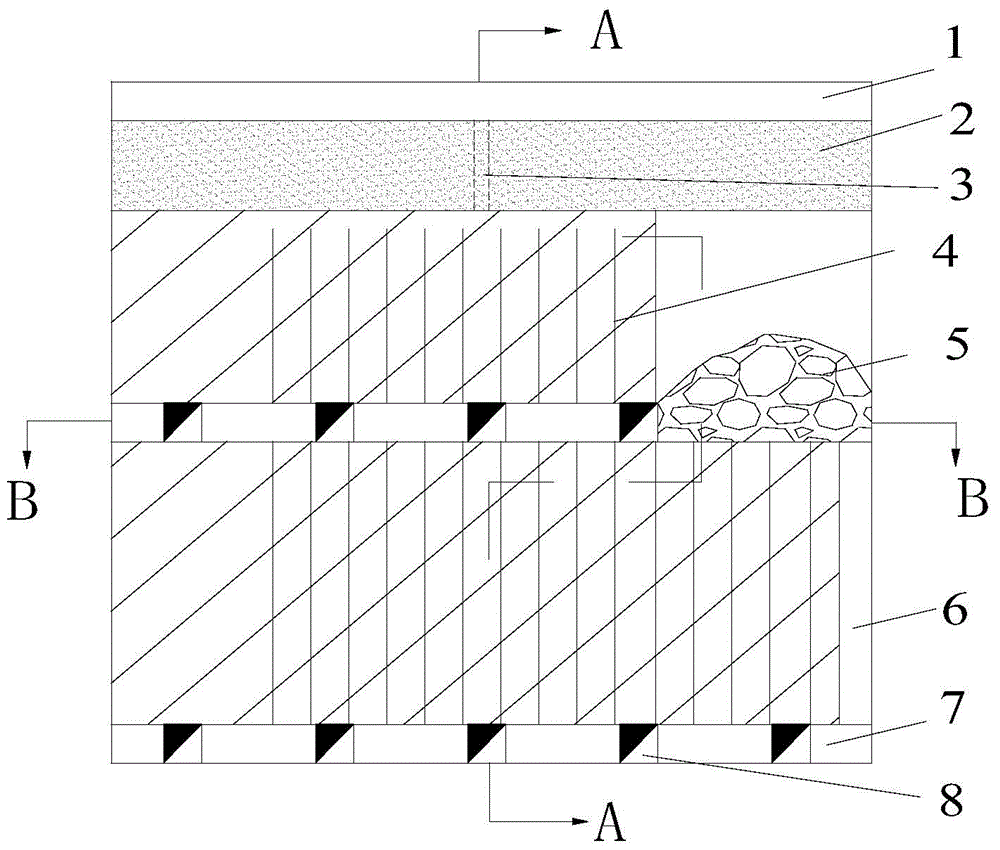

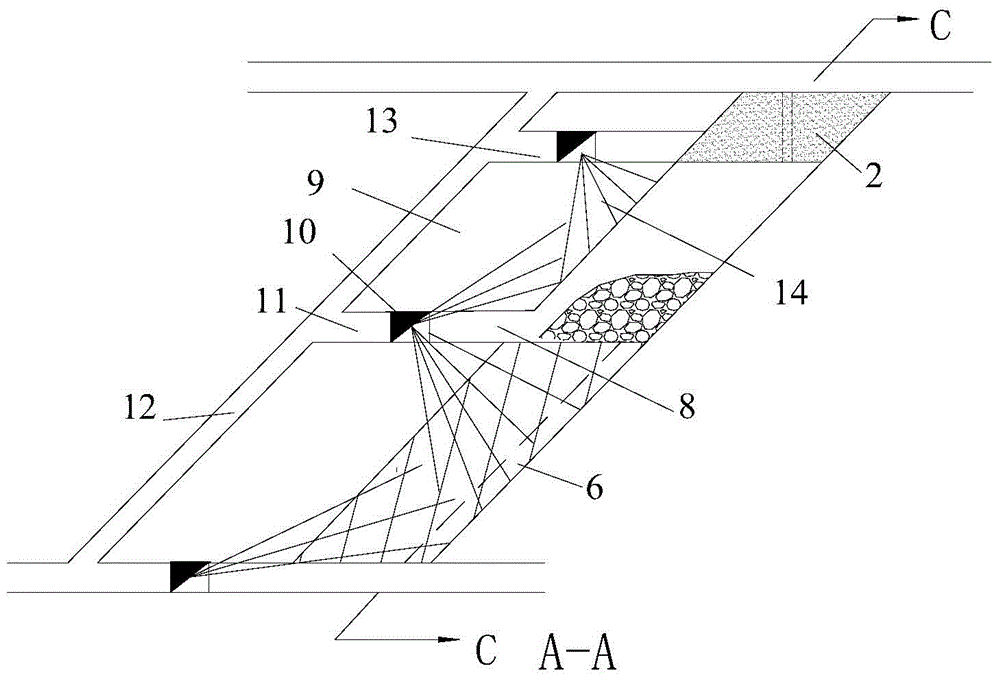

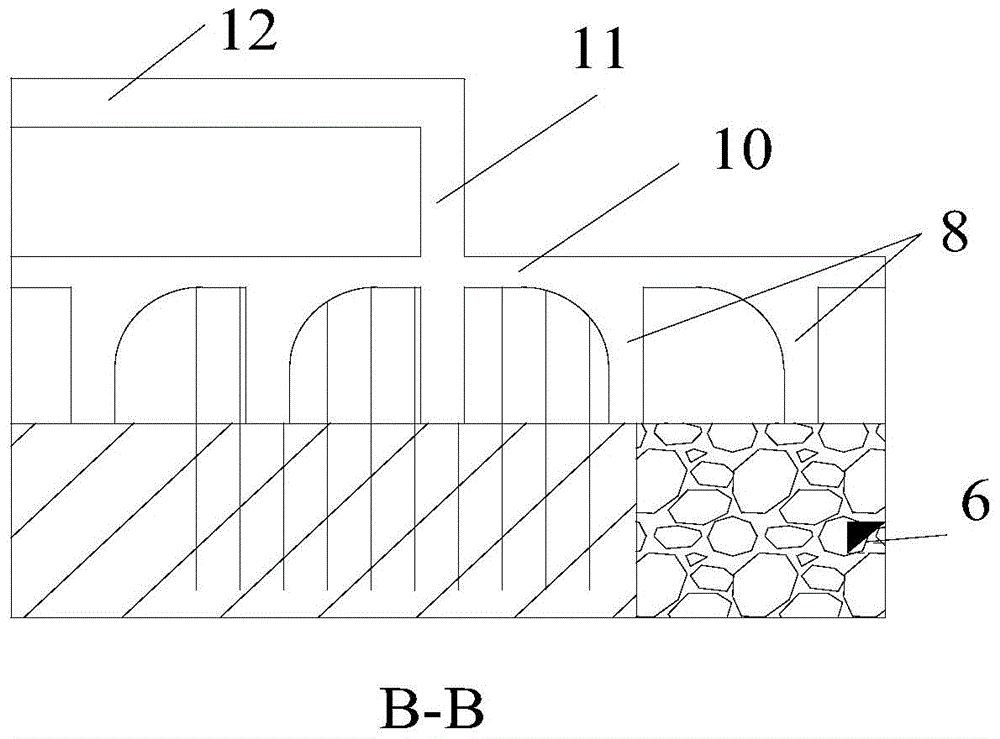

Stope structure arrangement method applicable to gently inclined medium and thick ore body combination sectioned mining

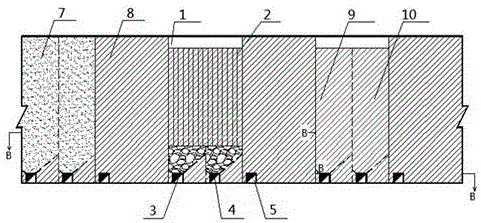

ActiveCN110388210AReduce preparation timeReduce the amount of quasi-engineeringUnderground miningSurface miningEngineeringTailings

