Synchronous mining shrinkage stoping method for double-layer mine variety inclined ore body

A technology of double-layer minerals and mining methods, which is applied in surface mining, underground mining, special mining, etc., can solve the problems of inability to mine the lower layer of ore, large ore loss and dilution, and goaf caving, and shorten the mining activities. Time, high ore recovery rate, and the effect of reducing stope pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

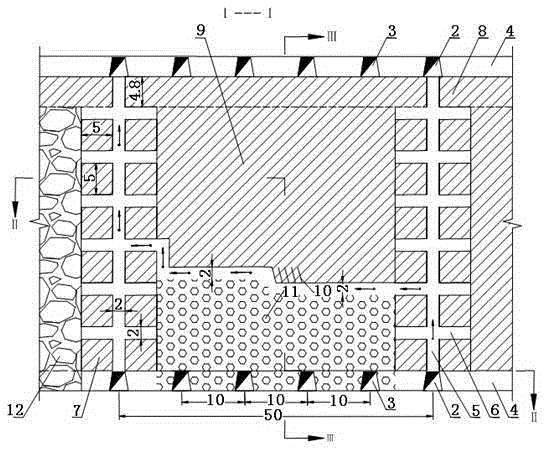

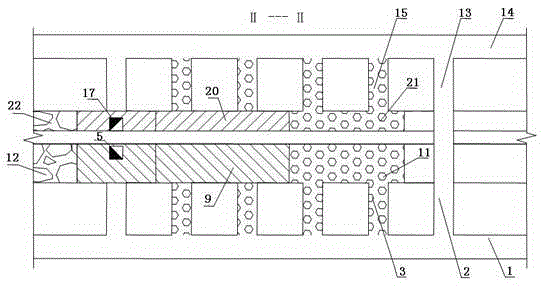

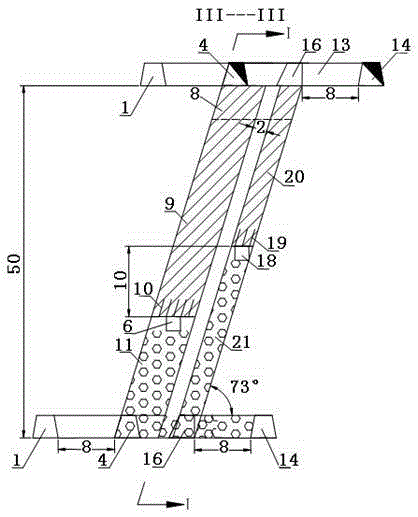

[0024] Example: When mining a certain iron-aluminum mine in Zhanjie Town, Qingzhen City, Guizhou Province, the inclination angle of the ore body is about 73°, the upper ore body is iron ore, with an average thickness of 5.92m, and the lower ore body is bauxite, with an average maximum thickness of 2.92 m, with a 1-2m interlayer in the middle. The traditional mining method of retaining ore is adopted, mining is carried out in layers, and the bottom structure adopts the ore pillar funnel to discharge the ore by itself. The exposed area of the empty area is large, the hidden danger of empty area collapse is large, and the loss of ore dilution is large.

[0025] Now adopt the nearly horizontal thin ore body mining method that the present invention provides to mine this ore body, concrete implementation mining steps are as follows:

[0026] 1) Stope layout

[0027] The stope is arranged along the ore body trend. The height of the middle section is 50m, the strike length of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com