Patents

Literature

52results about How to "Maximize heat transfer efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

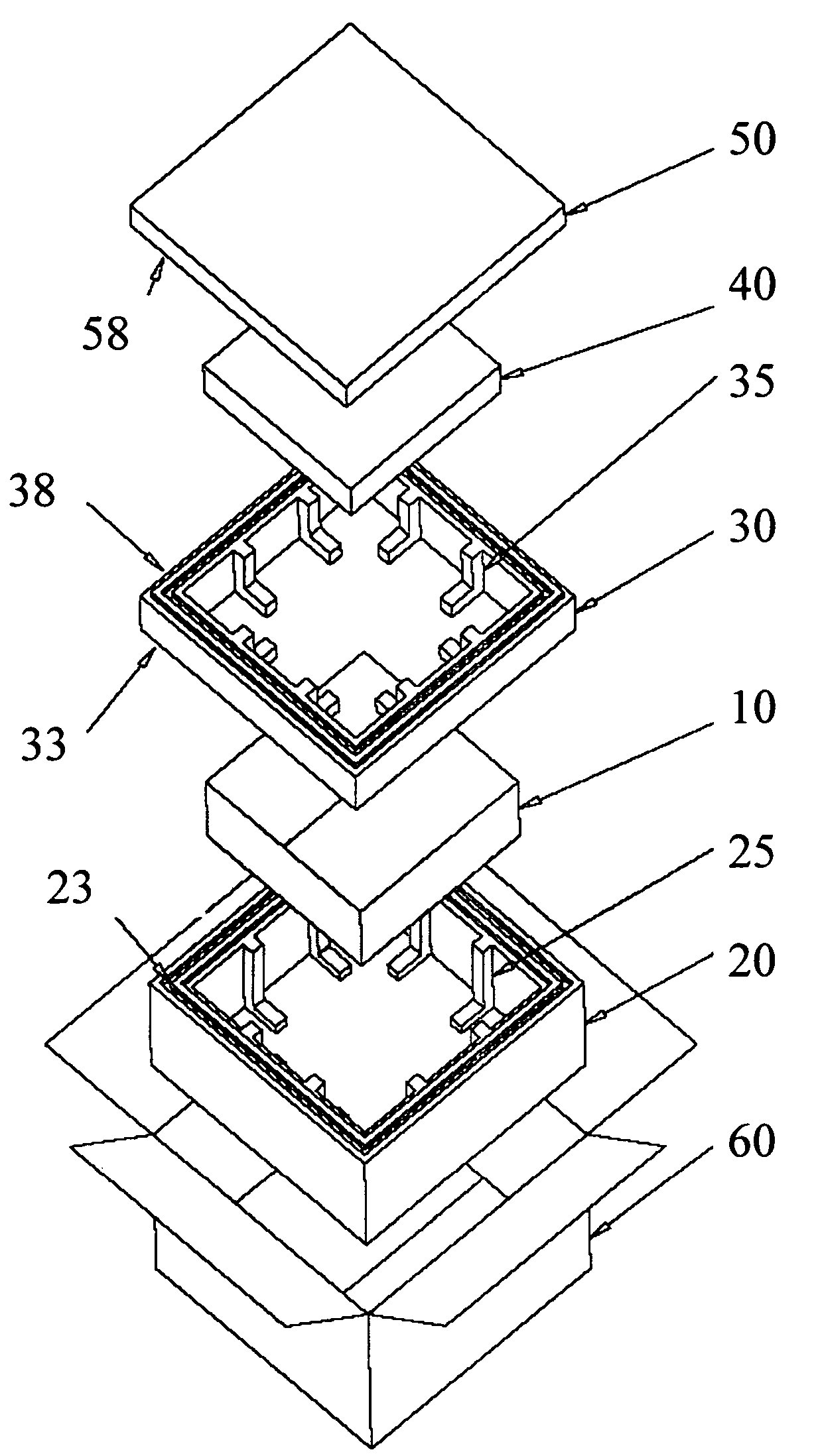

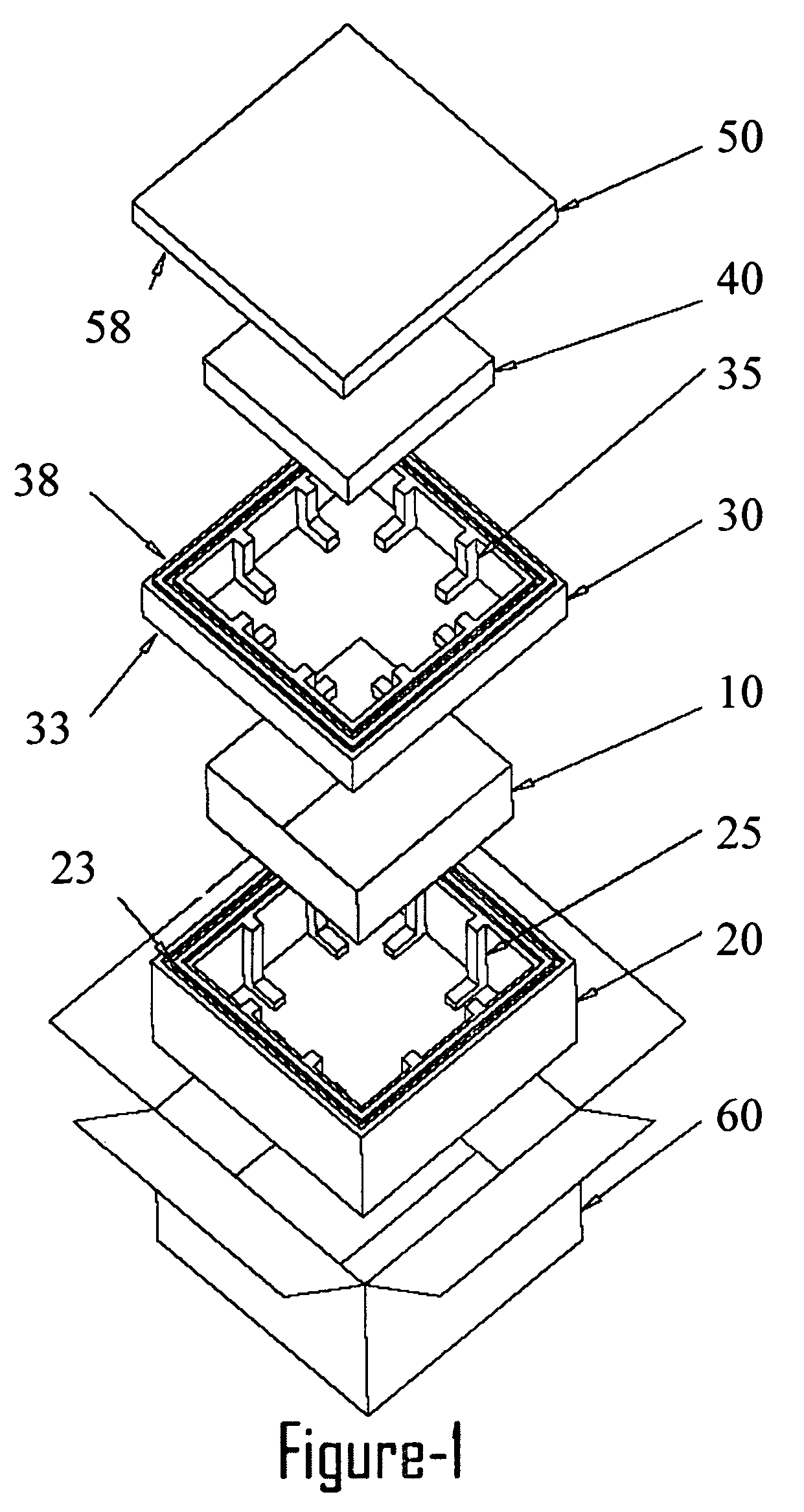

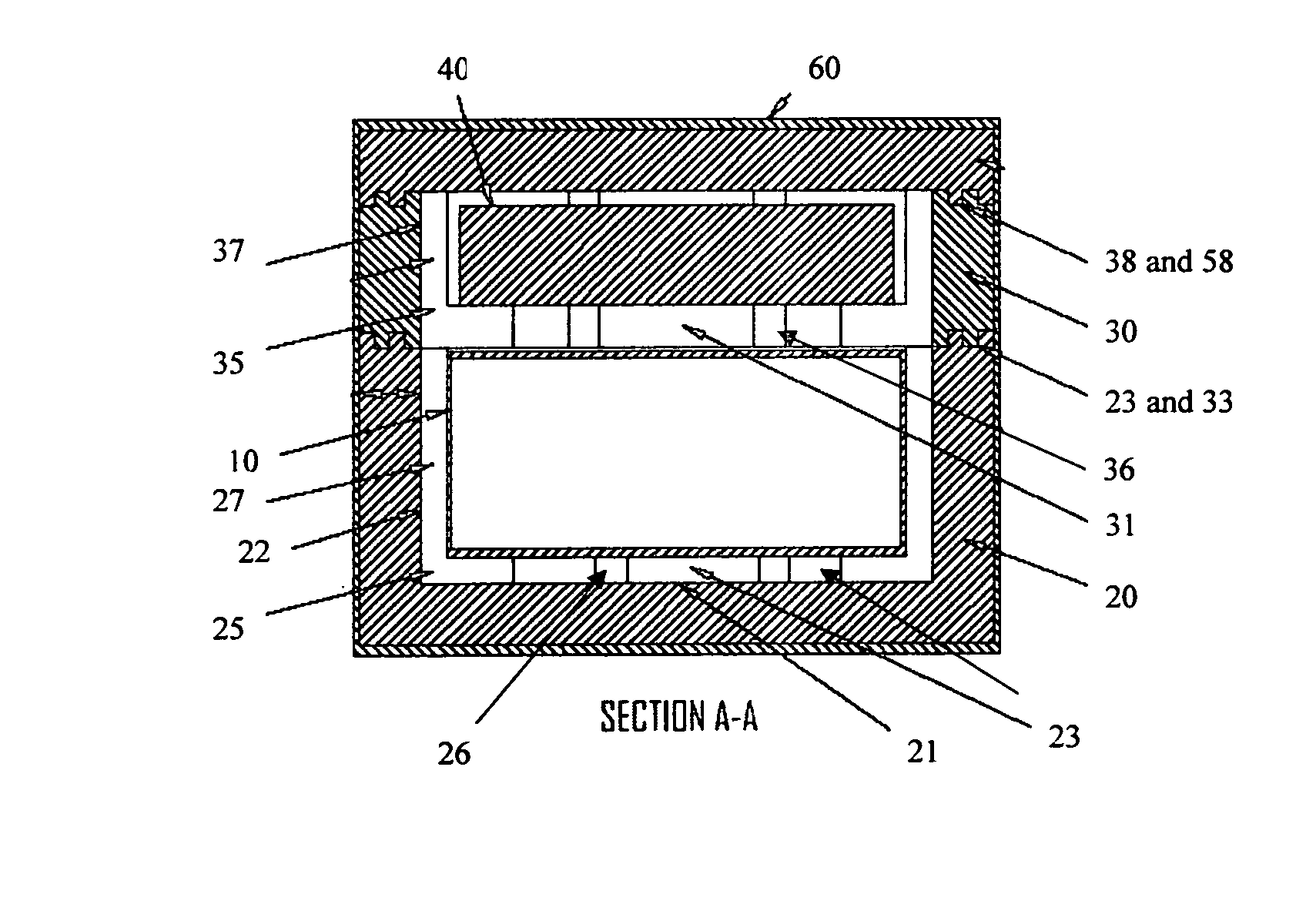

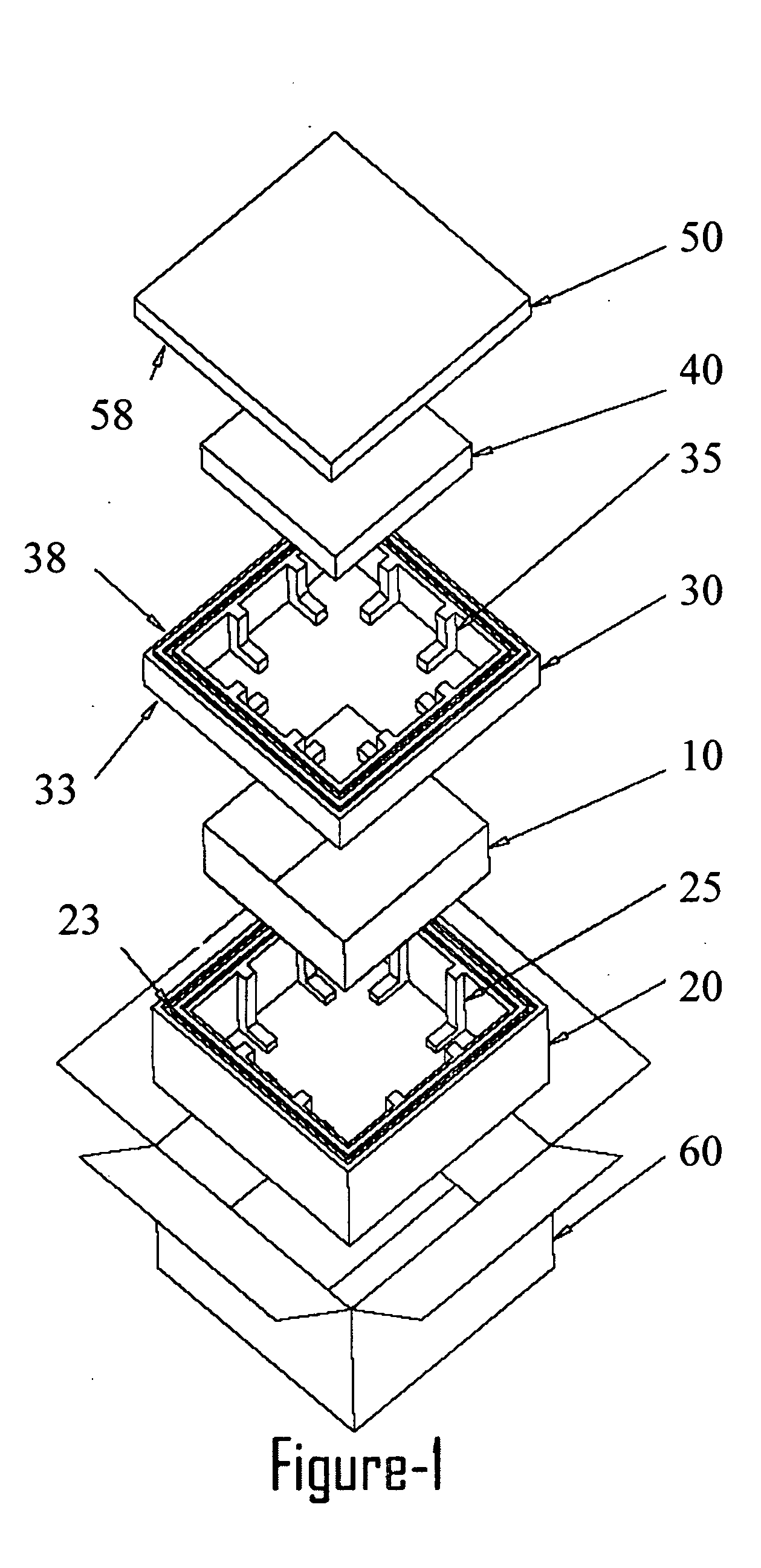

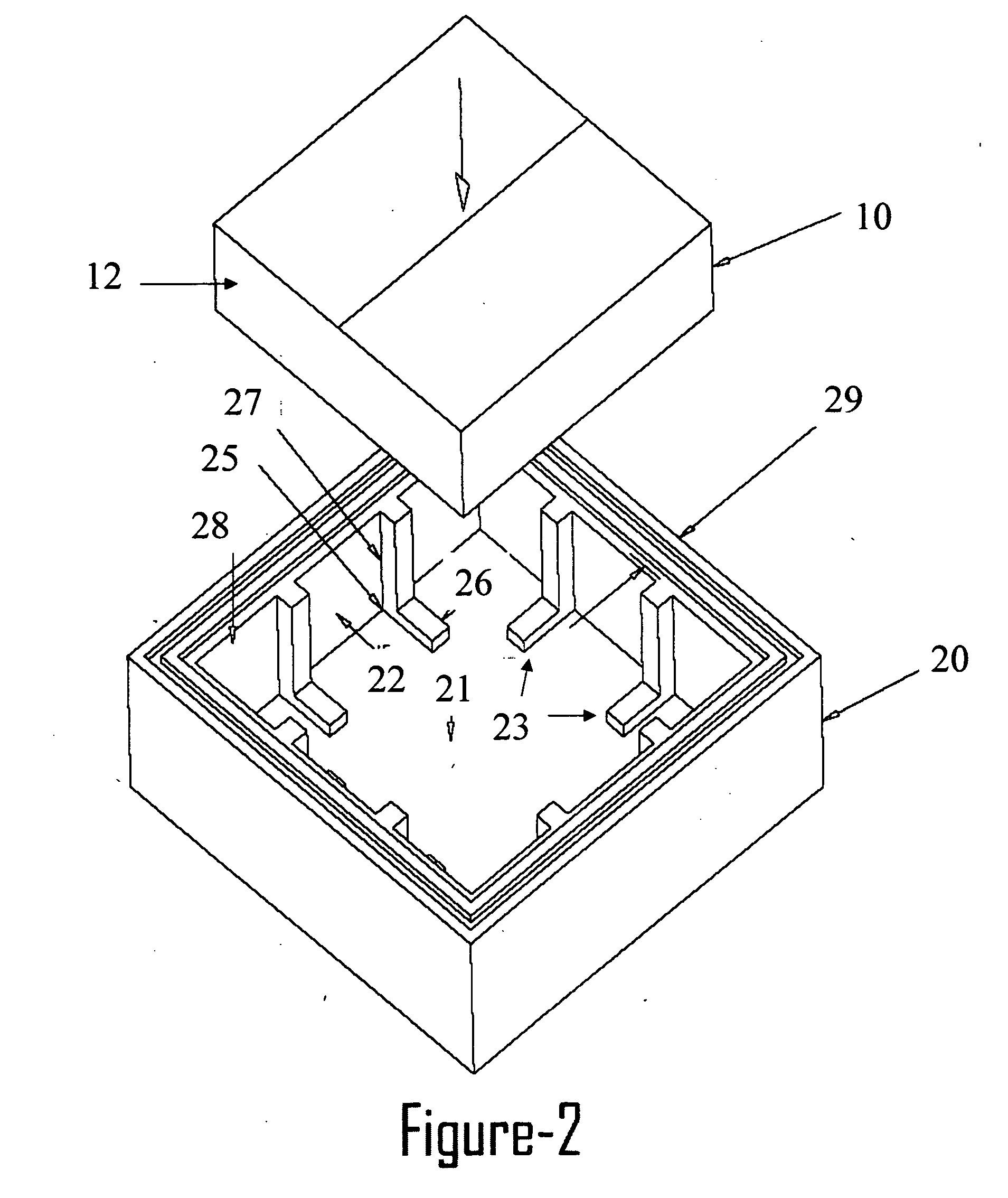

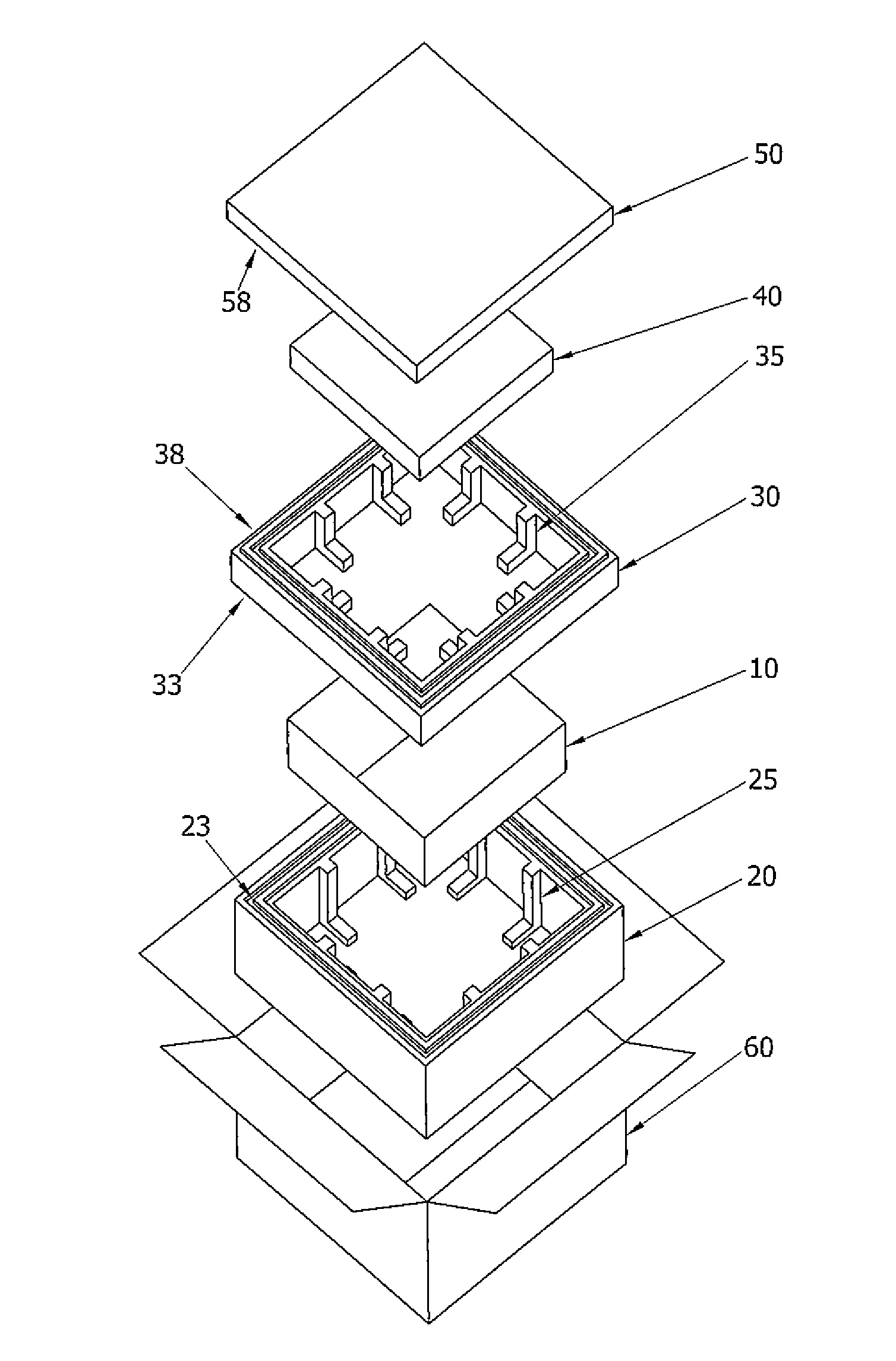

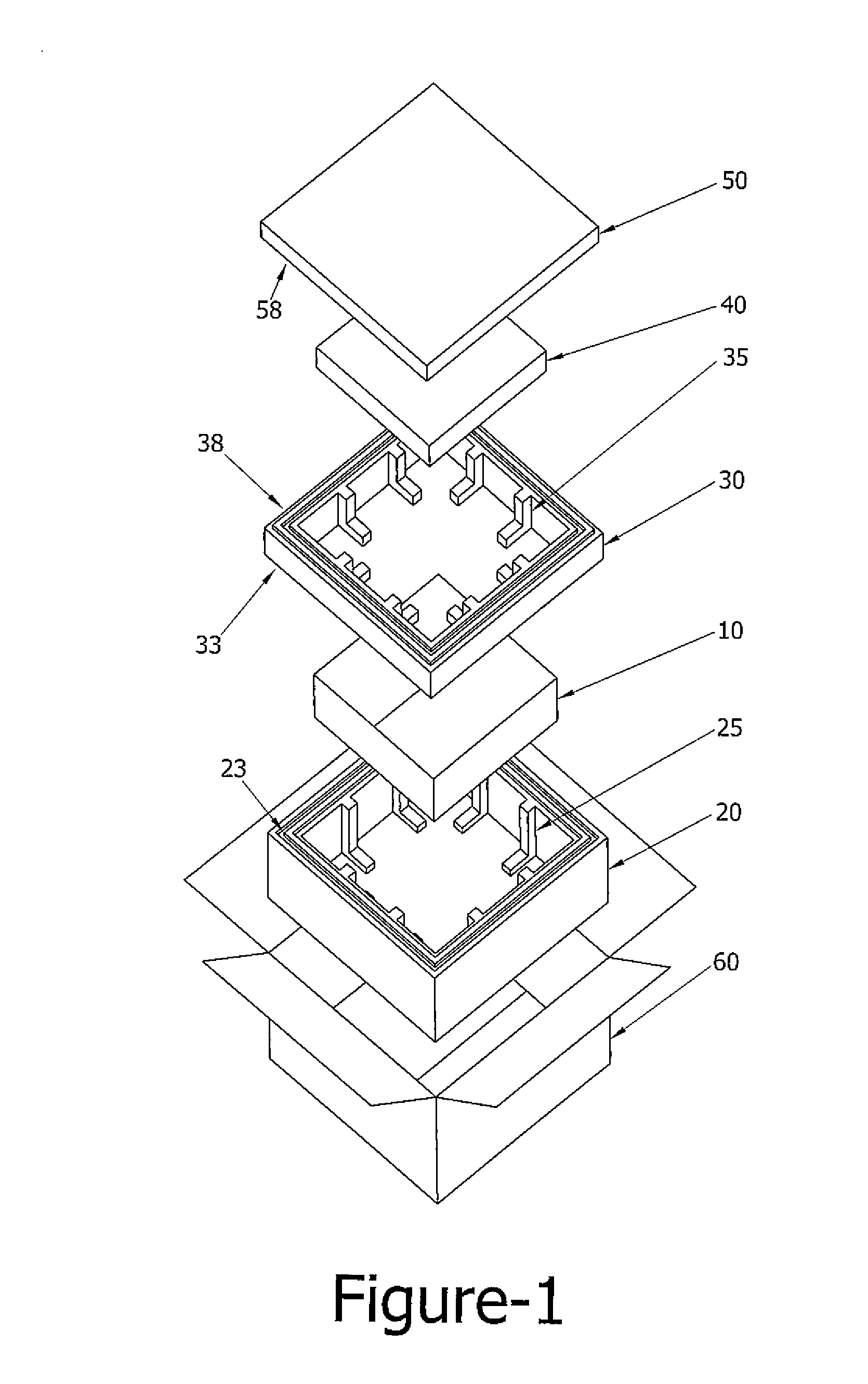

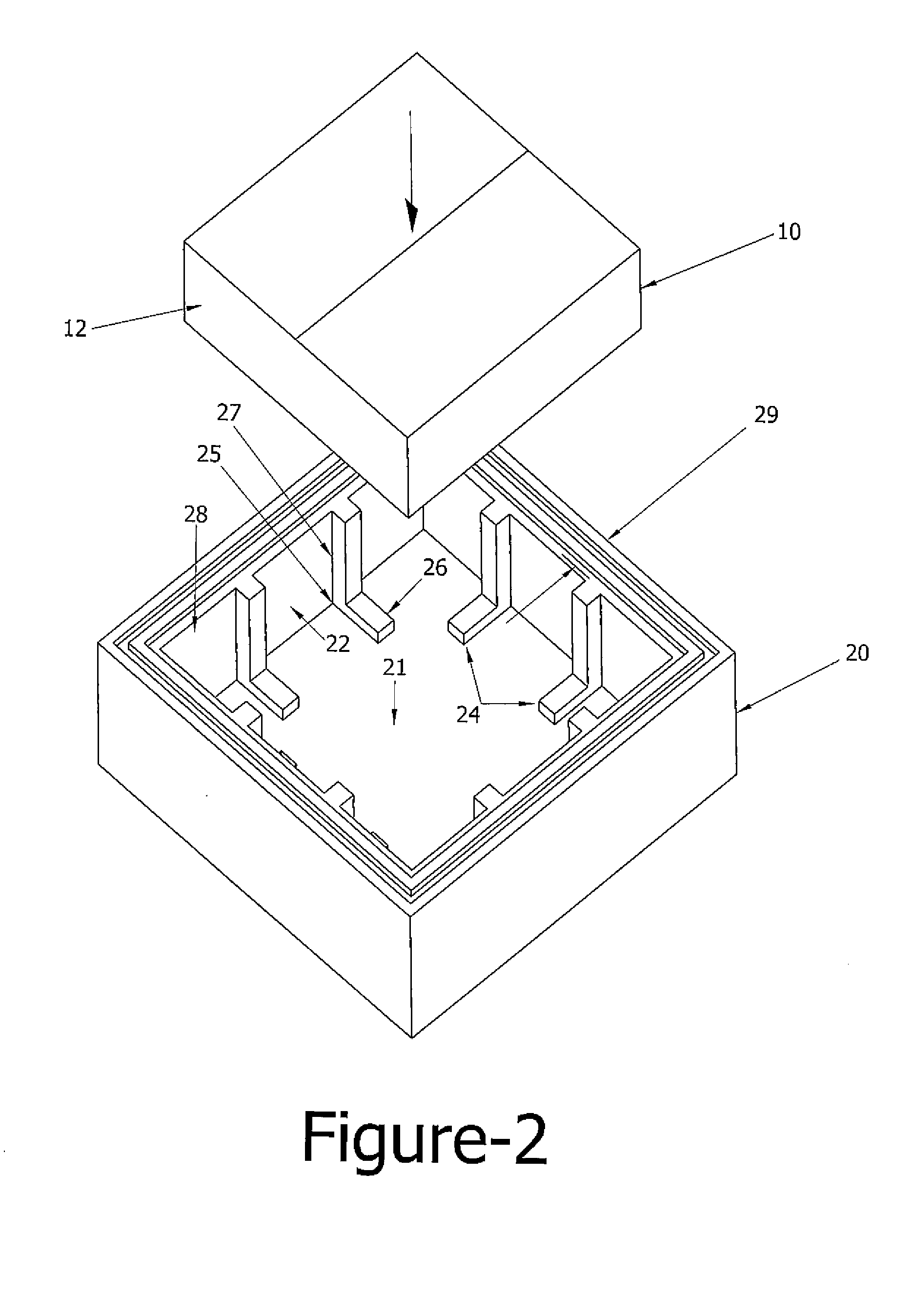

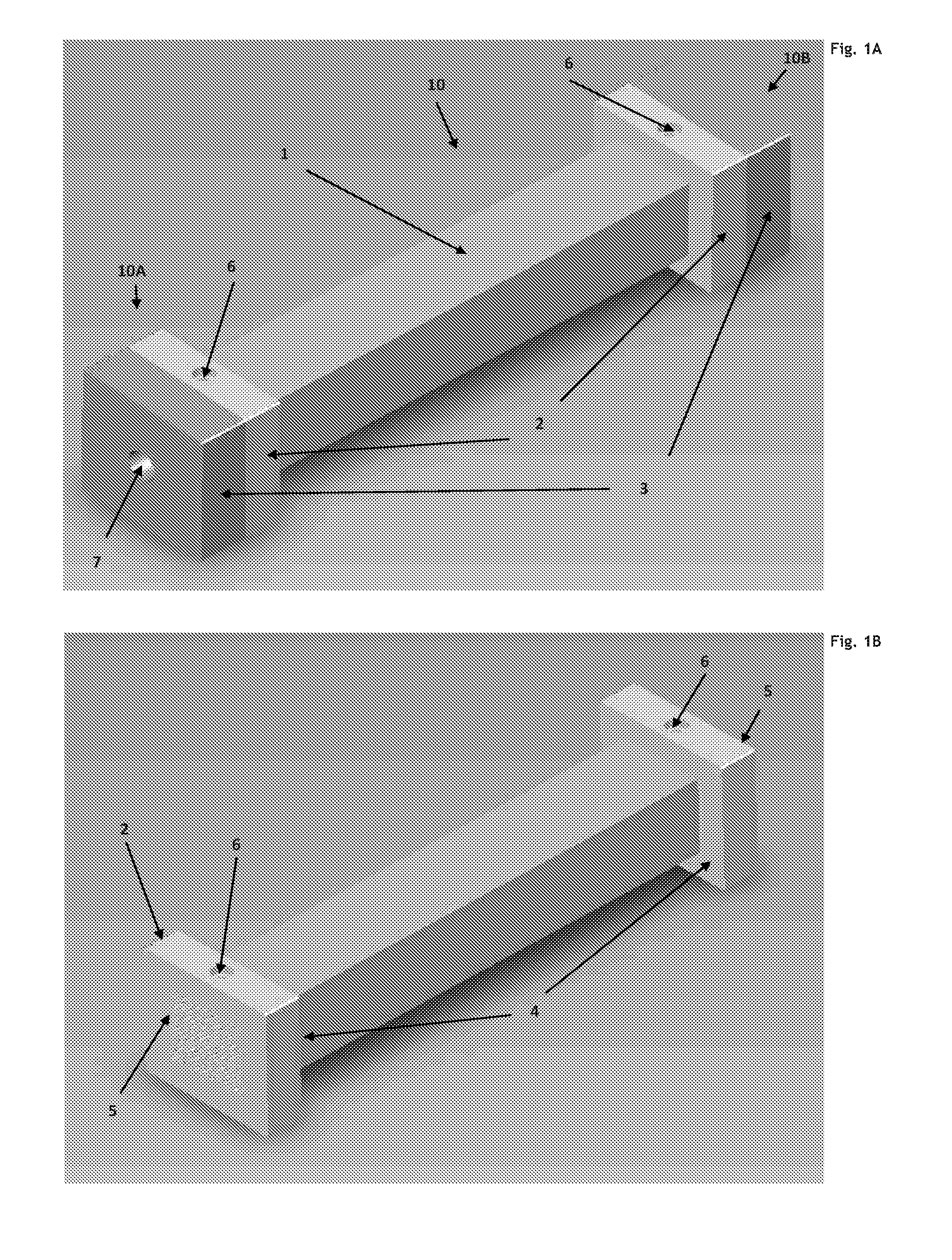

Insulated shipping container systems and methods thereof

InactiveUS7681405B2Improve cooling efficiencyIncrease temperatureLighting and heating apparatusLiquid dispensingInsulated shipping containerTemperature sensitive

An insulated shipping container system for transferring a temperature sensitive product comprising a substantially hollow insulated body having inner walls and outer walls defining a payload cavity to receive a payload and supports to space the payload from the insulated body thereby defining an internal air filled space to facilitate heat transfer. The insulated shipping container system further comprises a heat transfer element cavity configured to receive a heat transfer element and supports to space the heat transfer element from the insulated body thereby defining an internal air filled space to facilitate heat transfer. Also provided are methods for shipping temperature sensitive products and goods comprised of packing and assembling the insulated shipping container system disclosed herein.

