Novel aircraft carrier flying-off deck

A technology for take-off decks and aircraft carriers. It is applied in the direction of launching/dragging transmissions, etc. It can solve the problems of long time, not very long, and reducing the frequency of carrier-based aircraft.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

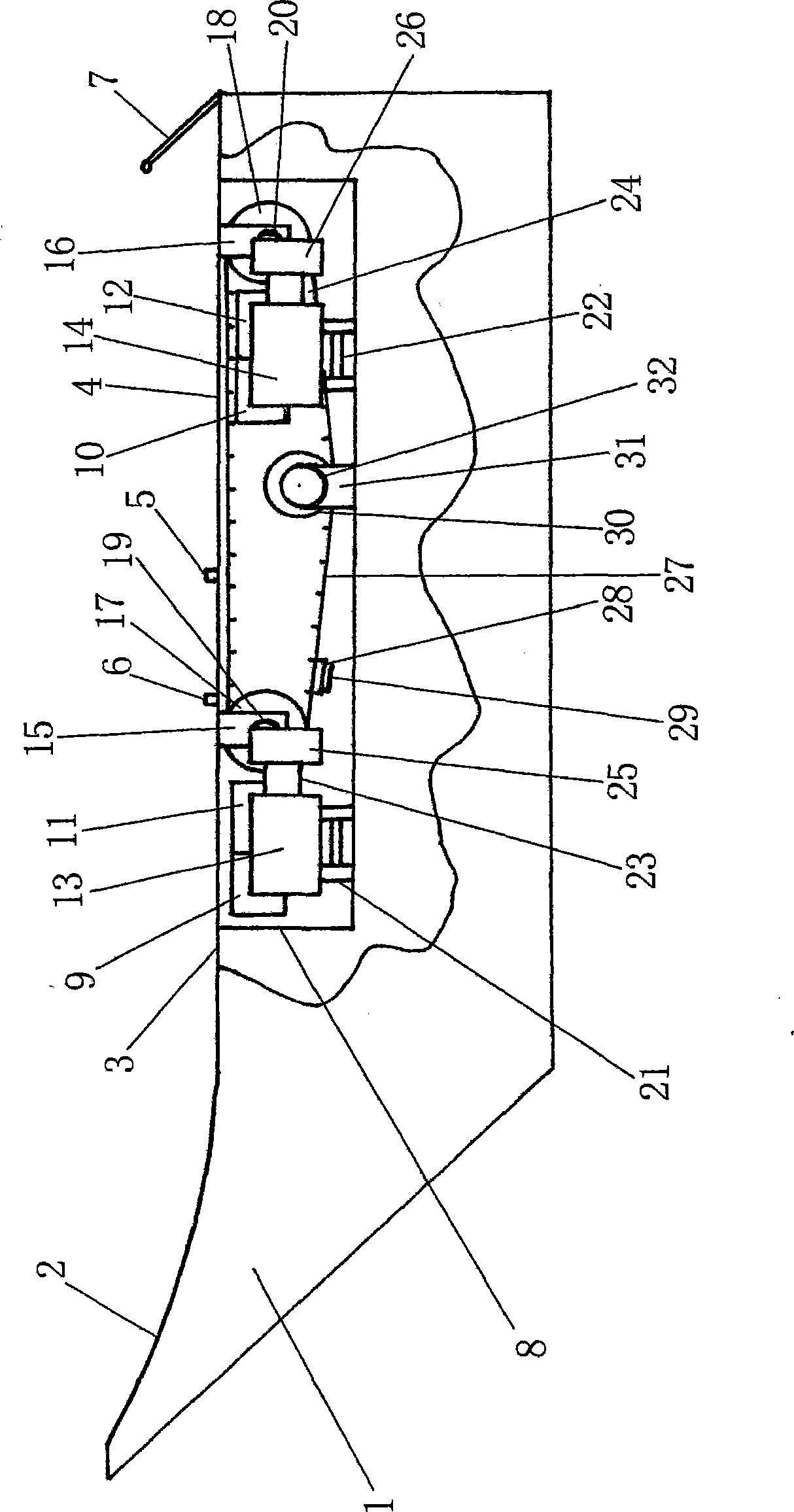

[0006] Although the new type aircraft carrier take-off deck is novel, it is not completely innovative, but an improvement to the existing stilted take-off deck. Mainly in the lower part of the starting section 4 on the stilted take-off deck, there is a carrier-based aircraft take-off acceleration equipment cabin 8, and two pairs of tank wheel mounting seats 15 and 16 are installed under the take-off deck. , on each pair of tank wheel mounts, there is an extended wheel axle, the front tank wheel mount 15 is equipped with a front tank wheel 17 through the axle, and the rear tank wheel mount 16 is equipped with a rear tank wheel 18 through the wheel axle, and the two tank wheels Link up with 27 circles of specially manufactured reinforced tank crawler tracks, a specially made special track shoe 28 is arranged on the specially manufactured reinforced tank crawler tracks 27, and a towing hook 29 that carrier-based aircraft is towed is arranged on it. On the bottom deck of the take-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com