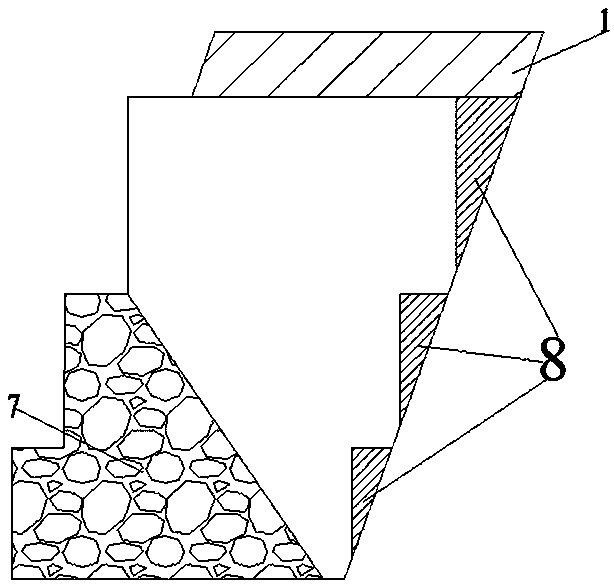

The invention discloses a stope structure arrangement method applicable to gently inclined medium and thick ore body combination sectioned mining. Lower sectional stopes (2) and upper sectional stopes(3) are alternately arranged in the vertical direction of an ore body every 10-15 m, each lower sectional stopes (2) and upper sectional stopes (3) are combined into a mining unit (1); studdings (4)are formed at the ends of the mining unit (1); cutting troughs are formed in the stopes with slot raises (10) as a free surface; ore falls into ditches (9); and ore is loaded in an ore loading approach road (8) through a carry-scraper, carried to an ore draw shaft (11) through an ore removal roadway (7), and then dropped to a haulage roadway (12) to be loaded and conveyed out. Every two sectionalstopes are divided into a mining unit for mining, projects such as the ore removal roadway, the ore draw shaft and a slope road linking taxiway are shared, the accurate mining cost is reduced, the preparation time for accurate mining work is saved, the mining efficiency is improved, mined waste rock can be processed into building materials for sale, and new storage space for tailings filling is additionally formed.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Copper ore mining process

InactiveCN108425673AHigh degree of controlHigh recovery rateMining devicesUnderground miningStopingMaceral

Relating to the technical field of mineral exploration, the invention provides a copper ore mining process. The process includes the steps of: (1) mining area setting, (2) prospecting, (3) mining, (4)stoping, and (5) desliming. The mining process provided by the invention has high control degree on the ore body, can effectively improve the copper ore recovery during mining and reduce the loss rate and dilution rate of copper ore, improves the utilization rate of mineral resources, provides resource guarantee for sustainable development of mines, and has good use value and application prospects.

Owner:广西华洋矿源材料有限公司

A False Roof Pillar Mining Method with Ore Reserved and Filled

ActiveCN108661646BImprove securityAvoid constructionUnderground miningSurface miningRoom and pillar miningEngineering

The invention provides an artificial roof room-and-pillar shrinkage subsequent filling mining method. The method comprises the steps that mine block structures are divided, specifically, an ore body is divided into multiple stages, ore chambers and ore pillars are divided in the stages in an ore body trend, and the ore chambers and the ore pillars are divided into multiple subsections; mining preparation and out seam mining preparation are conducted, specifically, a stage transportation haulage, a stage ore removal crosscut, a service ventilating raise, a subsection connection roadway, a filling inclined roadway and a drilling chamber are arranged; cutting is conducted; exploding is conducted, specifically, sector-shaped blast holes are drilled in the stage drilling chamber to cave down ores; stopping and ore removal are conducted, specifically, exploding is conducted from bottom to top in each stage, after each time of exploding, part of ores are transported from the stage ore removalcrosscut, remaining ores are shoveled out collectively on the stage ore removal crosscut after the ores are circulated to the topmost subsection ores are exploded and caved down, if the way of working to the dip is adopted during the stages, before upper stage stoping, an artificial roof is constructed on the top of the upper stage, and an artificial bottom is constructed on the bottom of the upper stage, and the artificial bottom of the upper stage is the stoping artificial roof of the next stage; and if the way of working from bottom up is adopted, the artificial roof of the next stage serves as the stoping artificial bottom of the upper stage.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Mining method of slanting uphill combined with downward approach cemented filling

ActiveCN112196538BEasy to transfer layersReduce the amount of quasi-engineeringUnderground miningBlastingMining engineeringSlag

The invention discloses a method for cementing and filling mining with an inclined uphill combined with a downward approach, comprising the following steps: a. Stope design, arranging stopes along the trend of an ore body, determining the width of the approach path according to the thickness of the ore body, and determining the degree of fragmentation of the ore body by determining the width of the ore body. Determine the height of the approach; b. Precise cutting works; c. Control the roof. After the construction is inclined up the hill, rock drilling tunnels along the veins, and after the approach, support with anchor nets; in areas with severe fractures, steel arches are used for auxiliary support , among which the exposed area of the inclined uphill and the opening of the entrance is relatively large, and the steel arch frame is used for intensive support; d. The ore is recovered, and after blasting and ventilation, the slag scraper, electric tricycle and electric rake are used to jointly extract the ore; e. Mechanical equipment transfer layer; f, cement filling. The invention has the characteristics of simple mechanical layer transfer, high safety, high ore extraction efficiency and simple construction technology, and is especially suitable for the mining of steeply inclined broken thin ore bodies.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

