Spray forming cooling system and method for decreasing temperature of ingot blank through spray forming cooling system

A spray forming and billet technology, applied in the field of spray forming cooling system, can solve the problems of lack of demand, the influence of microstructure, mechanical properties and machining performance, etc., and achieve fast cooling speed, high heat absorption efficiency and good mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

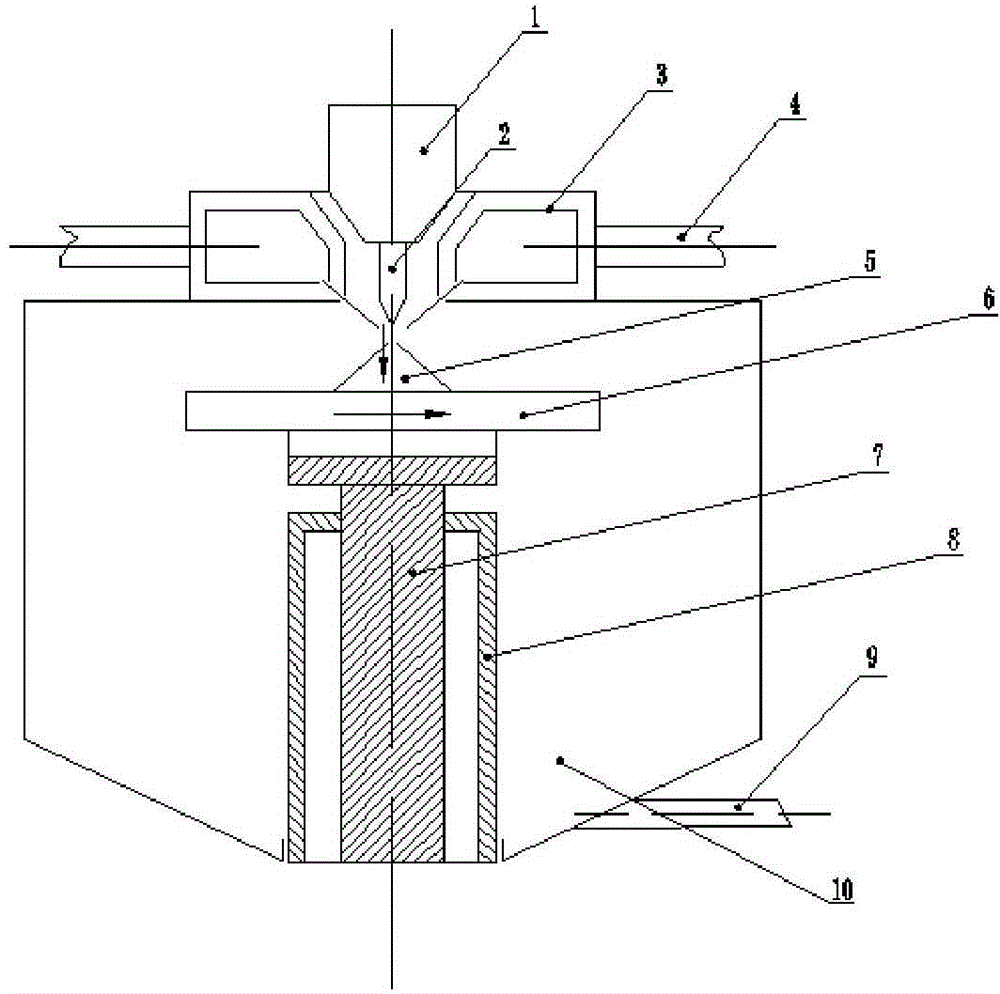

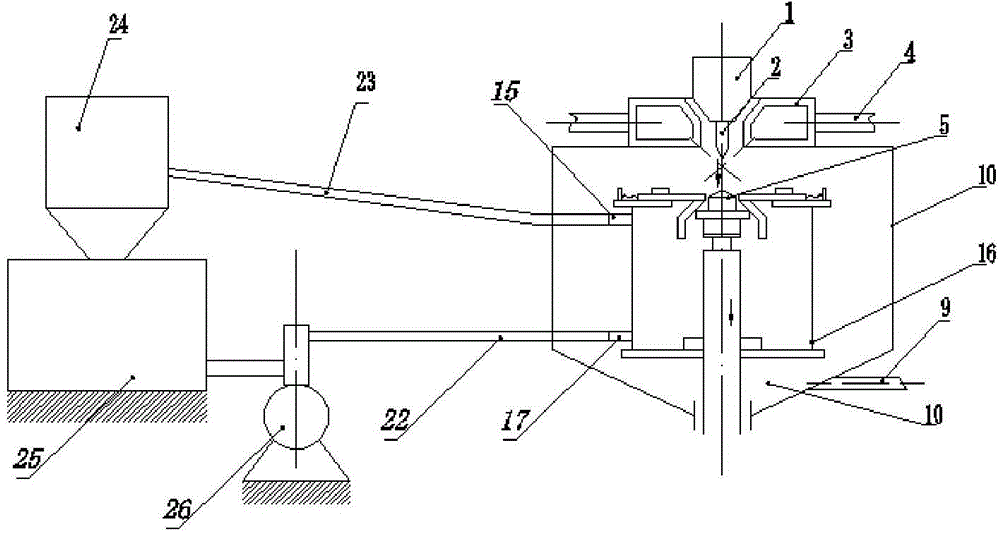

[0049] Such as Figure 2-4 As shown, an injection molding cooling system includes an injection molding device and a cooling system, and the cooling system includes a heat absorbing structure, a cooling device 24, a circulating power pump 26, a heat transfer medium and a heat transfer medium delivery pipeline, and the heat transfer medium delivers Pipelines sequentially connect the heat absorbing structure, the cooling device 24 and the circulating power pump 26 to form a heat conduction circuit;

[0050] The heat absorbing structure is located in the atomization chamber 10 of the injection molding device for cooling the ingot 5 or the tray 6, and the cooling device 24 is located outside the atomization chamber 10 of the injection molding device for cooling due to The heat conduction medium whose temperature rises after absorbing the heat of the atomization chamber 10;

