Spherical grid array encapsulation structure of base plate bottom glue encapsulation

An array packaging and structure technology, applied in the direction of semiconductor/solid-state device components, electrical components, electrical solid-state devices, etc., to achieve the effect of improving moisture resistance, reducing exposed area, and avoiding ball drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

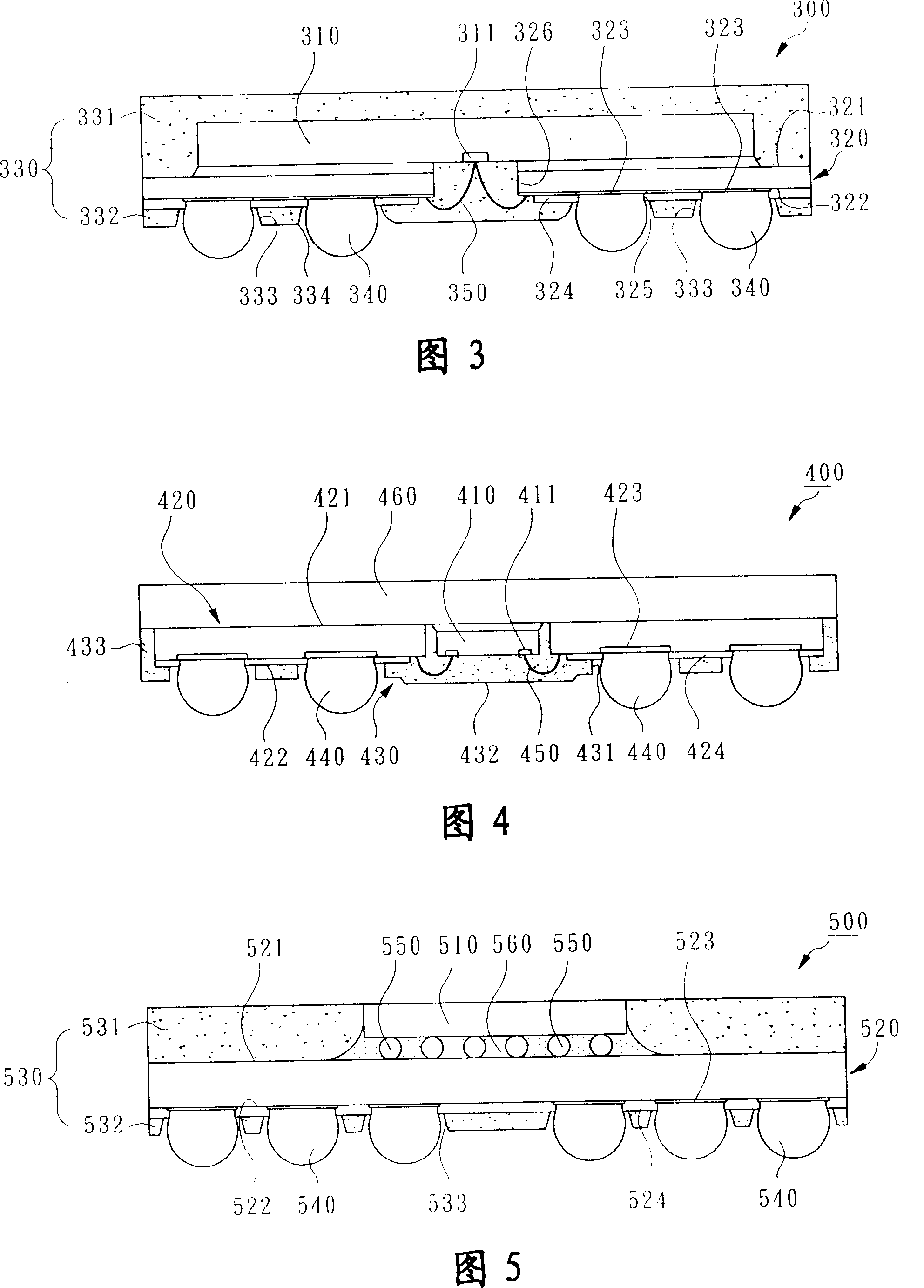

[0083] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation of the ball grid array packaging structure proposed according to the present invention, with reference to the accompanying drawings and preferred embodiments, Structure, characteristic and effect thereof are as follows in detail.