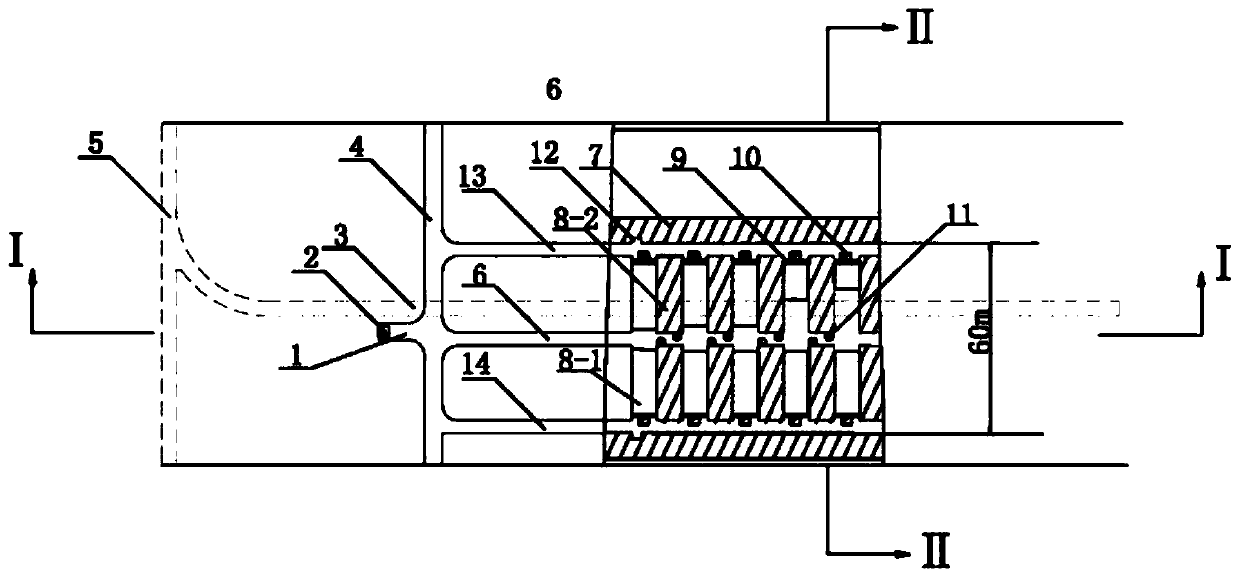

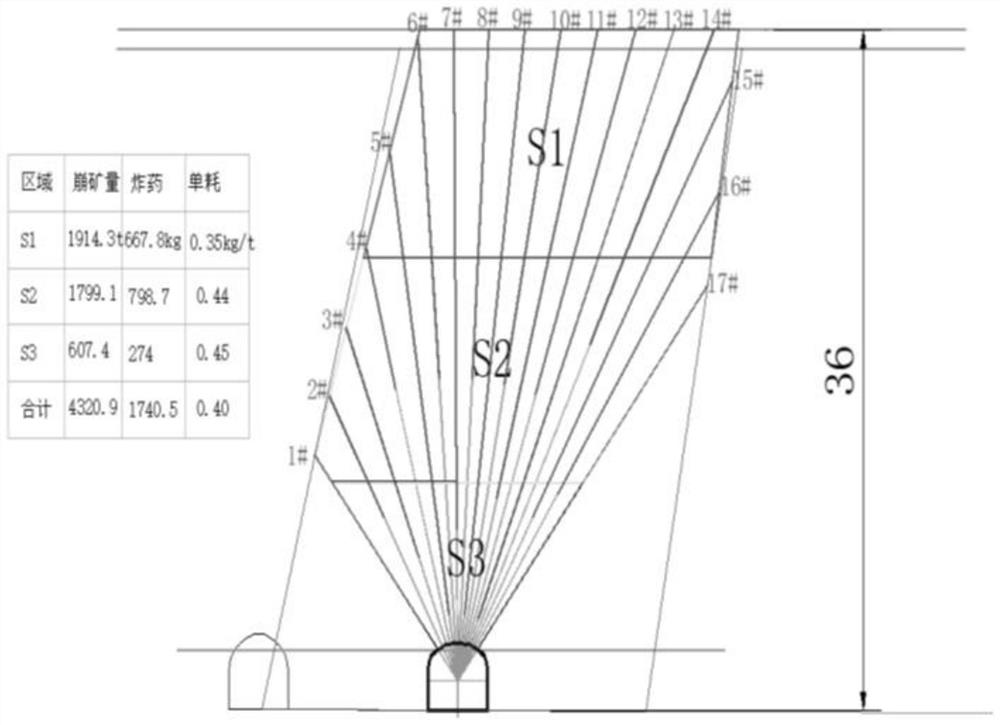

Novel 90-m high-middle-section fan-shaped deep hole stoping method

PendingCN113090265AReduce the amount of quasi-engineeringReduce cutting ratioUnderground miningBlastingMining engineeringRock cutting

