Combined oil well pump for preventing well flushing from polluting oil layer

An oil well pump and combined technology, applied in the field of combined oil well pumps, can solve the problems of long pump inspection period, limitations and hidden dangers, oil layer pollution, etc., and achieve the effect of simple structure and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with preferred embodiment, the specific implementation mode provided according to the present invention is described in detail as follows:

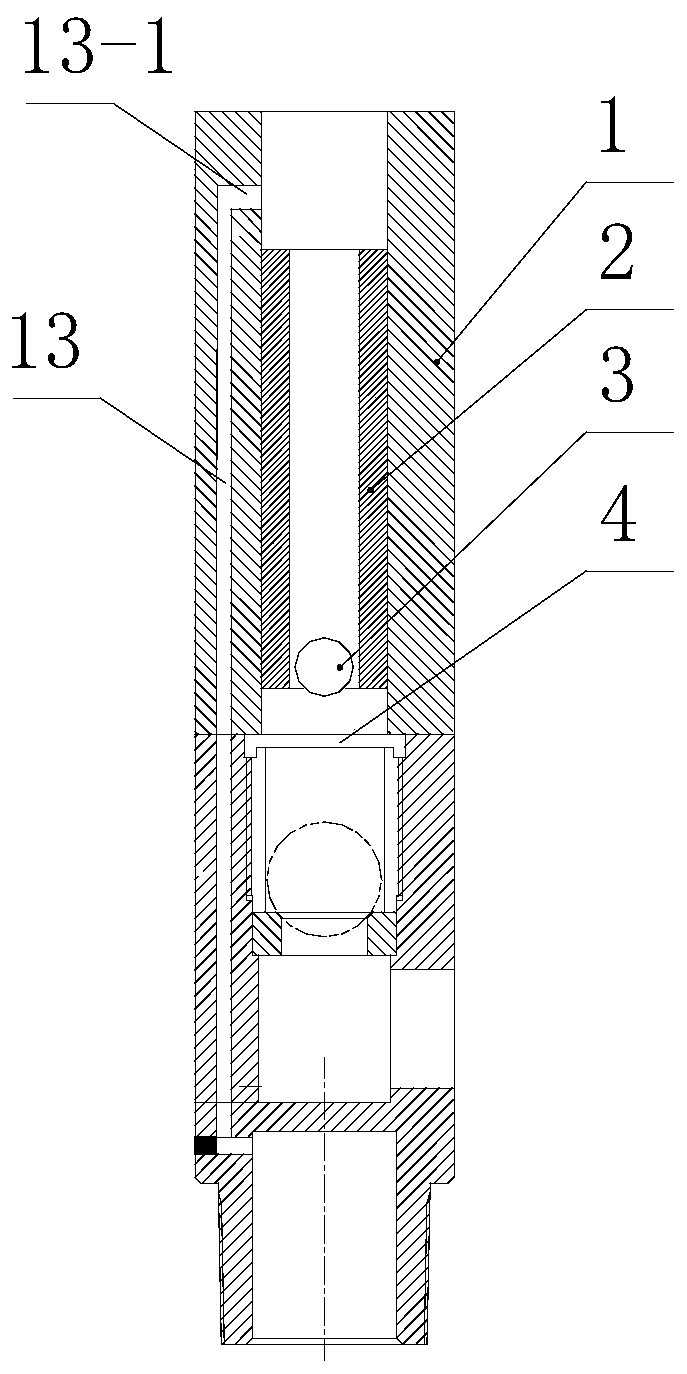

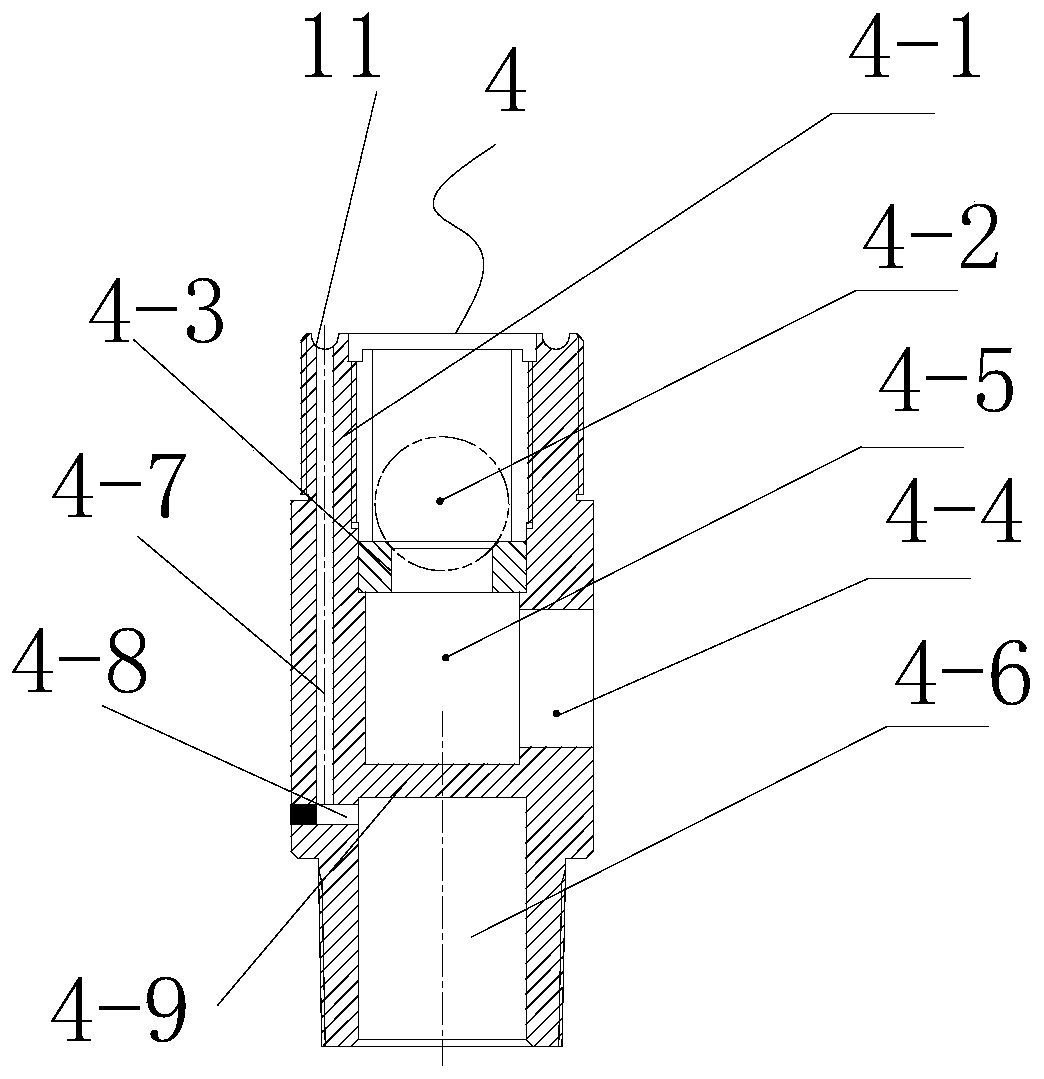

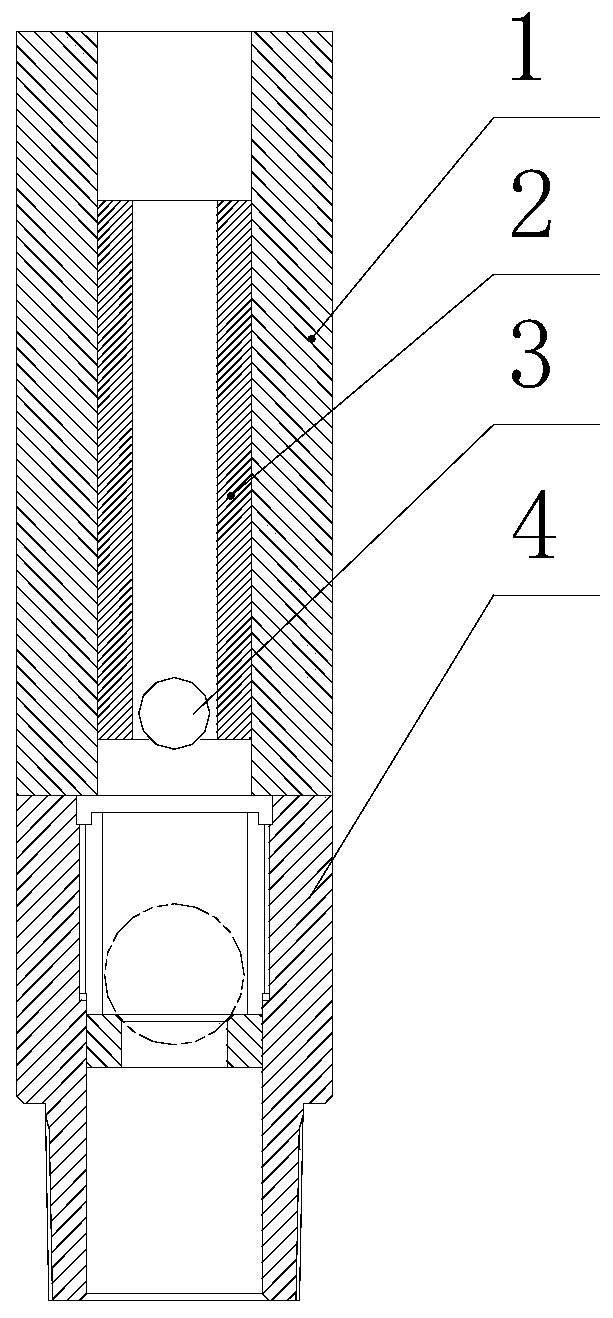

[0015] see attached figure 1 , this embodiment discloses a combined oil well pump for preventing well washing from polluting the oil layer, including an oil well pump barrel 1, a plunger assembly 2, a floating valve 3, a fixed valve 4, a diaphragm packer 5 and a plug 12 The pump barrel wall of the oil well pump is provided with a pump barrel diversion channel 13, the upper end of the pump barrel diversion channel is connected with a radial small hole 13-1 communicating with the inner cavity of the pump barrel, and the diameter of the upper end of the diversion channel is connected The location of the small hole is that when the plunger is at the bottom dead center, the radial small hole should communicate with the inner cavity of the pump barrel, so that the plunger is just connected with the inner cavity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com