Sieve tube process brine extraction device

A technology of screen pipe method and brine extraction, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of insufficient mining, low recovery rate, unfavorable energy saving and emission reduction, etc., and achieve the improvement of recovery rate, The effect of reducing mining costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

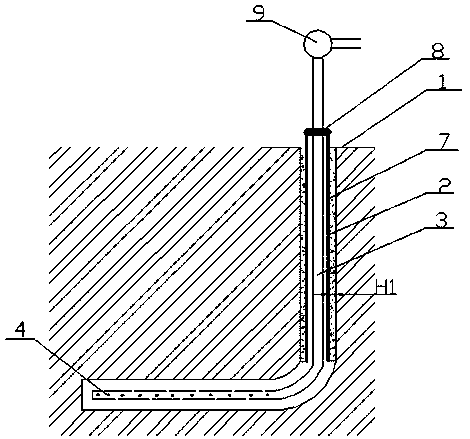

[0024] This implementation mode provides a kind of brine extraction device by screen tube method, such as figure 1 , is mainly composed of a deviated well 1, a deviated well casing 2, a center pipe 3 with a closed end and a water injection pump 9. The deviated well casing 2 is placed in the vertical section of the deviated well 1, and the outer wall of the deviated well casing 2 The inner wall of the well 1 is sealed with concrete 7; the central pipe 3 is placed in the casing 2 of the deviated well, and there is a preset distance H1 between the inner wall of the casing 2 of the deviated well and the outer wall of the central pipe 3, and the two are supported by The frame 8 is fixedly connected; the lower part of the central pipe 3 extends to overlap with the horizontal section of the inclined shaft 1, and a section of the side wall where the central pipe 3 overlaps with the horizontal section of the inclined shaft 1 has a number of water spouts 4 distributed along its length di...

Embodiment approach 2

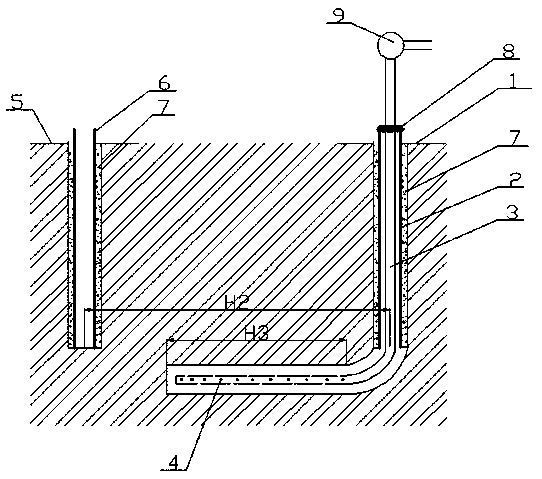

[0028] This embodiment is a further improvement of Embodiment 1. The main improvement is that in Embodiment 1, in practical applications, the length of the underground horizontal section of the inclined shaft 1 may be two to three hundred meters long. Under the action of water pressure, the water with high concentration needs to first pass through the horizontal section of the inclined well 1, then through the vertical section of the inclined well 1, and rise up through the space between the casing pipe 2 and the central pipe 3 of the inclined well to spray out the inclined wellhead. When the length of the underground horizontal section of 1 is long, the water pressure may not be able to press out the high-concentration water, or the press-out speed is relatively slow, but this embodiment can effectively solve the above problems.

[0029] Specifically, in this embodiment, as figure 2 As shown, another vertical well 5 is opened at a preset distance from the inclined well 1. Th...

Embodiment approach 3

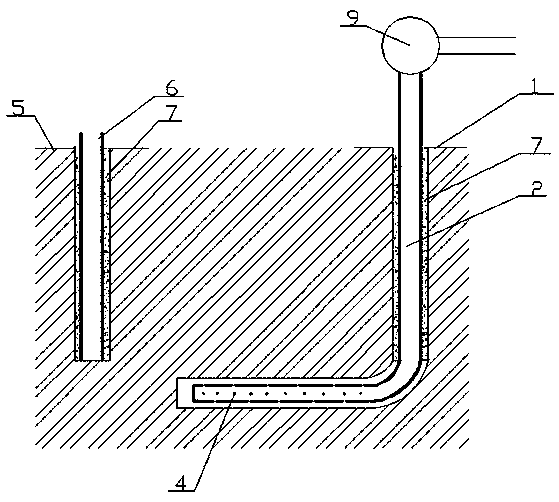

[0033] This implementation mode provides a kind of brine extraction device by screen tube method, such as image 3As shown, it is mainly composed of a vertical well 5, a vertical well casing 6, an inclined well 1, an inclined well casing 2 with a closed end, and a water injection pump 9. The vertical well 5 and the vertical section of the inclined well 1 are arranged in parallel, and the vertical well 5 and the inclined well 1 The distance H2 between them is greater than or equal to the length H3 of the horizontal section of the deviated well 1; the vertical well casing 6 is placed in the vertical well 5, and the outer wall of the vertical well casing 6 and the inner wall of the vertical well 5 are sealed by concrete 7 . The inclined well casing 2 is placed in the inclined well 1, and the outer wall of the vertical section of the inclined well casing 2 and the inner wall of the vertical section of the inclined well 1 are sealed by concrete 7 . The lower part of the inclined we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com