The invention discloses a novel 90-m high-middle-section fan-shaped deep hole stoping method, and relates to the technical field of mining processes. The novel 90-m high-middle-section fan-shaped deep hole stoping method comprises the following steps: S1, rock drilling level stoping preparation is designed, a panel is divided into two chambers in the ore body trend, the two chambers are the first chamber and the second chamber respectively, and a rock drilling chamber is constructed in each chamber in the rock drilling level in the ore body trend. According to the novel 90-m high-middle-section fan-shaped deep hole stoping method, the stoping preparation work amount of the chambers is small, the mining cutting ratio is low, and the stoping preparation cost is low; the dilution rate of the chambers is low; the blasting lumpiness is uniform, the lumpiness rate is low, and the secondary crushing cost is low; the perforation amount is small, the perforation cost is low, damage of blasting to chamber sides is small, and the stability of the chambers is good; and meanwhile, compared with an original VCR mining process, one rock drilling chamber can be omitted for each chamber, about 50% of stoping preparation work amount can be saved, the perforation cost is reduced by about 3 yuan / t, and the direct cost of blasting, ore removal and secondary crushing is reduced by 2.5 yuan / t by adopting a fan-shaped deep hole stoping process.

Owner:安徽马钢张庄矿业有限责任公司 +1

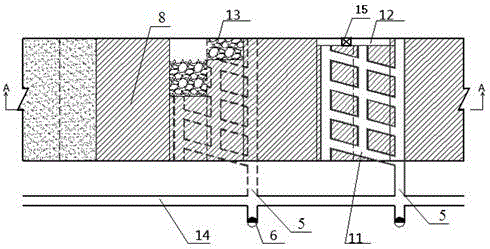

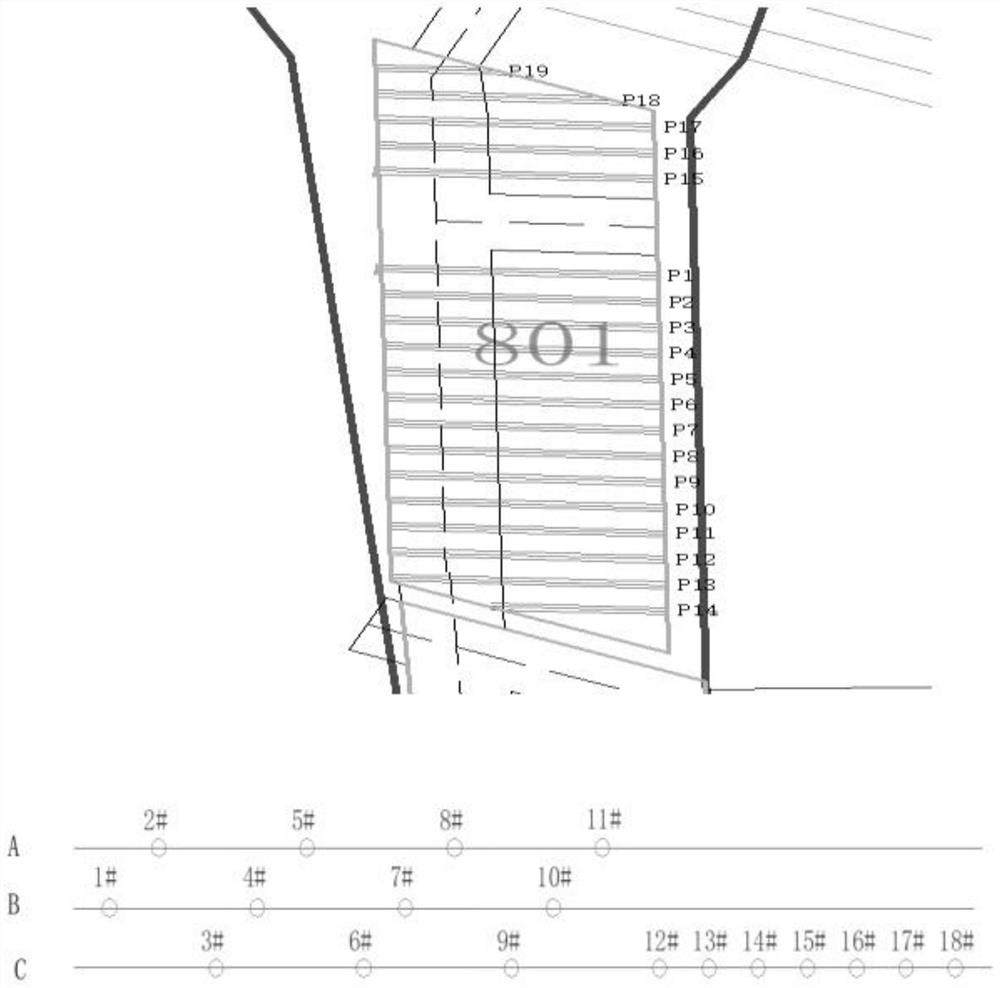

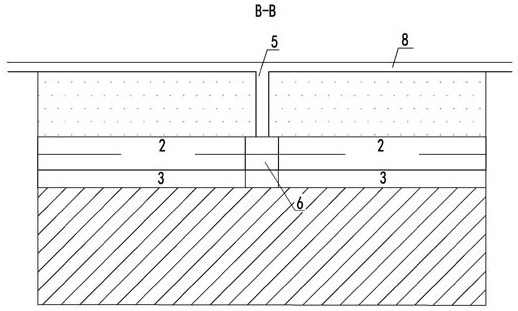

Downward layered up-down staggered drift filling mining method

PendingCN113187545AMining is safe and reliableLarge access sectionMining devicesMaterial fill-upMining engineeringMechanical engineering

The invention relates to a downward layered up-down staggered drift filling mining method. The downward layered up-down staggered drift filling mining method is realized through stope arrangement, mining preparation cutting, stoping, stope ventilation and stope filling, and comprises the following steps that firstly, a preparation layer is formed at the top of an ore body, a first layered drift is started to be stoped after the preparation layer drift is completely filled, a second layered drift is stoped after the first layered drift is completely filled, and after the second-layer drift is mined, a downward layered up-down staggered drift stope structure is formed; the next-layer drift and the previous-layer drift are staggered up and down by 3 m and are stoped at intervals, the distance is 5 m, the top of the drift is a filling body false top, the upper half parts of the two sides are filling bodies, the lower half parts are ore bodies, and the safety is high; the two sides of the access are not prone to caving, and stoping is safe and reliable; the access section is large, and the production capacity is high; the inlet road is stoped along the top plate of the upper layer, the stoping direction is easy to control, and the engineering quality is high; the stope production organization is simple; the stope is simple in structure, the accurate mining project is simple, and the accurate mining project amount is small; large trackless equipment can be used in the stope, so that the production efficiency of the stope is greatly improved; and the stope filling engineering system is simple.

