Method for mining inclined and steeply inclined thin ore body

A thin ore body, steeply inclined technology, applied in surface mining, mining equipment, underground mining and other directions, can solve the problems of ore body caving, the collapse of the surrounding rock on the upper wall, etc., to achieve strong operability and reduce the amount of mining engineering , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

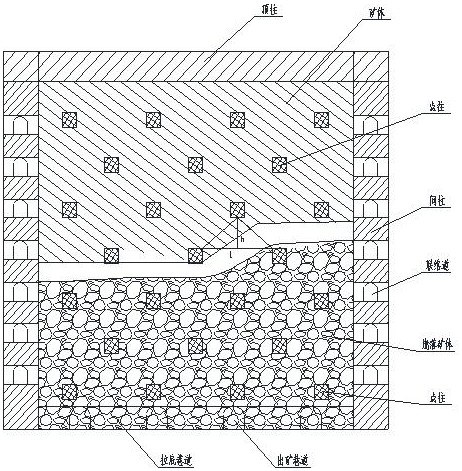

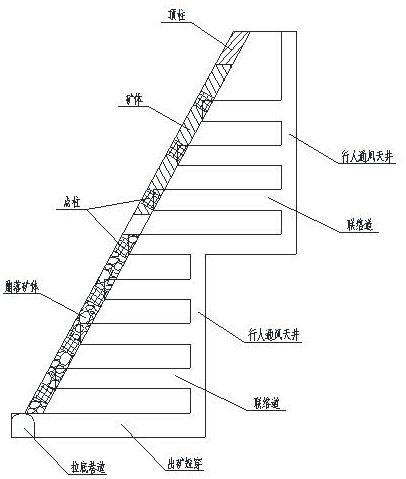

[0032] A copper mine in Gansu has delineated 5 blind small ore bodies on the main ore body through geological survey. The strike of the ore body is 320-340°, the dip angle is 53-71°, and the average thickness is 1.6-3m. The ore type is mainly infected chalcopyrite. The surrounding rocks of the upper and lower walls of the ore body are quartz horn-porphyry tuff, with well-developed schistostic structures and local fissure water. The surrounding rock has a metamorphic clastic tuff structure, which appears off-white, gray and gray-green to the naked eye. The rocks are generally subjected to alterations such as sericitization, chloritization, silicification, carbonation, and pyritization, and the alteration is particularly intense at the interlayer of the ore body.

[0033] The mine design adopts the shallow hole retention method with flat bottom structure. During the mining process, the surrounding rocks of the upper wall collapse and the ore body caving often occurs, thereby i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com