Flexible coating

A skin and flexible technology, applied in the fields of material preparation, aerospace, and aviation, can solve the problems of insufficient flexibility of deformation ability, etc., and achieve the effects of enhancing surface smoothness, increasing take-off weight, and improving the induced drag of wing circulation distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

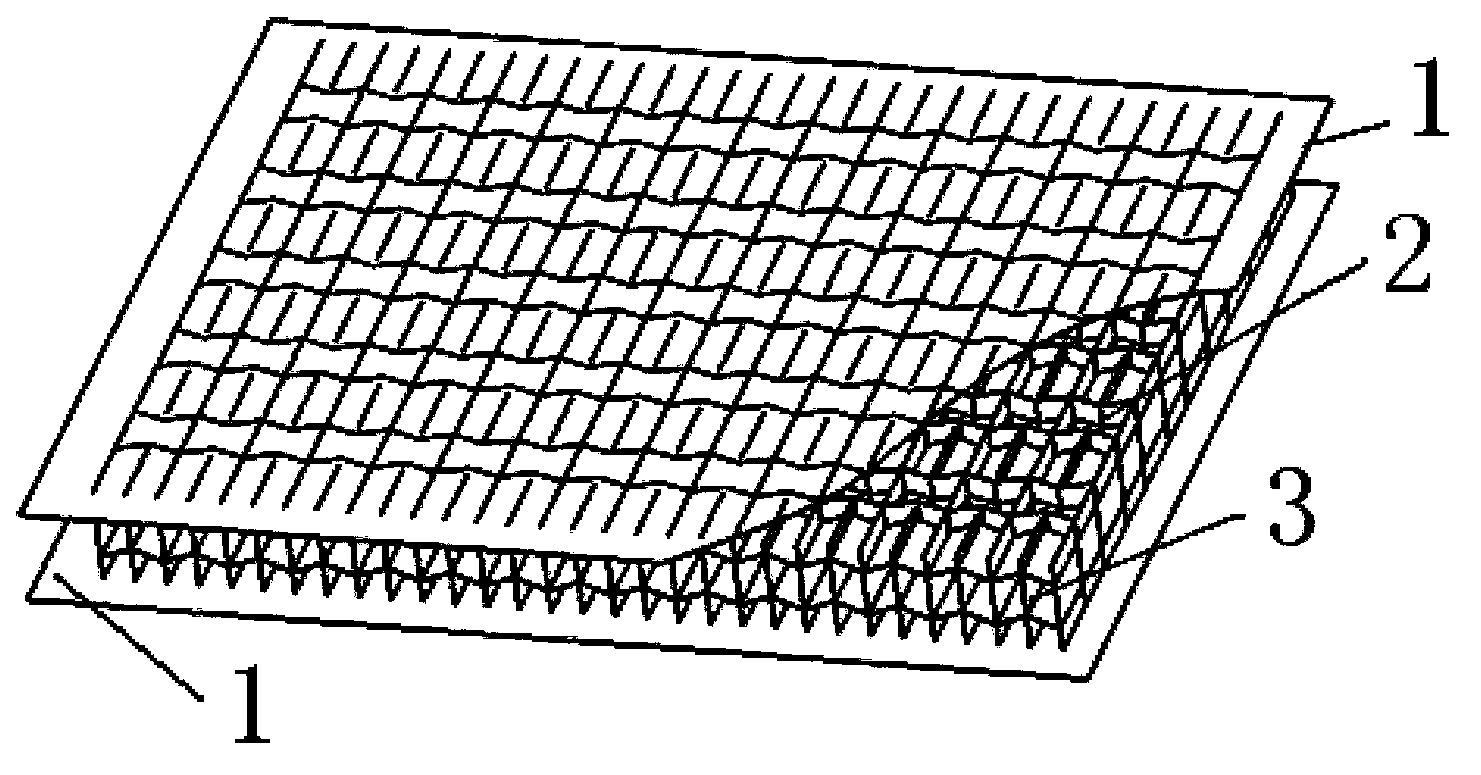

[0028] This embodiment is a skin of a flexible honeycomb sandwich structure used for aircraft wings, which is composed of several accordion-type honeycomb units 2 , several lattice-type honeycomb units 3 and panels 1 .