Owner:WILLIAMS ALTON

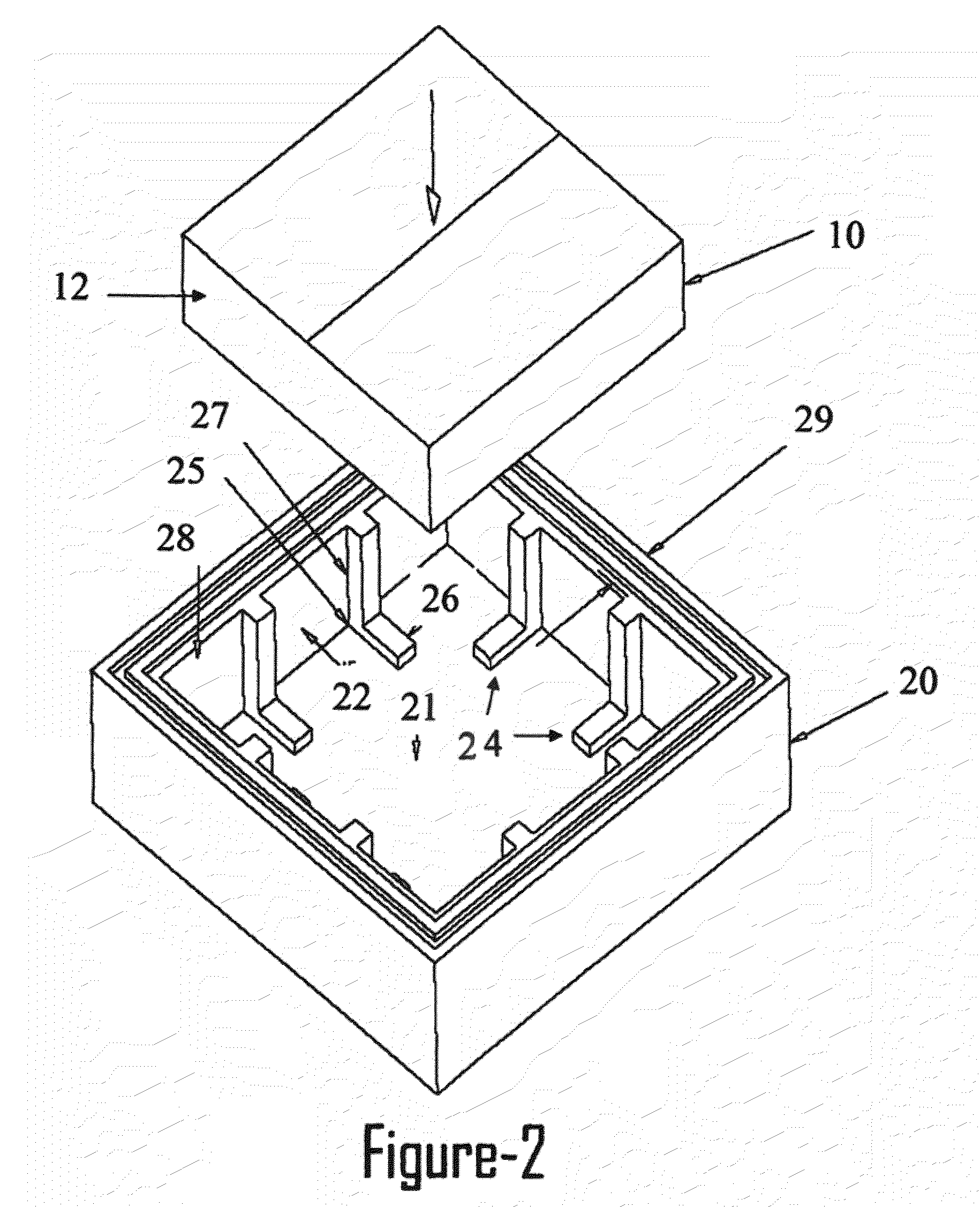

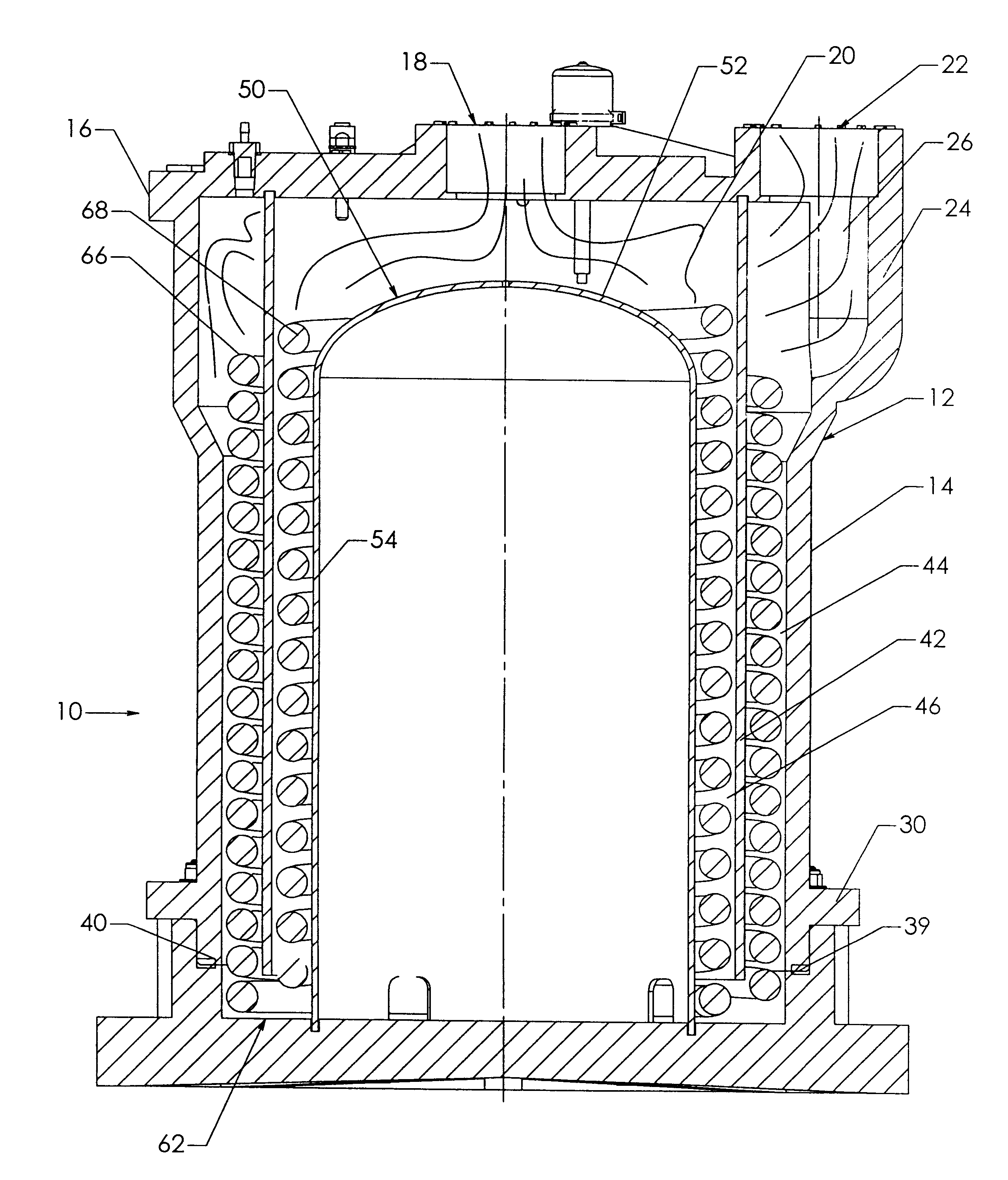

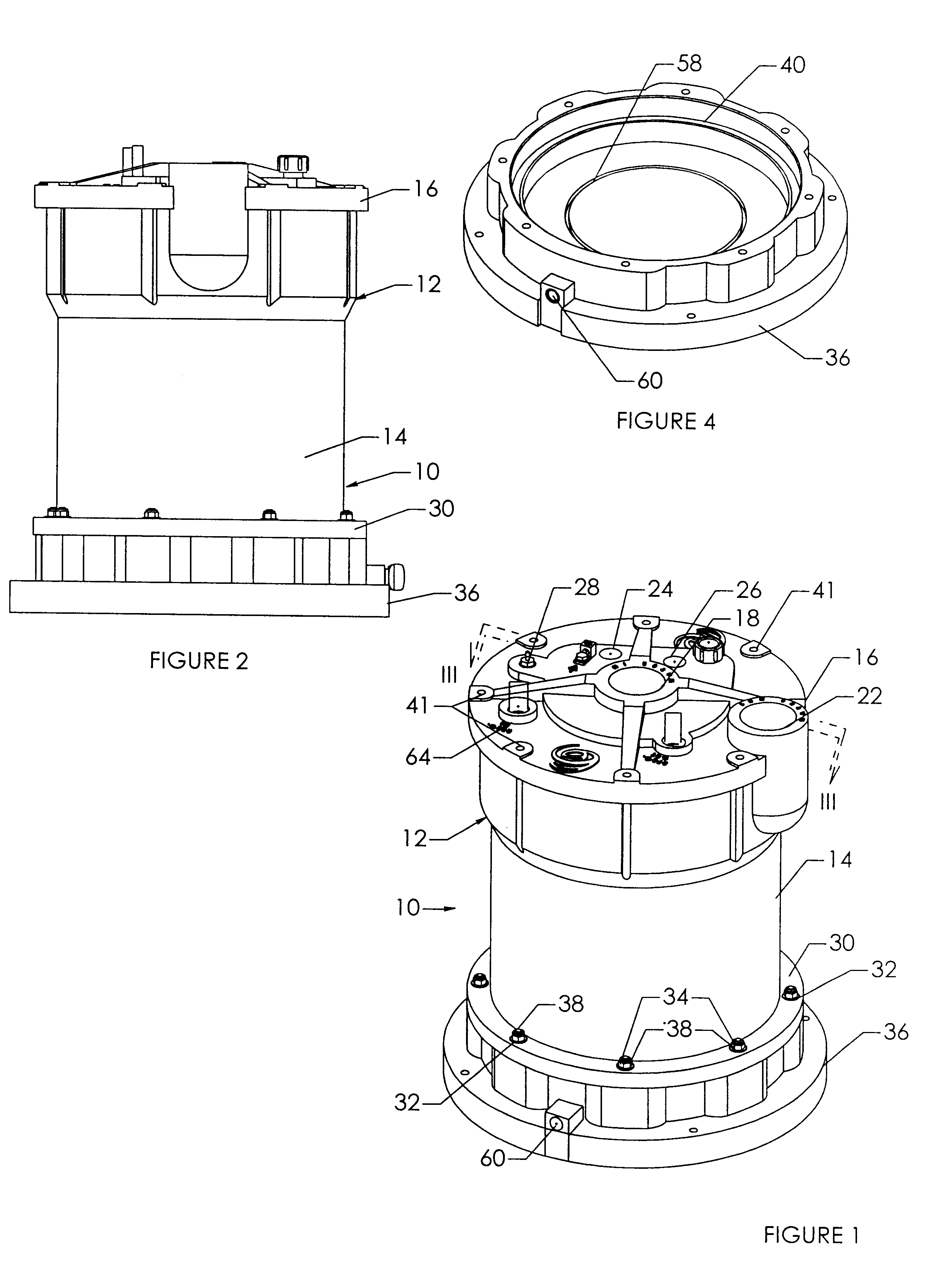

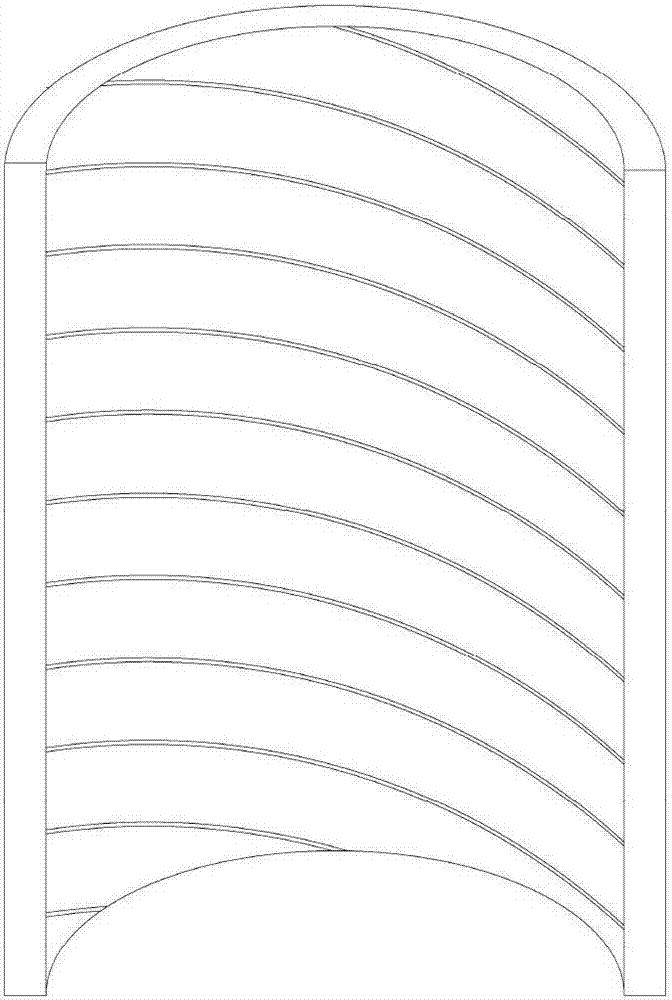

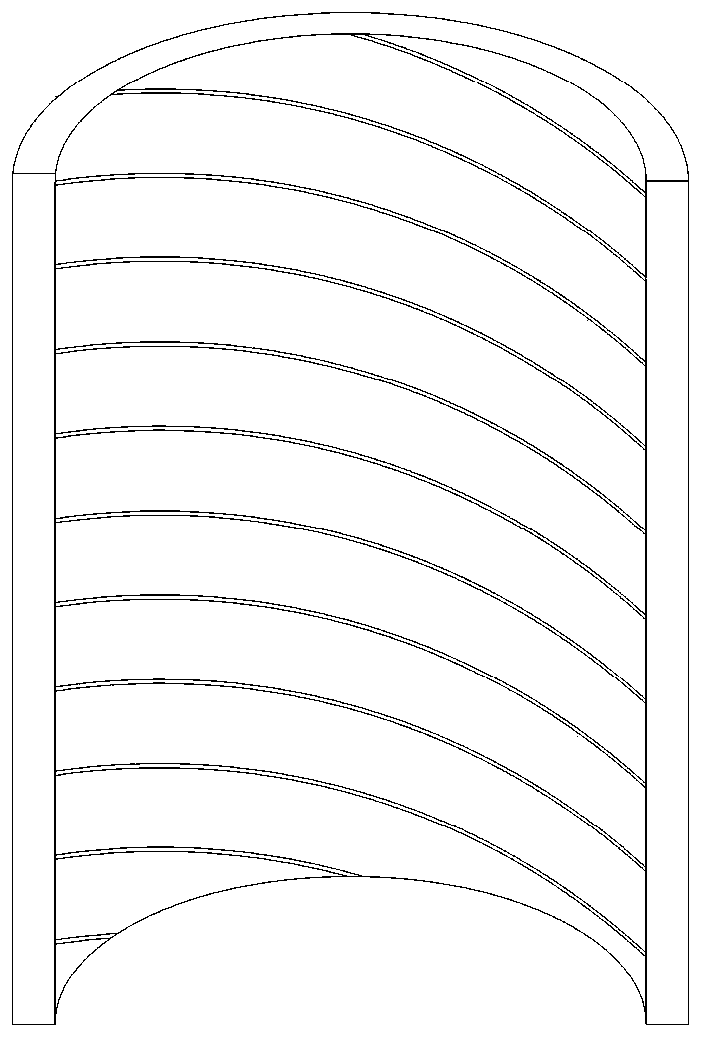

Heat exchanger with two-stage heat transfer

InactiveUS6499534B1Improve heat transfer performanceMinimize thermal losses to the atmosphereHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

A tube and shell heat exchanger is formed by a shell enclosing an internal sidewall which in turn receives an internally located flow controller outer and inner heat exchange cavities are formed between the outer shell and the internal shell and the internal shell and the flow controller, respectively. Helical convolutions of the conduit are provided in each of the heat exchange cavities for counter concurrent flow of fluid medium from one cavity to another. A bottom wall closes off the outer shell.

