Sill-free sublevel caving method with drift space greater than sublevel height

A technology of segmental caving and mining method, which is applied in ground mining, underground mining, special mining, etc., and can solve problems such as poor technical and economic indicators and low mine production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

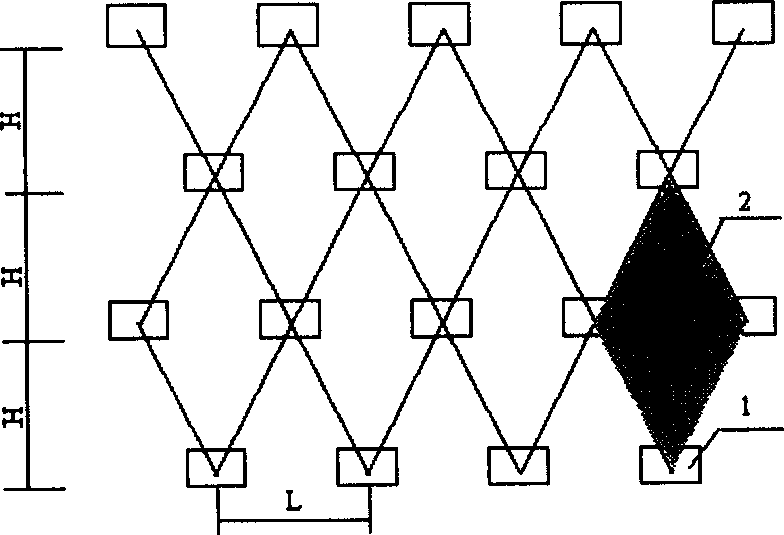

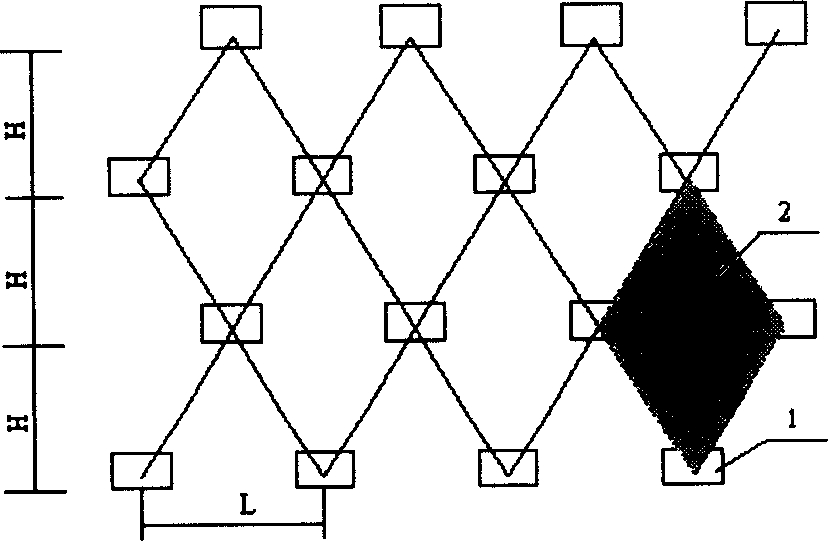

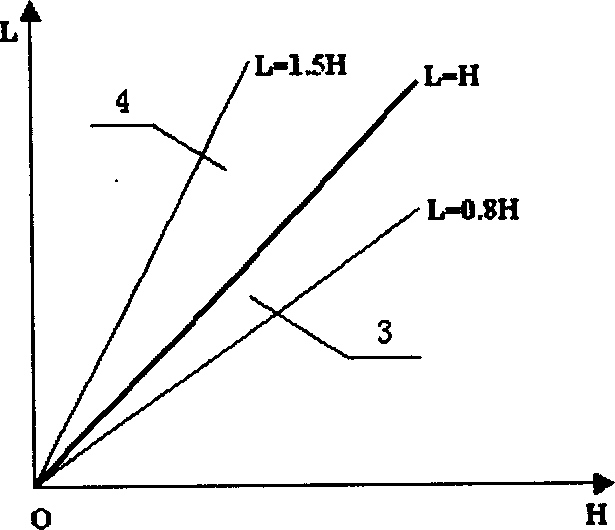

[0013] refer to figure 2 , 3 , the steps to determine the stope structural parameters of the pillarless segmental caving mining method with the approach distance greater than the segmental height are as follows: 1. According to the ore body occurrence conditions, mine production scale and other factors, select the appropriate segmental height H; 2. , after the subsection height is selected, according to the method for determining the subdivision height H of the approach distance L=(1.0~1.5), that is, the value range of the present invention is 4, and the approach distance L is determined. If the section height H=15 meters is taken, according to the determination method of the approach distance L=(1.0~1.5)·section height H, L=1.33×H can be taken, then L=1.33×15 meters=20 meters; Segment height H=12.5 meters, according to the determination method of approach distance L=(1.0~1.5)·segment height H, desirable L=1.2*H, then L=1.2*12.5 meters=15 meters. The specific implementation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com