[0051] The heat transfer medium circulates in the heat conduction circuit under the action of the circulati...

Embodiment 2

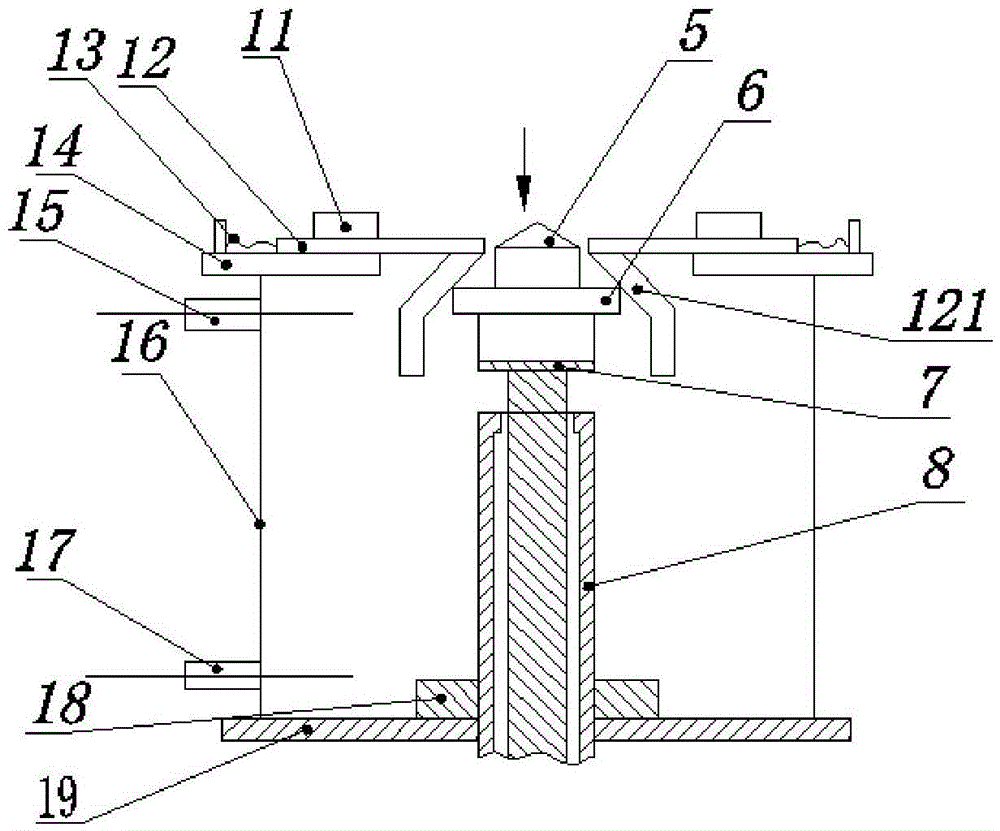

[0072] Such as Figure 5-6As shown, compared with Embodiment 1, the difference of this embodiment is that the structure of the heat-absorbing structure is different. The heat-absorbing structure of this embodiment is as follows: the bottom of the tray 6 is airtightly fixed with an inner heat-conducting sleeve 27, forming The inner wall of the inner heat conduction sleeve 27 and the bottom of the tray 6 enclose an inner heat conduction chamber, the inner heat conduction sleeve 27 is externally connected to the outer heat conduction sleeve 28, and the outer heat conduction sleeve 28 is fixed on the fixed sleeve 30, The side wall of the inner heat-conducting sleeve 27 is provided with a heat-conducting medium inlet 17 and a heat-conducting medium outlet 15, and the position of the outer heat-conducting sleeve 28 corresponding to the heat-conducting medium inlet 17 is provided with a first annular groove 281, and the heat-conducting medium The delivery pipeline passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com