Annular arrangement route mining method

A mining method and a technology of circular arrangement, applied in the field of model tests, can solve the problems of reduced mining quantity, poor ventilation effect of approach mining, and unstable strength of cemented filling body, etc., and achieve high safety production factor and poor loss. The effect of low rate and small exposed area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049]The present invention provides a mining method with circular arrangement approach, comprising the steps of:

[0050] S100. Construct the main contact road, the left stope contact road, and the right stope contact road to find out the ore body according to a certain distance;

[0051] S200. In the delineated ore body, along the left and right sides of the stope main contact road, excavation along the vein is carried out in parallel according to a certain interval, respectively connected with the left stope contact road and the right stope contact road, and the construction cutting work reaches the one-step road specification;

[0052] Before carrying out S200, it is necessary to determine the safety production specifications of the route.

[0053] S300. Construct a vertical ventilation and drainage well upward at the centerline position of the approach at the intersection of the left stope access road and the right stope access road; construct concrete at the intersection...

Embodiment 2

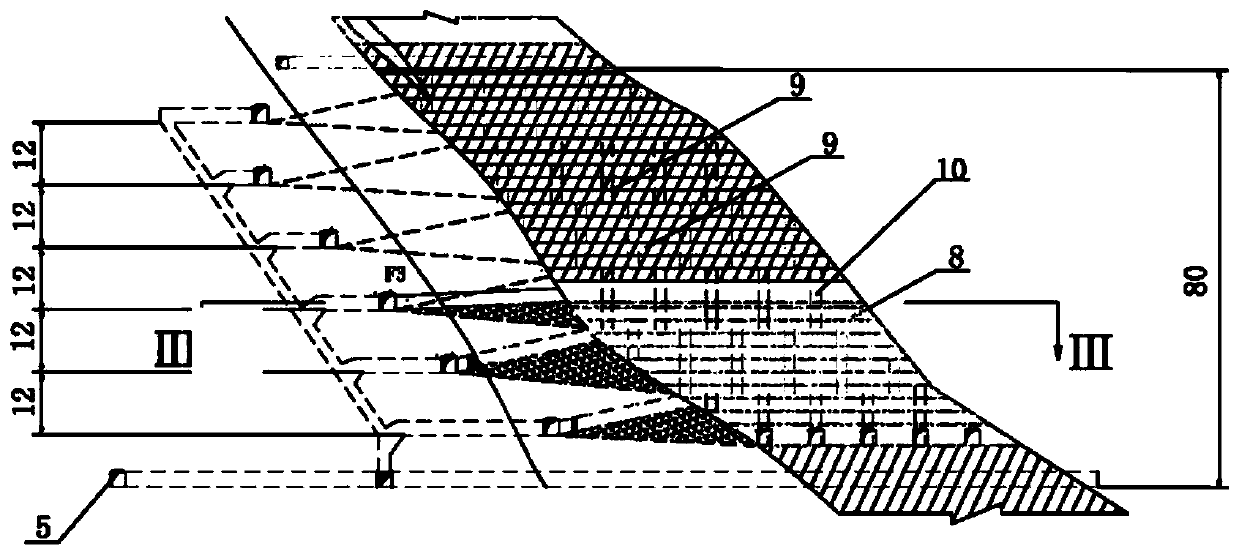

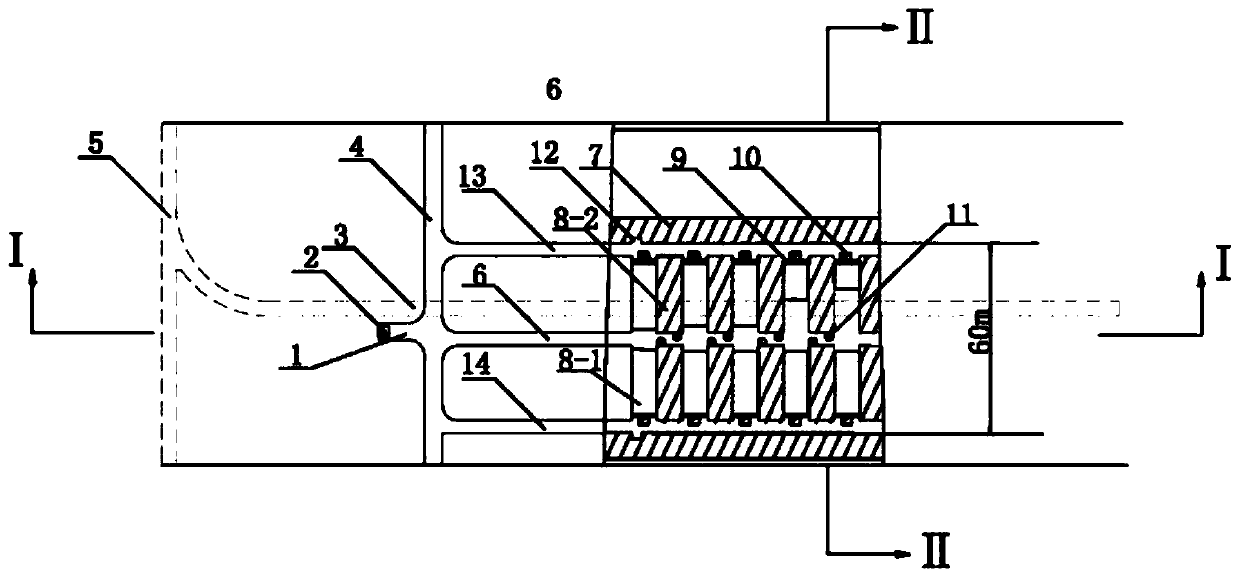

[0071] combine figure 1 , figure 2 as well as image 3 As shown, take the stope mining of line 54-55 in the middle section of -140 in a certain mining area as an example:

[0072] Step 1. Construct three stope access roads 6 along the segmented roadway 4 at a certain interval to find out the ore body. The specifications of the stope access roads 6 are all 3.6m*3.2m. Shovel into mine shaft 2;

[0073] Step 2. Open in the delineated ore body along the main contact road 6 of the stope at intervals of 10m, and excavate along the vein parallel to the direction of the ore body. The connecting road 14 is connected, and the excavation brush of the stepping road 8-1 is enlarged to the specification of 5.0m*3.8m;

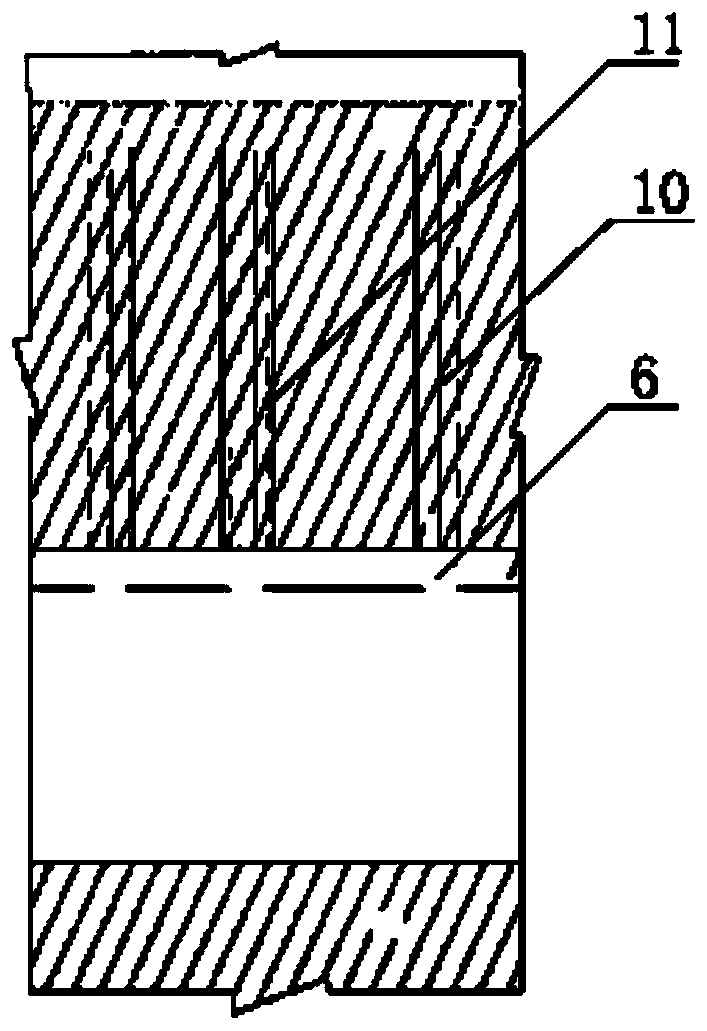

[0074] Step 3. Construct a vertical ventilation and drainage well 10 upwards at the top plate at the central line position of the approach at the intersection of the left stope connecting road 13 and the right stope connecting road 14. The length of the ventilation and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com