Owner:AQUACAL

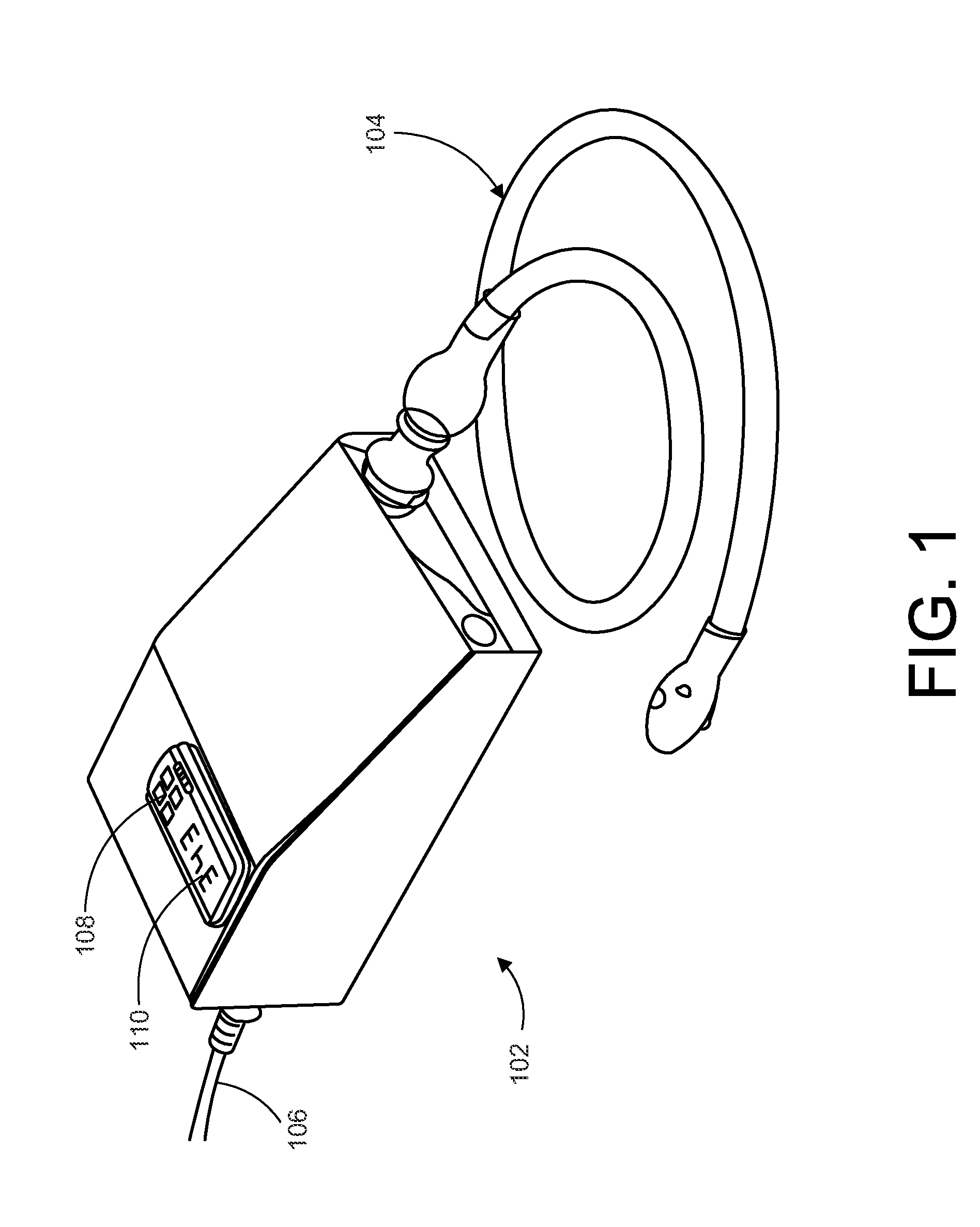

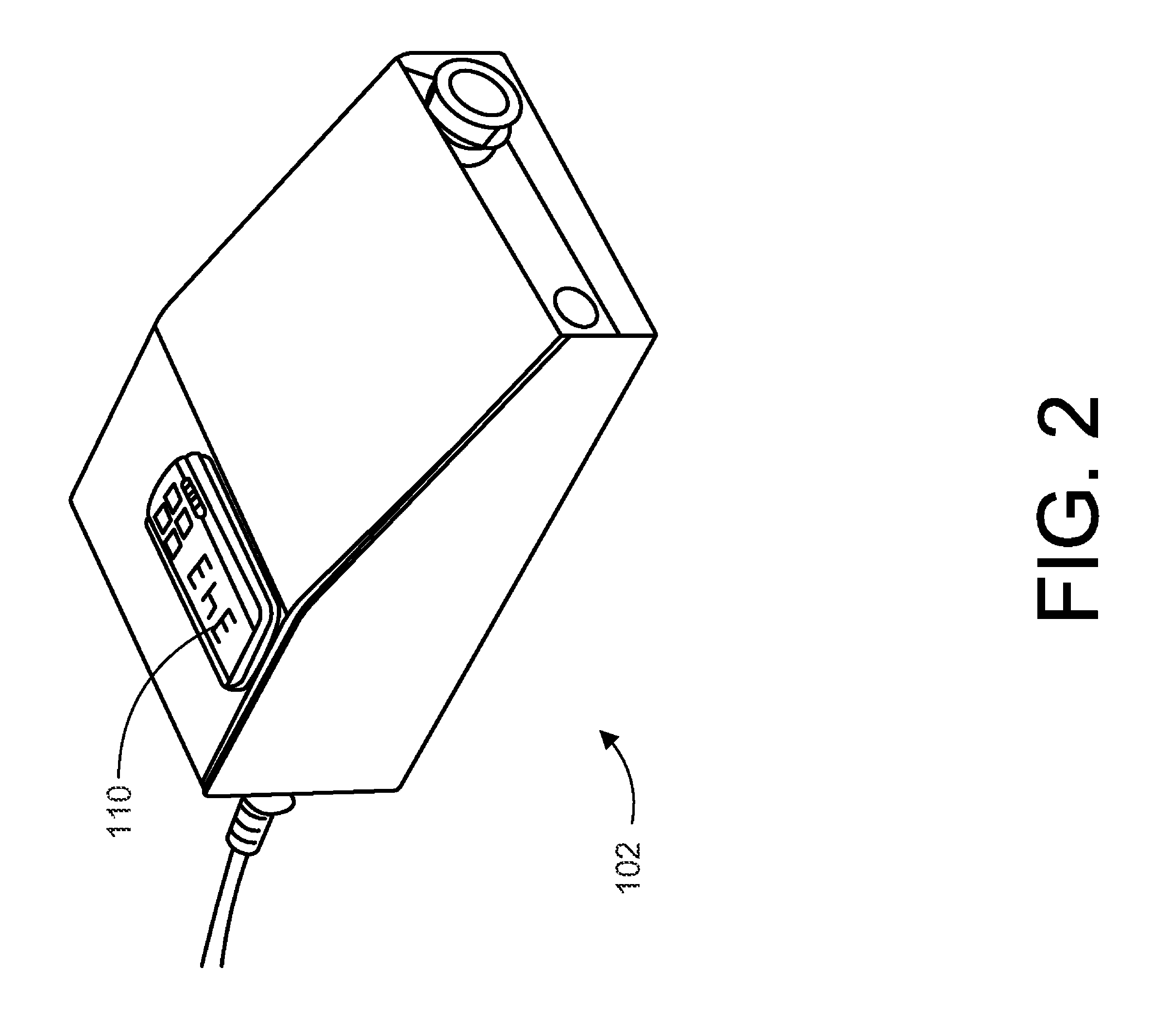

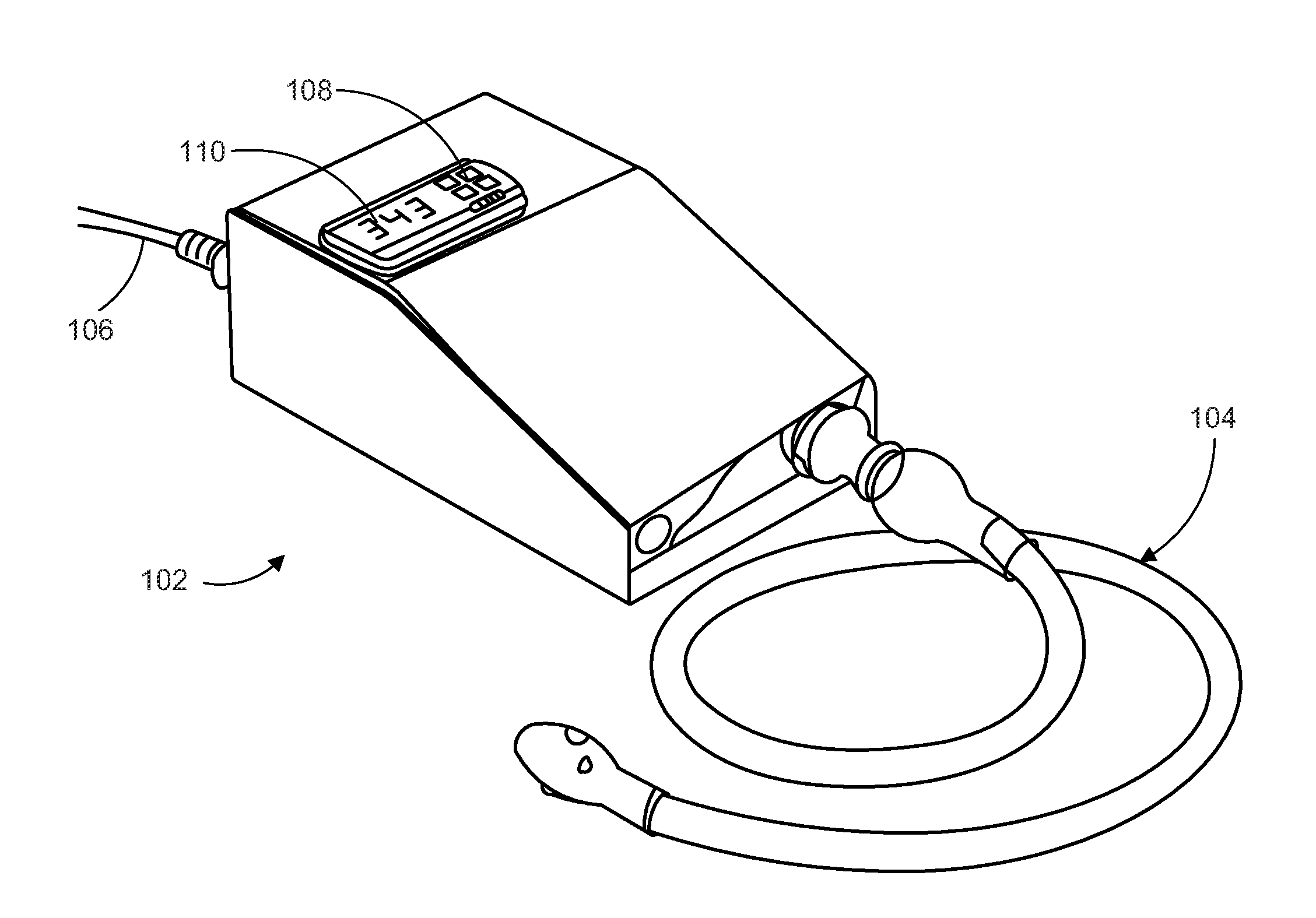

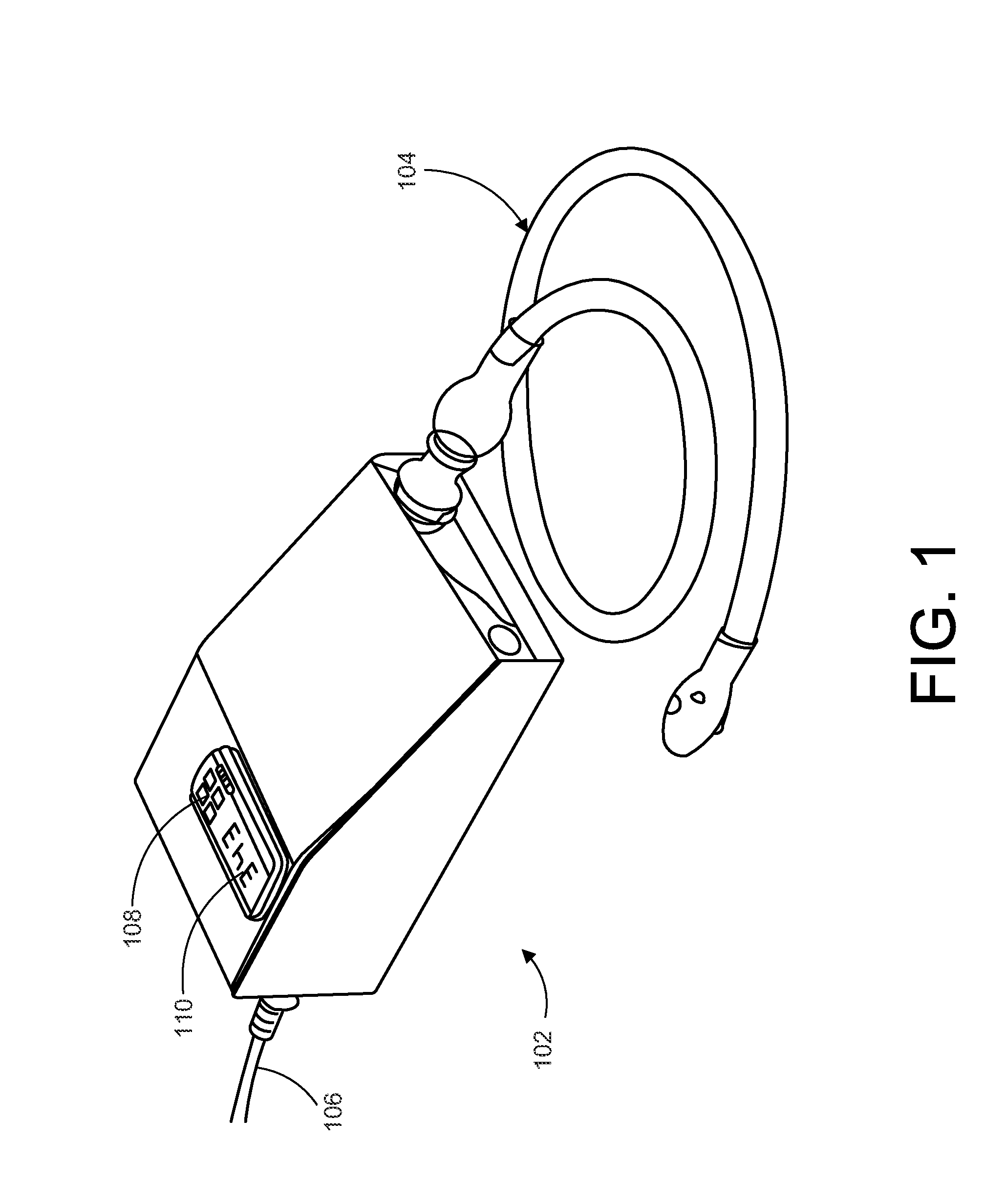

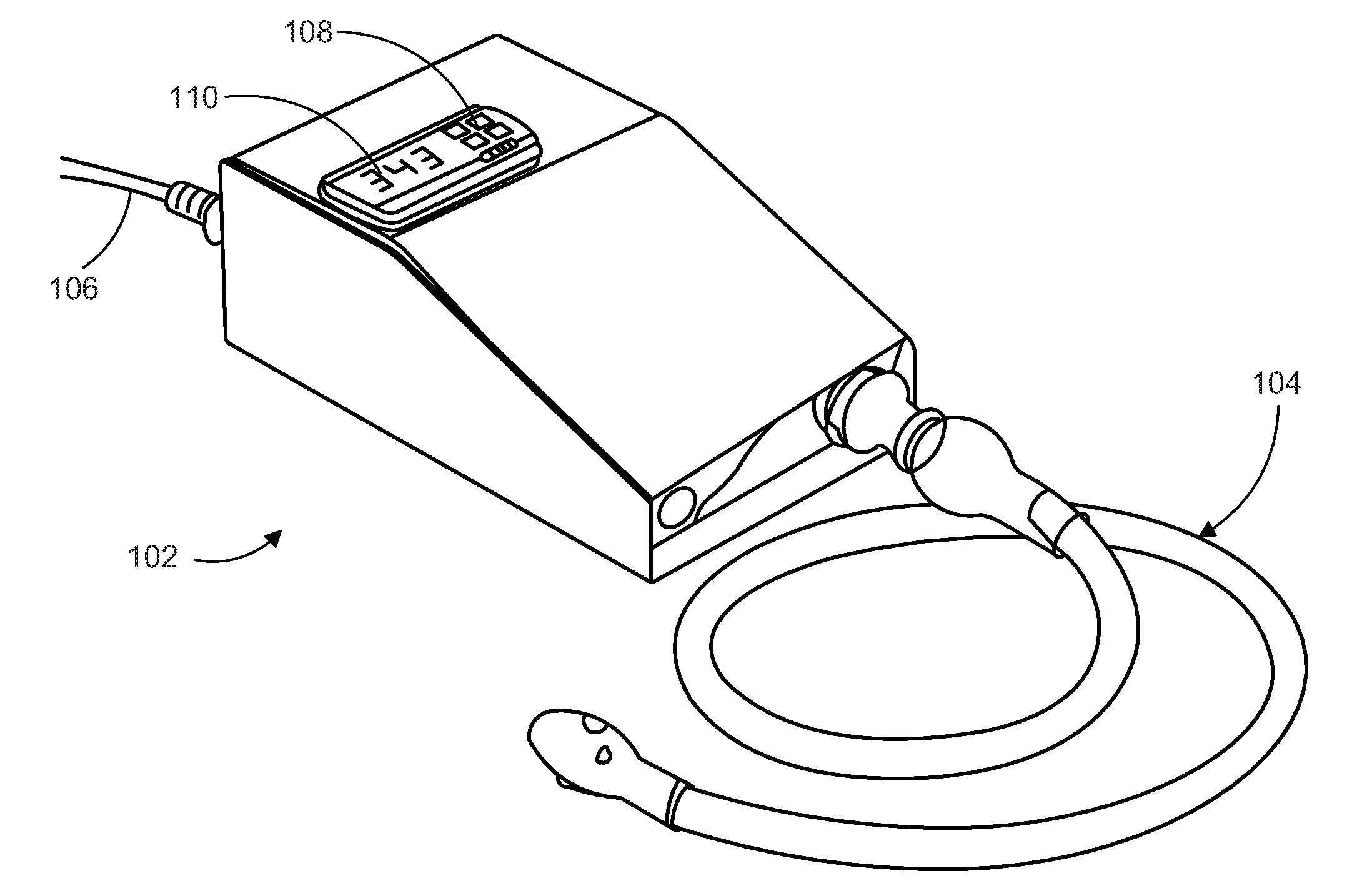

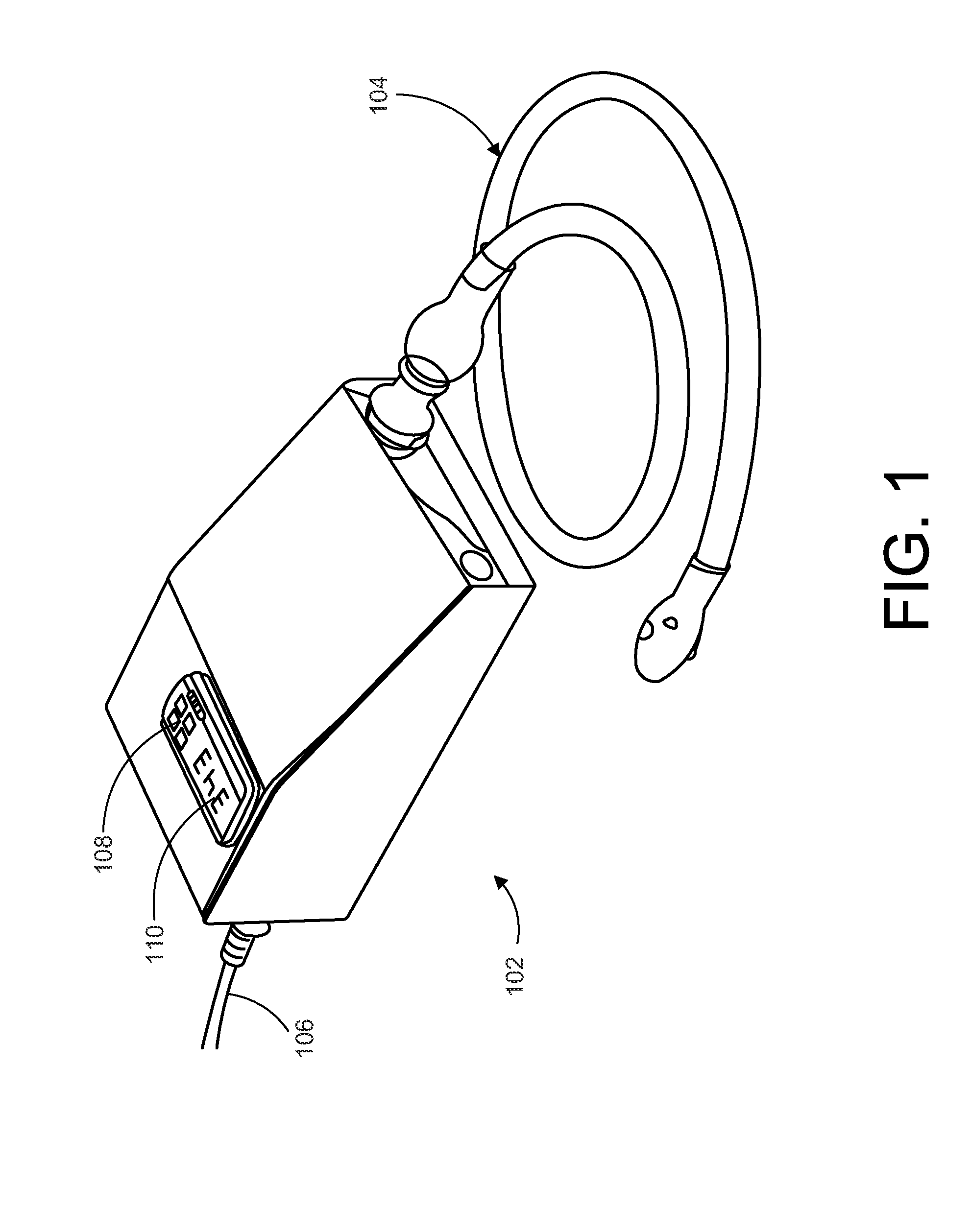

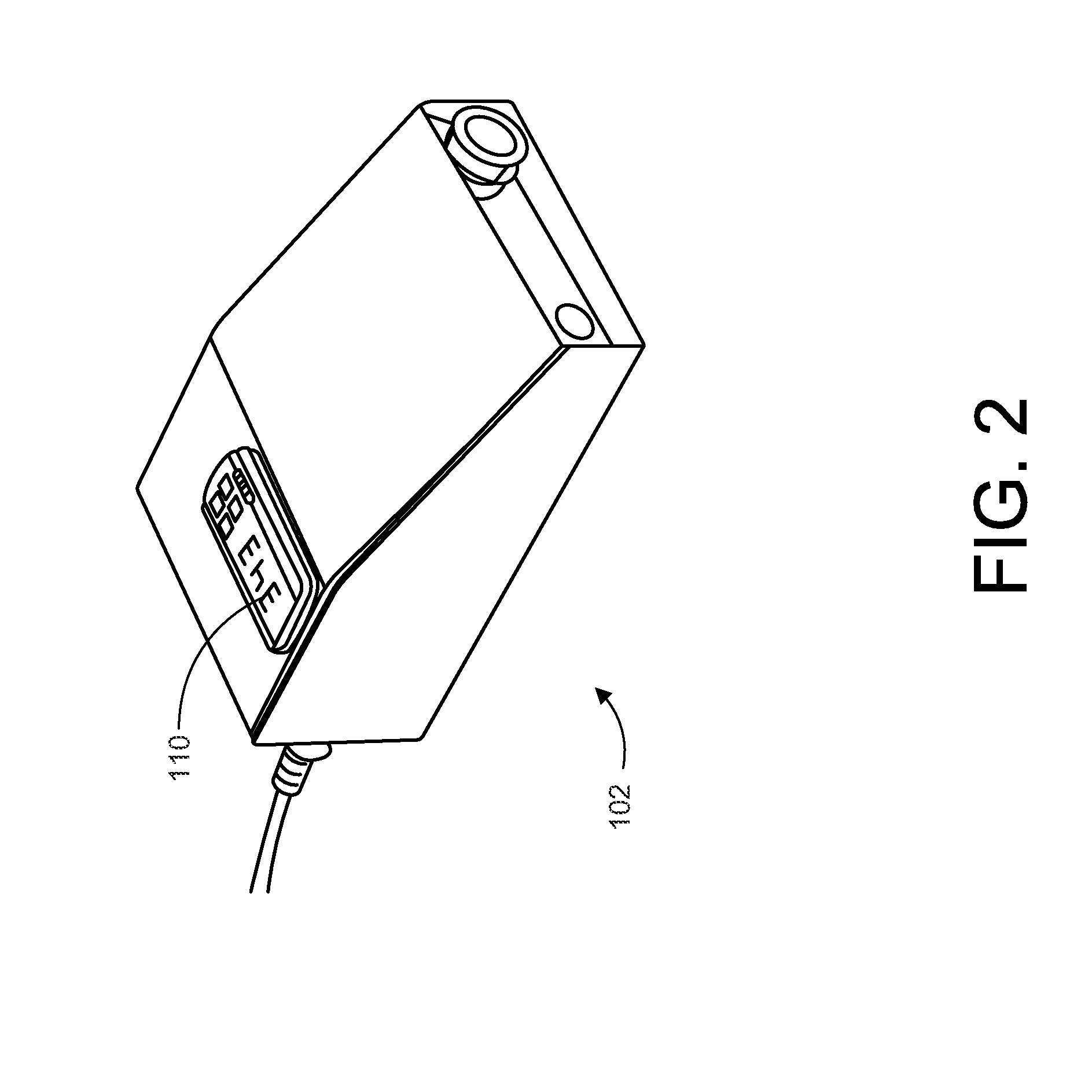

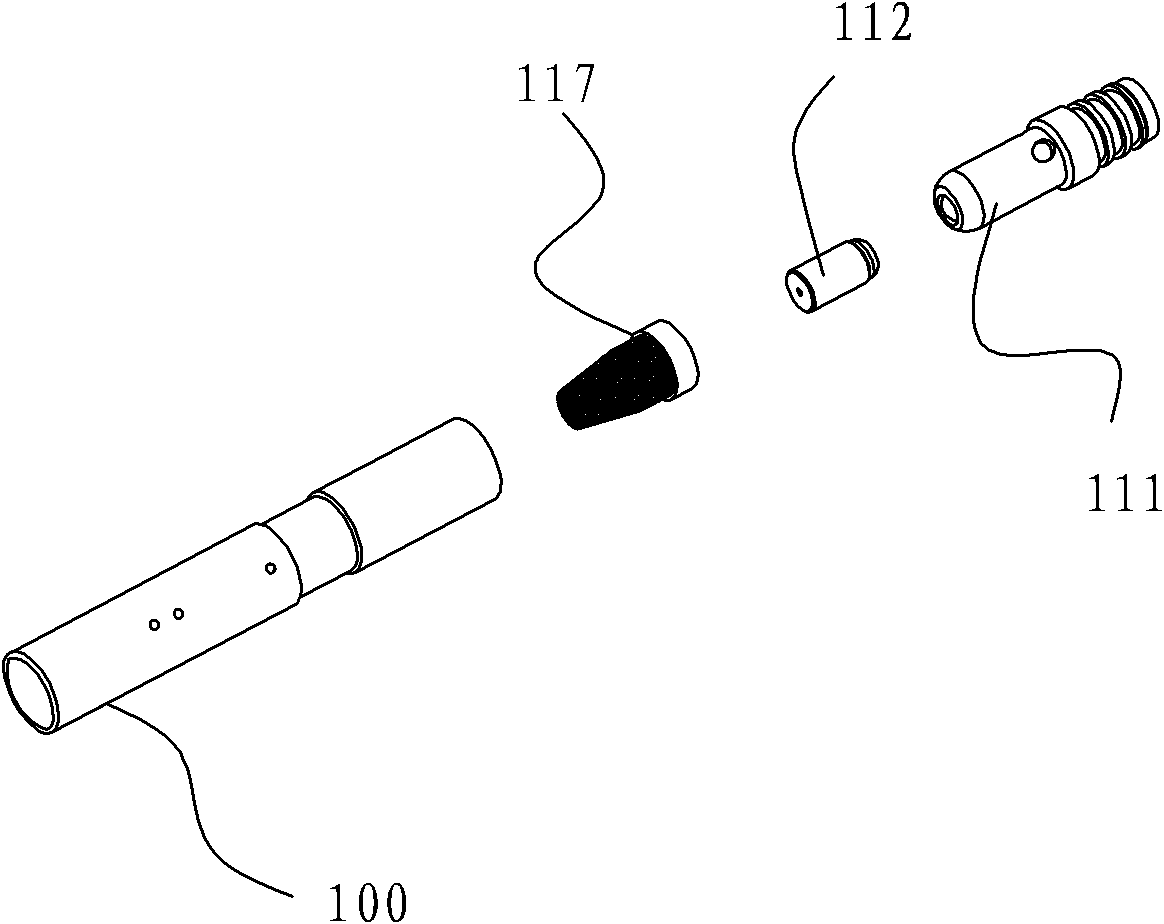

Vaporizer heating assembly and method of regulating a temperature within the vaporizer heating assembly

InactiveUS8739788B2Maximize heat transfer efficiencyRespiratorsOther heat production devicesTemperature controlProximate

A method of regulating a temperature within a vaporizer heating assembly includes providing a vaporizer heating assembly that includes a vapor inhalation device shaped to contain a vapor and deliver the vapor to a user's mouth without expelling the vapor into the atmosphere, an airflow chamber mechanically coupled to the vapor inhalation device, a heating chamber disposed within the airflow chamber, a fan in fluid communication with an air passageway defined by an interior surface of the airflow chamber and an exterior surface of the heating chamber, a temperature probe disposed proximate, but not in direct physical contact with the airflow chamber, and a temperature controller thermally coupled to the temperature probe and communicatively coupled to the heating chamber, the temperature controller operable to control a temperature output of the heating chamber in response to temperature information received from the temperature probe. The method further includes the steps of sensing a temperature of an area surrounding a portion of the airflow chamber with the temperature probe, communicating the sensed temperature of the area surrounding a portion of the airflow chamber to the temperature controller, operating the fan to direct air into a proximal end of the airflow chamber, sensing with the temperature probe a change in the temperature of the area surrounding the portion of the airflow chamber, and communicating the sensed temperature change to the temperature controller.

Owner:VAPORFECTION INT

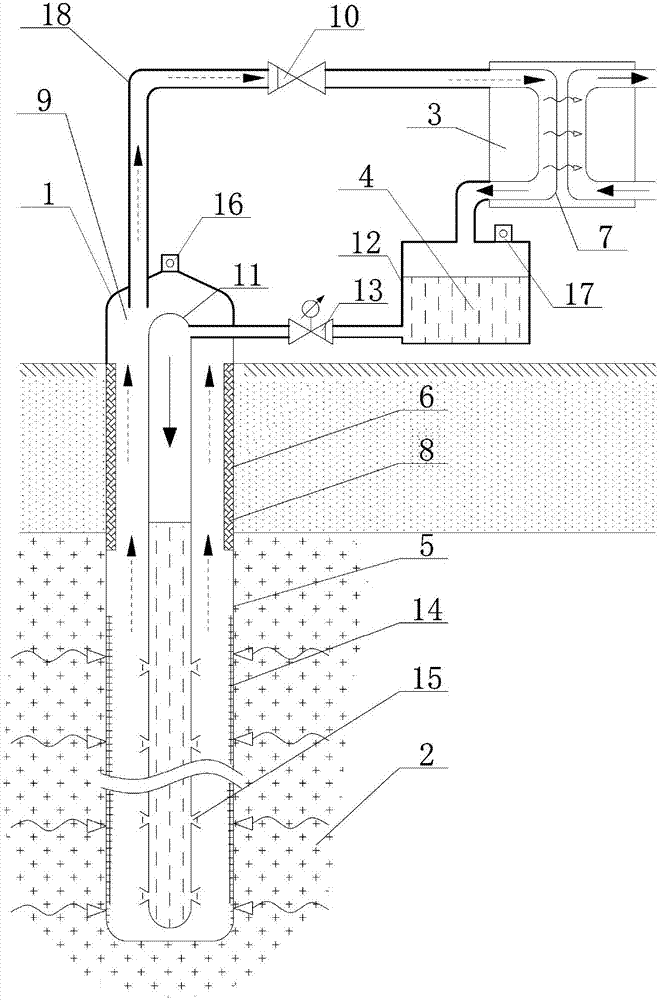

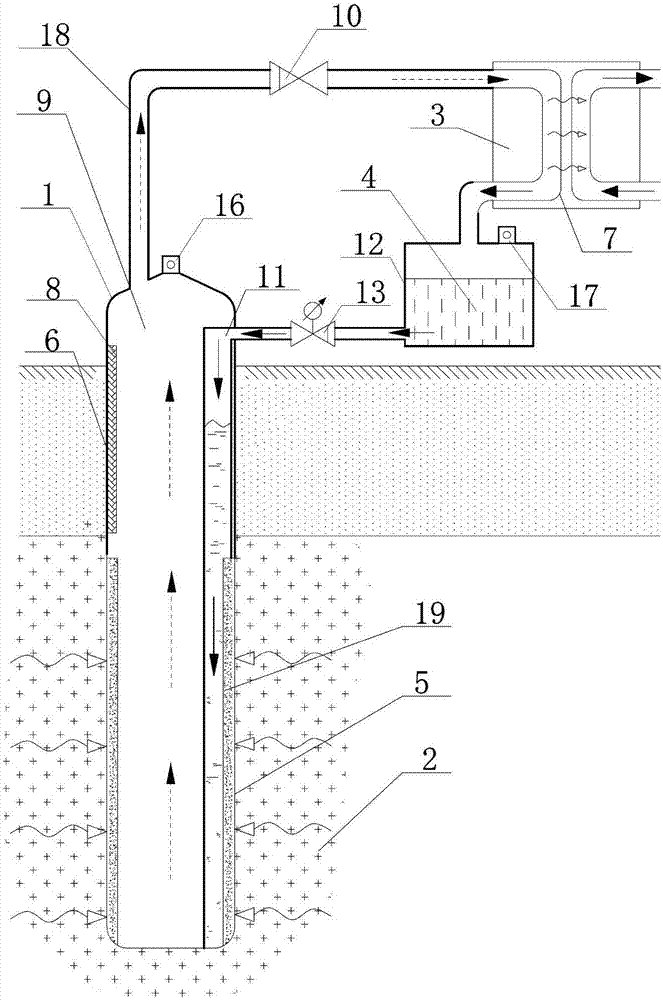

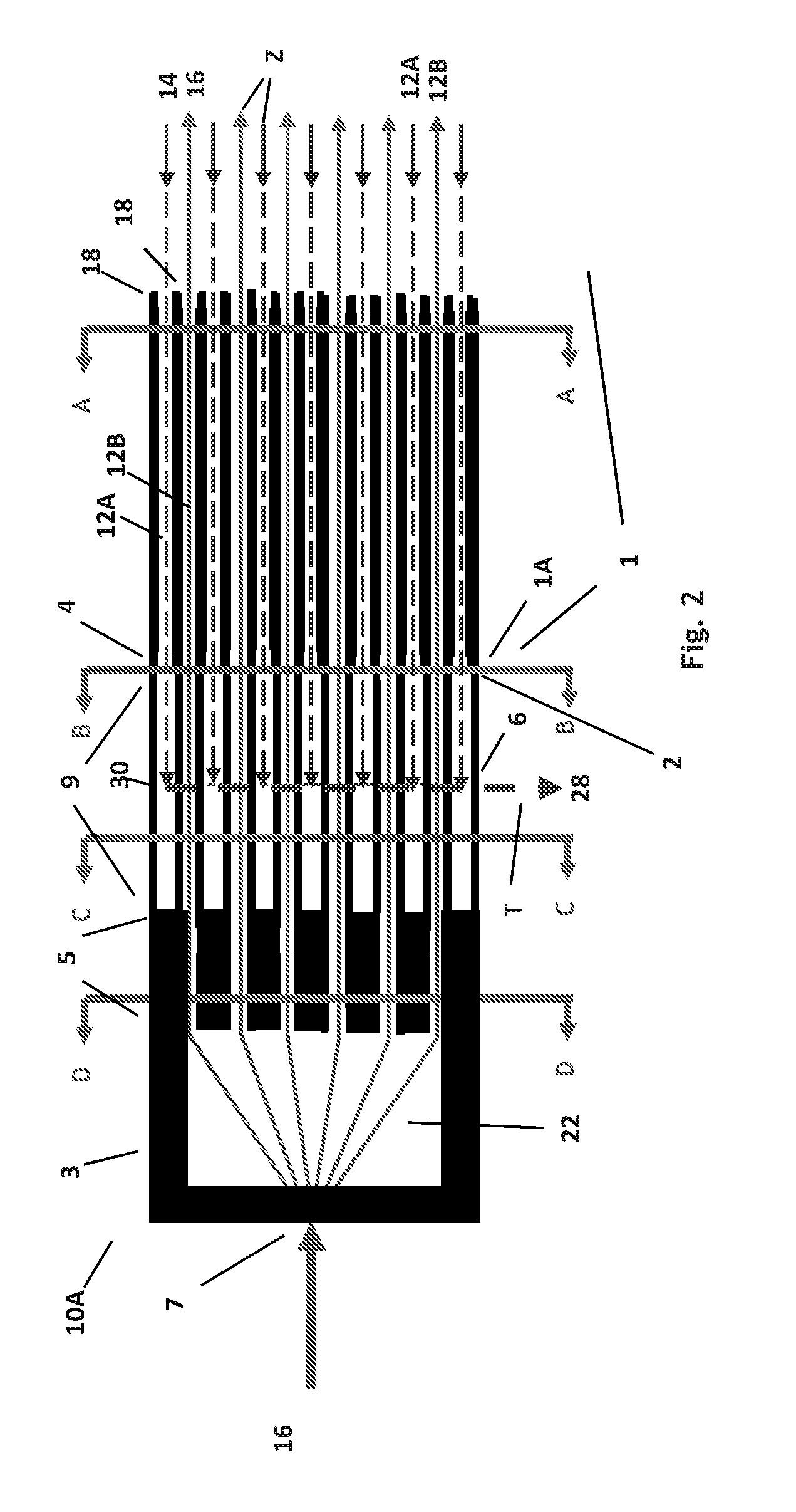

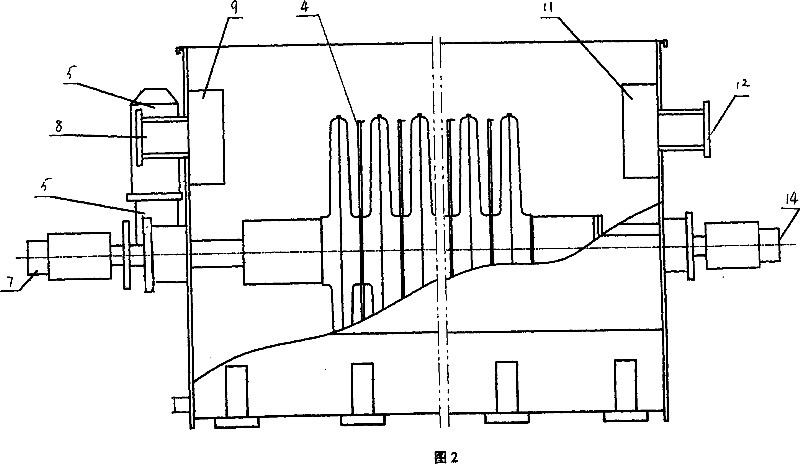

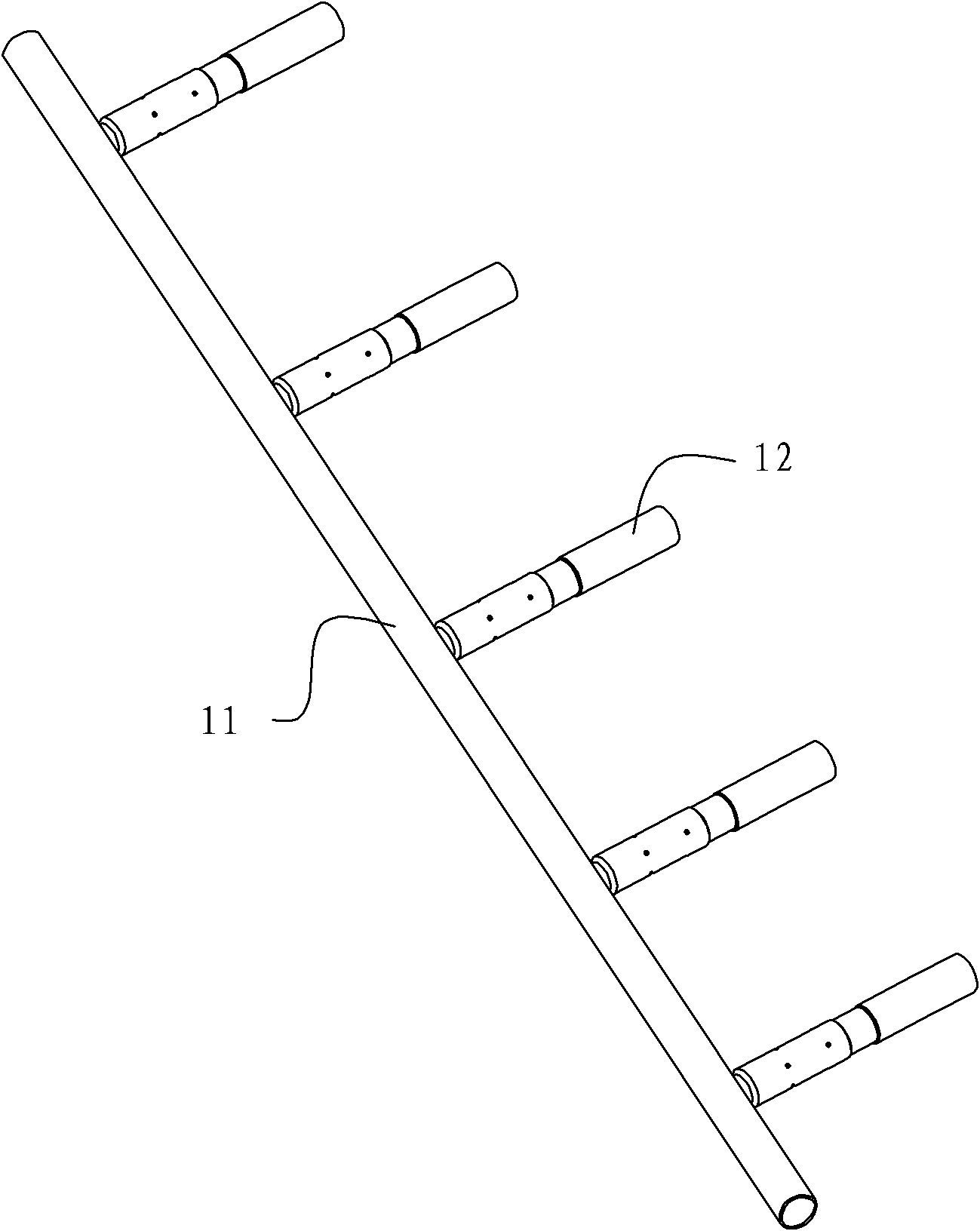

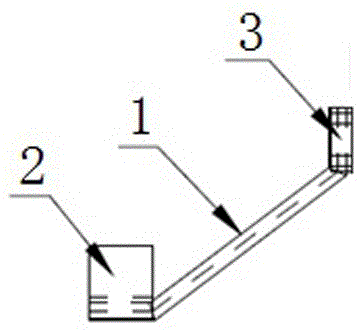

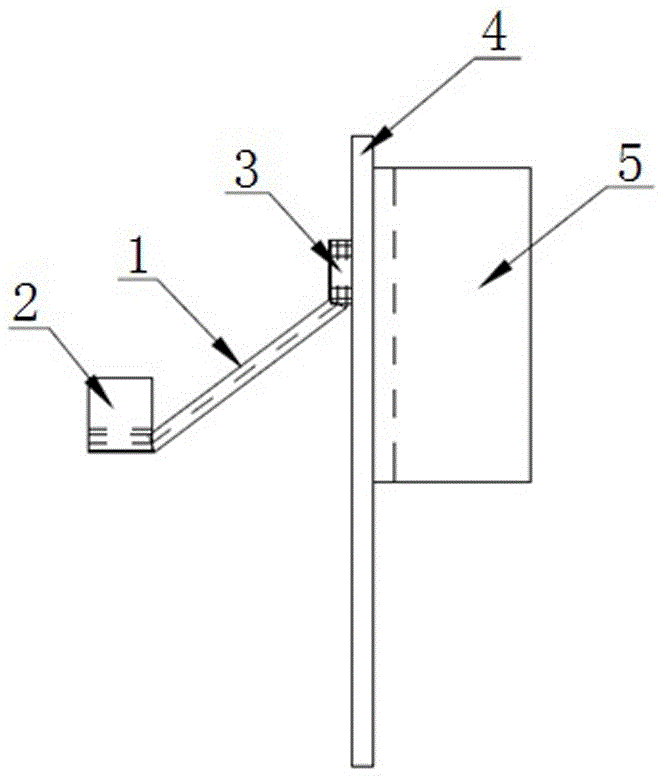

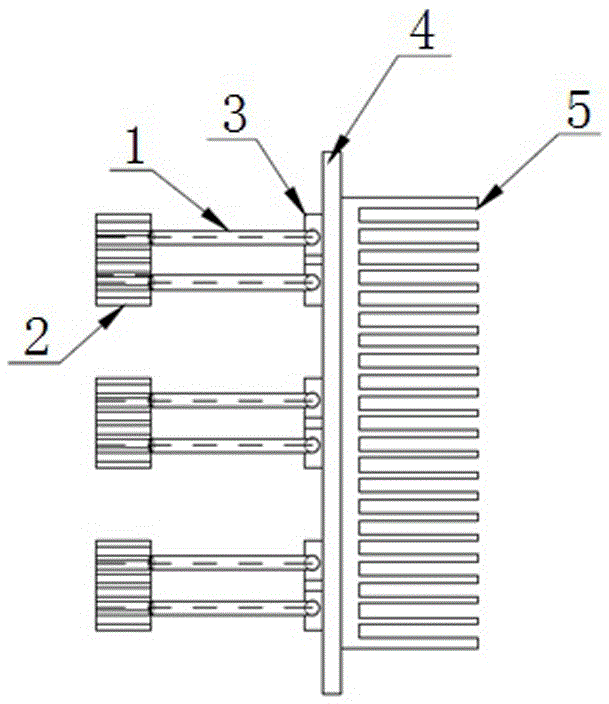

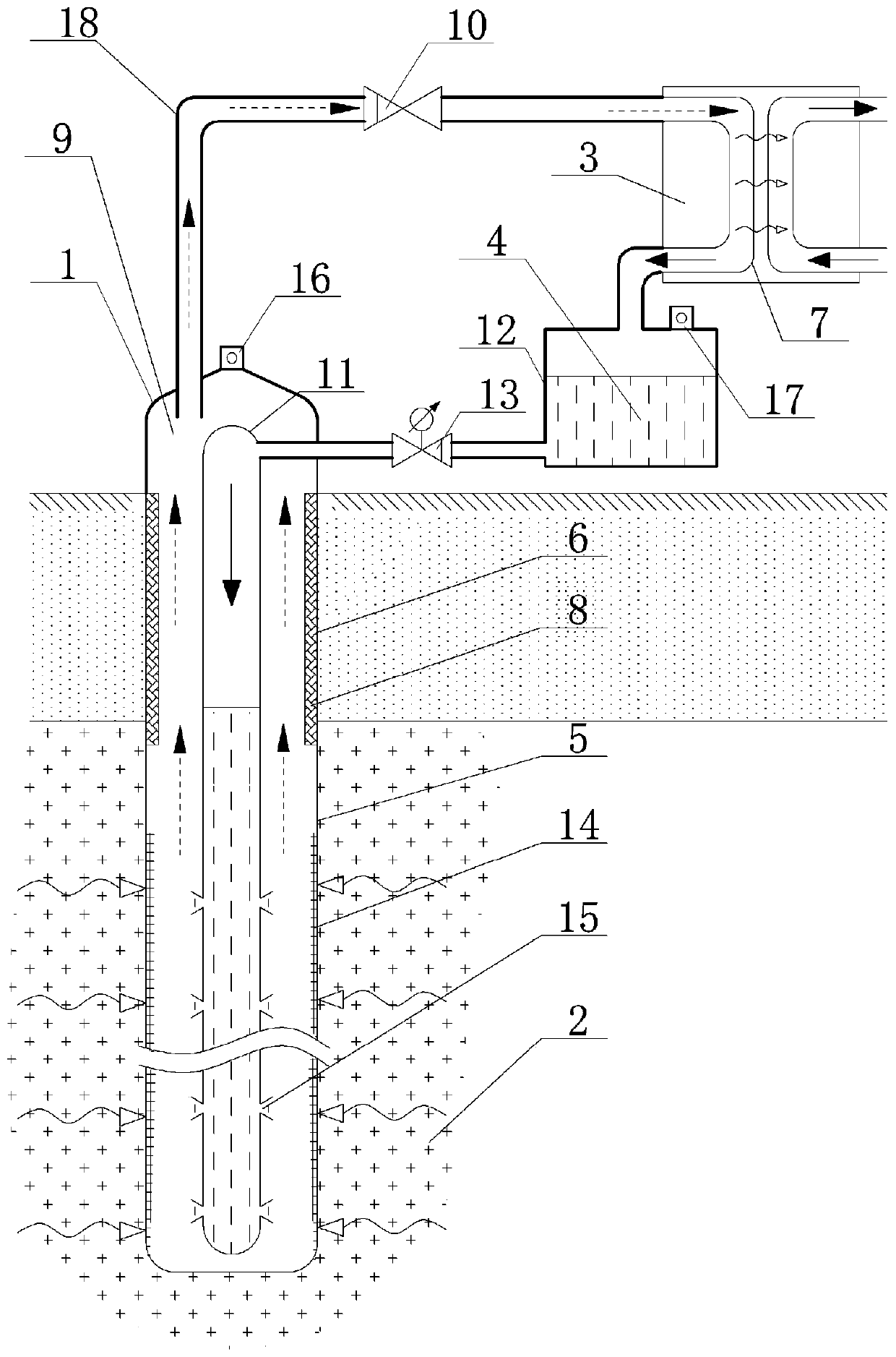

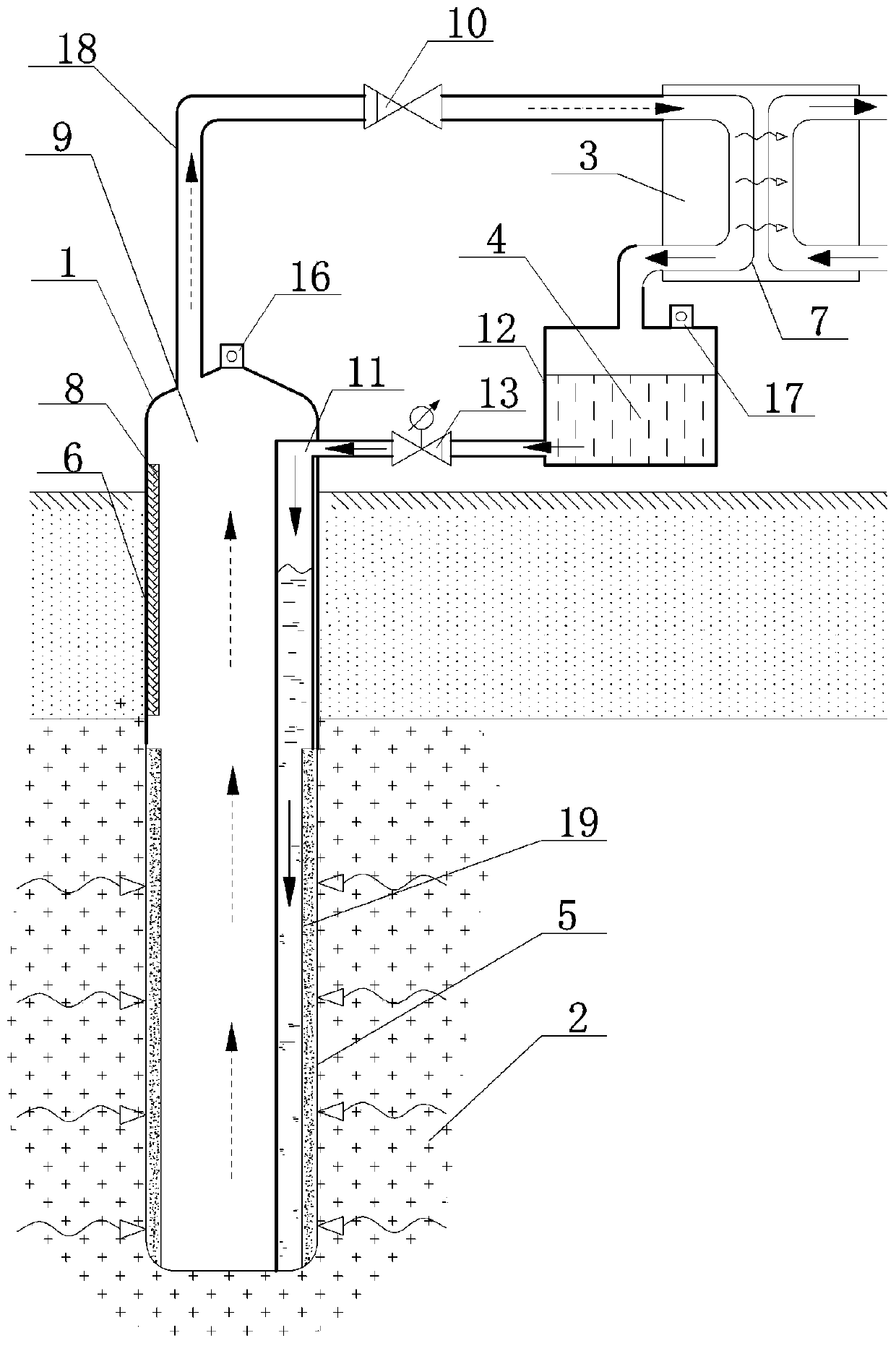

Loop heat pipe type terrestrial heat exploitation system with adjustable and controllable working medium circular flow

ActiveCN107144035AAchieve miningAvoid lostOther heat production devicesGeothermal energy generationEvaporationEngineering

The invention discloses a loop heat pipe type terrestrial heat exploitation system with adjustable and controllable working medium circular flow. The loop heat pipe type terrestrial heat exploitation system comprises a casing pipe type loop heat pipe, an earth surface heat exchanger and a liquid storage box. The earth surface heat exchanger and the liquid storage box are both located on the ground. The casing pipe type loop heat pipe comprises an evaporation section, a heat insulation section and a backflow section. The evaporation section is located in a high temperature heat reservoir. The earth surface heat exchanger is provided with a condensation section, and the condensation section and the outside carry out heat exchange. A one-way valve or a steam pump is arranged between the heat insulation section and the condensation section. A one-way throttle valve is arranged between the liquid storage box and the backflow section. The evaporation section, the heat insulation section, the condensation section, the liquid storage box and the backflow section are communicated in sequence end to end. Working medium fluid of the liquid storage box enters the evaporation section through the backflow section, and the liquid working medium fluid entering the evaporation section generates film boiling after absorbing heat. According to the loop heat pipe type terrestrial heat exploitation system, the working medium fluid of the liquid storage box passes through the backflow section, the liquid phase backflow mode and the boiling mode of the evaporation section are controlled, the effective filling factor of the terrestrial heat pipe can be adjusted in real time, and therefore terrestrial heat energy is stably and efficiently extracted.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Insulated shipping container systems and methods thereof

InactiveUS20060230778A1Improve cooling efficiencyIncrease temperatureAir-treating devicesLighting and heating apparatusInsulated shipping containerTemperature sensitive

An insulated shipping container system for transferring a temperature sensitive product comprising a substantially hollow insulated body having inner walls and outer walls defining a payload cavity to receive a payload and supports to space the payload from the insulated body thereby defining an internal air filled space to facilitate heat transfer. The insulated shipping container system further comprises a heat transfer element cavity configured to receive a heat transfer element and supports to space the heat transfer element from the insulated body thereby defining an internal air filled space to facilitate heat transfer. Also provided are methods for shipping temperature sensitive products and goods comprised of packing and assembling the insulated shipping container system disclosed herein.

