Sublevel open stoping method ground pressure control method of inclined large and thick ore bodies

A technology of thick ore body and control method, which is applied in surface mining, earthwork drilling, underground mining, etc., and can solve the problems of large mining quantity, limited application range, and easy caving of surrounding rock on the stope wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

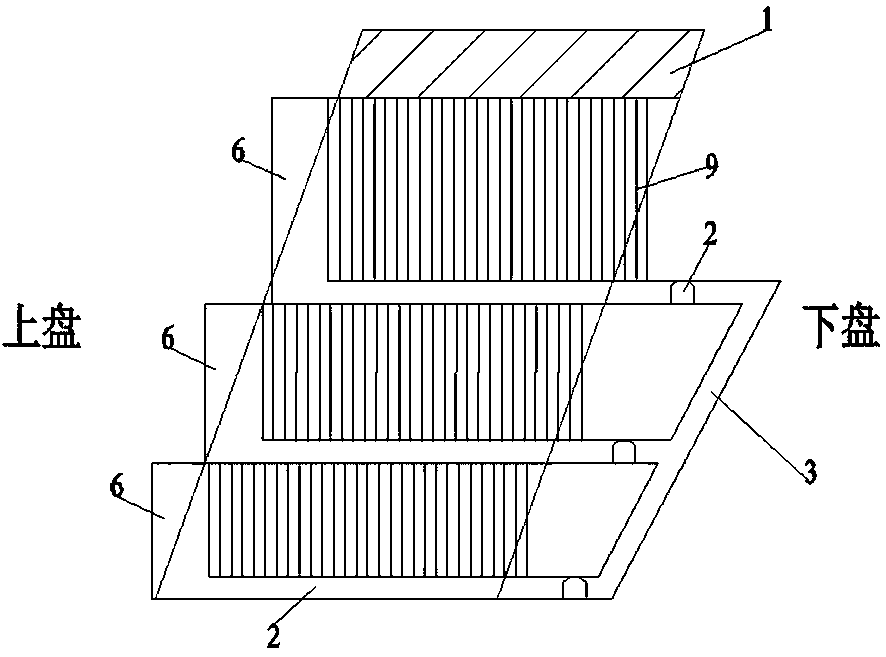

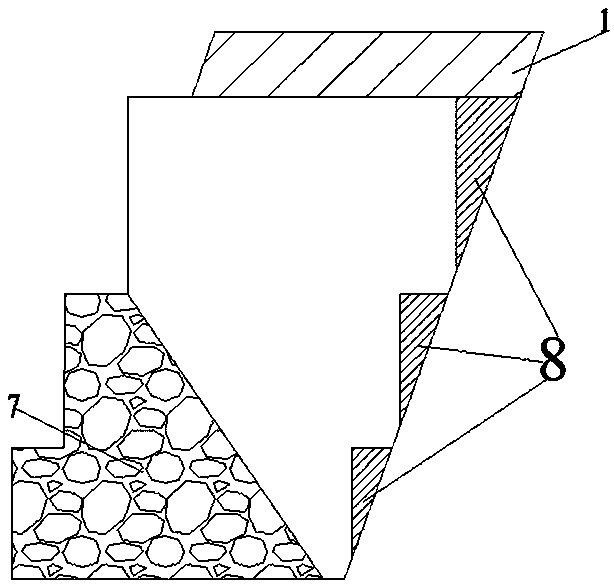

[0015] Such as figure 1 , 2 , 3, a method for ground pressure control of inclined thick and large ore body segmented open-field method, ① first divide the mine house into three segments along the vertical direction, the height of the first segment is 12m, and the height of the second segment The height of the three sections is 14m, and the height of the three sections is 18m. A 6m thick top column is left on the upper part of the three sections, and the total height of the mine house is 50m.

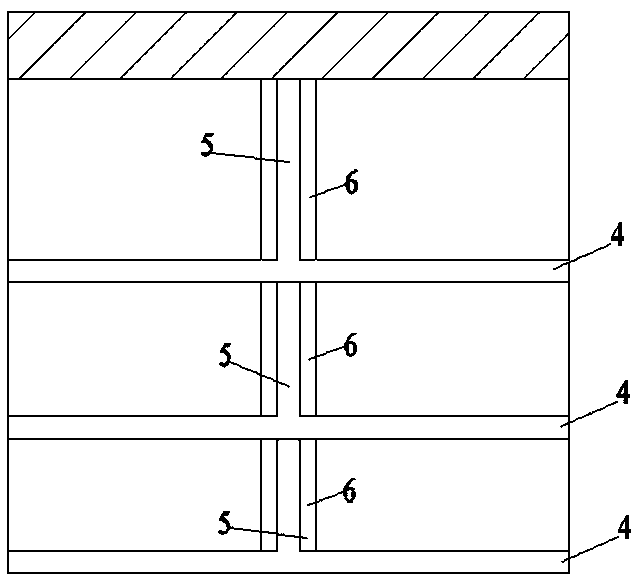

[0016] ②A vein-along roadway 2 is arranged at each segment of the footwall of the mine house, and the vein-along roadway 2 is arranged along the ore body. Rock-drilling roadways are arranged in the direction of the body. The distance between the rock-drilling roadways is generally between 15 and 20m. A cutting entry 4 is arranged on the upper wall of the house, and the cutting entry 4 is parallel to the ore body trend. A vertical cutting shaft 5 is arranged upward in the middle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com