Tension-plate shape measurement-adjusting instrument

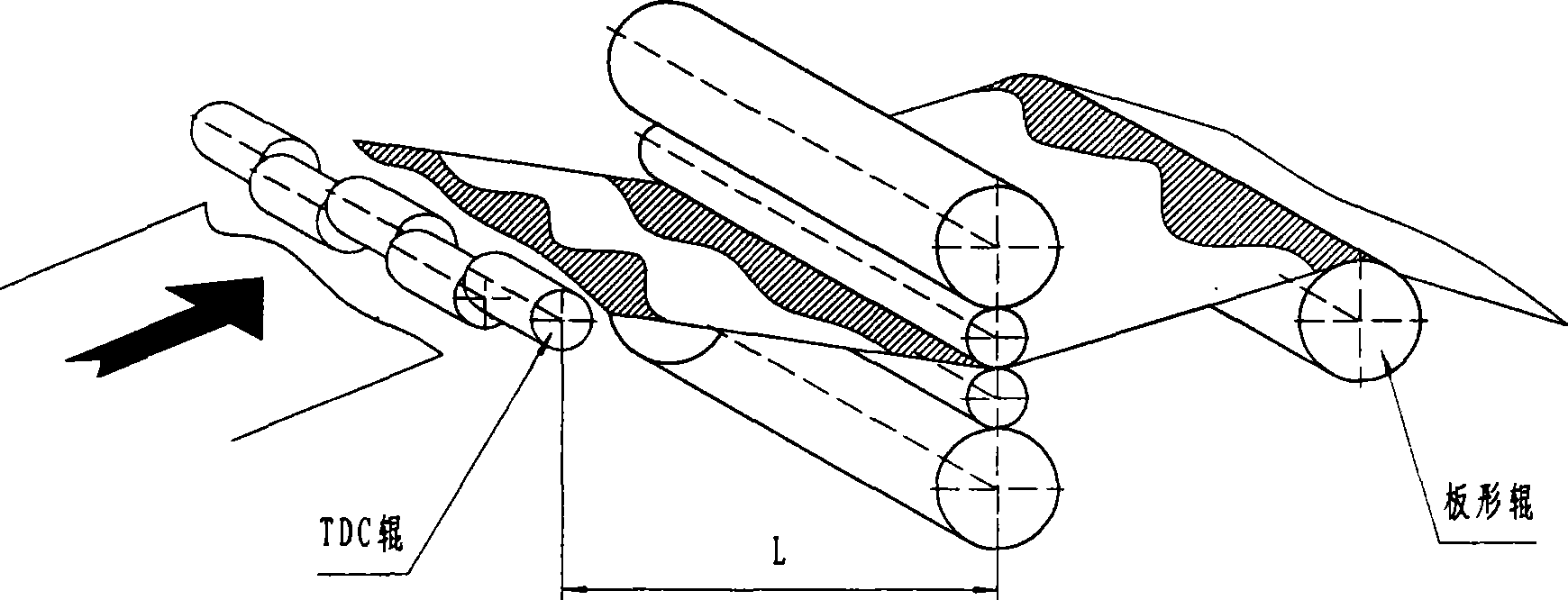

A tension and plate shape technology, applied in tension/pressure control, metal rolling, etc., can solve the problems of low distribution density, complex structure, large length of segmented rolls, etc., to improve the accuracy of detection-control and expand the control range , the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