Owner:WILLIAMS ALTON

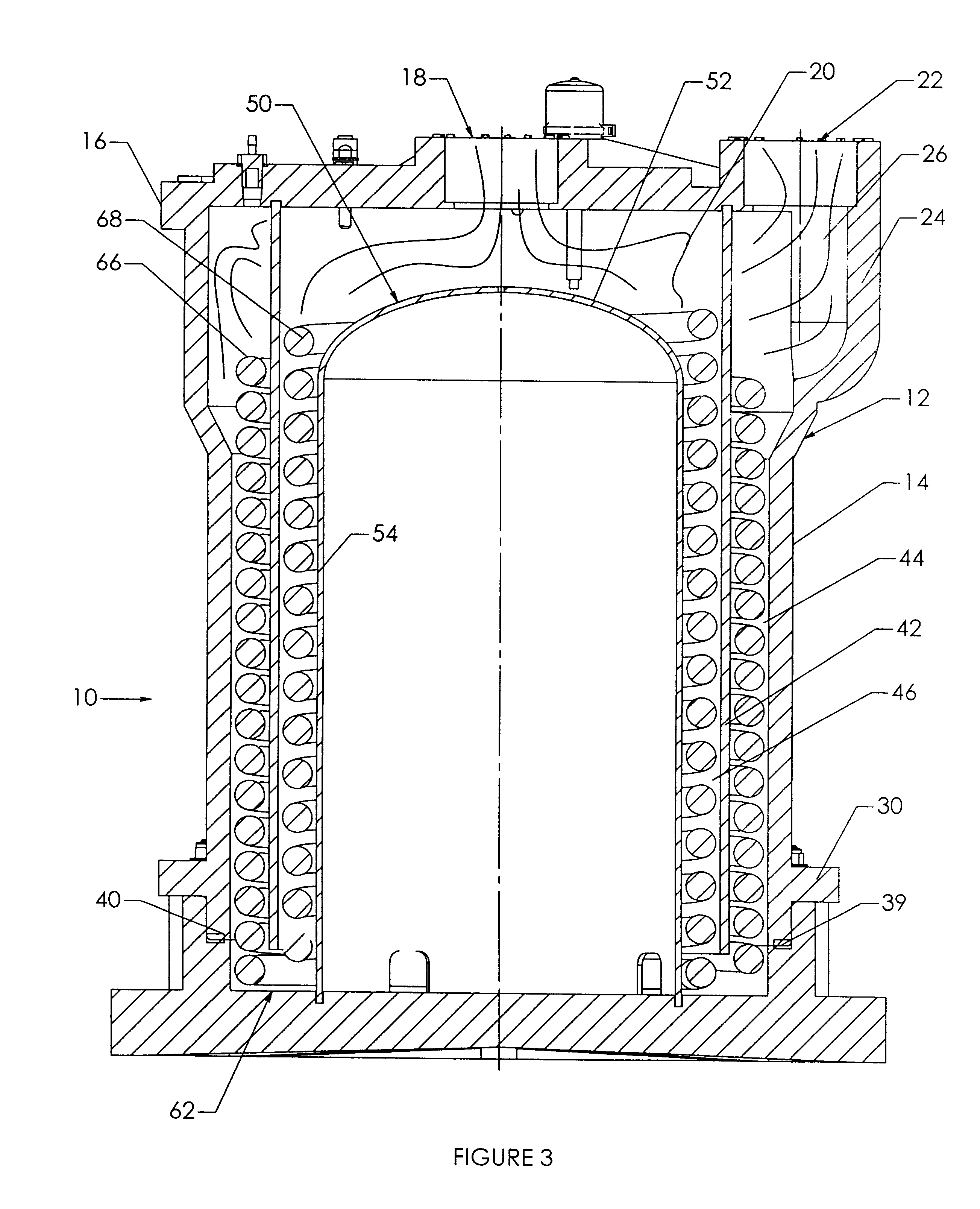

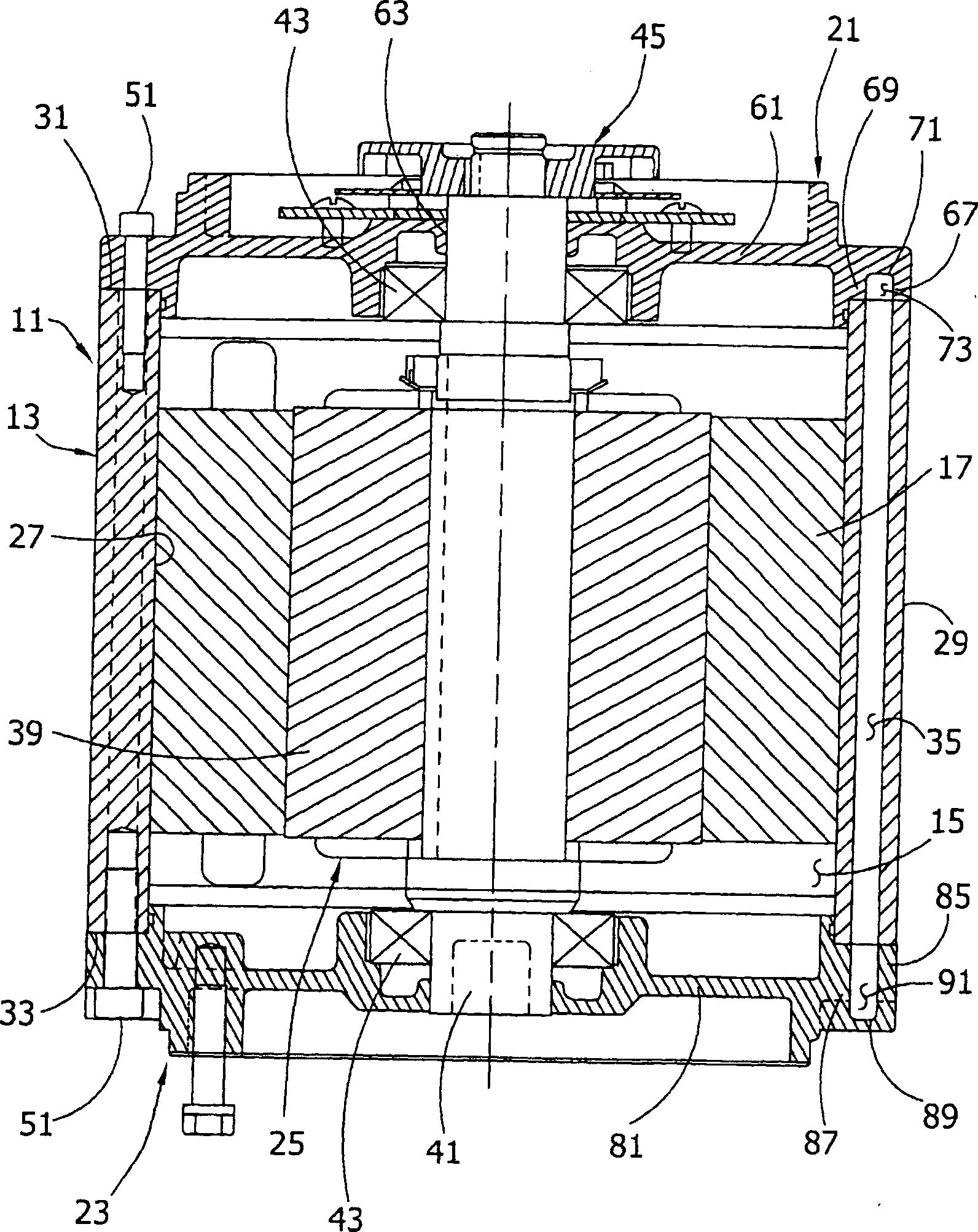

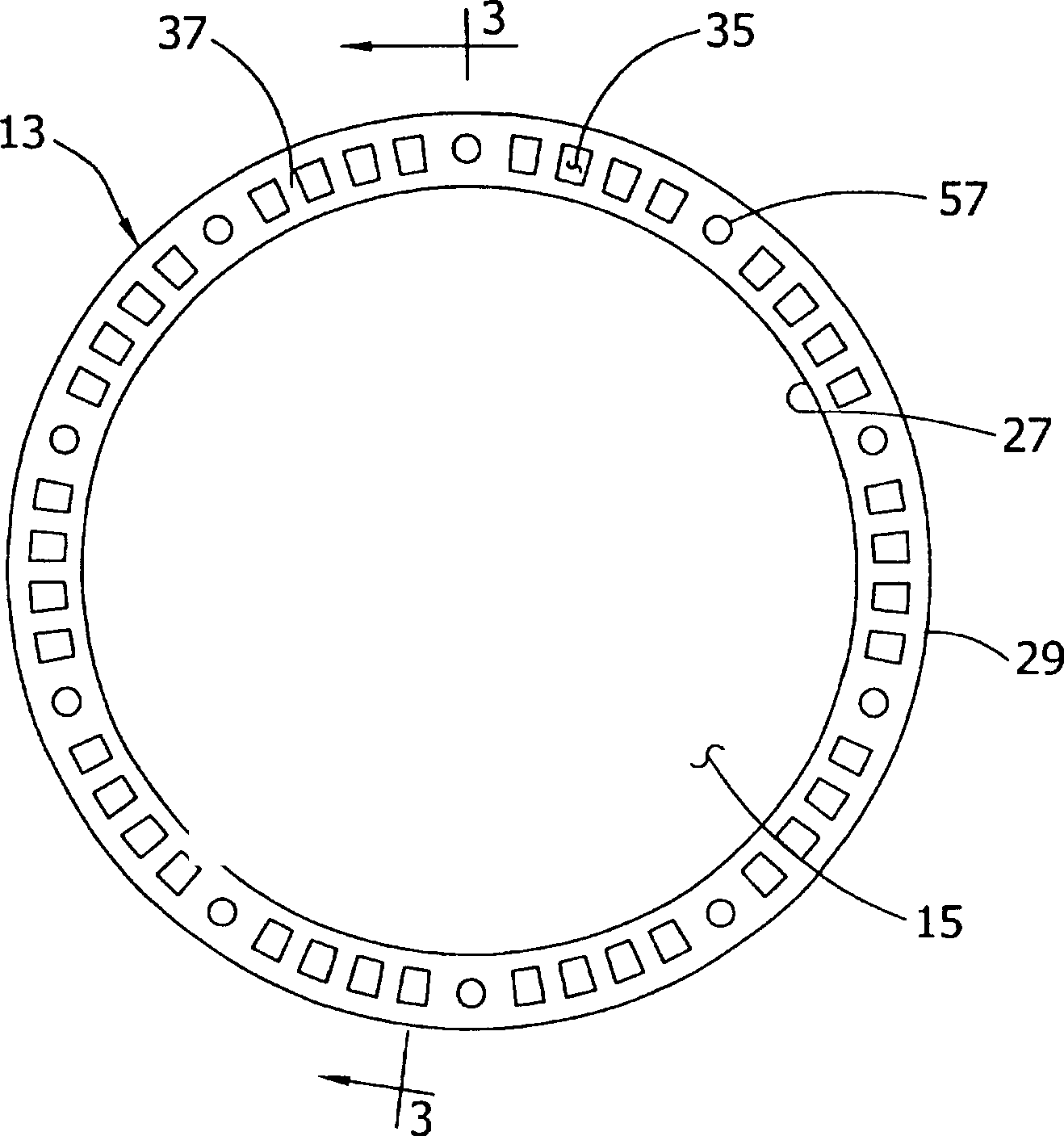

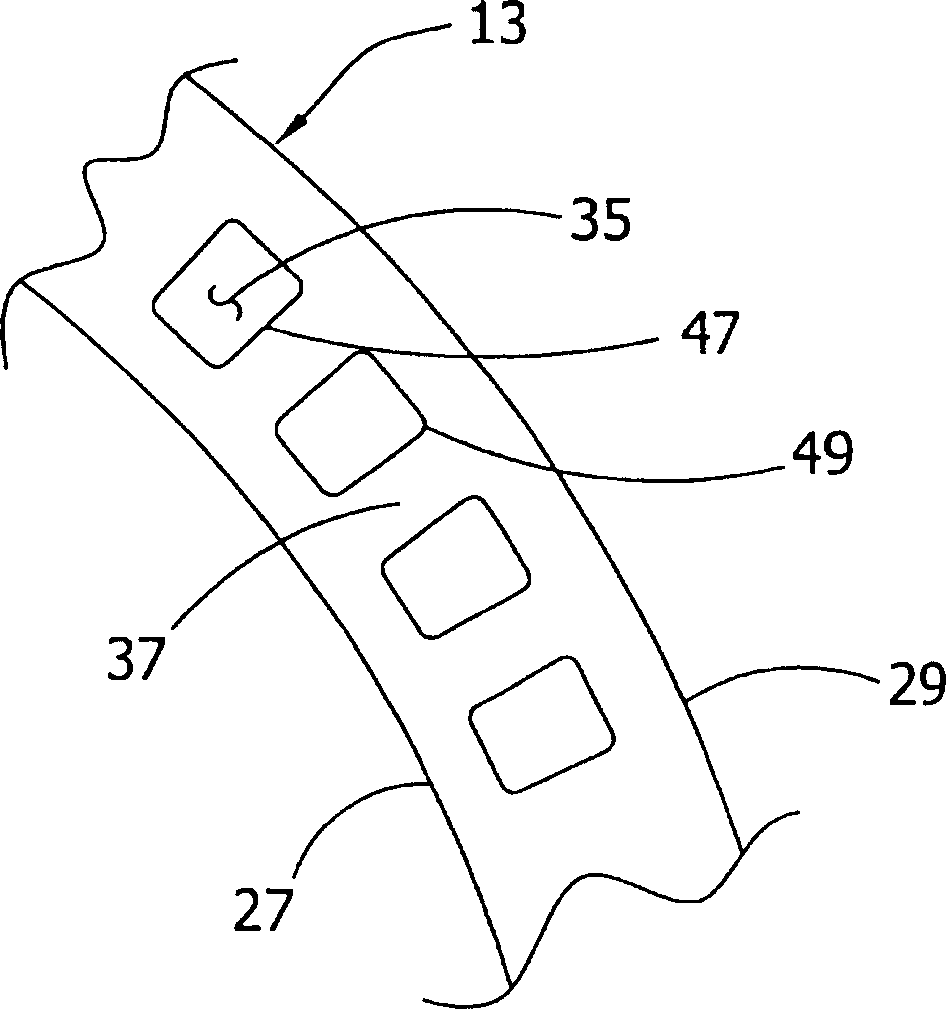

Cooling jacket for electric machines

InactiveCN1656662AQuantity minimizationMaximize heat transfer efficiencyCooling/ventillation arrangementSupports/enclosures/casingsCoolant flowElectric machinery

A cooling jacket for cooling the stator of an electric machine. The jacket includes a cooling jacket body having a cylindric inner surface defining a cavity for receiving the stator of a motor, axial flow passages in the body for the flow of a coolant, and end caps connected to opposite ends of the body. Coolant flows through an inlet in one of the end caps and is directed through the flow passages along at least one serpentine path to an outlet. Each flow passage has a cross sectional shape defined entirely by three or more substantially linear sides.

Owner:EMERSON ELECTRIC CO

Vaporizer heating assembly and method of regulating a temperature within the vaporizer heating assembly

A method of regulating a temperature within a vaporizer heating assembly includes providing a vaporizer heating assembly that includes a vapor inhalation device shaped to contain a vapor and deliver the vapor to a user's mouth without expelling the vapor into the atmosphere, an airflow chamber mechanically coupled to the vapor inhalation device, a heating chamber disposed within the airflow chamber, a fan in fluid communication with an air passageway defined by an interior surface of the airflow chamber and an exterior surface of the heating chamber, a temperature probe disposed proximate, but not in direct physical contact with the airflow chamber, and a temperature controller thermally coupled to the temperature probe and communicatively coupled to the heating chamber, the temperature controller operable to control a temperature output of the heating chamber in response to temperature information received from the temperature probe. The method further includes the steps of sensing a temperature of an area surrounding a portion of the airflow chamber with the temperature probe, communicating the sensed temperature of the area surrounding a portion of the airflow chamber to the temperature controller, operating the fan to direct air into a proximal end of the airflow chamber, sensing with the temperature probe a change in the temperature of the area surrounding the portion of the airflow chamber, and communicating the sensed temperature change to the temperature controller.

Owner:VAPORFECTION INT

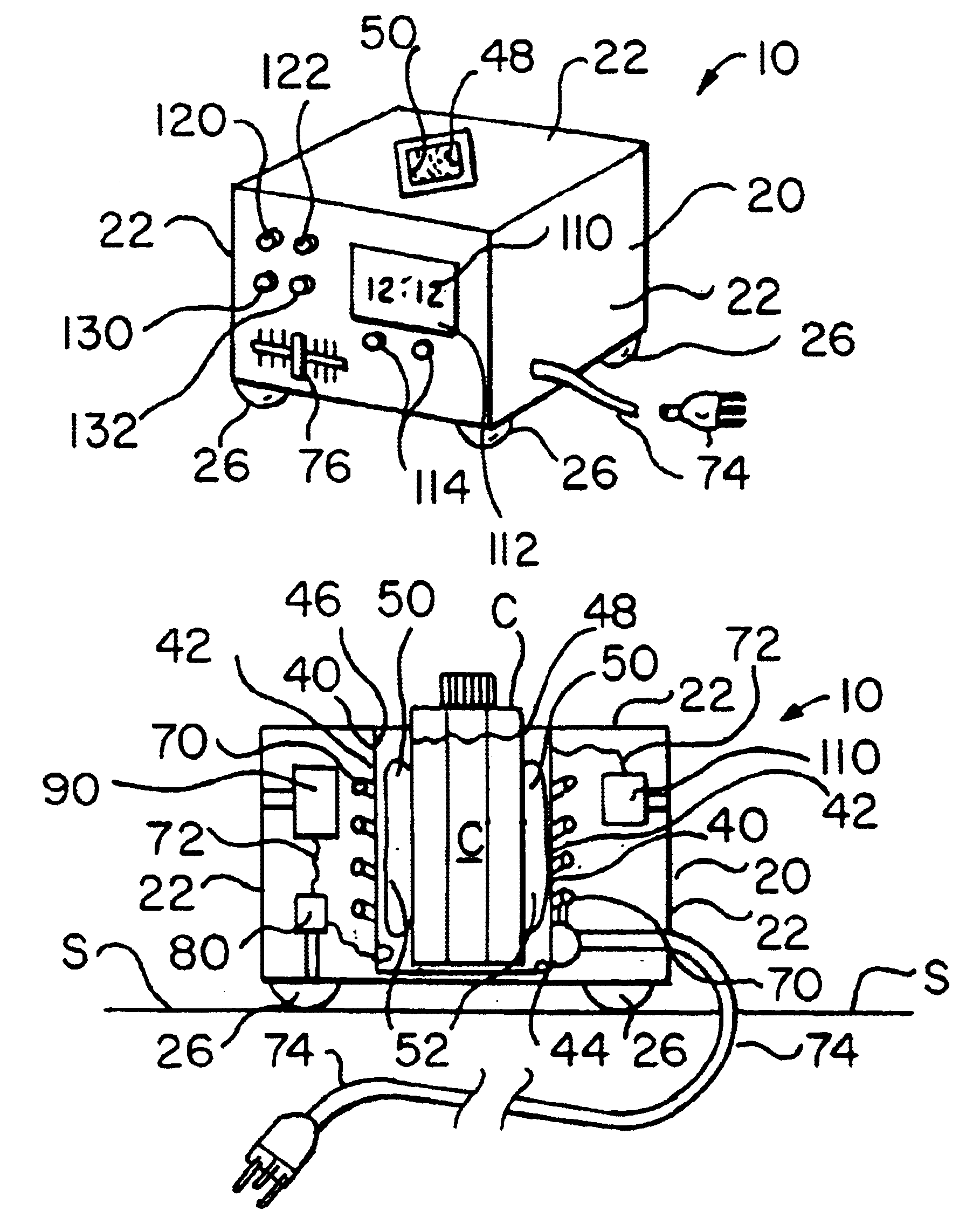

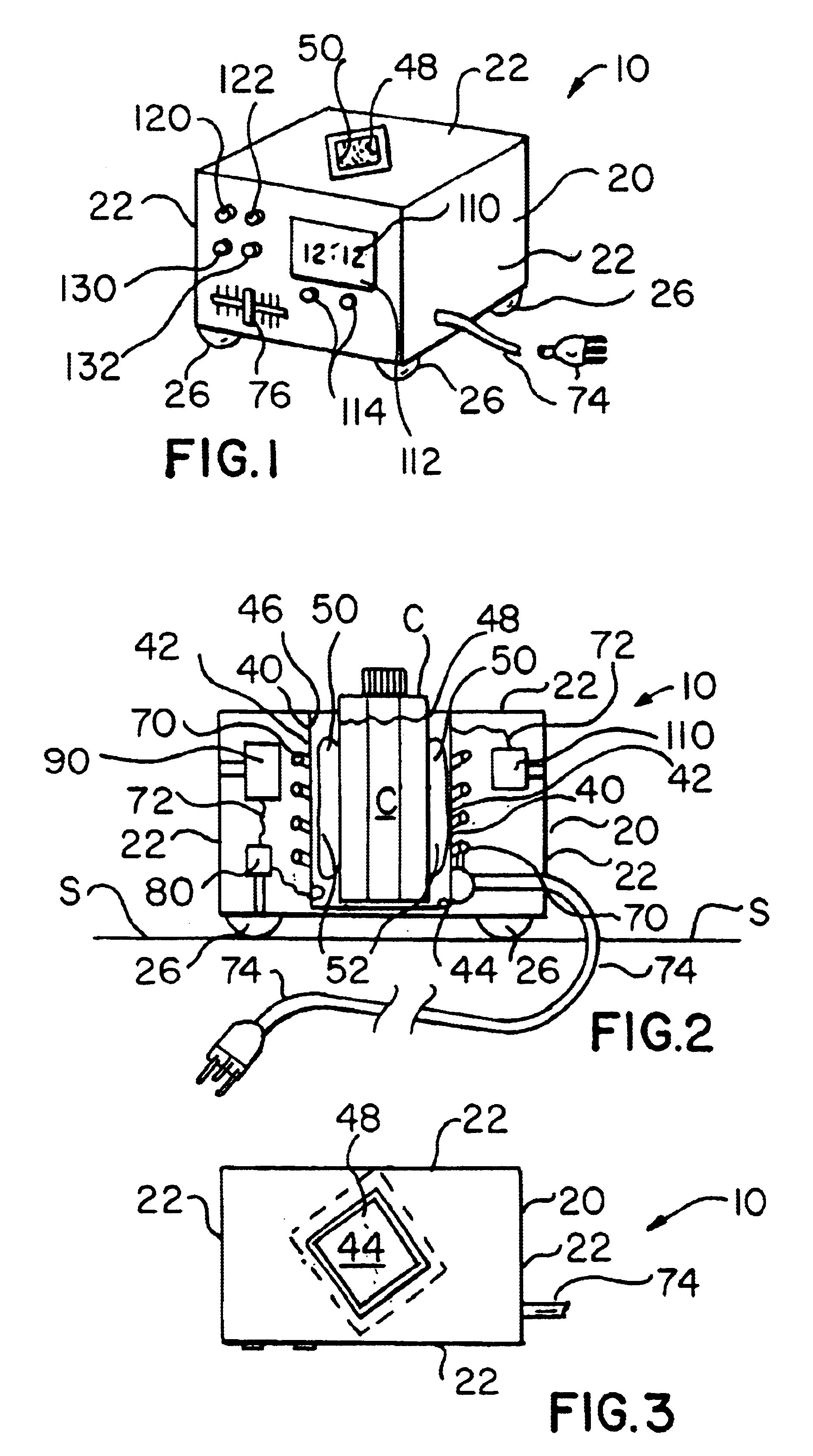

Artificial tears container warming apparatus

InactiveUS6870137B1Maximize heat transfer efficiencyMinimize escapeHolders and dispensersOther accessoriesEngineeringElectric power

A warming apparatus for receiving and heating a product container includes a heating chamber having a chamber side wall and a chamber bottom wall defining a chamber having a chamber interior surface and a chamber port through which a product container is inserted into and removed from the chamber; a heating element adjacent to one of the chamber side wall and the chamber bottom wall, for heating a product container within the chamber; an apparatus circuit electrically connected to the heating element for supplying electric power to the heating element; a flexible chamber liner within the chamber for receiving a product container and deforming to the shape and size of the product container; and a flowable heat transfer substance retained by the chamber liner adjacent to the chamber interior surface for flowing as the chamber liner deforms to the shape and size of a product container.

Owner:CLAPP MICHAEL G

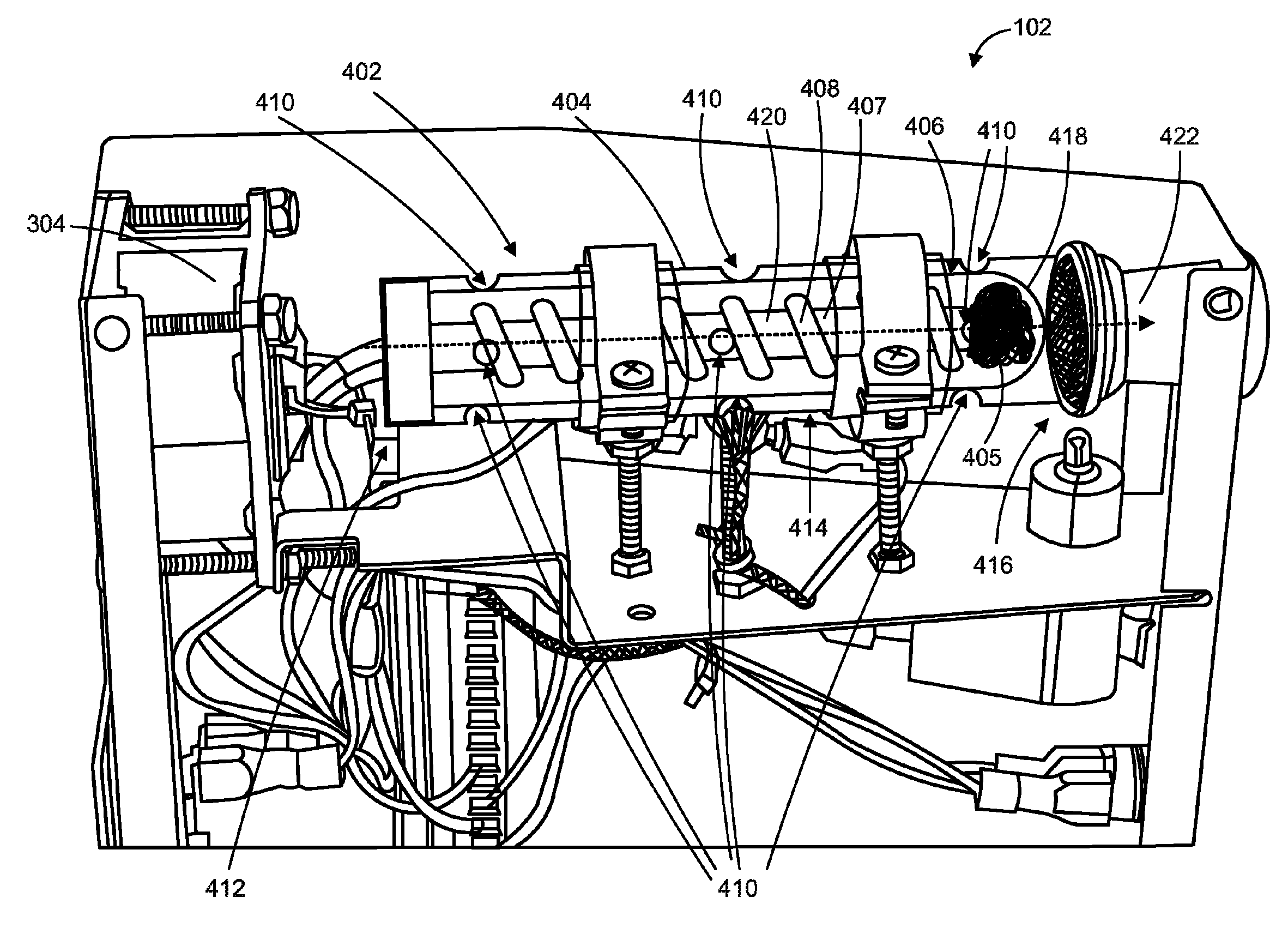

Vaporizer heating assembly

InactiveUS20120152246A1Maximize heat transfer efficiencyRespiratorsMedical devicesBiomedical engineeringAirflow

A vaporizer heating assembly includes an airflow chamber having a proximal end, a distal end opposite the proximal end, and a glass body connecting the proximal end to the distal end. A heating chamber is located within the airflow chamber and includes an elongated glass body and a heating element located within the elongated glass body of the heating chamber. A fan is in fluid communication with the proximal end of the airflow chamber and an attachment adapter is mechanically coupled to the distal end of the airflow chamber in a sealing arrangement, where the attachment adapter forms an attachment port for a vapor receiving element.