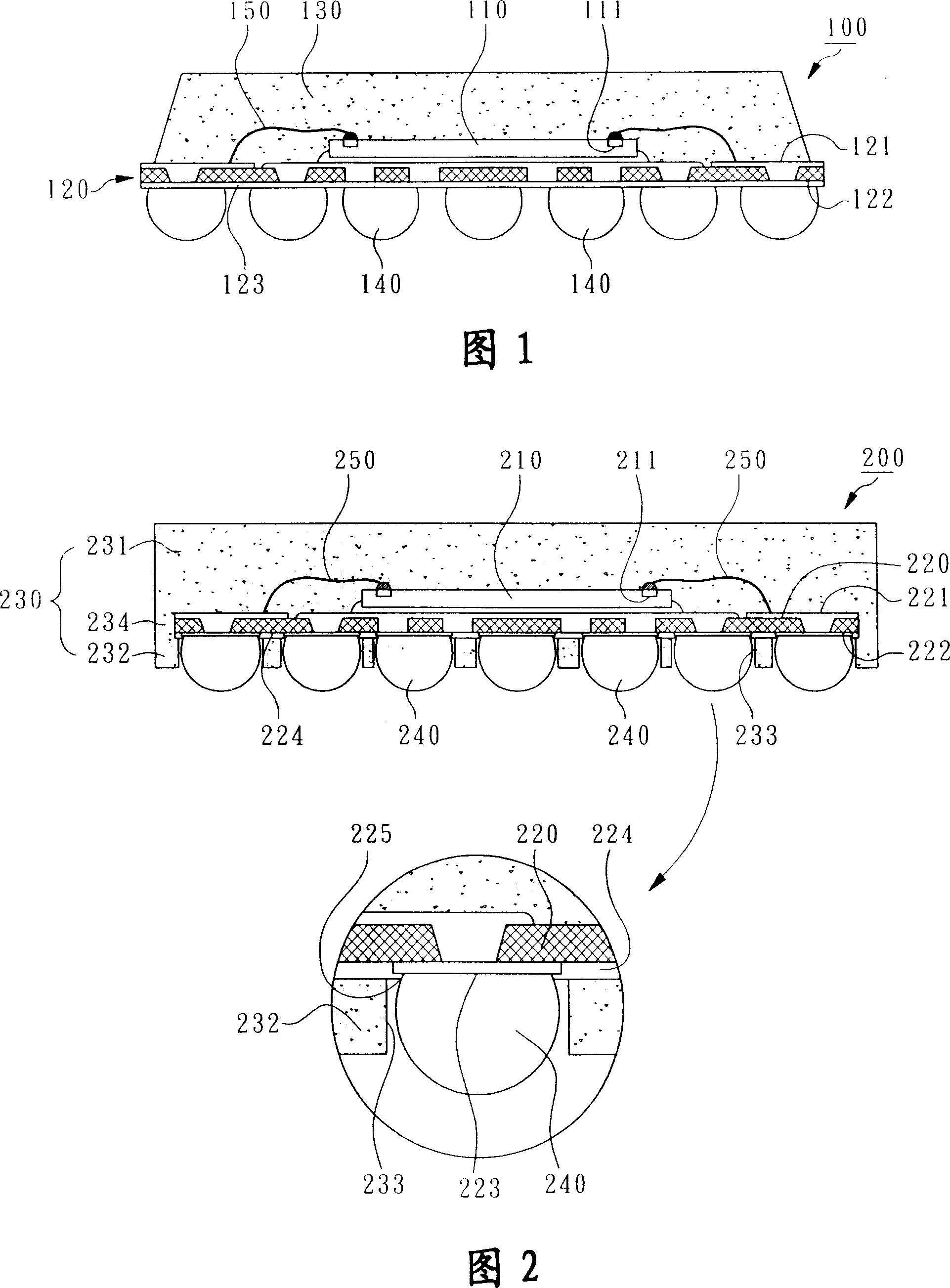

[0084] Please refer to FIG. 2 , which is a schematic cross-sectional view of a ball grid array package structure according to a first embodiment of the present invention. The BGA structure 200 mainly includes a chip 210 , a printed circuit board 220 , a molding compound 230 and a plurality of solder balls 240 .

[0085] The chip 210 is made of semiconductor material and can be an integrated circuit chip 210 with a plurality of welding pads 211 on its active surface.

[0086] The substrate 220 is used to carry the chip 210 and be electrically connected to the chip 210. The substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com