A Combined Filling Mining Method for Complicated Ore Body

A technology for filling mining and ore bodies, which is applied in the direction of fillings, ground mining, mining equipment, etc., can solve problems such as poor operation safety performance, difficult site management, and complicated construction technology, so as to achieve a good mining operation environment and reduce mining losses. The effect of small dilution and great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The selected ore body is a broken complex ore body in China, which is characterized by: thick ore body, relatively broken ore body and surrounding rock, weathered and highly corroded hanging wall surrounding rock, extremely poor stability, and frequent occurrence of ground pressure , It is difficult to mine. Generally speaking, the ore body and surrounding rock are all unstable rock masses.

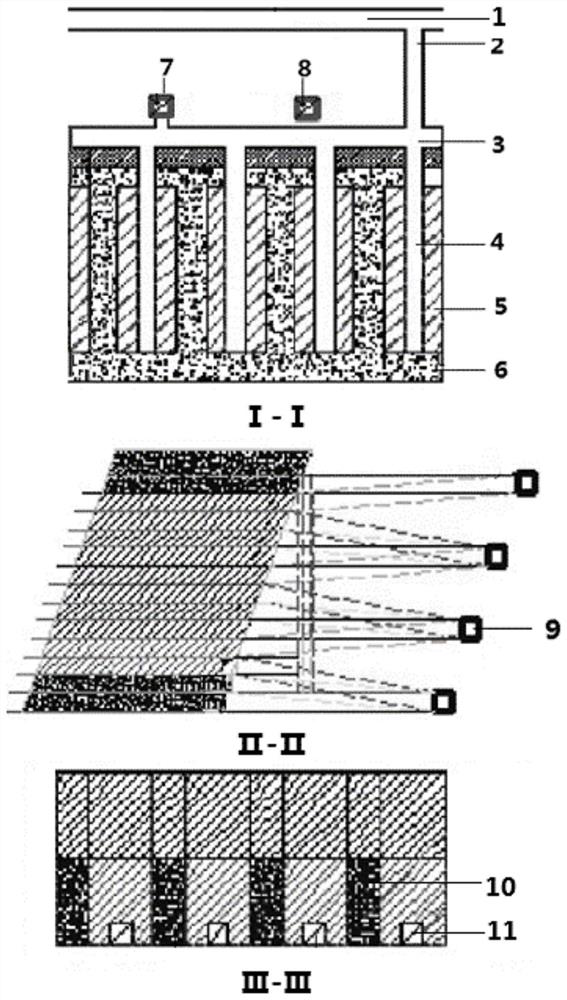

[0040] see figure 1 As shown, the present invention provides a combined filling and mining method for complex ore bodies. The combined filling mining method adopts a mining method that combines the upward horizontal layered approach filling method with the segmented and striped filling method, including the following steps:

[0041] S1. Stope division: The stope is arranged along the direction of the ore body, and the width is the horizontal thickness of the ore body; the height of the middle section of mining is 60m, and it is composed of three sections with a height of 20m; each...

Embodiment 2

[0052] The selected ore body is a broken complex ore body in China.

[0053] see figure 1 As shown, the present invention provides a combined filling and mining method for complex ore bodies. The combined filling mining method adopts a mining method that combines the upward horizontal layered approach filling method with the segmented and striped filling method, including the following steps:

[0054] S1. Stope division: The stope is arranged along the direction of the ore body, and the width is the horizontal thickness of the ore body; the height of the mining middle section is 45m, and it is composed of three sections, and the section height is 15m; each section is divided into 4 horizontal sections Layers are mined in a layered sequence from bottom to top. The layered mining height is 3.75m, and the layered approach is 4m×4m in size.

[0055] S2. Mining and cutting engineering: including segmental transportation lane 1, segmental connecting road 2, chute 8, filling shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com