Owner:VAPORFECTION INT

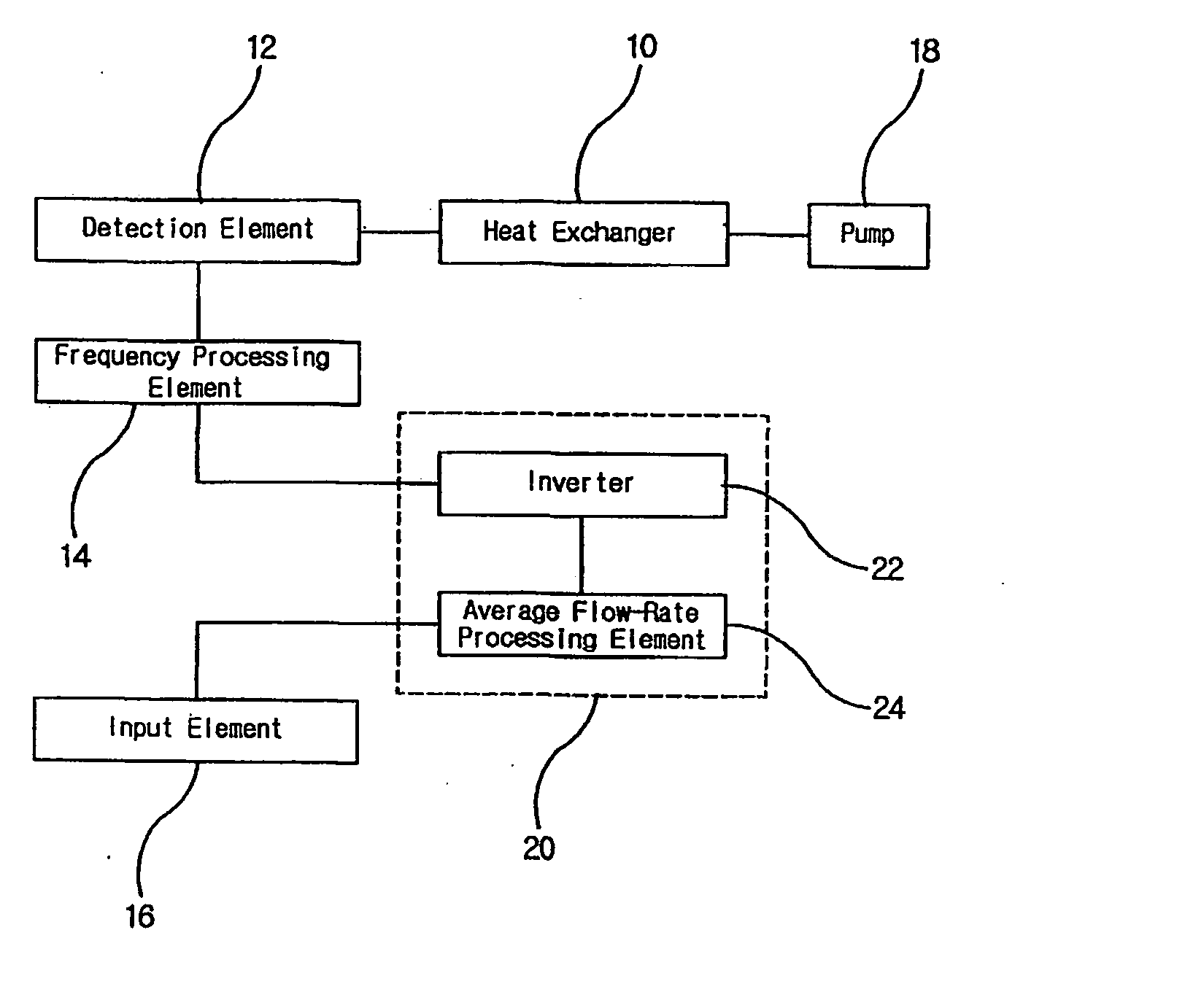

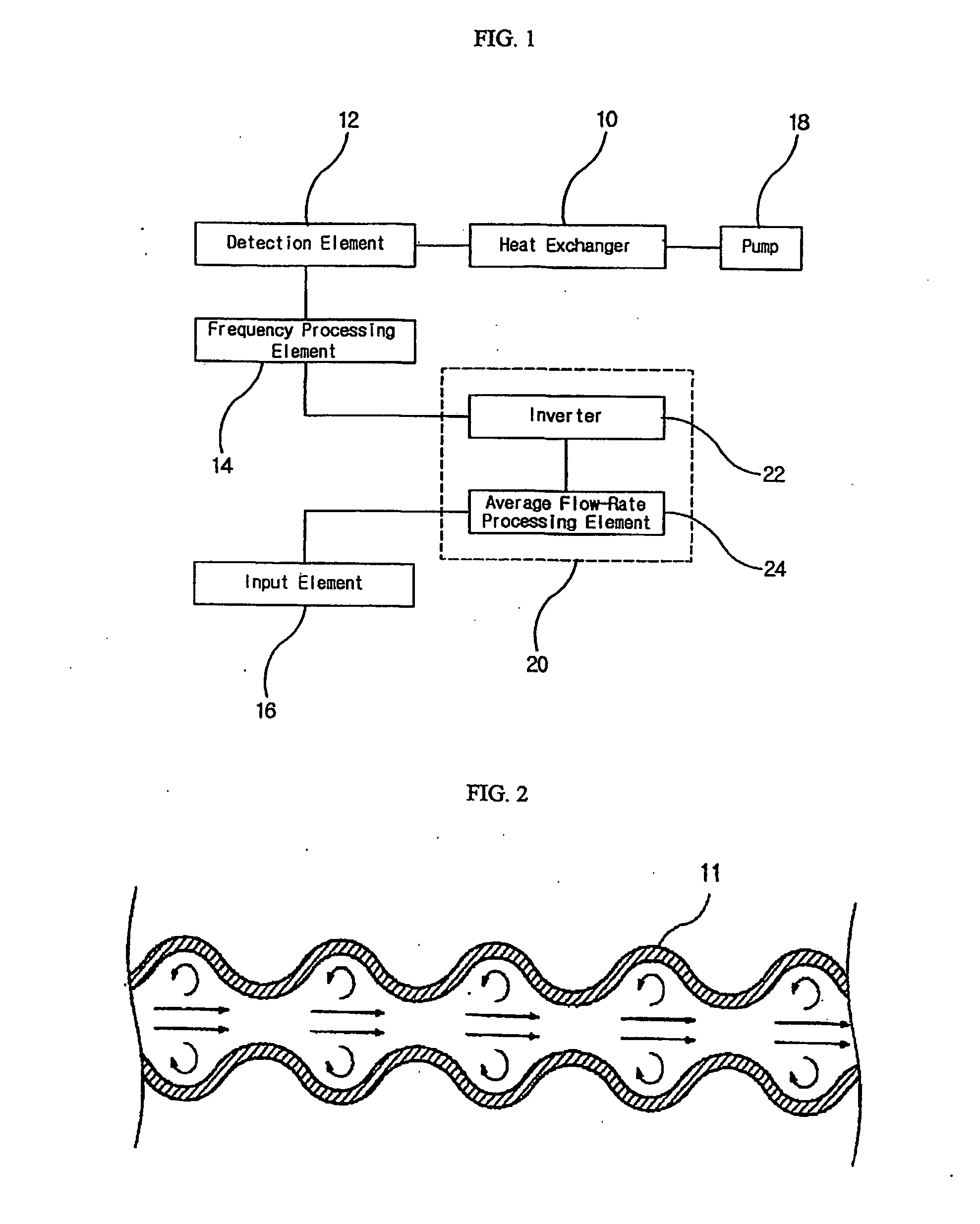

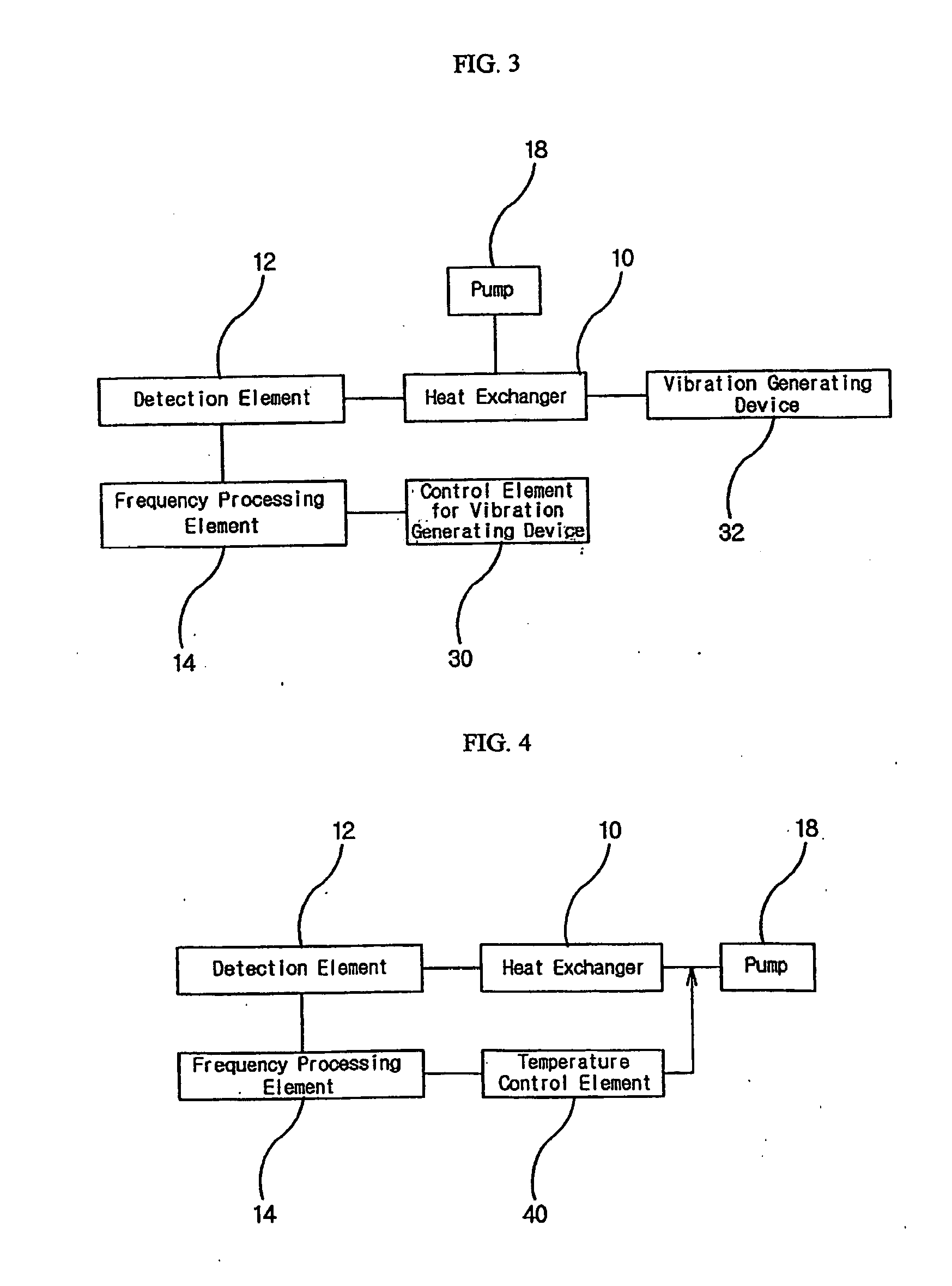

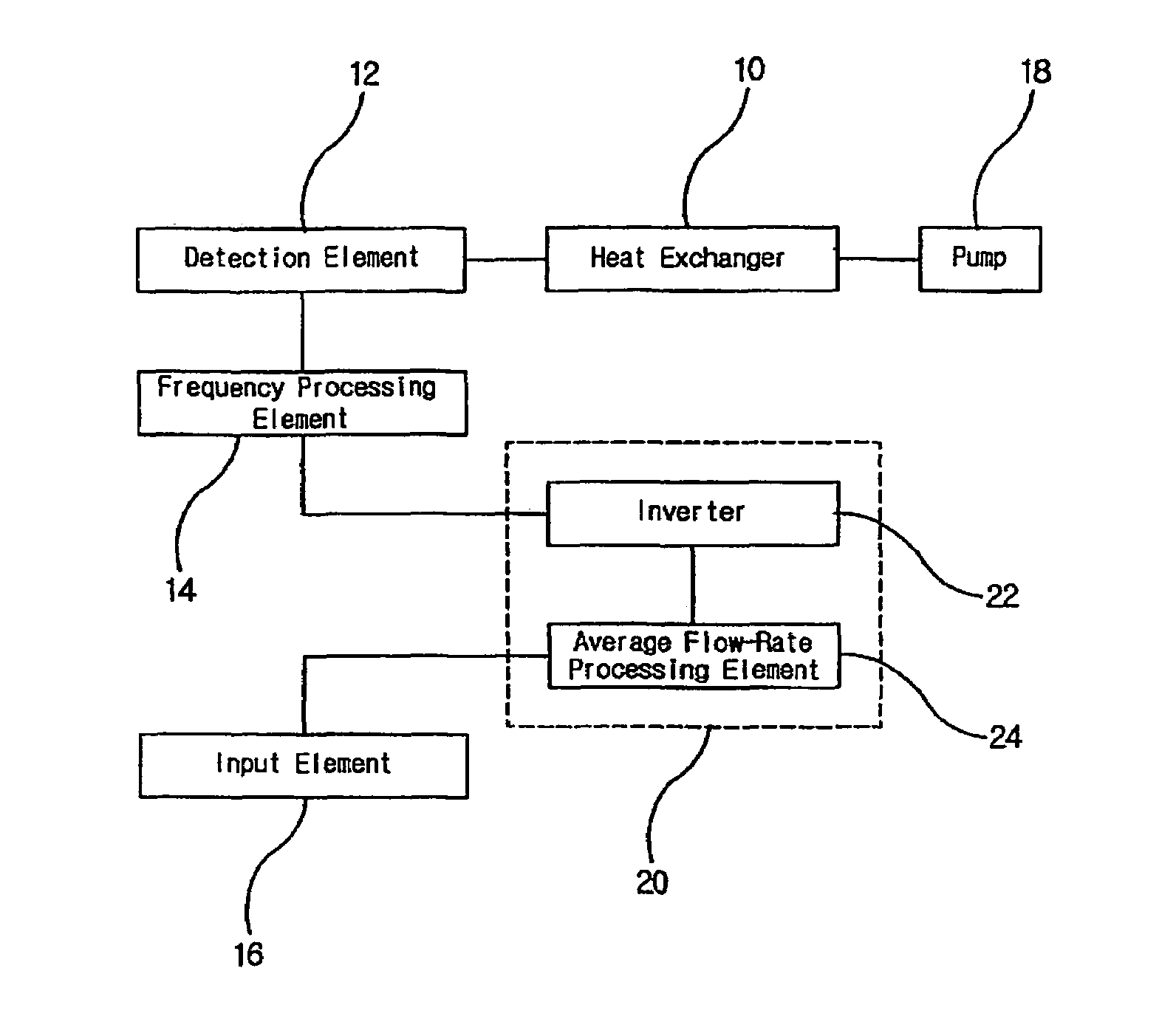

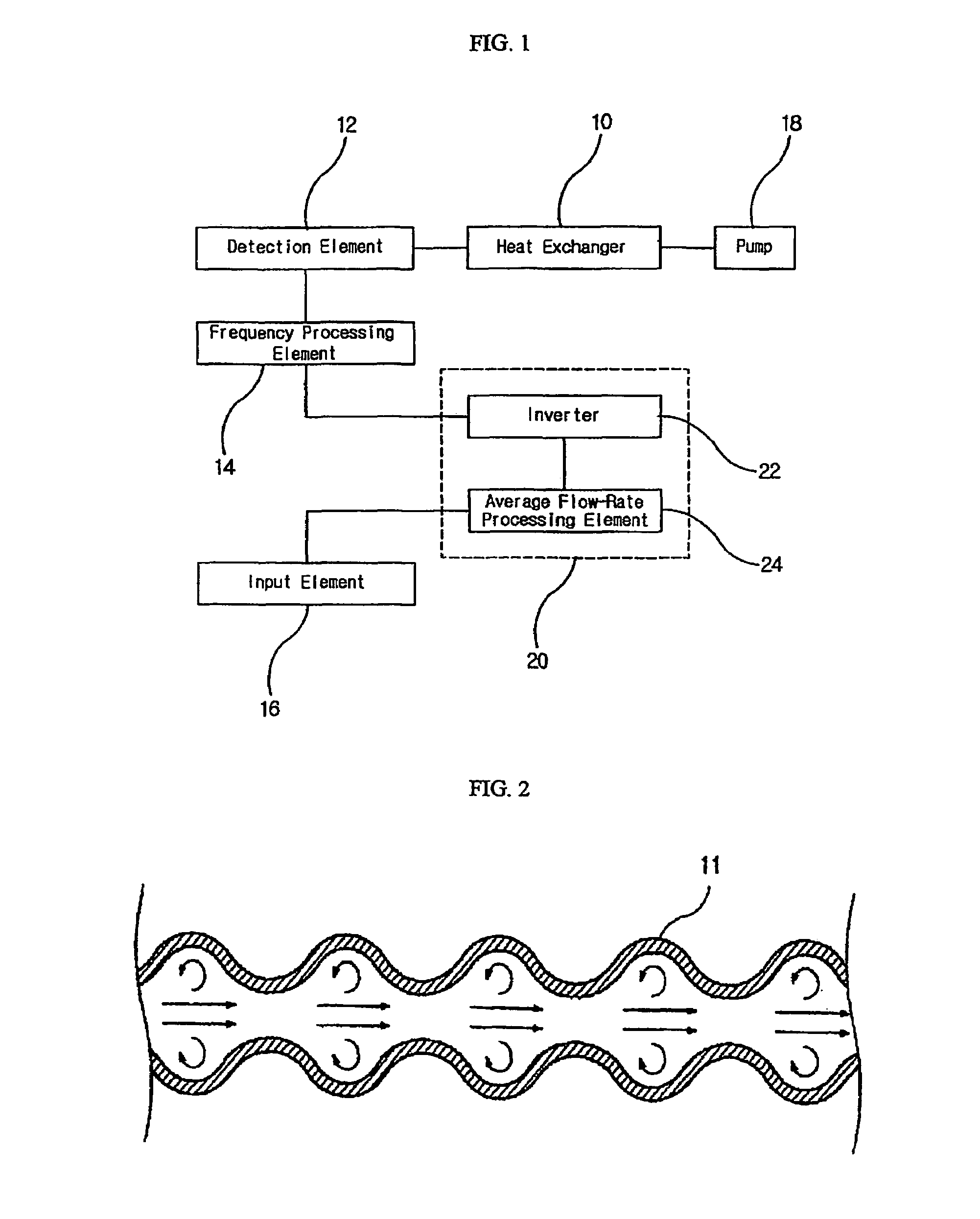

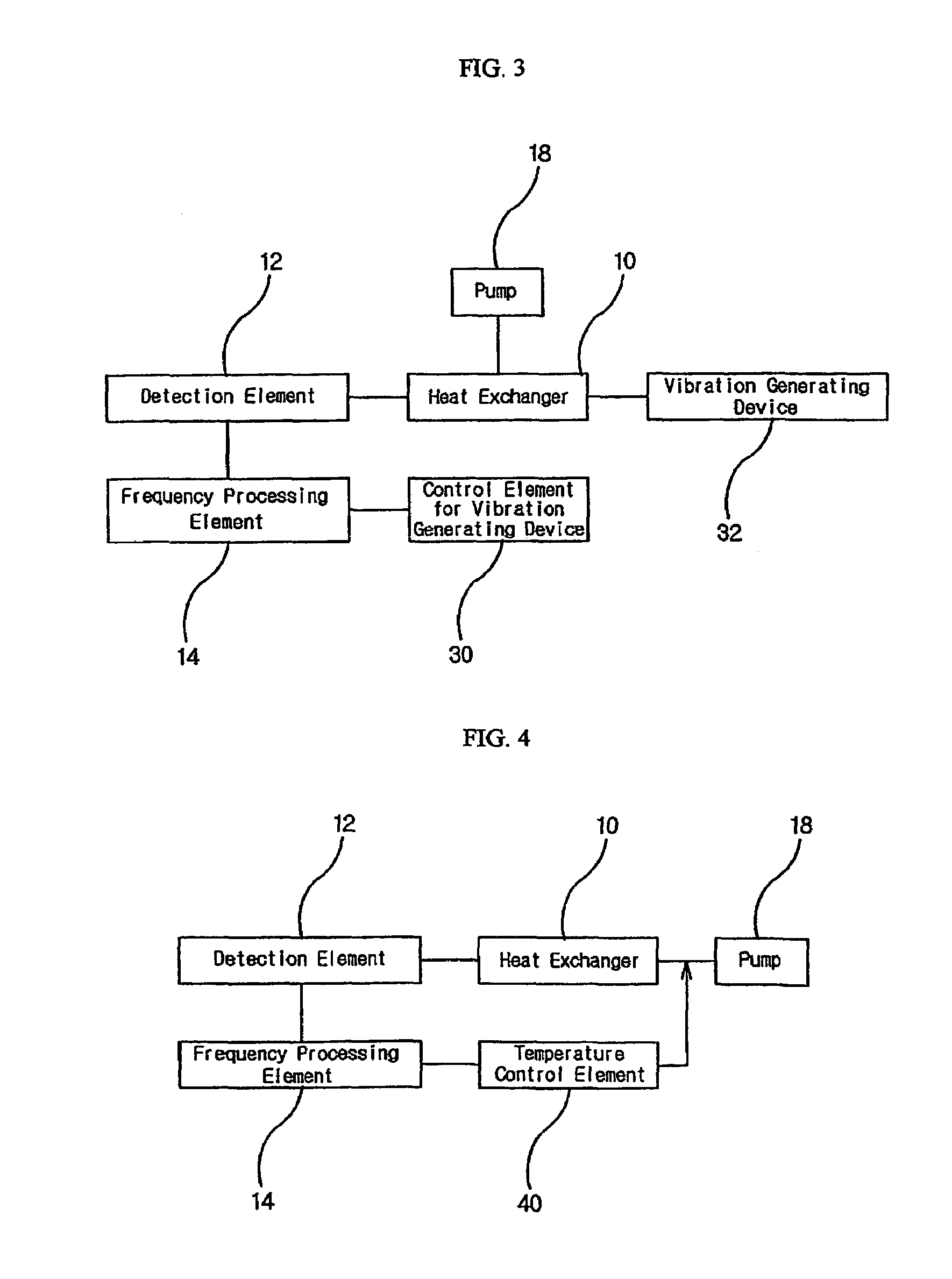

Feed-back control system for heat exchanger with natural shedding frequency

InactiveUS20050115703A1Maximize heat transfer efficiencyForce measurement by measuring frquency variationsAir-treating devicesResonanceControl system

The invention relates with the feed-back control system of a heat exchanger by use of the flow resonance phenomenon which maximizes the heat transfer efficiency by generating the flow disturbances of a heat transfer medium. If a heat transfer medium is periodically stimulated at the characteristic frequency of a heat exchanger, the flow resonance frequency, which is dependent upon the flow conditions of heat transfer medium and the geometries of a heat exchanger, the disturbances of heat transfer medium is increased to the extent that heat transfer is dramatically high. This system is composed of the detecting part for the detection of flow characteristics, the processing part for the determination of flow resonance frequency, and the stimulating part which excites a heat transfer medium at the calculated flow resonance frequency.

Owner:BSTECH

Insulated shipping container systems and methods thereof

InactiveUS20100147837A1Improve cooling efficiencyIncrease temperatureLighting and heating apparatusLarge containersInsulated shipping containerTemperature sensitive

An insulated shipping container system for transferring a temperature sensitive product comprising a substantially hollow insulated body having inner walls and outer walls defining a payload cavity to receive a payload and supports to space the payload from the insulated body thereby defining an internal air filled space to facilitate heat transfer. The insulated shipping container system further comprises a heat transfer element cavity configured to receive a heat transfer element and supports to space the heat transfer element from the insulated body thereby defining an internal air filled space to facilitate heat transfer. Also provided are methods for shipping temperature sensitive products and goods comprised of packing and assembling the insulated shipping container system disclosed herein.

Owner:WILLIAMS ALTON

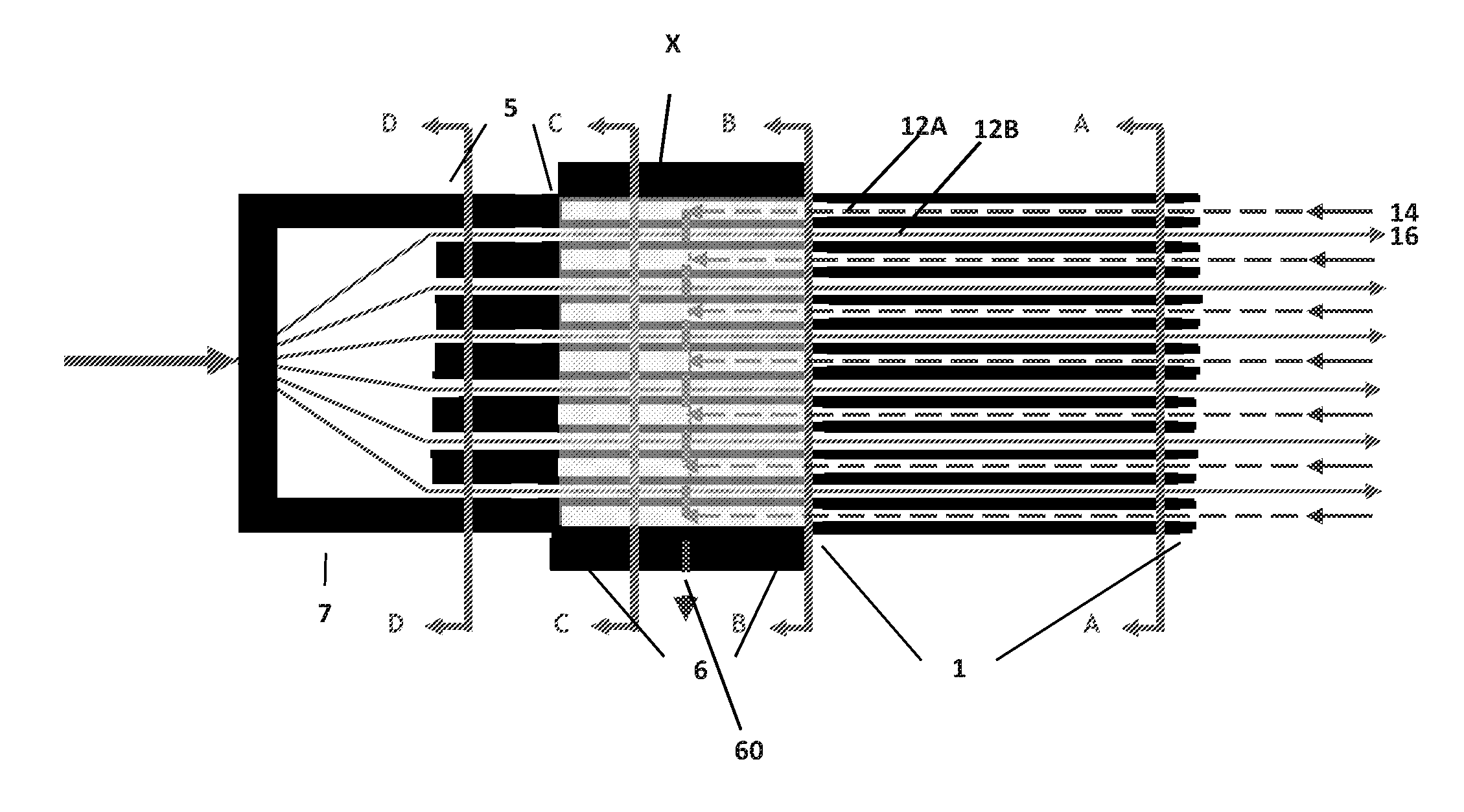

Countercurrent heat exchanger/reactor

ActiveUS20160003552A1High heat transfer rateFacilitates huge savingChemical/physical/physico-chemical microreactorsChemical/physical/physico-chemical reactor detailsCounter flowCheckerboard pattern

Counter-flow heat exchanger is constructed with plenums at either end that separate the opposing fluids, the channels of which are arrayed in a checkerboard patterns, such that any given channel is surrounded by channels of opposing streams on four sides—laterally on both sides and vertically above and below.

Owner:THAR ENERGY

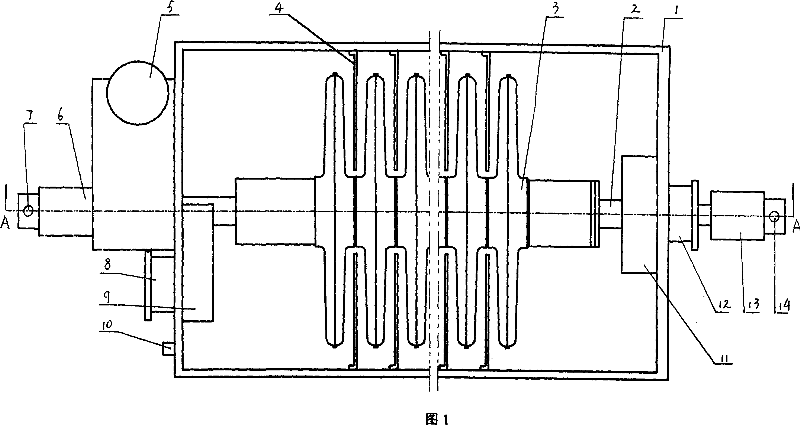

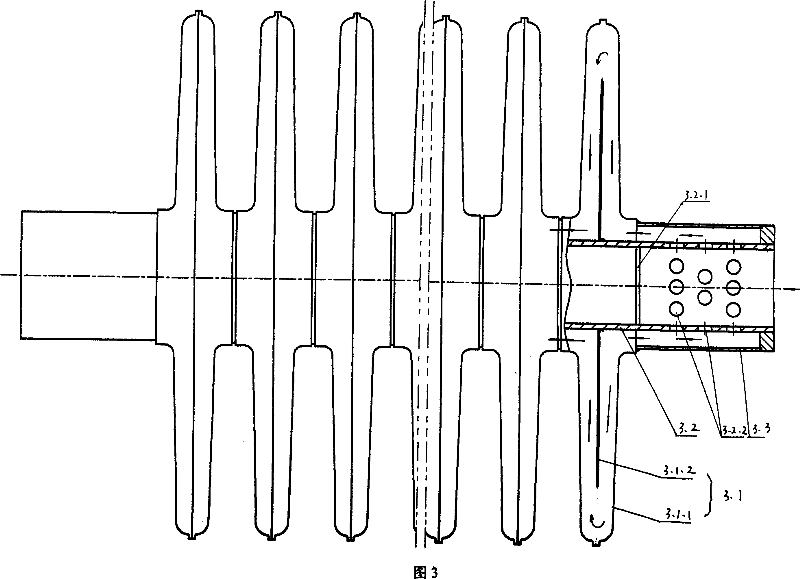

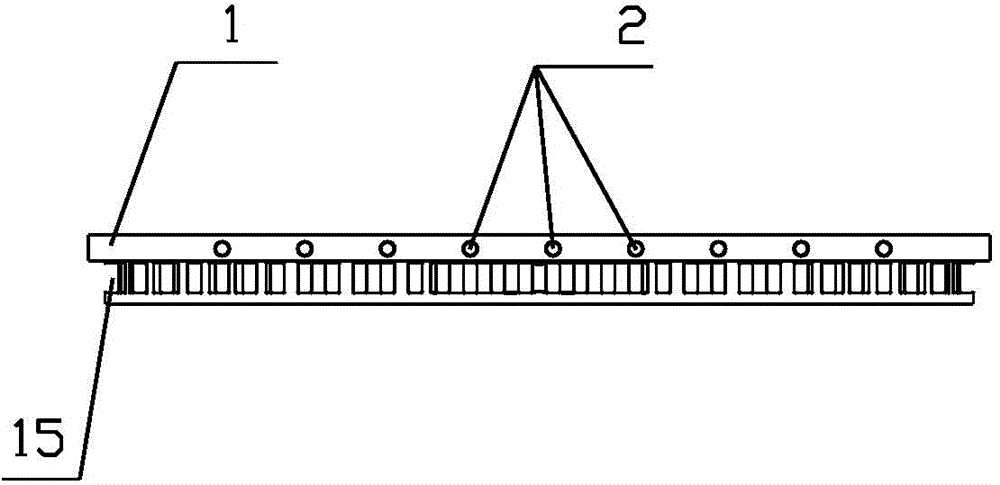

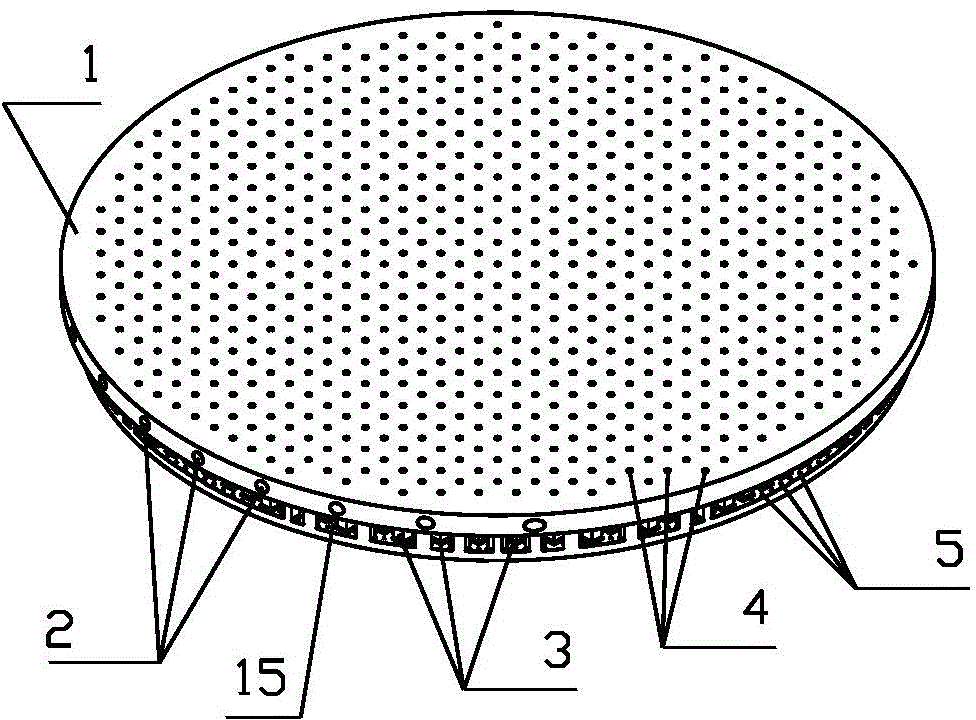

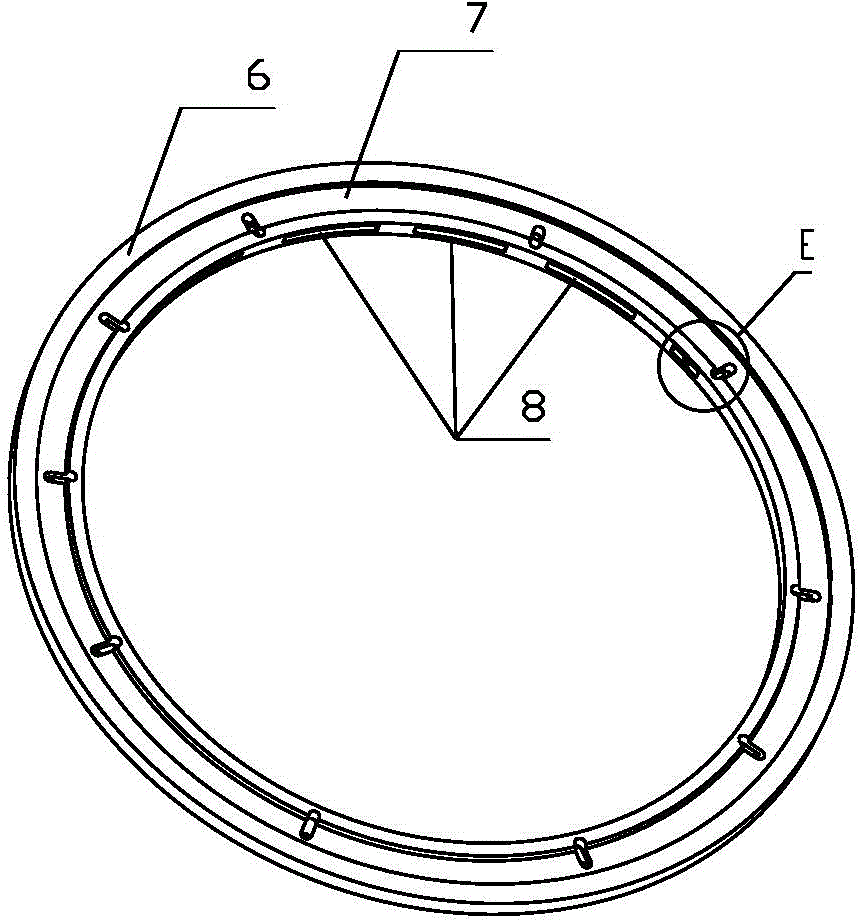

Disc shape self-cleaning waste-water thermal energy recoverer

InactiveCN101042285AImprove heat transfer efficiencyMaximize heat transfer efficiencyMoving conduit heat exchangersThermal energyWastewater

It relates to a round plate self cleaning waste water energy recovery device that comprises the case, main shaft, heat exchanging plate component, guide flow plate and rotating joint, waste water inlet on the case, waste water outlet and guide flow plate, both ends of main shaft connected to rotary joints, clean water inlet and outlet on the rotary joint, heat exchanging plate component cased on the main shaft that comprises the heat plate, inner sleeve tube, heat exchanging plate with several plates in hollow structure, inner sleeve tube both ends having flow resistance baffle plate, several water inlet and outlet holes on the tubular wall, tubular sleeves outside the tube, two tube sleeves inner cavity connected with top and tail two heat exchanging plate, and the rest of the heat exchanging plate interconnected with the heat exchanging plate. It can not make impurities in the waste water stick to the surface of the heat exchanging element to improve heat exchanging efficiency.

