Partition combined cut-and-filling stoping method

A filling mining method and stope technology, applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of low degree of mechanization and mechanical utilization, large overall mining and cutting engineering volume, and small mining engineering volume, etc., to achieve The effect of extending the length and scope, reducing the amount of engineering work to be adopted, and the amount of engineering work to be approved is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

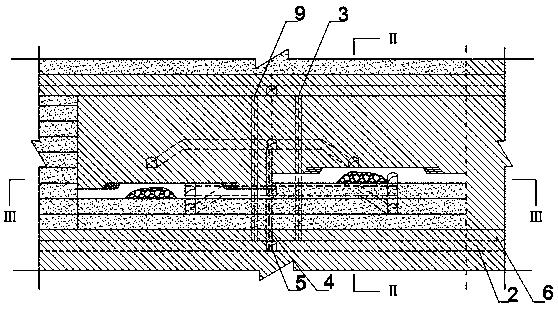

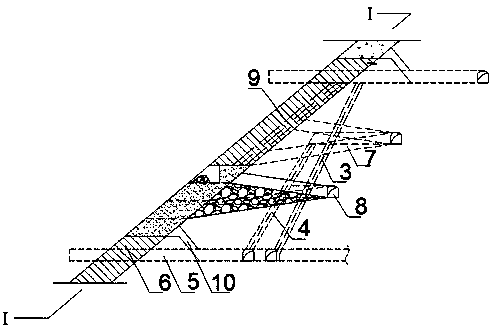

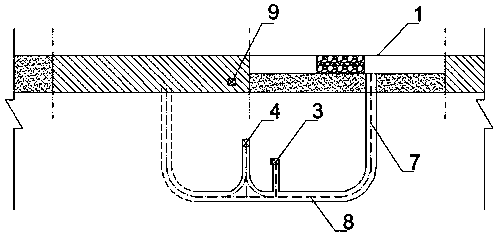

[0030] Below in conjunction with accompanying drawing and embodiment, the zoning combined filling mining method provided by the present invention is further analyzed, step 1: arranging the stope: the stope is divided into left and right stope along the ore body trend, and one front and one back; the stope is along the vertical direction The upper part is divided into three sections, and each section is divided into three layers;

[0031] Preferably, step 1: the total stope length is 100m, the section stope length is 50m, and the distance between the front and back of the section is 4.4m; the stope height is 40~50m, the height of each section is 13~17m, and the height of each layer is 4.4m~5.5m ;

[0032] Step 2: Construct the vertical ore body through the vein prospecting roadway to the bottom pillar, construct the inclined shaft of the stope boundary to the top of the bottom pillar, and construct the bottom level roadway along the direction of the ore body near the position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com