Downward layered up-down staggered drift filling mining method

A technology of access filling and mining method, which is applied in the fields of filling, mining equipment, mining equipment, etc., can solve the problems of high requirements for access mining, large amount of mining engineering, and small access section.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

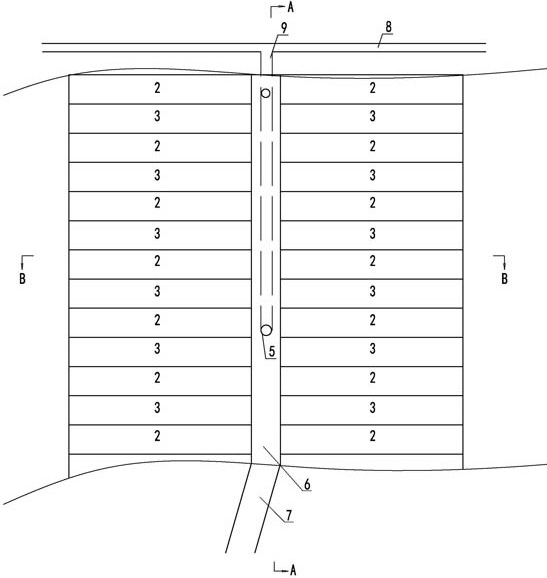

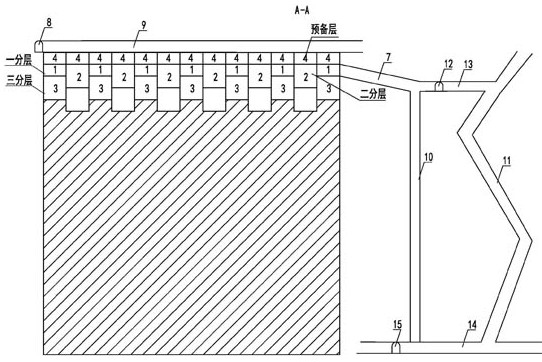

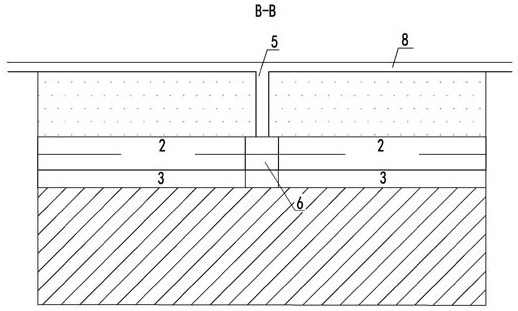

[0052] The ore body mined in a certain mine is a small and medium-sized broken ore body, with a middle section height of 60m and a section height of 15m. The panel area is divided according to the principle of equal area, and the panel area is divided along the strike of the ore body. The length of the panel area is 100m in the strike direction, and the width is the horizontal thickness of the ore body. Excavate the segmented connecting road 13, the segmented road 12, and the layered connecting road 7 from the mining slope 11 to enter the ore body, and excavate the layered road 6 perpendicular to the ore body, and the filling return air shaft 5 is arranged in the layered road 6, The filling return air shaft 5 communicates with the upper vein-piercing filling air return channel 9 and the vein-along filling air return channel 8, and a chute 10 is arranged near the layered connecting road 7, and the chute 10 is connected with the lower middle section along the vein transportation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com