Owner:王君健 +1

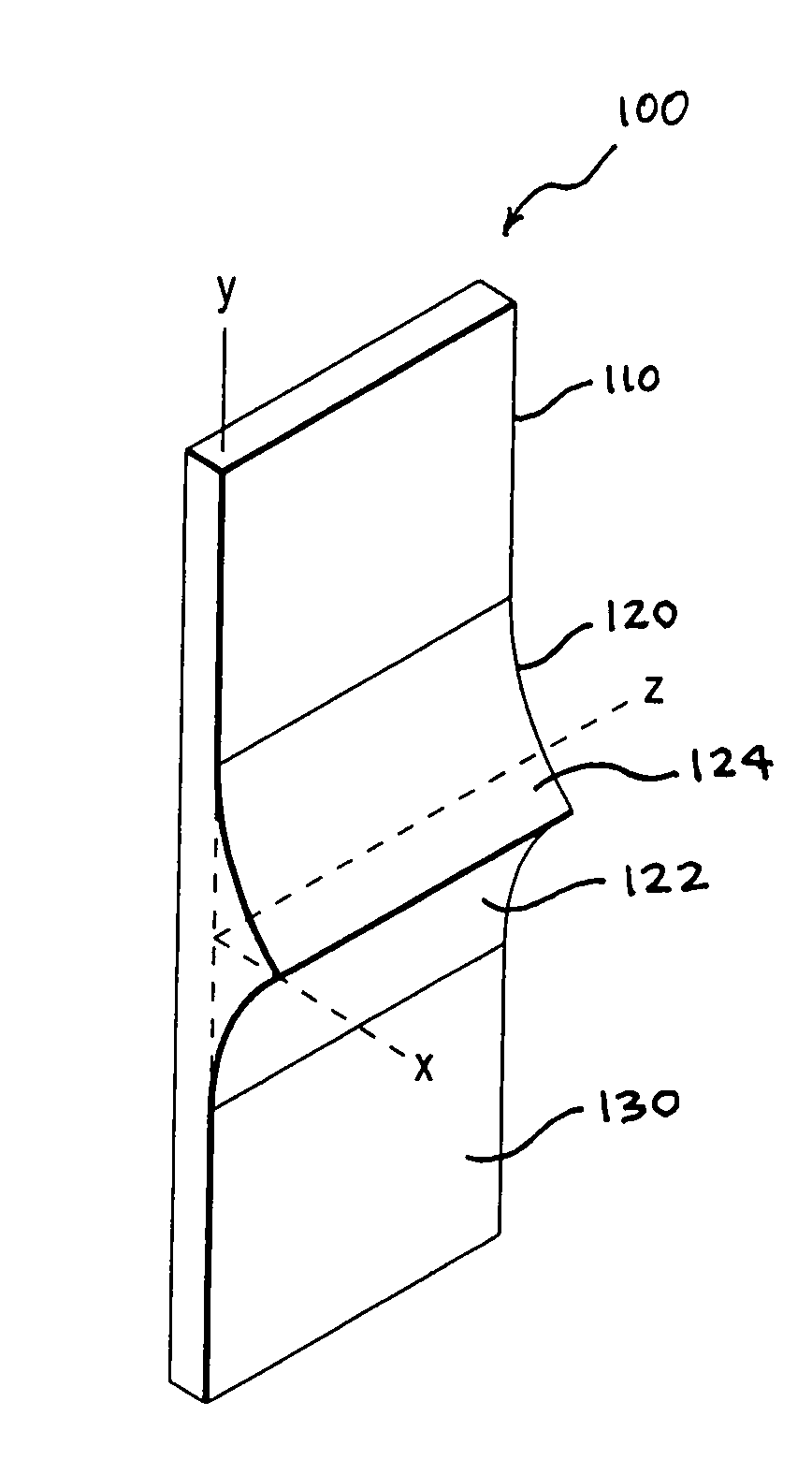

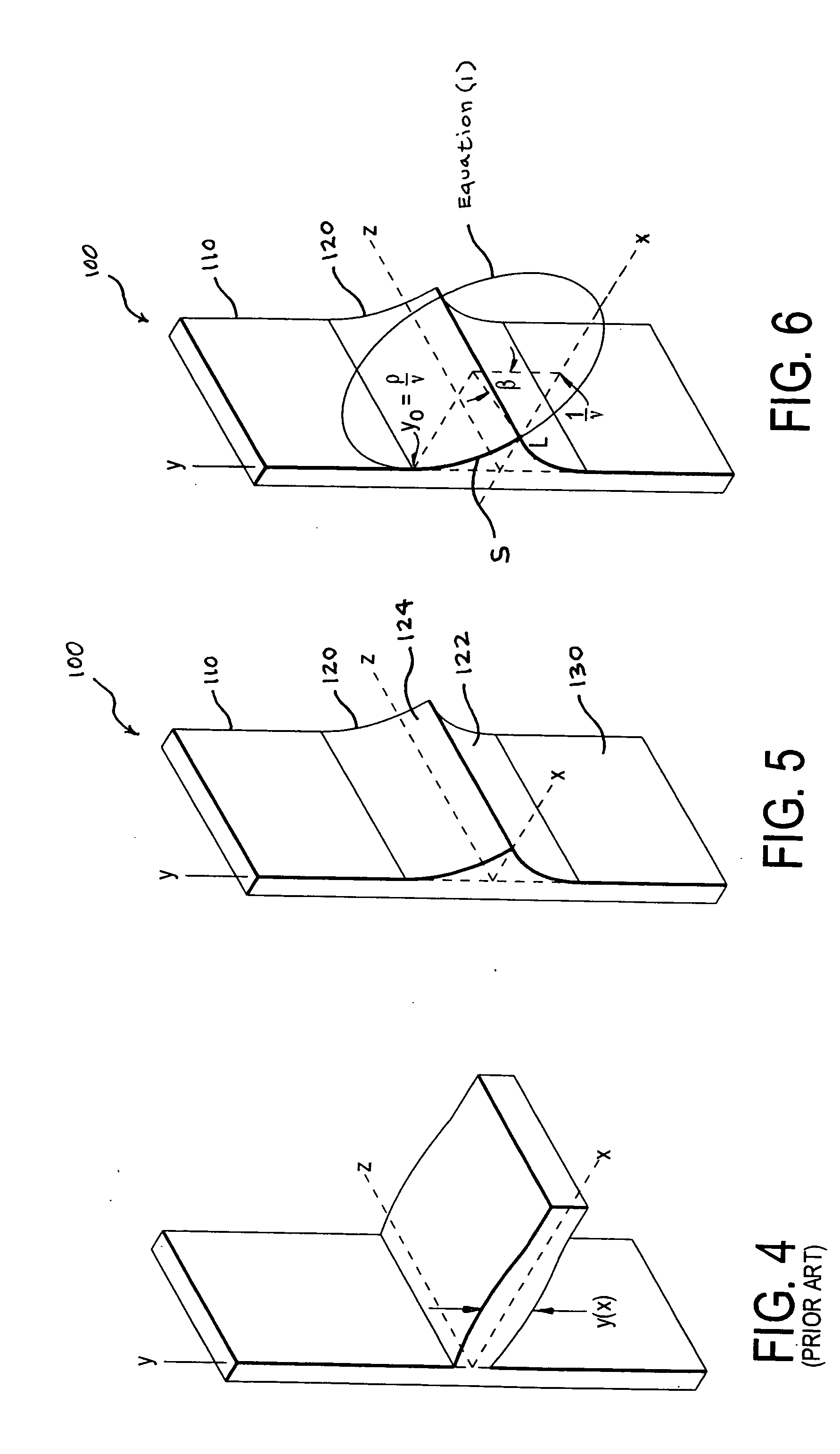

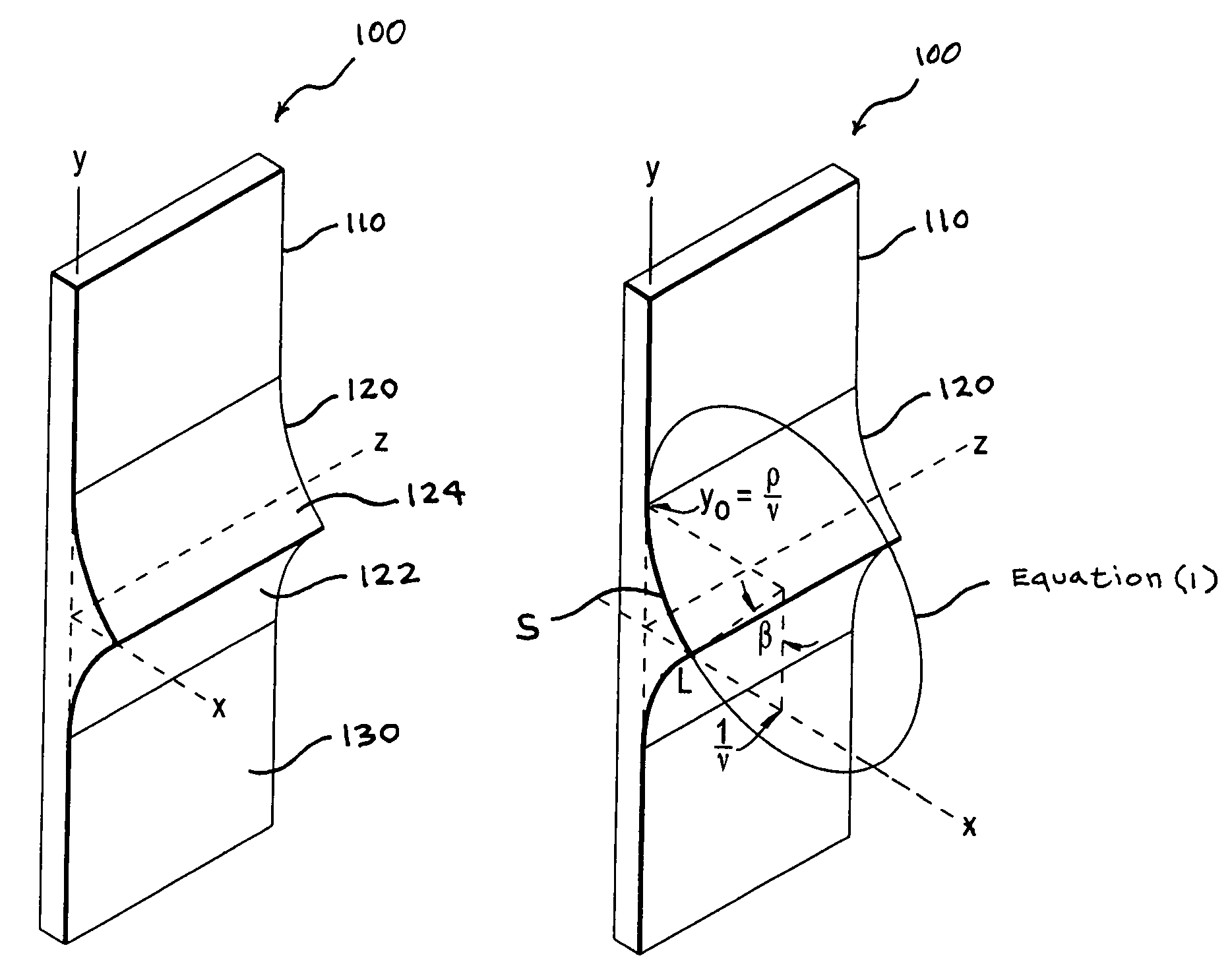

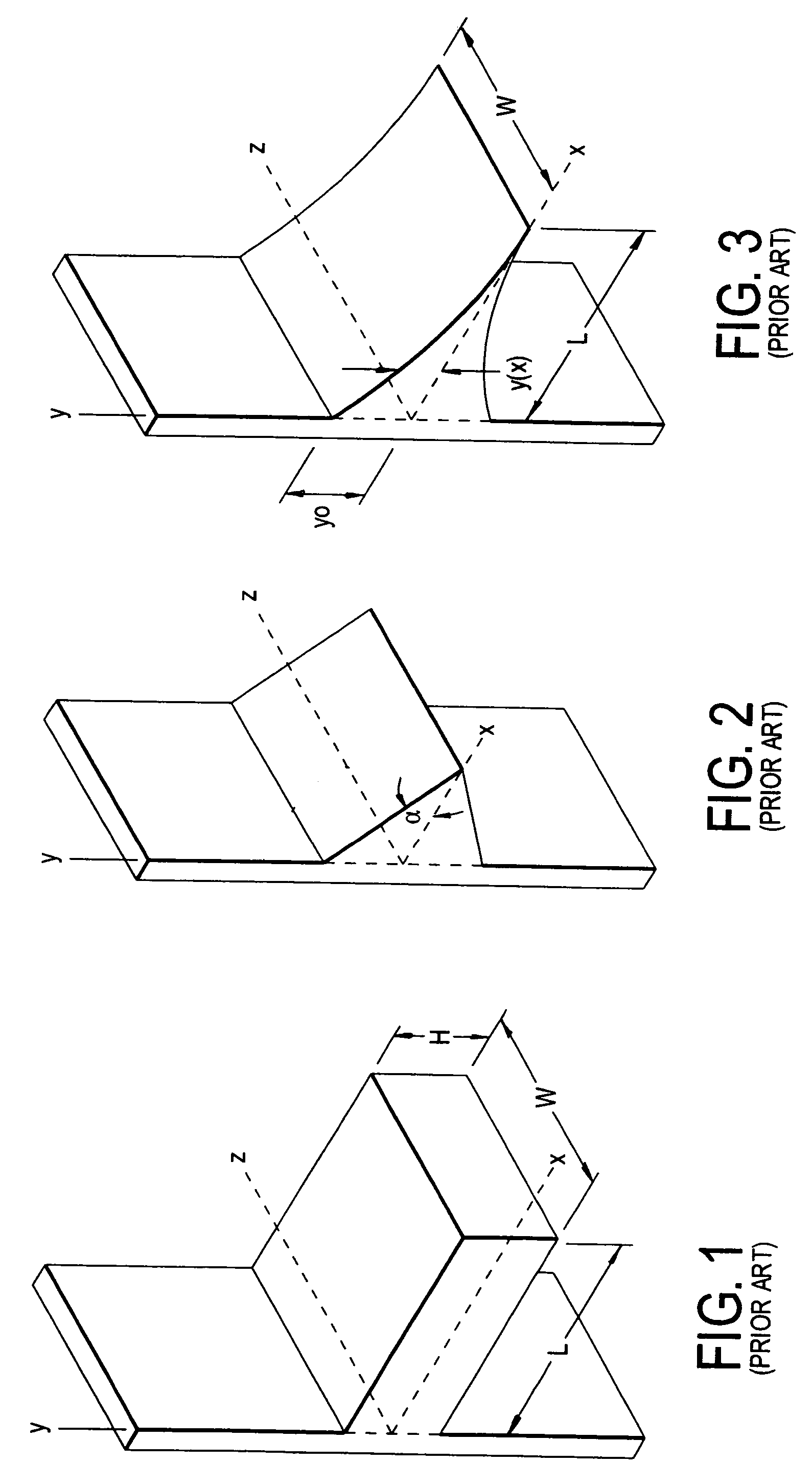

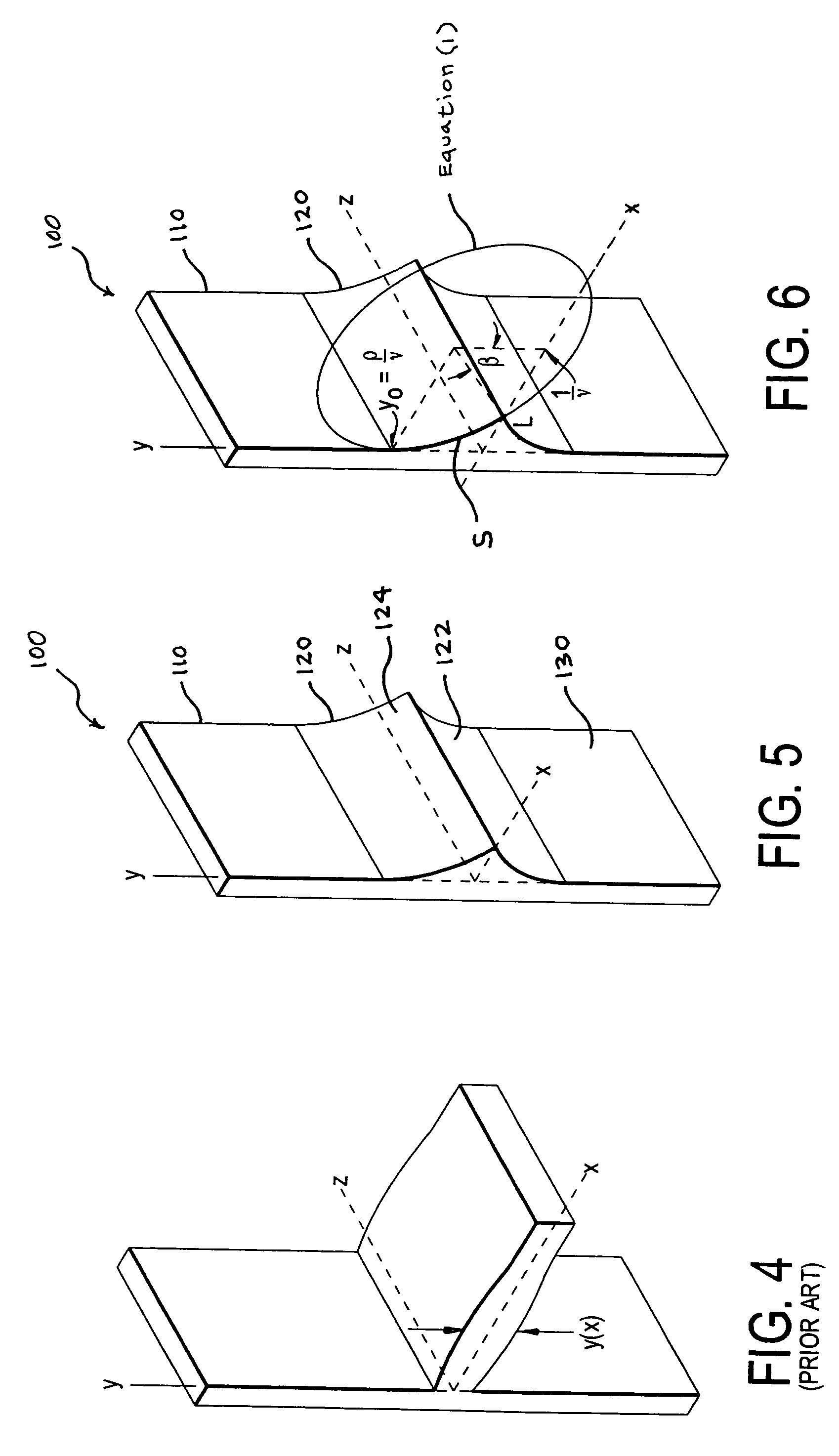

Heat exchange device

InactiveUS20050189099A1Heat transfer efficiency be maximizeMaximize heat transfer efficiencyHeat transfer modificationLaminated elementsThermal conductivityHeat flow

A heat transfer device having a heat source for collecting waste heat from a heat-generating system, the heat transfer device having fins in which the shape of the sides of the fins is preferably circular according to the general expression (x-1γ)2+(y-ργ)2=1γ2,where γ=hk,h is the heat transfer coefficient between the fin and the surrounding fluid, k is the thermal conductivity of the fin material, ρ=qok θo,qois the heat flow through the fin semi-base per unit depth and θ0 is the difference between the temperatures of the heated surface and the surrounding fluid.

Owner:UNIVERSITY OF ROCHESTER

Heat exchange device

InactiveUS7290598B2Maximize heat transfer efficiencyMetal-working apparatusHeat transfer modificationHeat flowEngineering

A heat transfer device having a heat source for collecting waste heat from a heat-generating system, the heat transfer device having fins in which the shape of the sides of the fins is preferably circular according to the general expression(x-1γ)2+(y-ργ)2=1γ2,whereγ=hk,h is the heat transfer coefficient between the fin and the surrounding fluid, k is the thermal conductivity of the fin material,ρ=qokθo,qois the heat flow through the fin semi-base per unit depth and θ0 is the difference between the temperatures of the heated surface and the surrounding fluid.

Owner:UNIVERSITY OF ROCHESTER

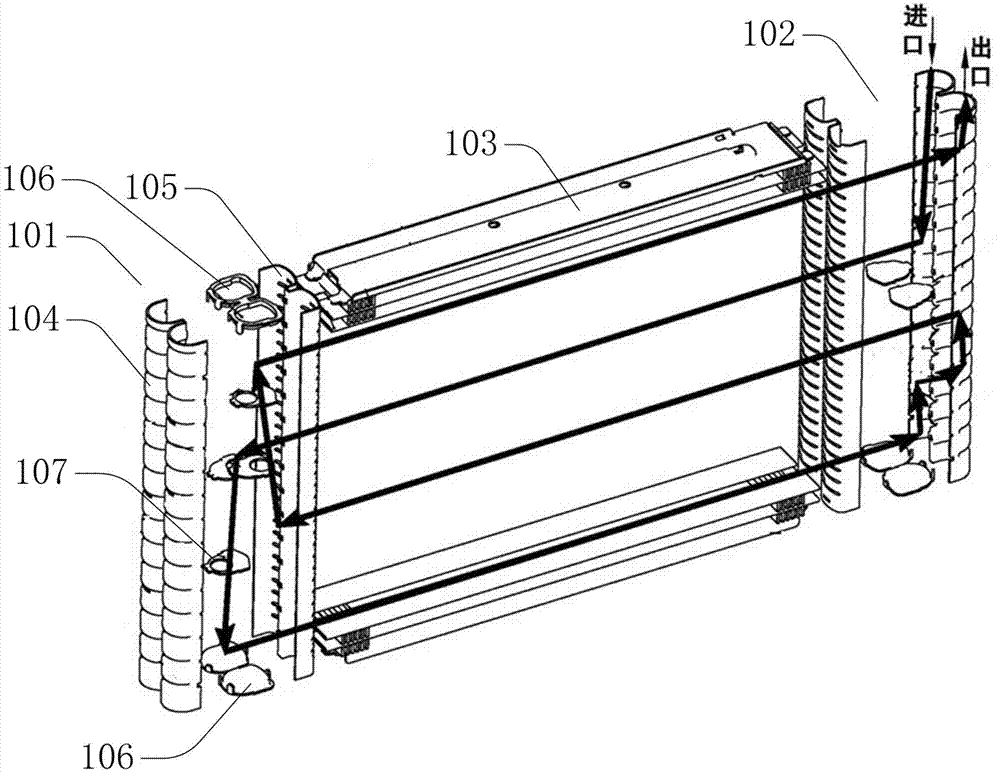

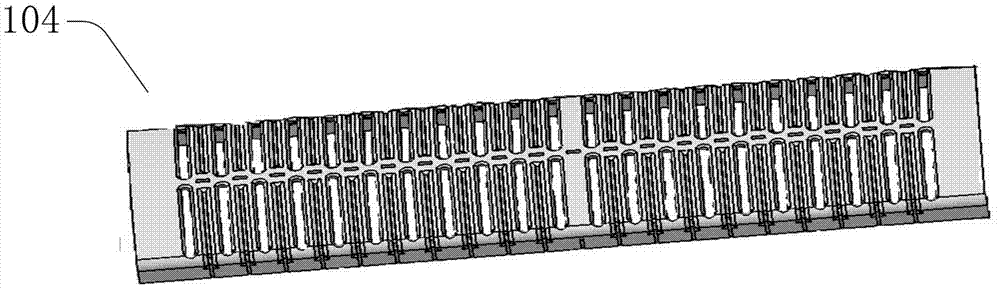

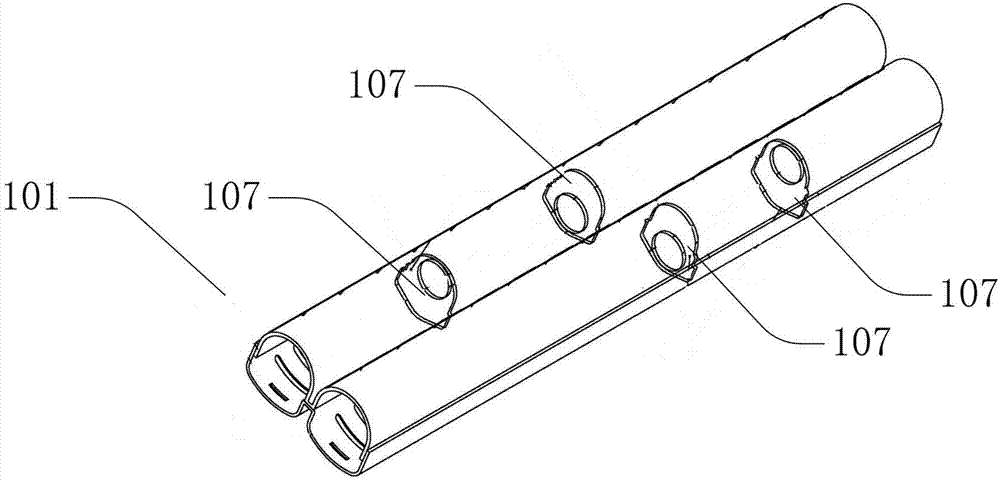

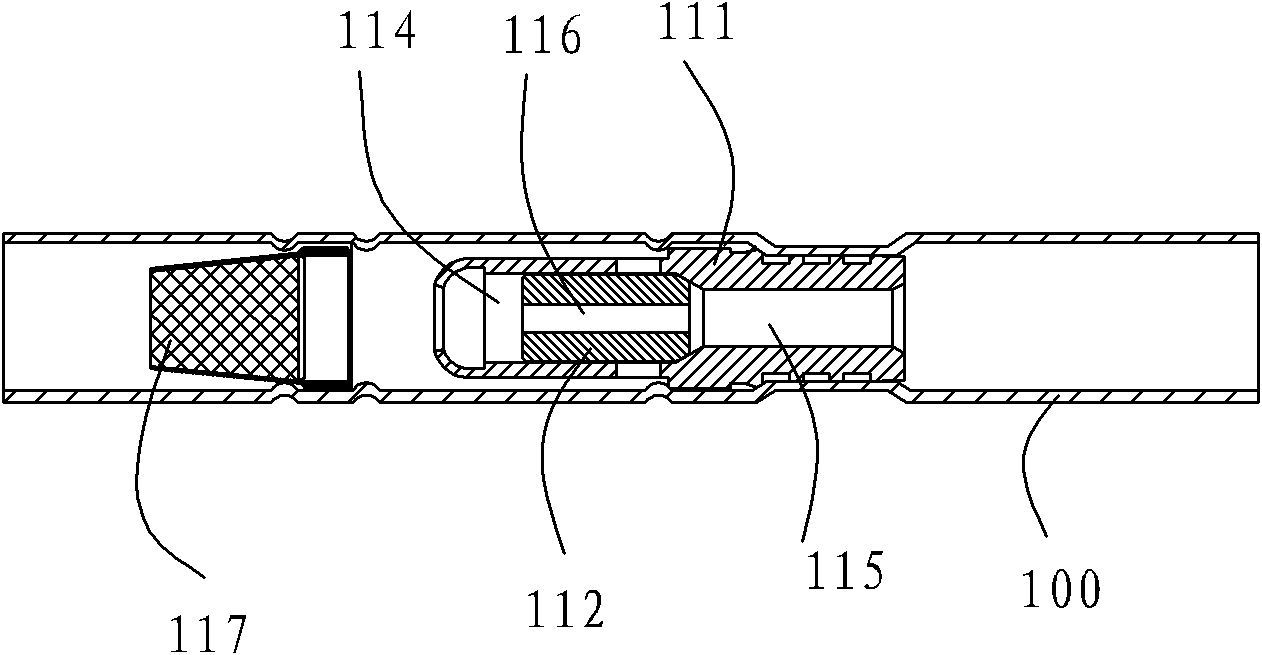

Collecting pipe and parallel flow evaporator using same

InactiveCN102778165ASimple structureEasy to installEvaporators/condensersHeat exchanger casingsArchitectural engineeringEvaporator

The invention provides a collecting pipe and a parallel flow evaporator using the same. The collecting pipe comprises a first pipe cavity, a second pipe cavity, a first seal cover and a second seal cover, wherein the first pipe cavity is parallel to the second pipe cavity, the axial directions of the first pipe cavity and the second pipe cavity are parallel to the length direction of the collecting pipe, the first seal cover is positioned on one end of the collecting pipe, and the second seal cover is positioned on the other end of the collecting pipe. The collecting pipe also comprises a first positioning plate, a second positioning plate, a first perforated plate and a second perforated plate which are arranged in the collecting pipe, wherein the first positioning plate and the second positioning plate are respectively arranged on the middle parts of the first pipe cavity and the second pipe cavity; one end of the first perforated plate is connected with the first seal cover, the other end of the first perforated plate is inserted into an opening hole of the first positioning plate, one end of the second perforated plate is inserted into an opening hole of the second positioning plate, the other end of the second perforated plate is connected with the second seal cover, and the first perforated plate and the second perforated plate are of a U-shaped structure and are provided with a plurality of holes distributed along the length direction. The collecting pipe has the advantages of simple structure, convenience in installation, installation labor-hour saving, low manufacturing cost and high generality degree.