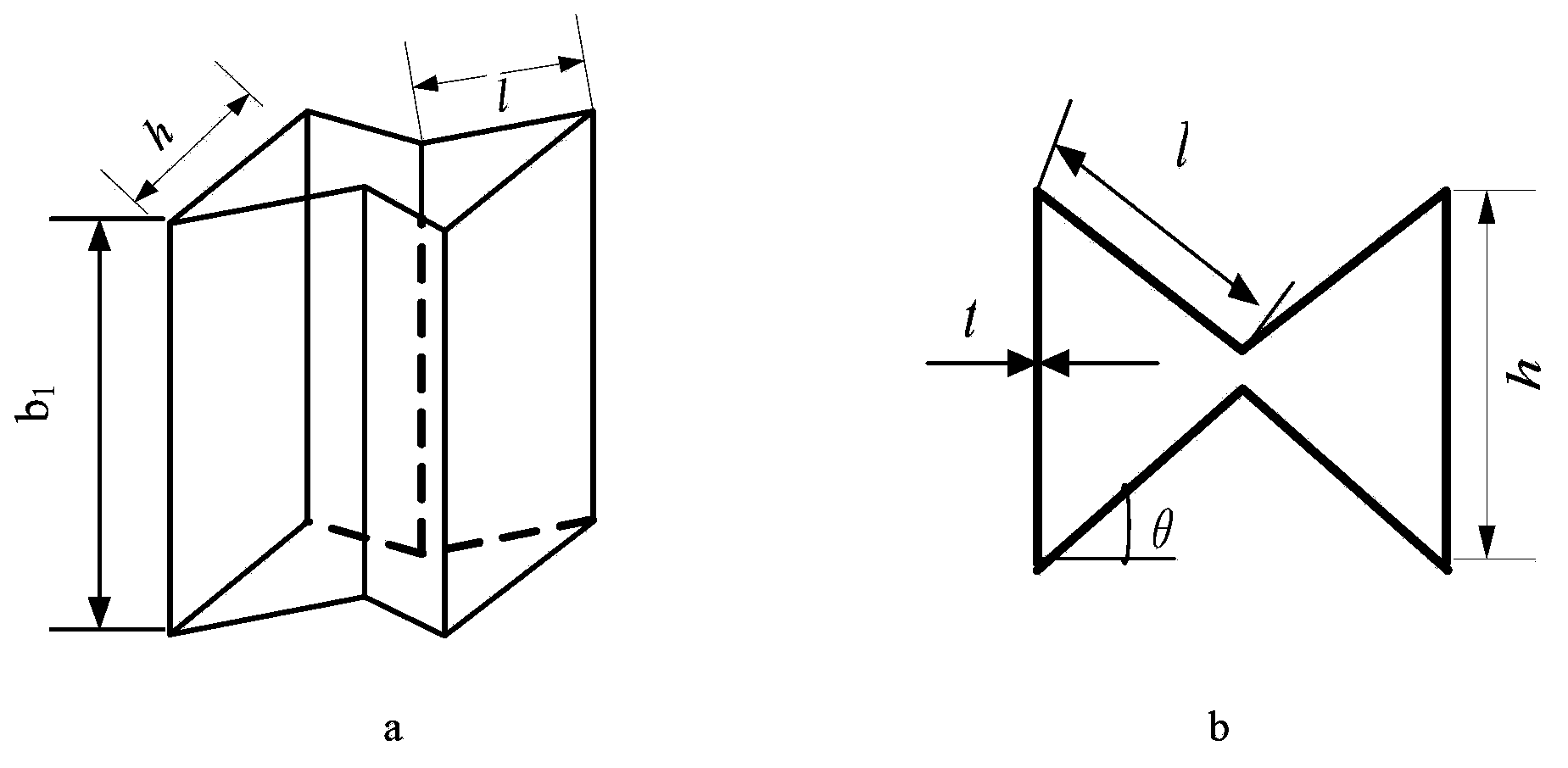

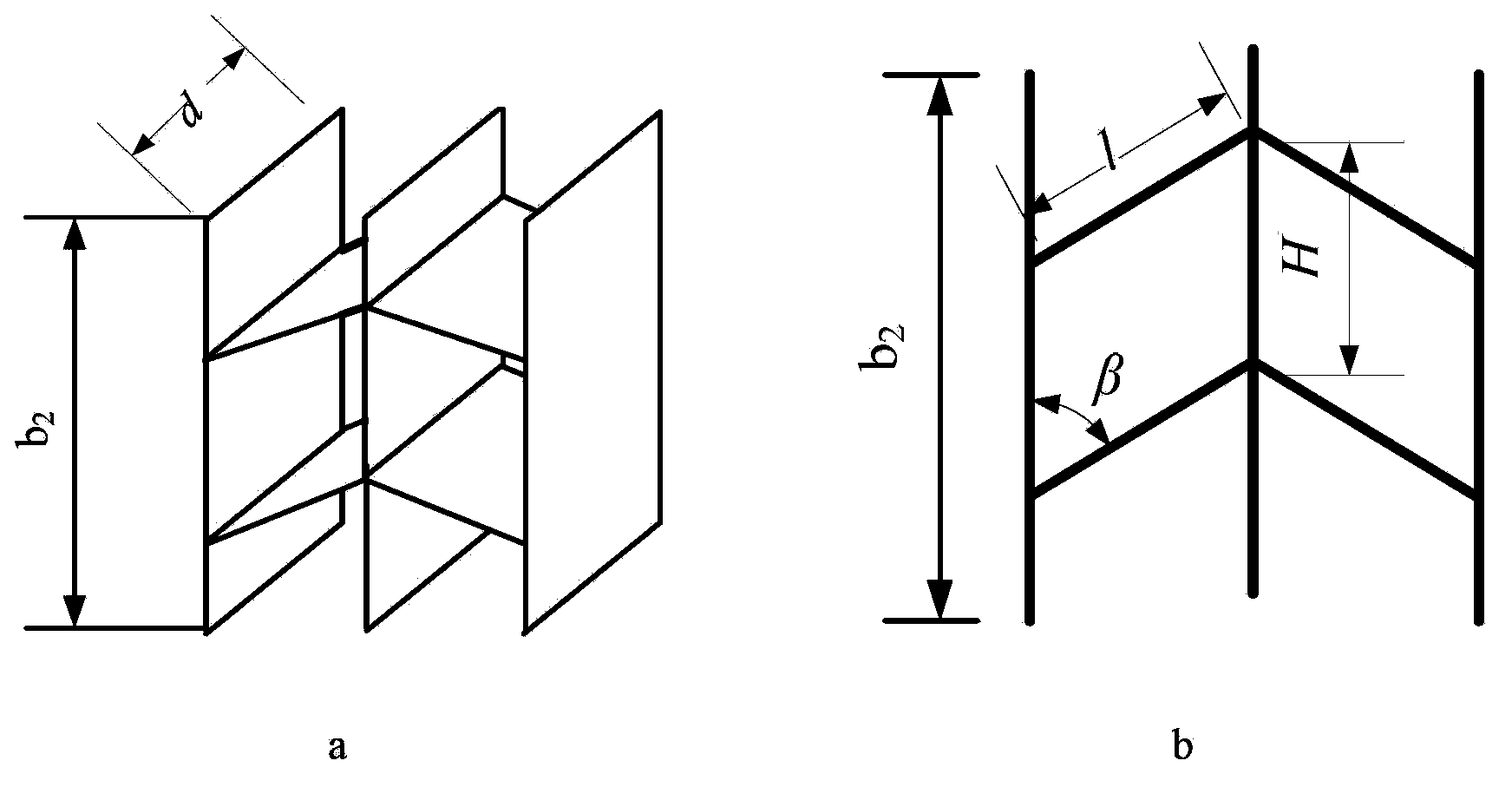

[0029] The accordion-type honeycomb unit 2 is a rectangular shell with sidewalls on both sides shrinking inwardly, and the distance between the center of the length direction of the sidewalls on both sides of the accordion-type honeycomb unit 2 is 1 / 5-3 of the width of the accordion-type honeycomb unit 2 / 4, so that the side walls on both sides of the accordion-type honeycomb unit 2 form two inclined walls 1 respectively. An inclination angle θ is formed between the inclined wall and the horizontal plane, and the inclination angle θ is 60°-15°. In this embodiment, the distance between the center of the length direction of the side walls on both sides of the accordion-type honeycomb unit 2 is 6 mm, and the width h of the accordion-type honeycomb unit 2 is 10 mm...

Embodiment 2

[0036] This embodiment is a flexible honeycomb sandwich panel for an aircraft fuselage, which consists of several accordion-type honeycomb units 2 , several lattice-type honeycomb units 3 and panels 1 .

[0037] The accordion-type honeycomb unit 2 is a rectangular shell with sidewalls on both sides shrinking inwardly, and the distance between the center of the length direction of the sidewalls on both sides of the accordion-type honeycomb unit 2 is 1 / 5-3 of the width of the accordion-type honeycomb unit 2 / 4, so that the side walls on both sides of the accordion-type honeycomb unit 2 form two inclined walls 1 respectively. An inclination angle θ is formed between the inclined wall and the horizontal plane, and the inclination angle θ is 60°-15°. In the present embodiment, the distance between the center of the length direction of the side walls on both sides of the accordion-type honeycomb unit 2 is 7mm, and the width h of the accordion-type honeycomb unit 2 is 14mm, making 3 / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com