Novel method for collaboratively exploiting underground double stopes of underground mine

A double stope, new method technology, applied in underground mining, surface mining, mining equipment and other directions, can solve the problems of reducing the amount of mining and cutting, not effectively solving the problems of improving production capacity, poor safety, etc., to improve mining efficiency, Achieve the effect of large-scale mining and production capacity improvement of mines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

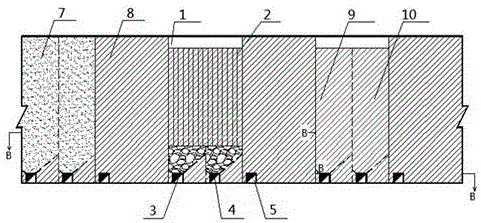

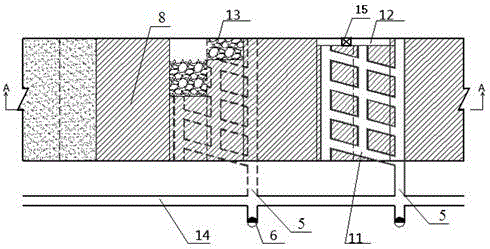

[0024] In order to further describe the present invention, below in conjunction with accompanying drawing, a kind of new method of cooperative mining of underground double stope of underground mine of the present invention is described in more detail.

[0025] Depend on figure 1 A schematic diagram of the longitudinal layout of the stope structure of the new method of the double stope cooperative mining in the underground mine shown in the present invention and combined with figure 2 It can be seen that the novel method of double stope cooperative mining under a kind of underground mine of the present invention adopts and adopts following technology, step:

[0026] 1) Divide multiple ore blocks along the ore body trend, and each ore block is divided into two mines—left mine 9 and right mine 10; the ore blocks are mined at intervals, and the interval between two adjacent mining blocks The ore pillar 8 is left; the length of the ore block and the length of the ore pillar 8 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com