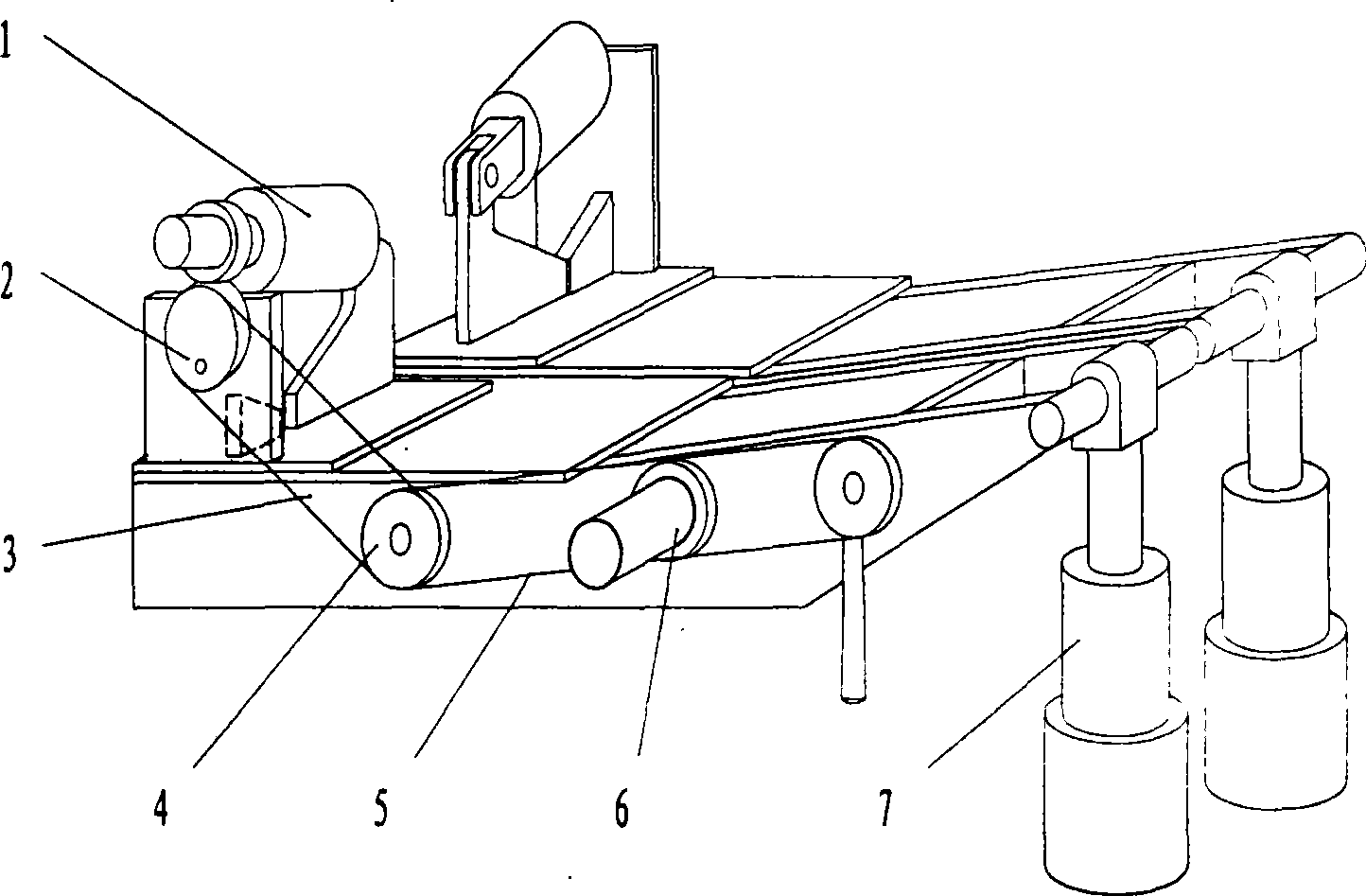

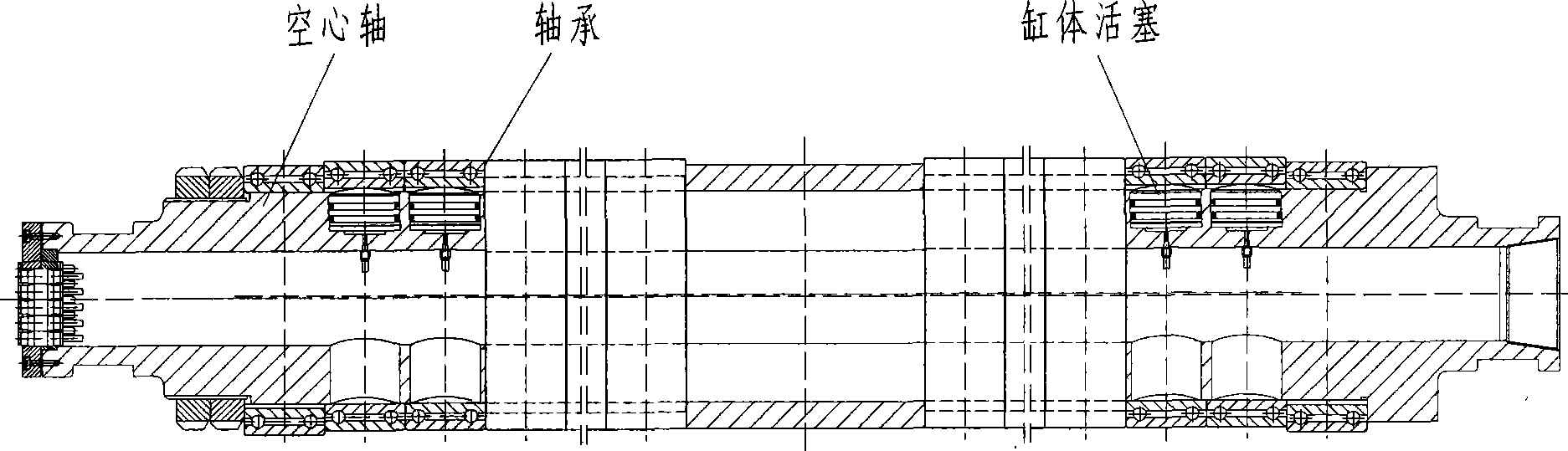

[0037] attached Figure 7 It is the structural diagram of the tension-shape measuring-adjusting instrument with vertical sliding type segmented roller position adjustment mechanism of the present invention, it mainly consists of two frames (36), two sets of vertical sliding type segmented roller position adjustment mechanisms ( 37) and the tensile stress distribution control roll (39) or the tensile stress distribution control roll bending device (40) etc. installed on the position adjustment mechanism slide block (38).

[0038] The two lifting cylinders (42) of the vertically sliding segmented roller position adjustment mechanism are respectively installed on the bottom or top of the two racks, and are hinged with the slider. The slider is installed in the chute of the rack and driven by the lifting cylinder. . A position sensor is installed inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com