Diagonal ore-break-down medium-length hole mining method for steeply-inclined thin vein ore body

A thin ore body, steeply inclined technology, applied in surface mining, underground mining, special mining and other directions, can solve the problem of high labor intensity of workers, and achieve the effect of saving mining engineering, reducing dilution and loss, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

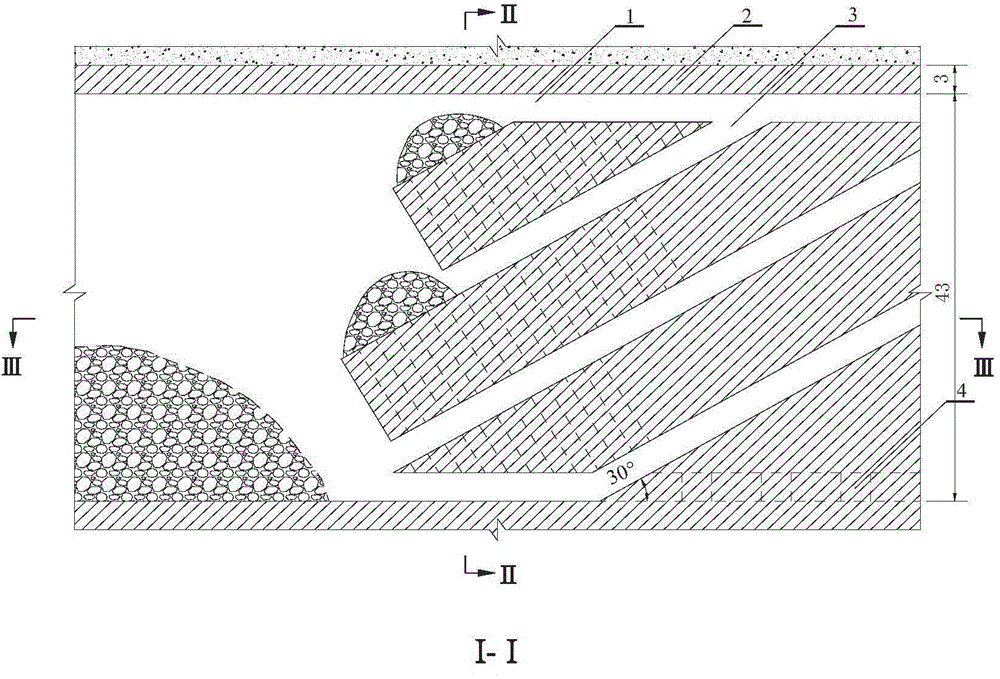

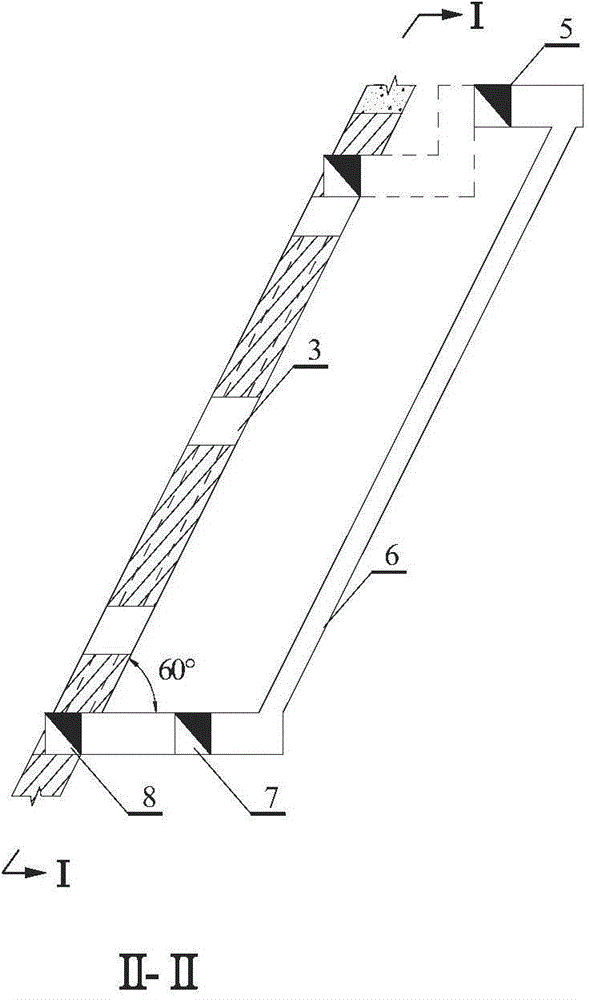

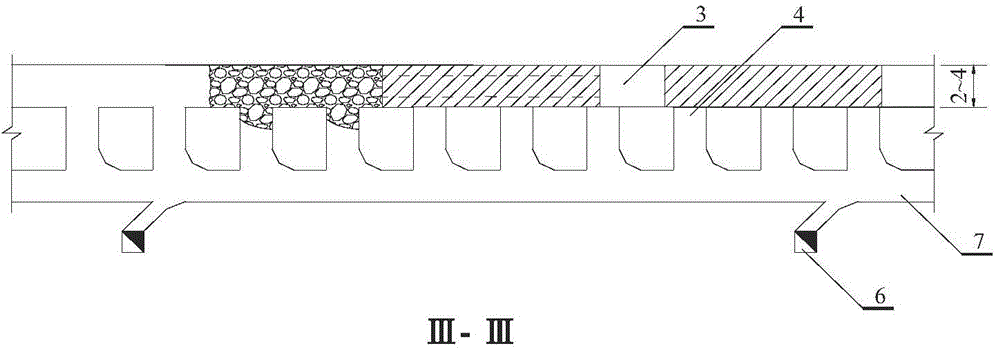

[0027] The medium-deep hole mining method of pseudo-inclined ore-falling in the steeply inclined thin ore body vein provided by the present invention, see figure 1 , figure 2 and image 3 , the specific steps are as follows:

[0028] 1) Arrange the stope along the ore body trend, divide the room pillars and sections according to the inclination direction of the ore body, the height of the middle section is 46m, the height of the sections is 10m, the width of the room pillar is determined according to the stability of the ore rock; Arrange the transportation level roadway 7 in the stage; along the stage, the transportation level roadway 7 is excavated into the ore exit horizontal roadway 4 every 8m to the ore body; the bottom level roadway 8 is set horizontally along the vein, and the rock drilling prospecting goes up the mountain gradually in parallel according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com