Owner:SONGZ AUTOMOBILE AIR CONDITIONING

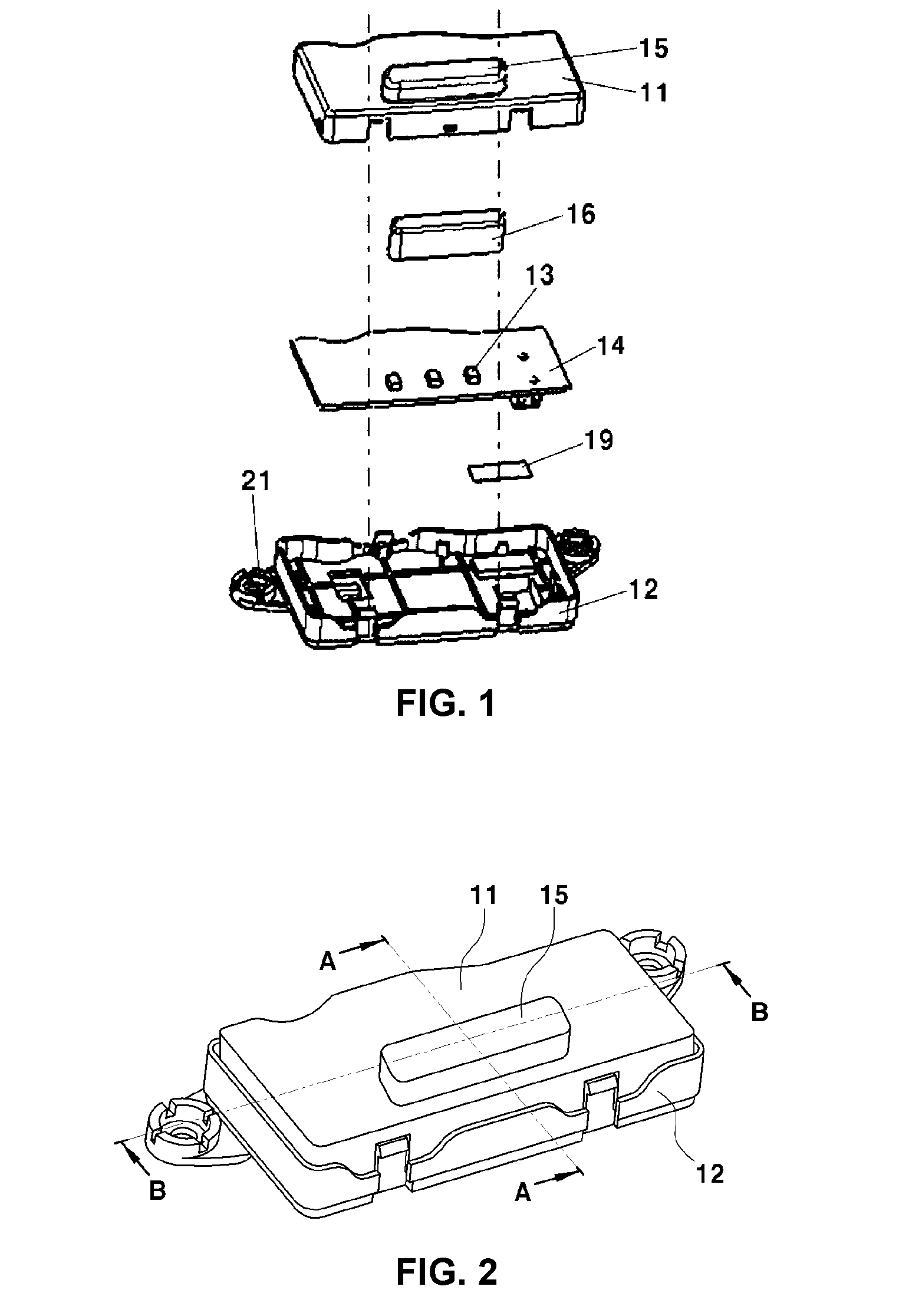

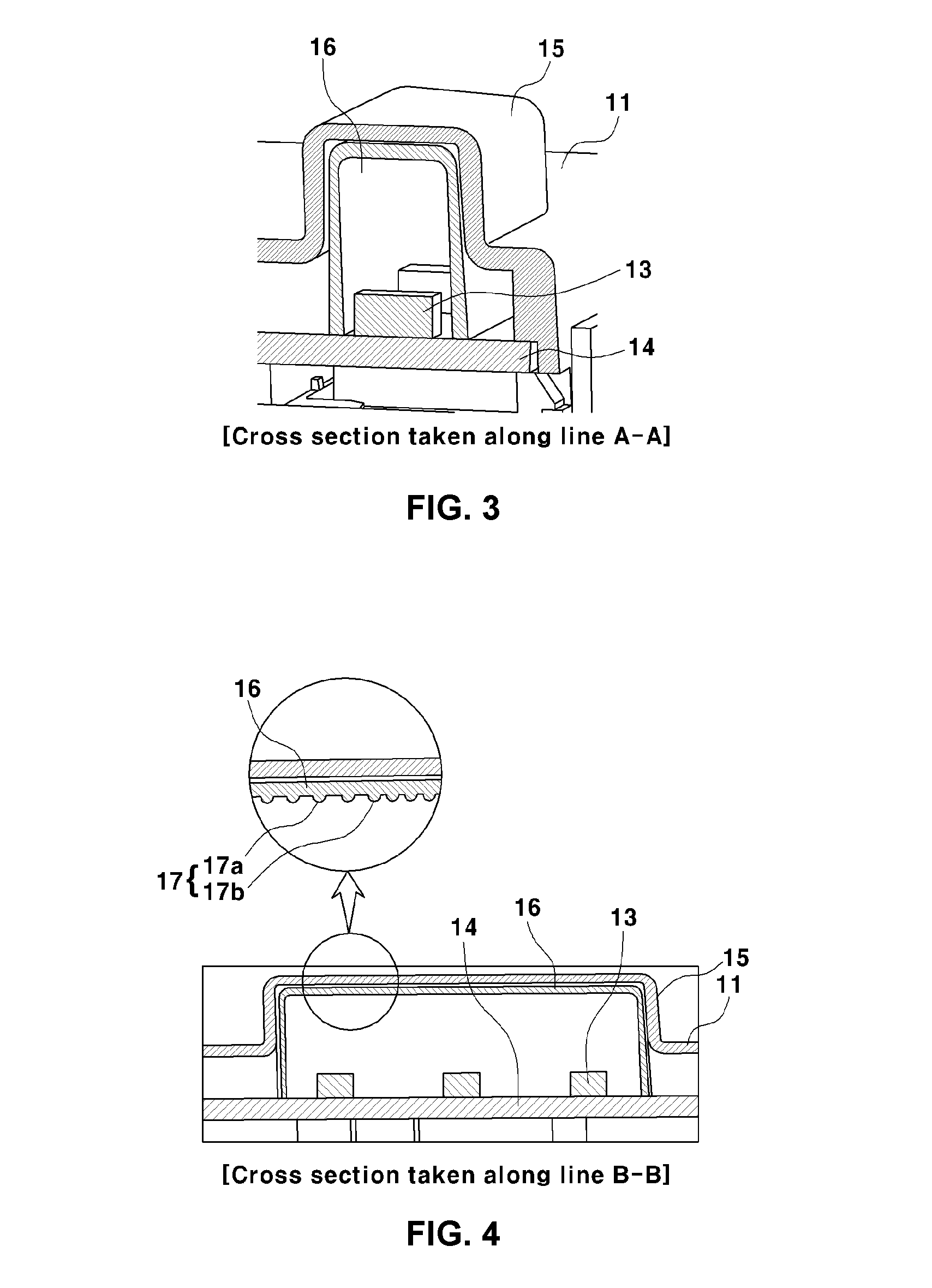

Battery charging status indicator for electric vehicle

ActiveUS20160233706A1Lower assembly costsReduce component countCircuit monitoring/indicationDifferent batteries chargingBattery state of chargeBattery charge

A charging status indicator of an electric vehicle installed at one side of a charging status indicator cover to indicate a charging status of the electric vehicle as an illumination may include a lens-integrated lamp housing and a printed circuit board (PCB) housing which are vertically coupled to each other, a PCB installed in the PCB housing and having a plurality of Light Emitting Diodes (LEDs) mounted thereon, and a diffusion cap diffusing LED.

Owner:HYUNDAI MOTOR CO LTD +1

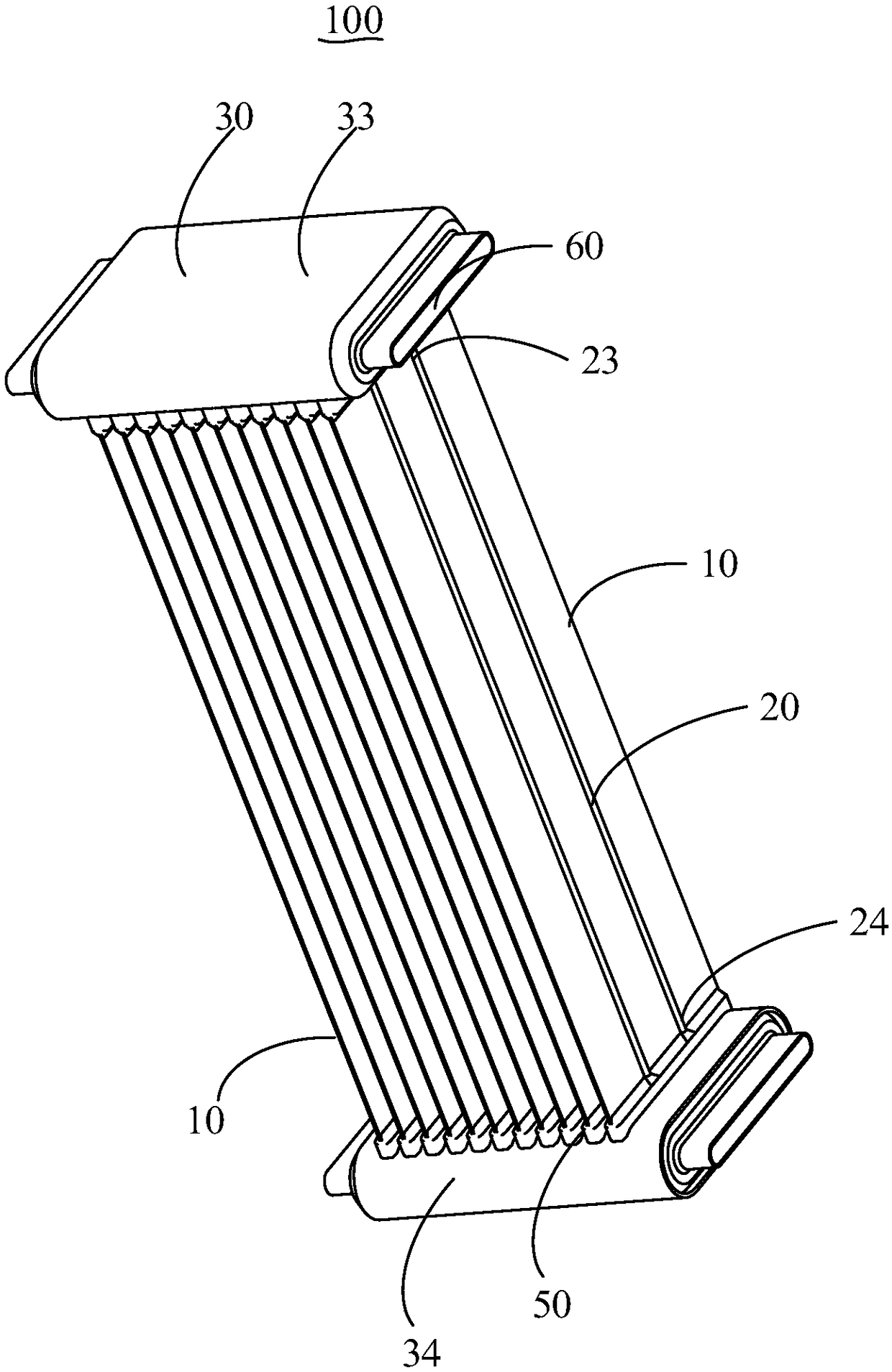

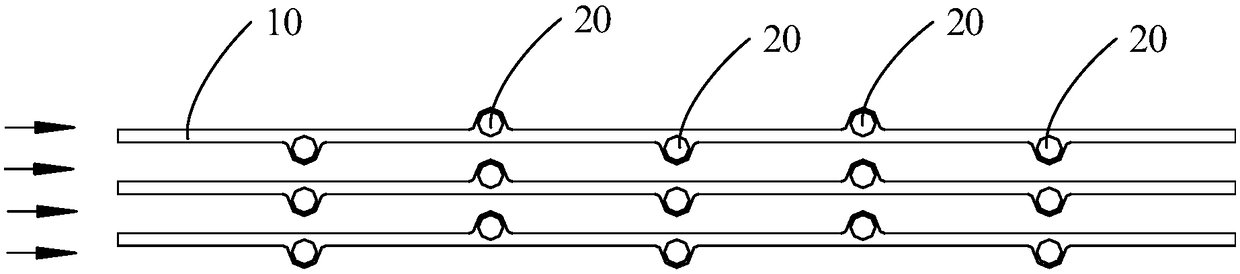

Heat exchanger and heat exchange apparatus

InactiveCN108562176AMaximize heat transfer areaMaximize the heat transfer effectHeat exhanger finsStationary conduit assembliesEngineeringMicro heat exchanger

The invention provides a heat exchanger and a heat exchange apparatus. The heat exchanger comprises: a plurality of fins that are arranged at intervals; a plurality of heat exchange pipes extended onthe surface of the fins or formed in the fins. The heat exchanger and the heat exchange apparatus have the advantage the heat exchange pipes and the fins are high in heat exchange quantity and heat exchange efficiency.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Temperature-controllable double-gas channel spraying plate with uniform gas spraying function

InactiveCN104789943AReduce volumeHigh heat transfer efficiencyChemical vapor deposition coatingHeat transfer efficiencyConvective heat transfer

The invention discloses a temperature-controllable double-gas channel spraying plate with a uniform gas spraying function and mainly solves the problems of low heat transfer efficiency, large size of a spraying part and the like caused by non-reasonable structure in the prior art. The temperature-controllable double-gas channel spraying plate with the uniform gas spraying function is structurally characterized in that two gas channels and a snake-like liquid heat transfer medium channel are arranged inside the spraying plate; the two gas channels are isolated from each other; the snake-like liquid heat transfer medium channel is high in heat transfer efficiency. The two isolated gas channels and the snake-like liquid heat transfer medium channel are formed by combining an upper spraying plate, a diffusion baffle, a gas inlet ring, a closed ring and a spraying pore plate included by the part. A convective heat transfer position is arranged on one side of small spraying holes in a form of welding two parts to form a liquid-state heat transfer medium channel, so that the heat transfer efficiency is maximized, process requirements on simultaneous charging of two gases into cavities or switching of the cavities for reaction under controllable temperature conditions are met, the size of a spraying part is reduced, the heat transfer efficiency is improved, and the reliability of the spraying part is guaranteed.

Owner:PIOTECH CO LTD

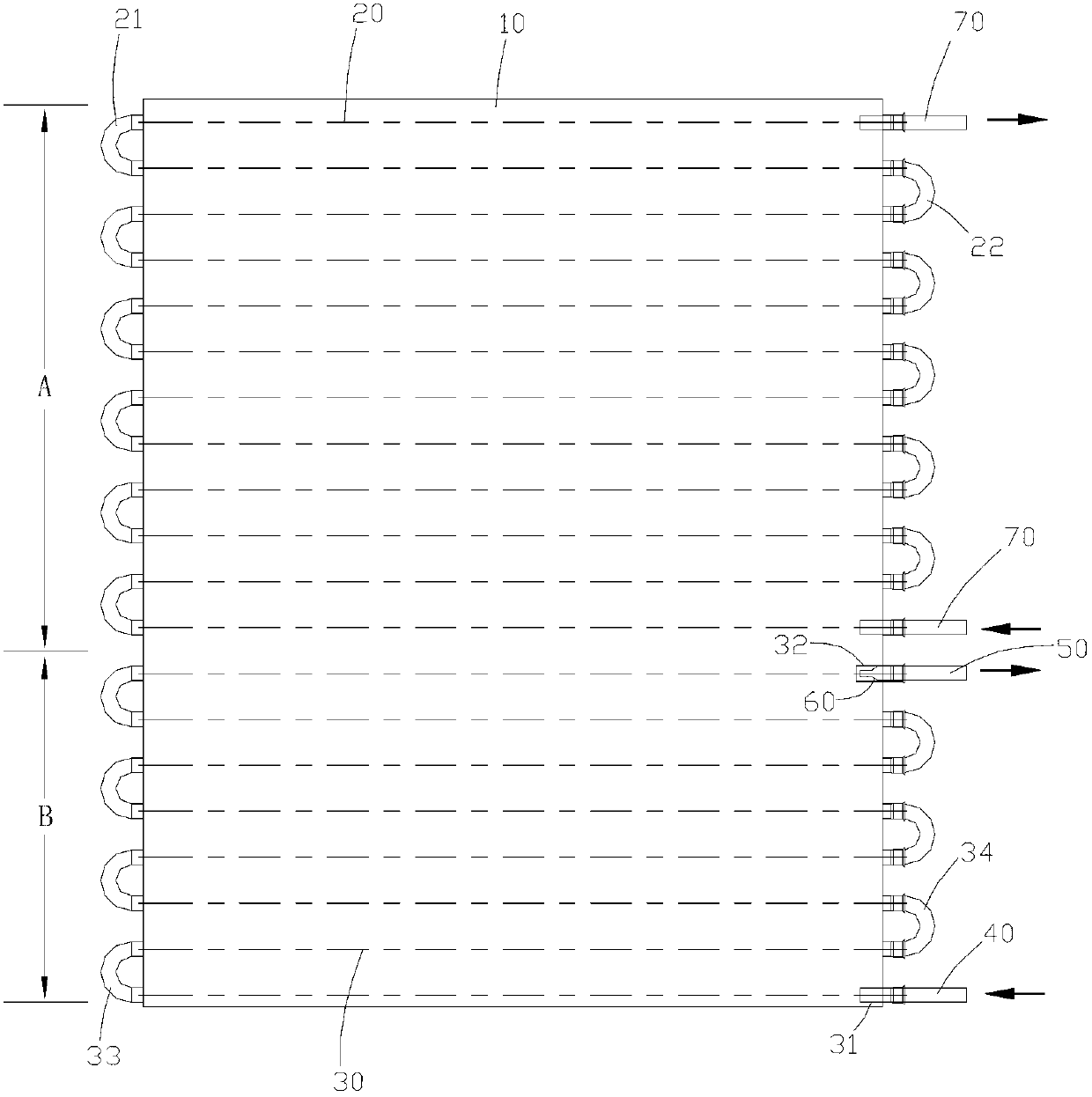

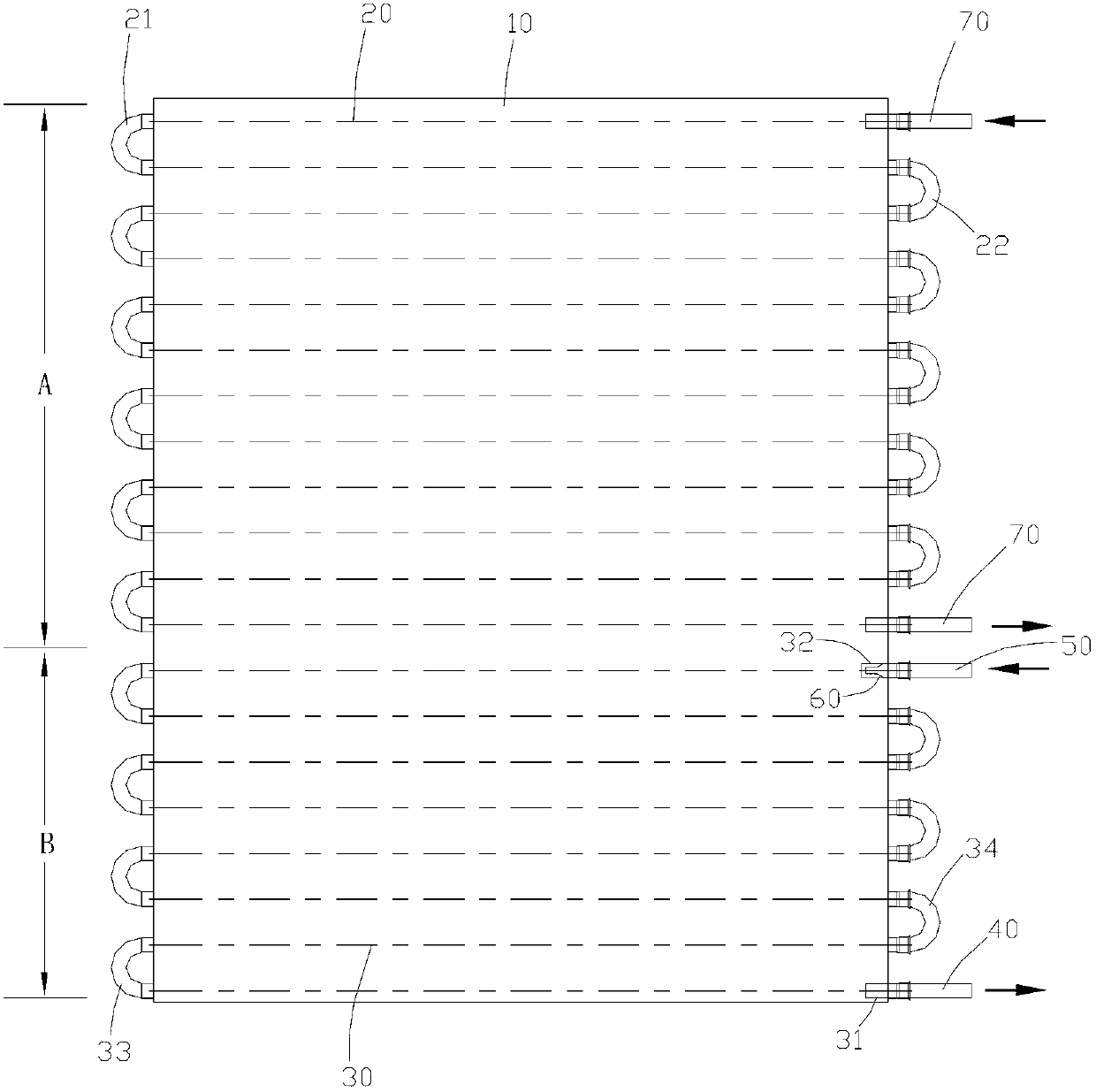

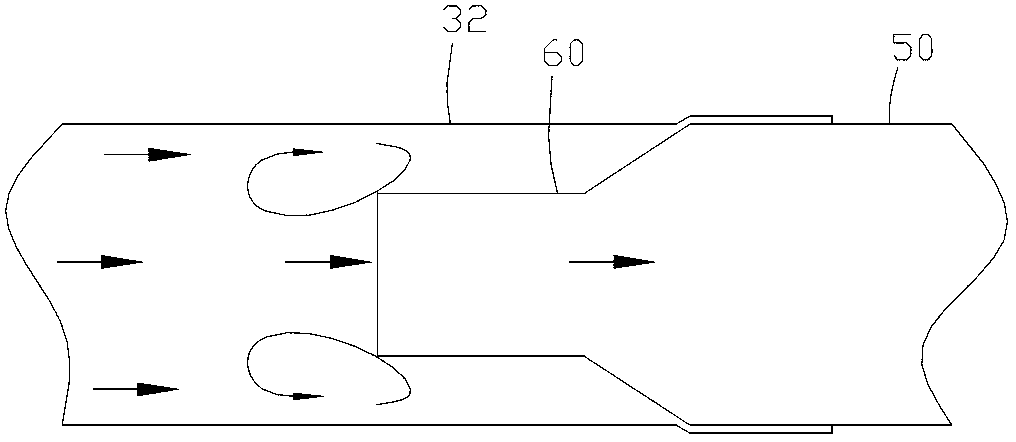

Air conditioner heat exchange system and air conditioner comprising same

InactiveCN102121771AMaximize heat transfer efficiencyAperture can be adjustedFluid circulation arrangementEngineeringDistributor

The invention discloses an air conditioner heat exchange system and an air conditioner comprising the same. The air conditioner heat exchange system comprises a distributor and a heat exchanger consisting of multiple heat exchange units, wherein the distributor is provided with multiple flow splitting holes in one-to-one correspondence and communicated with the heat exchange units; and a throttle valve is arranged between each flow splitting hole and the corresponding heat exchange unit. According to the heat exchange system disclosed by the invention, as the throttle valves are arranged between the heat exchange units and the flow splitting holes of the distributor, by adjusting the throttling aperture of the throttle valves according to the different heat exchange efficiencies of the heat exchange units, the refrigerant of corresponding flow is enabled to pass through the heat exchange units, and the heat exchange efficiency can be maximized.

Owner:赵敏

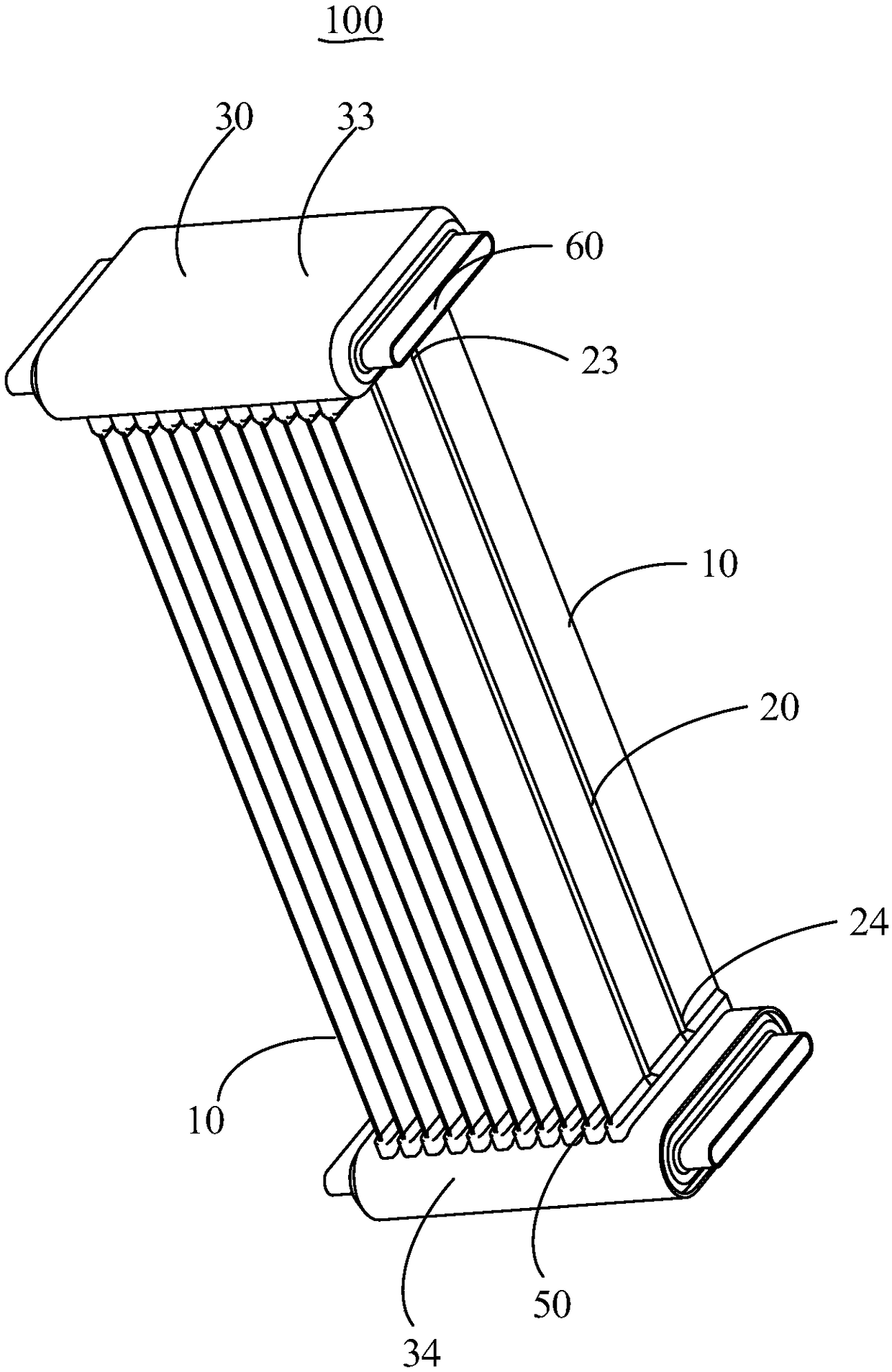

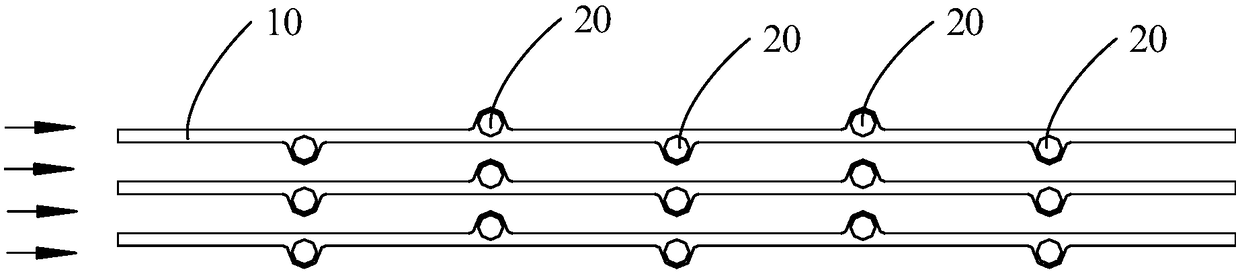

Heat exchanger and heat exchange equipment

PendingCN108592654AMaximize heat transfer areaMaximize the heat transfer effectEvaporators/condensersStationary conduit assembliesMiniaturizationEngineering

The invention provides a heat exchanger and heat exchange equipment. The heat exchanger comprises a plurality of fins, heat exchange tubes and an unilateral collecting flow tube, wherein the pluralityof fins are arranged at intervals, the heat exchange tubes extends to the surfaces of the fins or are formed in the fins, and the heat exchange tubes are arranged in a buckling and folding shape; theunilateral collecting flow tube is arranged at one end in the length directions of the fins, the unilateral collecting flow tube comprises an inflow passage and an outflow passage, wherein the inflowchannel and the outflow channel are arranged at the two ends in the width direction of the fins correspondingly; and the two ends of the heat exchange tubes correspondingly communicate with the inflow channel and the outflow channel. According to the heat exchanger and the equipment, the heat exchanger and the heat exchange equipment has the advantages of being compact in structure, high in heatexchange, high in heat exchange efficiency and capable of realizing miniaturization design of the heat exchanger.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

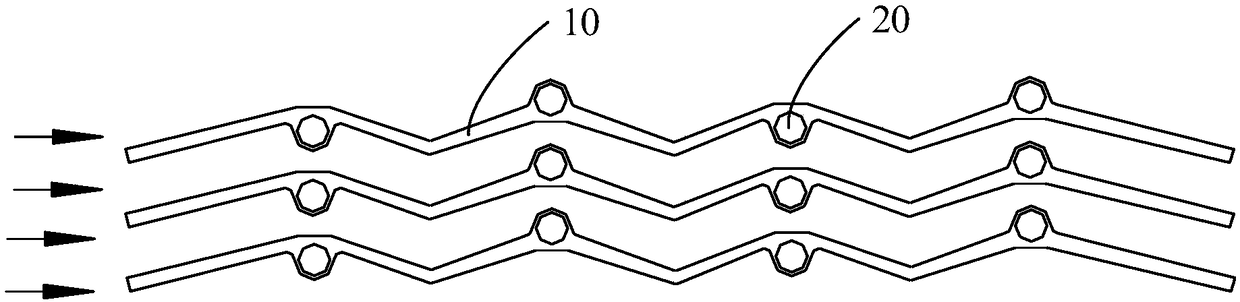

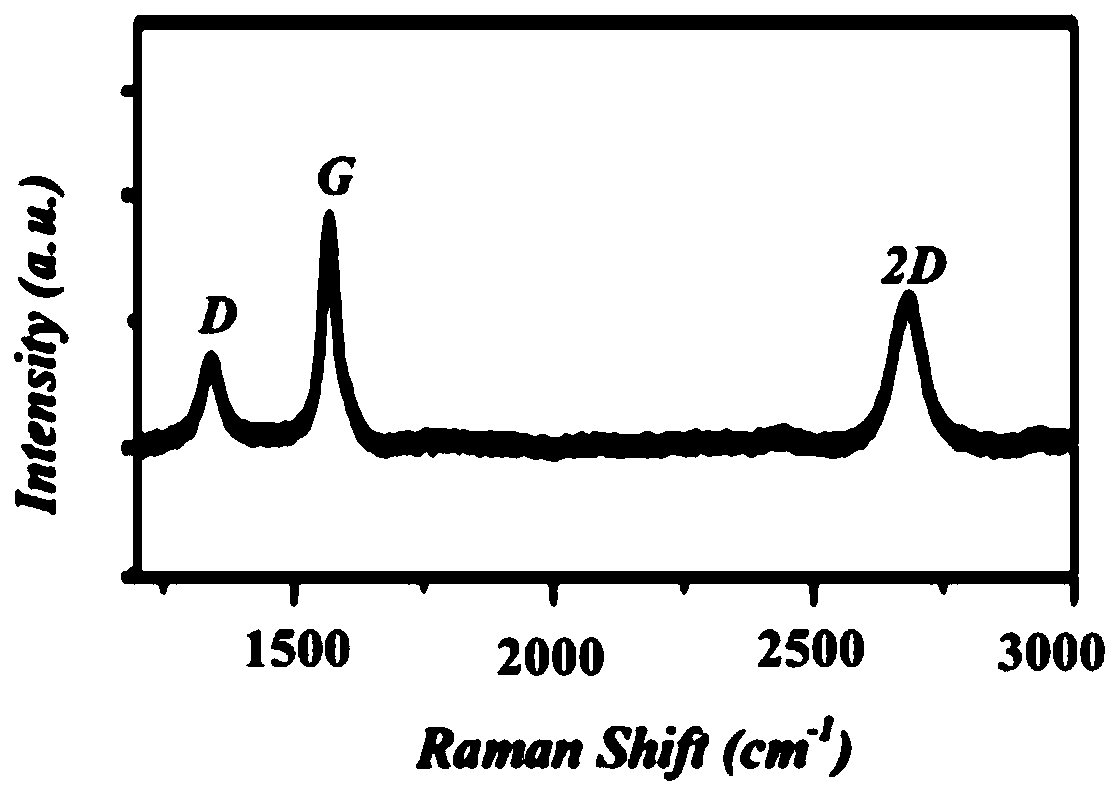

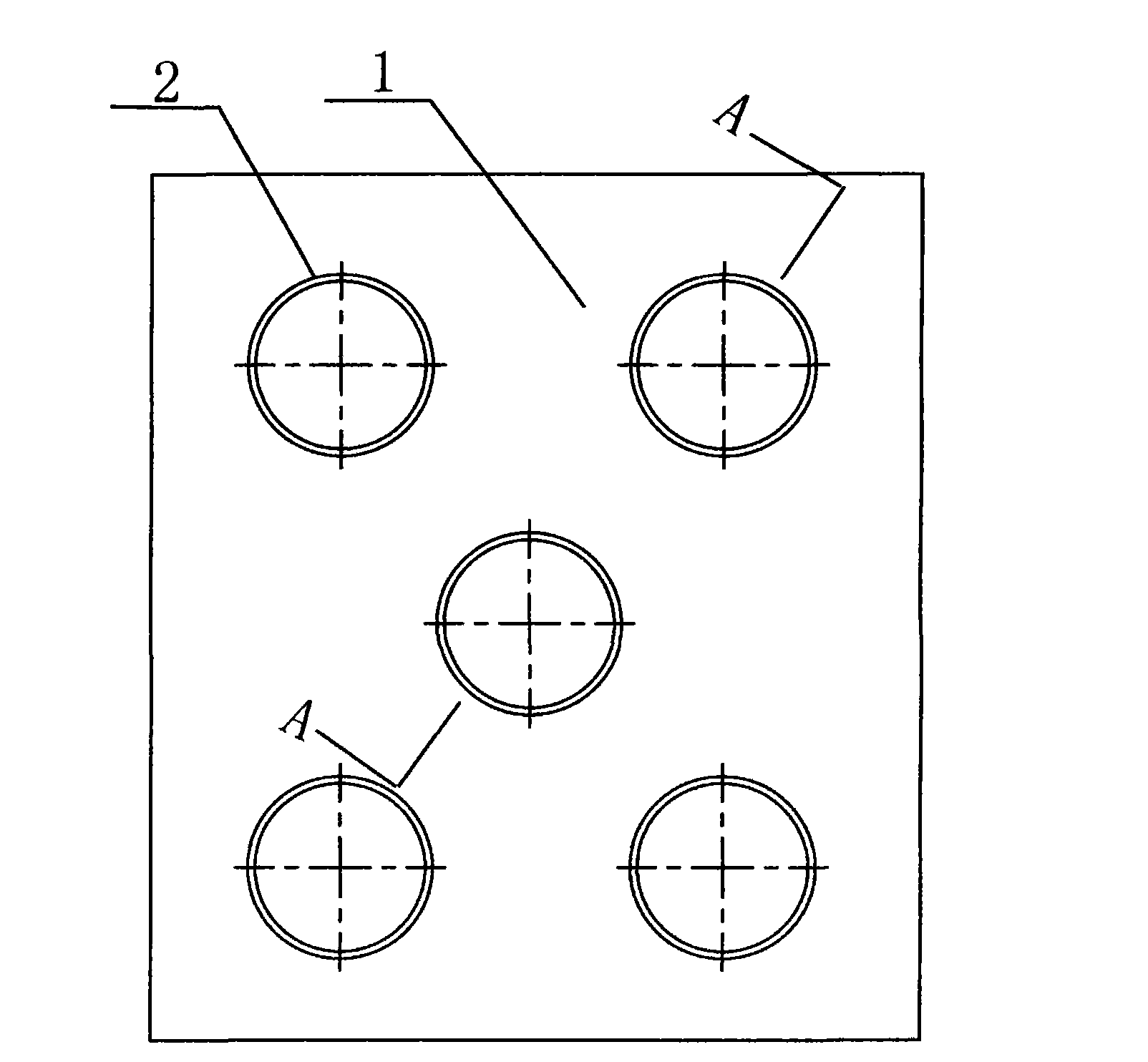

Microchannel radiator for air conditioner

InactiveCN110470154AThree-dimensional structure is stableMaximize heat transfer efficiencyMaterial nanotechnologyStationary tubular conduit assembliesNanofiberMechanical stability

The invention belongs to the technology field of household air conditioning heat dissipation and particularly relates to a microchannel radiator for an air conditioner. According to the microchannel radiator for the air conditioner, the surfaces of fin pieces of the radiator are coated with a graphene heat dissipation coating, the graphene heat dissipation coating comprises electrically-treated graphene, a silicon oxide nanofiber material and nano-copper particles, and the nano-copper particles are deposited in a composite material formed by the electrically-treated graphene and silicon oxidenanofiber through a way of electrodeposition. By means of the microchannel radiator for the air conditioner, under the premise of ensuring the three-dimensional structure stability, the heat conduction effect is maximized, and meanwhile, the mechanical stability can be enhanced.