Owner:金川镍钴研究设计院有限责任公司 +1

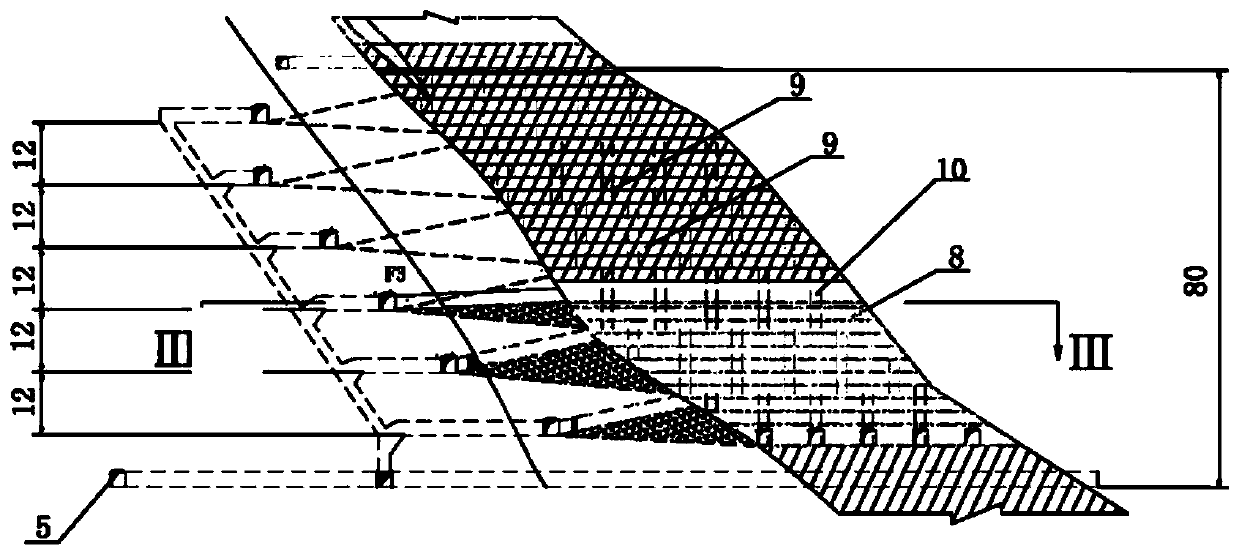

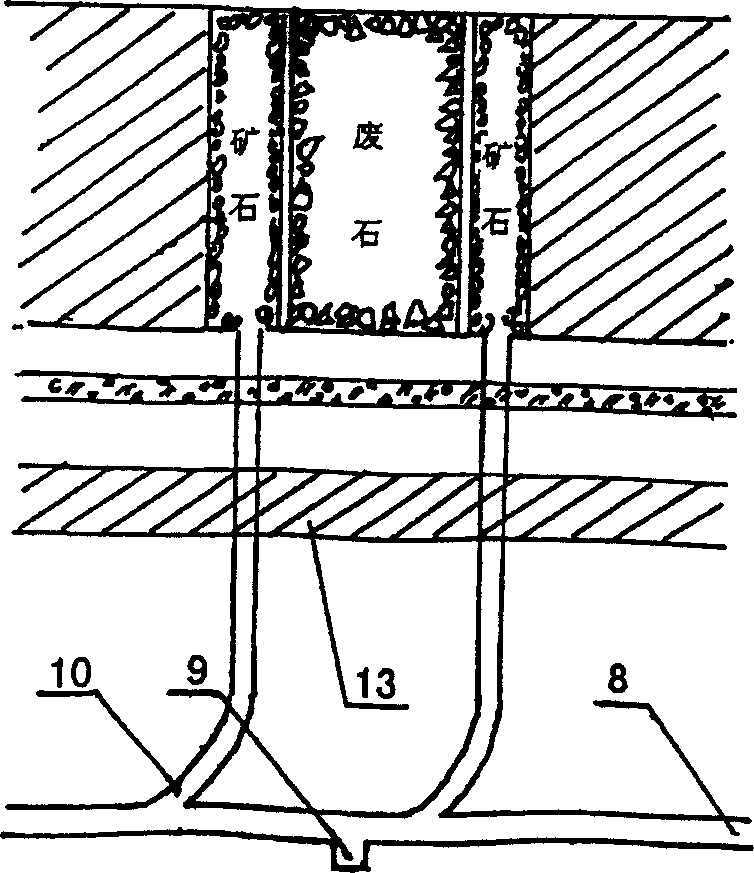

A mining method of underground mine with two adjacent stopes and one mining roadway

ActiveCN108625856BReduce the amount of quasi-engineeringControl mining boundariesUnderground miningBlastingRock cuttingStoping

The invention discloses a mining method for an underground mine with an ore-drawing roadway arranged between every two adjacent stopes. The mining method comprises the steps that an ore body is divided into a plurality of ore blocks along the trend of the ore body, the length of each ore block is 40-80 m, then each ore block is divided into an ore chamber and a jamb, and a middle column is arranged between the bottoms of each ore chamber and the corresponding jamb; a hanging wall in-vein air return roadway and a footwall in-vein transportation roadway are arranged along the trend of the ore body, and the footwall in-vein transportation roadway is arranged outside the ore body and is parallel to the trend of the ore body; an orepass is arranged on the other side of the footwall in-vein transportation roadway; and when the thickness of the ore body is larger than 40 m, the ore chambers and the jambs are arranged perpendicular to the trend of the ore body, each ore-drawing roadway betweenthe bottoms of the two corresponding adjacent stopes is arranged perpendicular to the trend of the ore body, the length of each stope is equal to the length of the ore blocks, the width of each stopeis 13-20 m, the height of each stope is 40-100 m, and drilling chambers are arranged at the bottom of the upper-middle section. In the mining method, during two-step stoping, tunneling in a filling body is not needed, and the novel method is large in production capacity, small in mining project amount and efficient.

