Two-step upward high-layering bagging cut-and-filling stoping method

A backfill mining method and high stratification technology, which is applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of large amount of mining engineering, complex filling process, low mining production efficiency, etc., to reduce the complexity and reduce the The effect of selecting the right amount of work and reducing the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

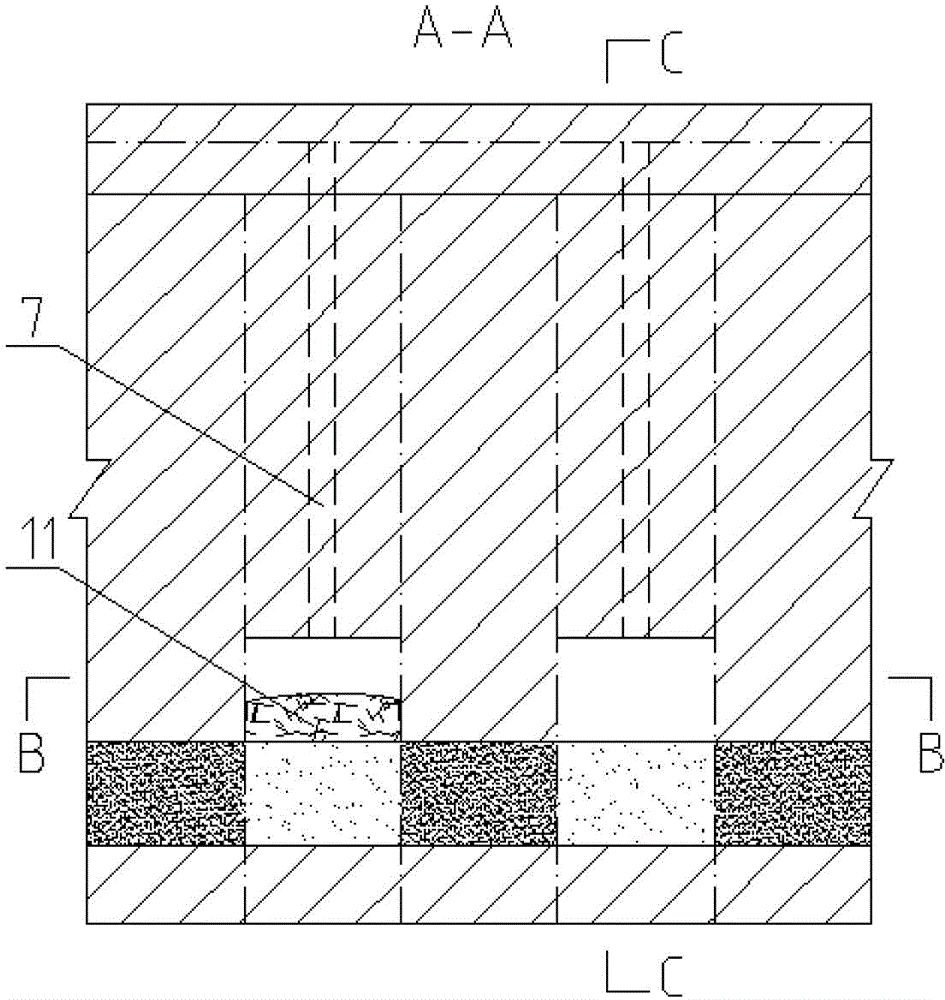

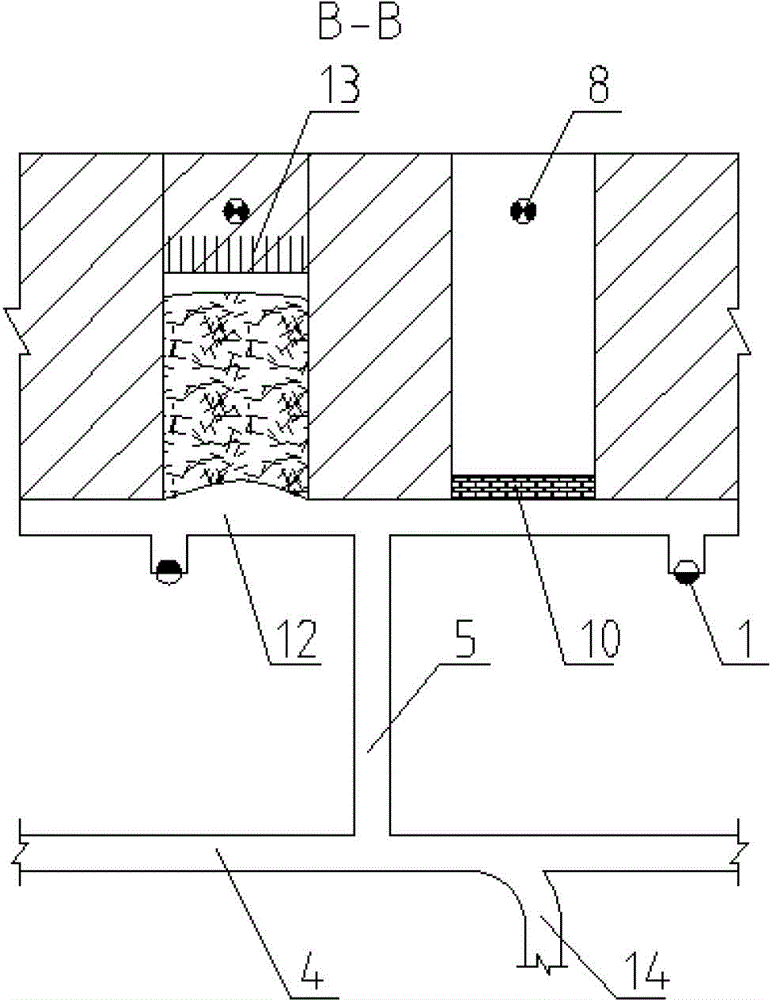

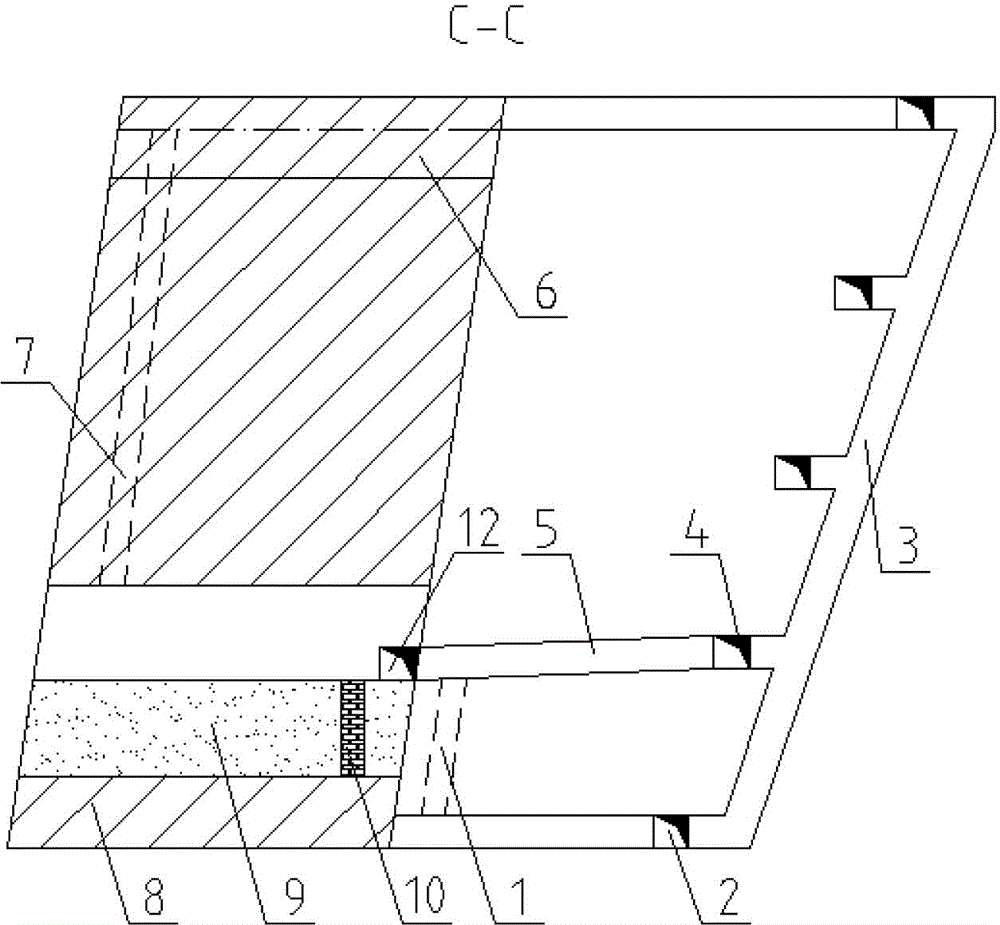

[0011] The present invention will be further described below in conjunction with the accompanying drawings and a specific embodiment. Such as Figure 1~Figure 3 As shown, a two-step high-layer bag-fill mining method includes the following steps:

[0012] A. Stope layout and division

[0013] The two-step high-layer bag-fill mining method is adopted. The height of the middle section is 60m, and the top and bottom columns are left in the middle section. The thickness of the bottom column is 6m, and the thickness of the top column is 4m. When the thickness of the ore body is greater than 30~40m, the stope is arranged vertically to the direction of the ore body, and the ore body is divided into mine room and mine pillar, and the stope is mined in two steps, and the width of the stope is 12m. High stratification is adopted during mining, and the stratification height is 7.5~8m.

[0014] B. Mining and cutting project layout

[0015] Arrange ramps in the footwall of the ore body,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com