Owner:安徽大昌矿业集团有限公司

Filled mining method

InactiveCN1186519CShort filling lengthHigh speedUnderground miningSurface miningUltimate tensile strengthMineralogy

Owner:广东金鼎黄金有限公司

Method for safely and efficiently recovering panel pillars by using sublevel open-stope subsequent filling method

ActiveCN113586057AMining preparation time is shortThe recovery process is safe and reliableUnderground miningSurface miningMining engineeringRetaining wall

The invention discloses a method for safely and efficiently recovering panel pillars by using a sublevel open-stope subsequent filling method, A sublevel rock drilling roadway (5), a sublevel contact way (6), a stope slope ramp (7) and a sublevel vein-following contact way (8) of an original project are fully utilized, filling raises are arranged at intervals in the length direction of the panel pillars (3) according to design parameters in the upper section of the middle section of stoping, the filling raises are used for backfilling waste rocks to form a filling waste rock covering layer (9) according to the mining principle of a sill-pillar-free sublevel caving method, ore removal is completed under the covering layer, it is ensured that ore rocks in a stope are full, and retaining wall pillars (10) on the two sides are supported, so that the stoping safety is ensured. The method is high in ore recovery rate, high in recovery capacity, low in recovery cost, high in mechanization degree, safe in operation environment, free of goaf after recovery and free of hidden danger.

Owner:KUNMING UNIV OF SCI & TECH +2

A mining method for medium-thick ore body

ActiveCN104314567BHigh degree of controlHigh recovery rateUnderground miningSurface miningLoss rateProspecting

The invention discloses a mining method for a medium-thick ore body, which comprises the following steps: A. prospecting; B. mining and cutting the ore body; C. mining the ore body. In the mining method of the medium-thick ore body of the present invention, the ore prospecting roadway is perpendicular to the length of the main body of the ore body on the predetermined elevation until the entire ore body is broken down. The mining and cutting work is carried out on the main body of the ore body, and the top mining is carried out on the main body of the ore body by using the shallow hole ore retention method. The prospecting method of the present invention excavates the prospecting roadway in the ore body, which has a high degree of control over the ore body, can effectively increase the ore recovery rate during mining, reduce the ore loss rate and ore dilution rate, improve the utilization rate of mineral resources, and contribute to the sustainable development of mines. Development provides resource guarantee. The mining and cutting work performed on the ore body by the invention has good stability, safety and reliability, and can effectively improve the mining efficiency. Simultaneously, the present invention adopts the method of retaining ore in shallow holes to carry out top mining on the main body of the ore body, which has simple structure, convenient management, and small amount of mining work.

Owner:BAIYIN NONFERROUS GROUP

Combined hole sublevel open-stope subsequent filling mining method

InactiveCN111779485AFlexible and unified layoutAchieving a high degree of fitUnderground miningBlastingMining engineering

The invention discloses a combined hole sublevel open-stope subsequent filling mining method, which is especially suitable for ore body stoping with medium ore rock stability, medium average thicknessor above, large attitude change and sharply-thinned upper thickness. A stope is arranged along an ore body movement direction, the width of the stope is ore body thickness, the height of the stope ismiddle-section height, and the stope is divided into an upper shallow hole shrinkage stoping area and a lower sublevel open-stope stoping area according to an ore body attitude; firstly, the upper shallow hole shrinkage stoping area is subjected to stoping, and then, the lower sublevel open-stope stoping area is subjected to stoping; the upper shallow hole shrinkage stoping area is subjected to stoping by a shallow hole, the lower sublevel open-stope stoping area is subjected to stoping by a mid-depth hole, most ores which collapse from the upper shallow hole shrinkage stoping area and ores which collapse from the lower sublevel open-stope stoping area are shoveled from a bottom ore discharging structure together; and after stope stoping and ore removal are finished, each channel of the stope is plugged, and then, a goaf is filled. The combined hole sublevel open-stope subsequent filling mining method has the advantages of a low depletion loss rate, a small stope preparation cutting engineering quantity and the like.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Mining method of mid-deep hole falling with anchor cable support and subsequent filling in combined reconstruction structure

ActiveCN103437769BGuarantee of technical problems in safe and efficient miningSafe and efficient miningUnderground miningSurface miningEngineeringStoping

The invention discloses a medium-length hole ore breaking synergistic anchor cable support subsequent filling mining method of a combined reconstructed structural body. The method adopts downward type sublevel stoping, and comprises the following steps: firstly, excavating a top cut heading way in a hanging wall surrounding rock; building an artificial roof (reserved with a fill raise) along the ore body striking direction by adopting smooth blasting after top cut is completed; excavating a multifunctional roadway integrating the functions of rock drilling, supporting and ore removal along the ore body striking direction in the hanging wall surrounding rock; and arranging fan-shaped blast holes by medium-length holes, and arranging a surrounding rock grouting reinforcement and anchor cable support hanging wall project by utilizing the medium-length holes at the same time to integrate surrounding rock grouting reinforcement, ore breaking by blasting and anchor cable support. By adopting retreat type stoping and ore removal by a scraper, the method realizes safe, efficient and large-scale stoping of ore bodies. The mining method is suitable for mining the inclined ore bodies with surrounding rocks which are evenly and stably distributed, and has the characteristics of being small in stope preparation work amount, safe and reliable to operate, high in stoping efficiency, etc.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com