Owner:SHANDONG XITAI TIANGONG ENERGY SAVING TECH LTD

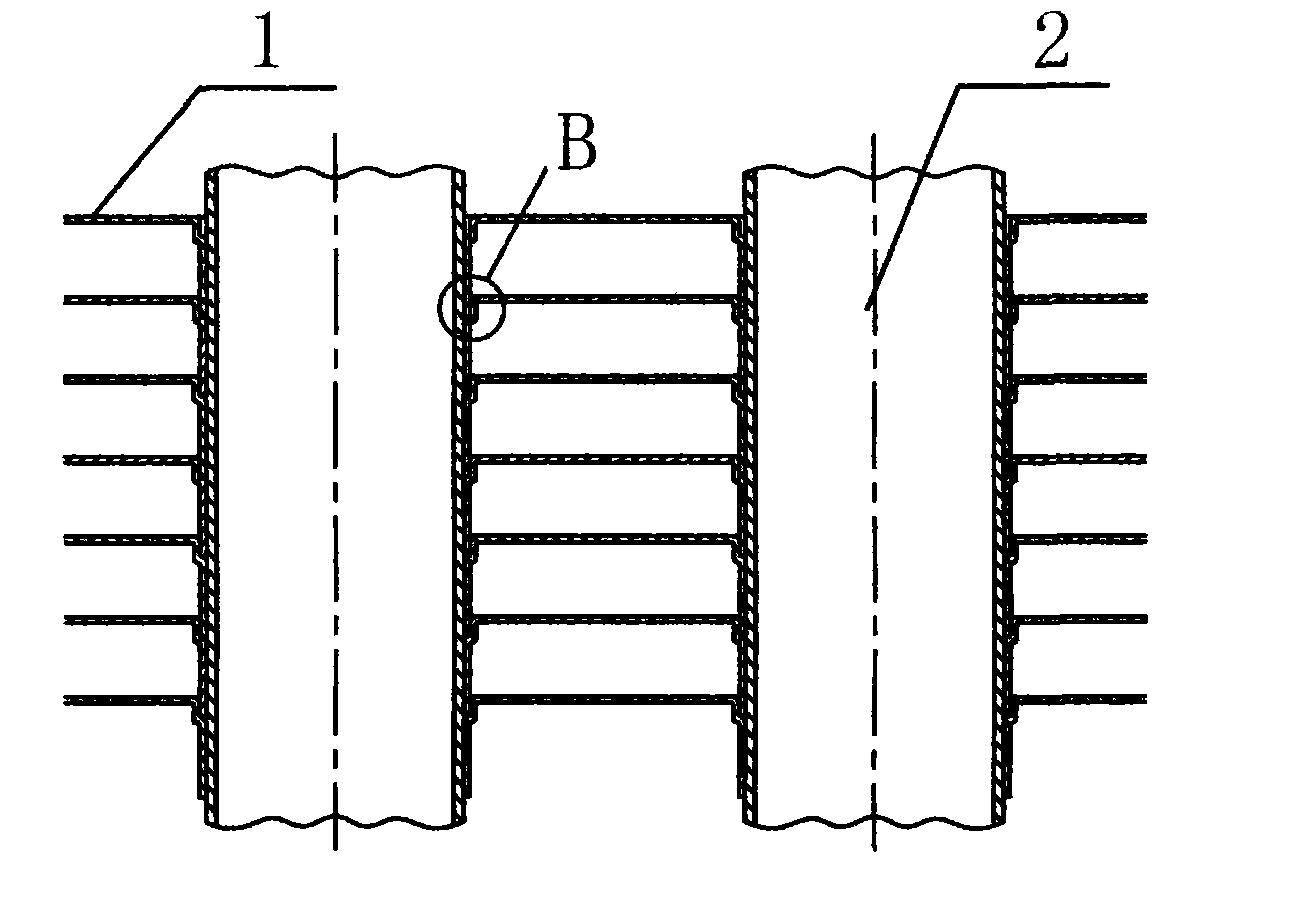

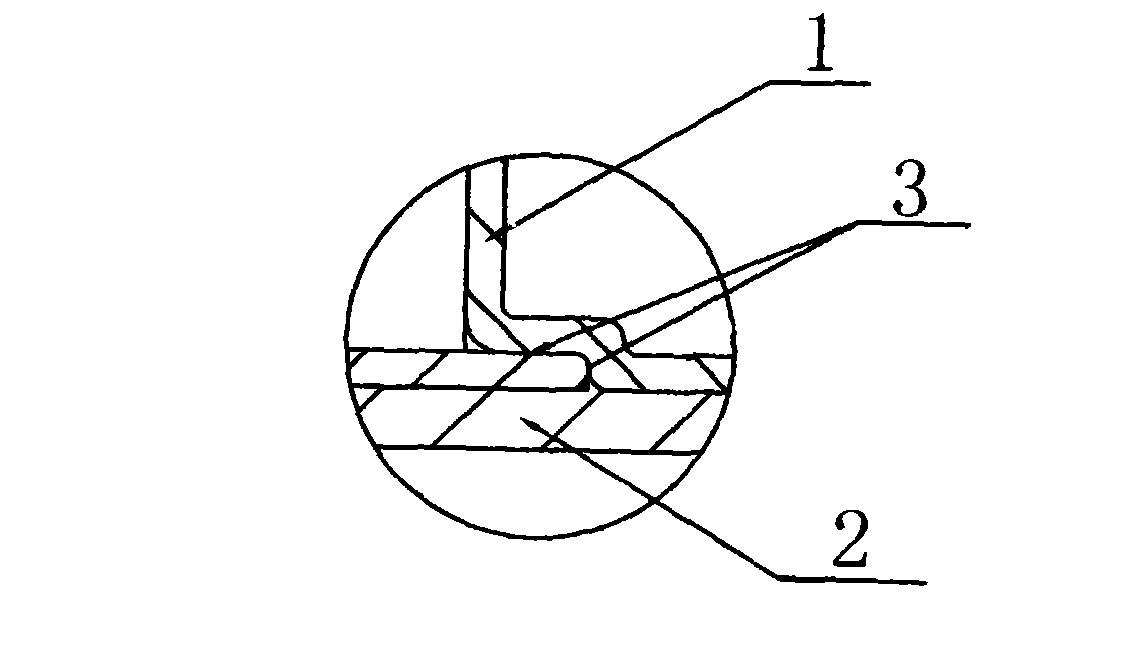

Anti-corrosion light high-efficiency finned type heat exchanger

The invention relates to an anti-corrosion light high-efficiency finned type heat exchanger, which comprises a plurality of laminated fins. A plurality of inner tubes are arranged on the fins; an insert grooves are arranged at joints of the fins and the inner tubes; and two adjacent fins are connected through the insert groove. In order to ensure the service life of the heat exchanger in a corrosive environment and improve corrosion resistance, the surface of each fin of the heat exchanger is subjected to ceramic and seal treatment to form a strong and compact anti-corrosion film, so that acid and alkali corrosion and oxidation are prevented. By the ceramic treatment technology, conditions are created for using light metal with low corrosion resistance. The anti-corrosion heat exchanger made of materials such as aluminum and an aluminum alloy, magnesium and a magnesium alloy, titanium and a titanium alloy and the like is realized. The close fit among the fins, and the close fit among the fins and the inner tubes are realized, a gap does not exist and a soldering process can be saved. Innovative designs are adopted, so the product has the advantages of high cost performance, good economic benefit, energy conservation and emission reduction, low manufacturing cost and easy marketing.

Owner:AIRSYS REFRIGERATION ENG TECH BEIJING

Gas-insulated switch cabinet, switch cabinet gas box and heat transfer system of gas box

InactiveCN106253102AAffect securityGuaranteed thermal conductivitySubstation/switching arrangement cooling/ventilationEngineeringHeat pipe

The invention provides a gas-insulated switch cabinet, a switch cabinet gas box and a heat transfer system of the gas box. The switch cabinet gas box comprises a heat pipe, wherein one end of the heat pipe is used for absorbing heat to form a hot end, a heat absorber is arranged at the hot end of the heat pipe, the heat absorber is close to an electrical component while the heat absorber is maintained a corresponding insulation distance with the electrical component so as to absorb heat generated by the electrical component to the greatest extent, the other end of the heat pipe is fixed on one side of a sealing plate so as to transfer the heat to the sealing plate to form a cold end, a heat dissipation device is arranged at the other end of the sealing plate, the cold end of the heat pipe and the heat dissipation device are correspondingly arranged at two sides of the sealing plate, and the gas box also comprises a fixing structure used for fixing the position of the cold end of the heat pipe. With the gas-insulated switch cabinet, the gas box thereof and the heat transfer system, provided by the invention, the heat generated by the electrical component can be rapidly transferred out of a box body.

Owner:XUJI GRP +2

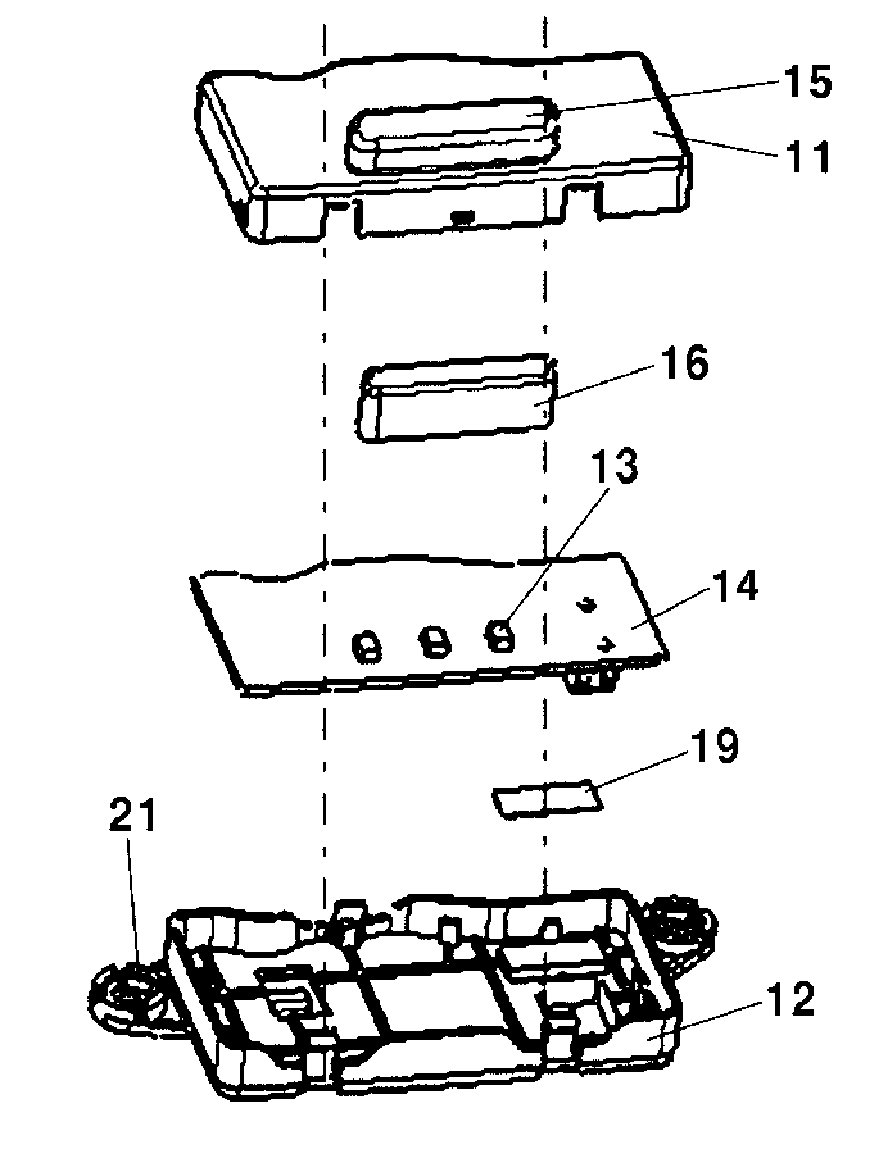

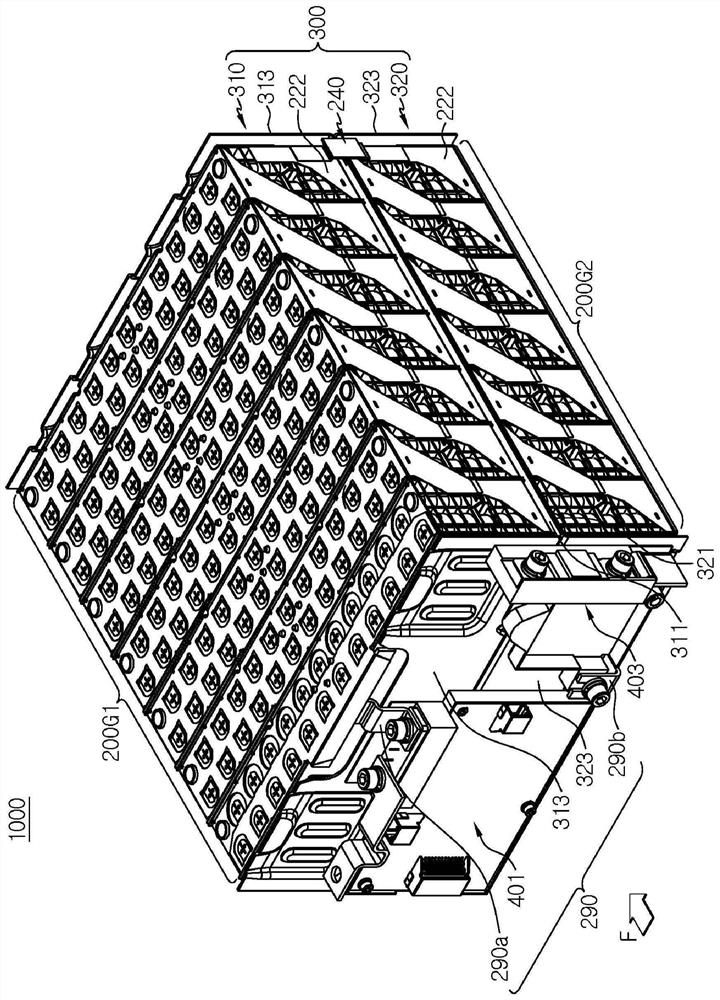

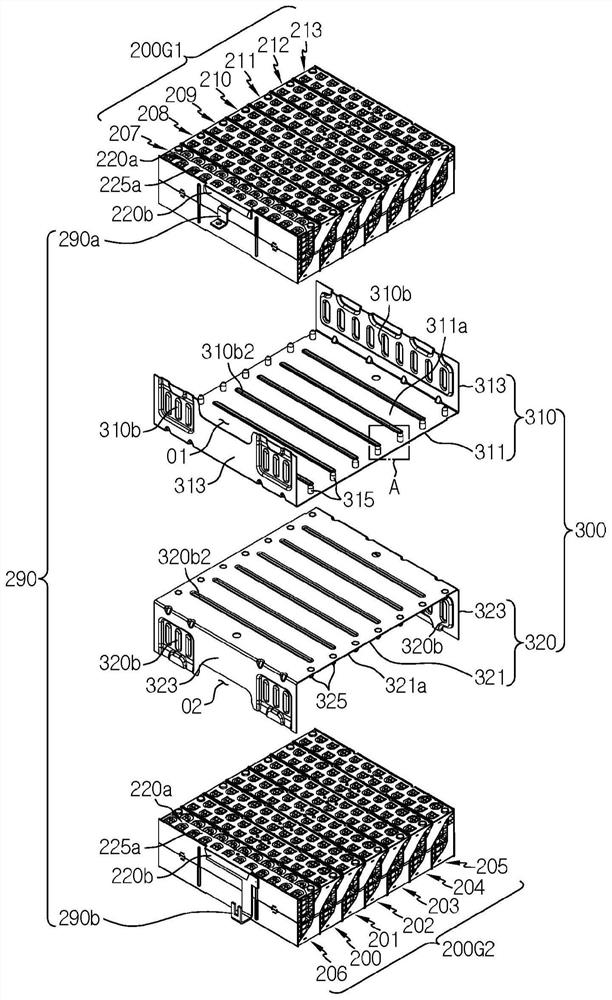

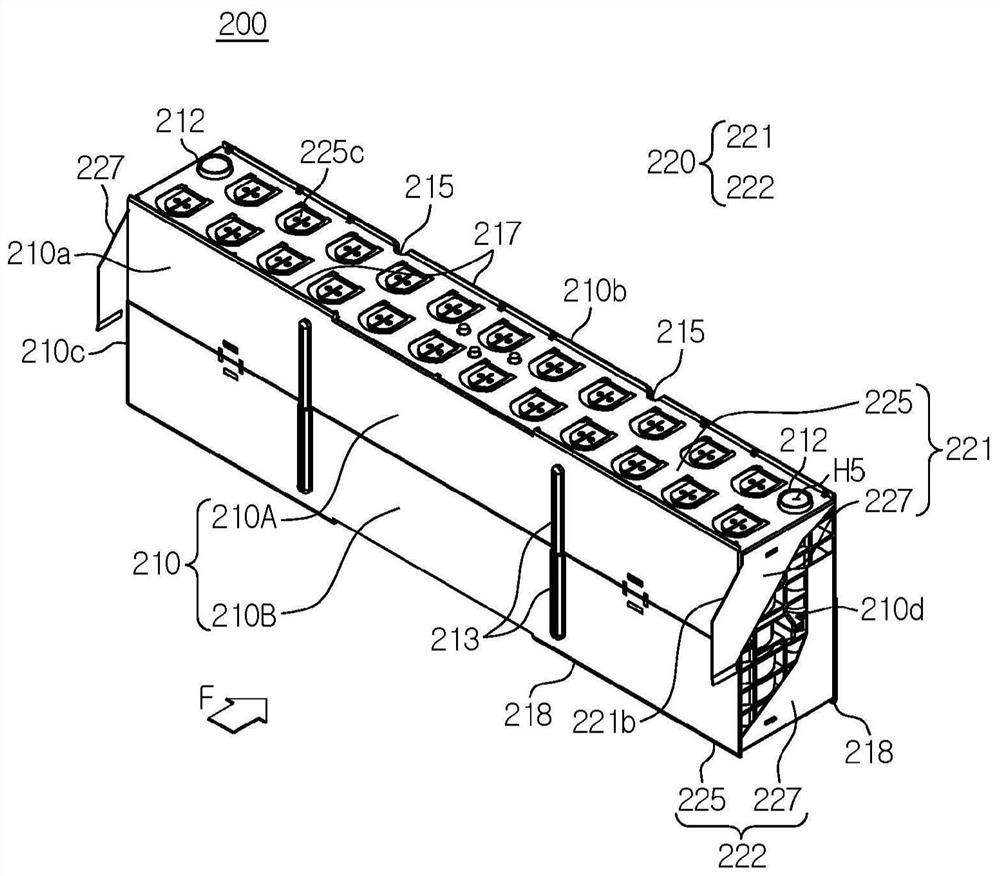

Battery pack comprising mounting structure

ActiveCN111630683AReduce manufacturing costEffective protectionCurrent conducting connectionsBattery isolationHigh energyStructural engineering

Owner:LG ENERGY SOLUTION LTD

A loop heat pipe geothermal mining system with adjustable working fluid circulation flow

ActiveCN107144035BAchieve miningMaximize heat transfer efficiencyGeothermal energy generationGeothermal collectorsThermal insulationEvaporation

The invention discloses a loop heat pipe type terrestrial heat exploitation system with adjustable and controllable working medium circular flow. The loop heat pipe type terrestrial heat exploitation system comprises a casing pipe type loop heat pipe, an earth surface heat exchanger and a liquid storage box. The earth surface heat exchanger and the liquid storage box are both located on the ground. The casing pipe type loop heat pipe comprises an evaporation section, a heat insulation section and a backflow section. The evaporation section is located in a high temperature heat reservoir. The earth surface heat exchanger is provided with a condensation section, and the condensation section and the outside carry out heat exchange. A one-way valve or a steam pump is arranged between the heat insulation section and the condensation section. A one-way throttle valve is arranged between the liquid storage box and the backflow section. The evaporation section, the heat insulation section, the condensation section, the liquid storage box and the backflow section are communicated in sequence end to end. Working medium fluid of the liquid storage box enters the evaporation section through the backflow section, and the liquid working medium fluid entering the evaporation section generates film boiling after absorbing heat. According to the loop heat pipe type terrestrial heat exploitation system, the working medium fluid of the liquid storage box passes through the backflow section, the liquid phase backflow mode and the boiling mode of the evaporation section are controlled, the effective filling factor of the terrestrial heat pipe can be adjusted in real time, and therefore terrestrial heat energy is stably and efficiently extracted.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

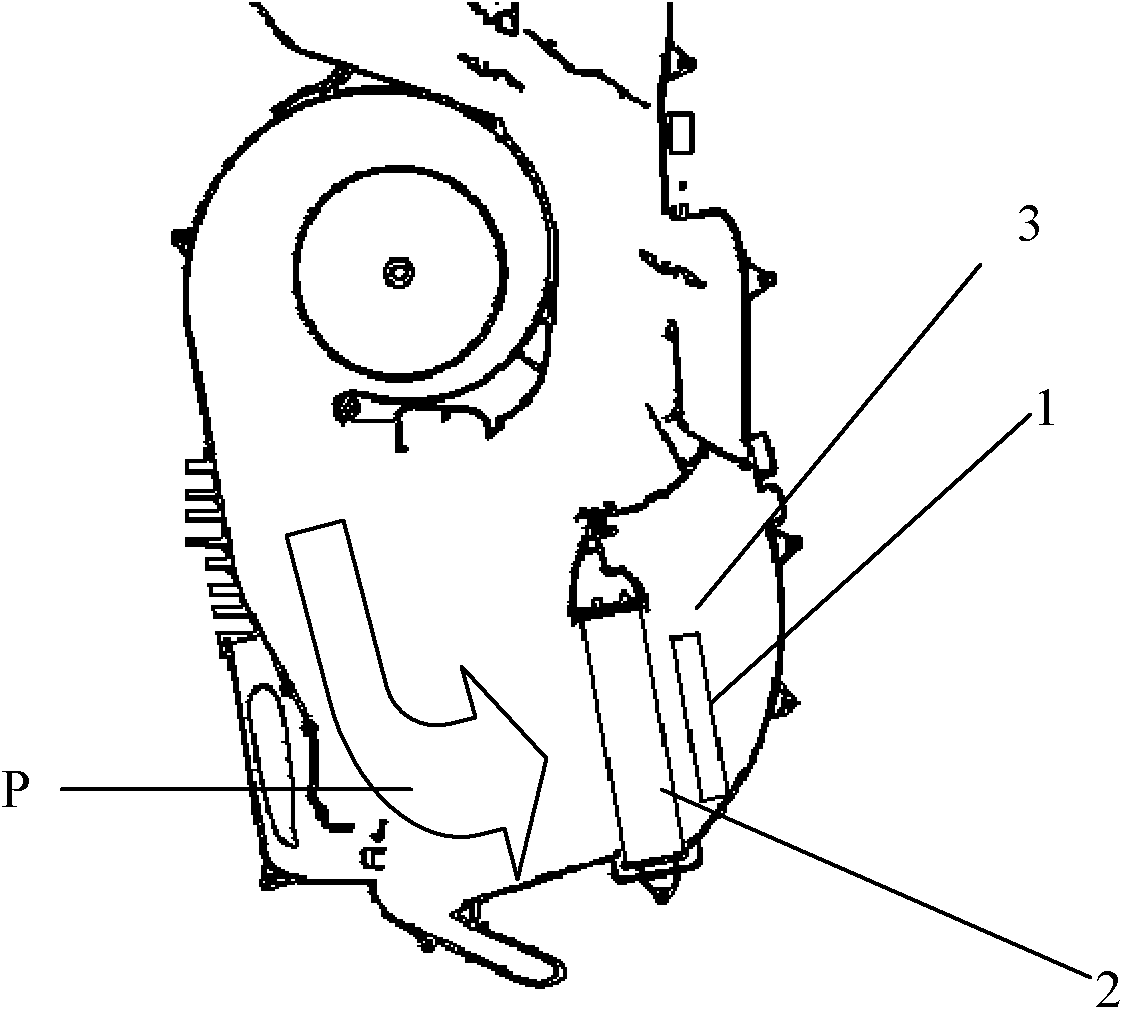

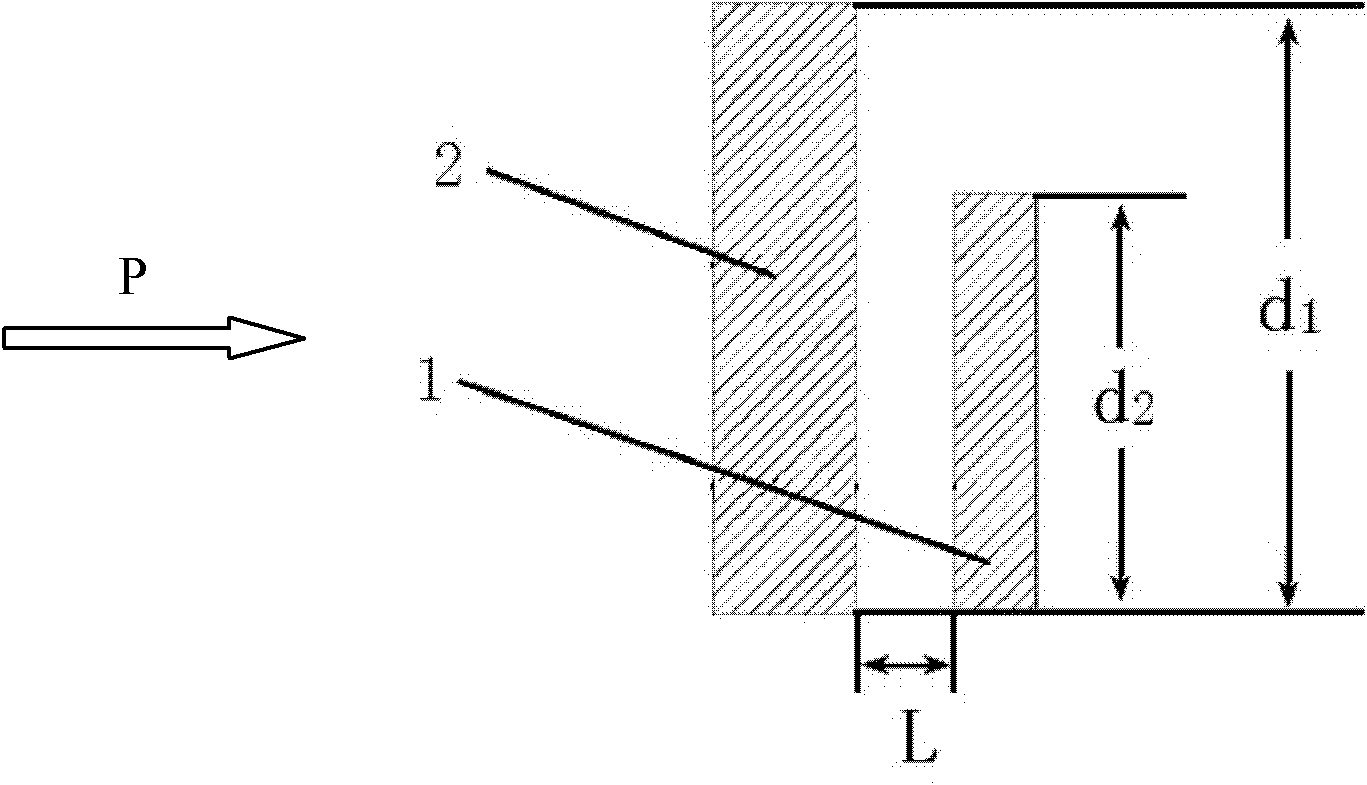

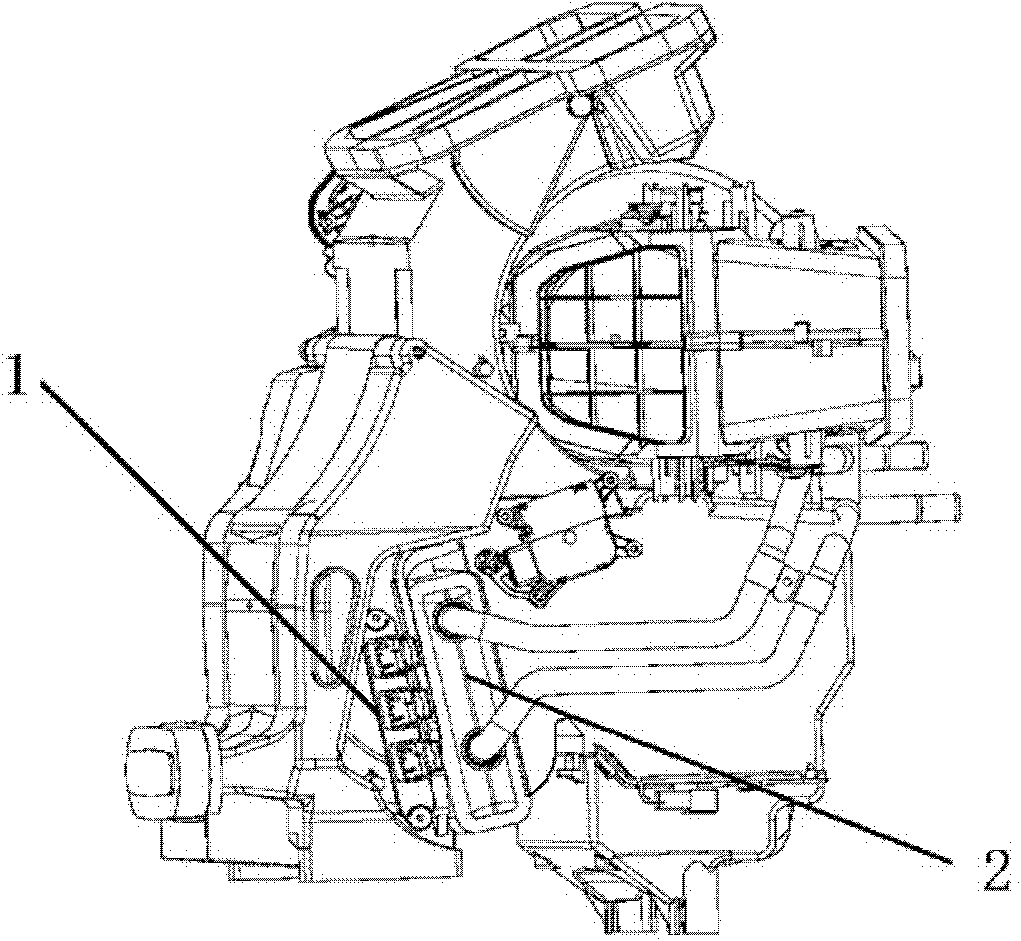

Automobile air conditioner and layout method thereof

InactiveCN102490571AMaximize heat transfer efficiencyLearn about featuresAir-treating devicesVehicle heating/cooling devicesAir volumeNew energy

The invention relates to a layout method of an automobile air conditioner, in particular to a layout method of an electric heater and a hot air core in the automobile air conditioner. The invention further relates to the automobile air conditioner manufactured according to the layout method thereof, and particularly relates to an automobile air conditioner in the field of new energy resources. The layout method of the automobile air conditioner includes layout of the electric heater and the hot air core, and is characterized in that both the electric heater and the hot air core are arranged in a main airflow area in an air conditioner box and are perpendicular to an airflow direction, sizes of the hot air core and the electric heater meet the formula: d2 / d2>=2 / 3, wherein d1 is the height of the cross section of the hot air core, and d2 is the height of the cross section of the electric heater. The air conditioner is manufactured according to the layout method. Technical problems that heat exchange efficiency of an electric heater and a hot air core of the prior art is low, and air volume loss of an air conditioner is high due to air pressure reduction are solved.

Owner:SHANGHAI BEHR THERMAL SYST

Bidirectional phase equilibrium heat exchanger, air conditioner and heat pump water heater

ActiveCN103216975AImprove heat transfer efficiencyMaximize heat transfer efficiencyEvaporators/condensersEvaporationEngineering

The invention provides a bidirectional phase equilibrium heat exchanger, comprising a fin group, a first heat exchange tube, a second heat exchange tube, a first inlet-outlet tube and a second inlet-outlet tube, wherein the first heat exchange tube and the second heat exchange tube are inserted into the fin group, the first and second heat exchange tubes are respectively positioned in the first heat exchange zone and the second heat exchange zone of the fin group, when in use, the heat exchange efficiency of the first heat exchange zone is higher than the heat exchange efficiency of the second heat exchange zone, the second heat exchange tube is provided with a first end and a second end which are respectively connected with the first and second inlet-outlet tubes, the first end and the second end are respectively used as an inlet end and an outlet end in the evaporation state, and are respectively used as an outlet end and an inlet end in the condensation state, and a flow resisting structure is arranged in a runner which leads to the second inlet-outlet tube from the second end of the second heat exchange tube. The bidirectional phase equilibrium heat exchanger can balance the fluid resistance of forward evaporation and reserve condensation, and realizes high-efficiency evaporation and high-efficiency condensation, so that the utilization rate of the heat exchanger is improved. The invention also provides an air conditioner and a heat pump water heater adopting the bidirectional phase equilibrium heat exchanger.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

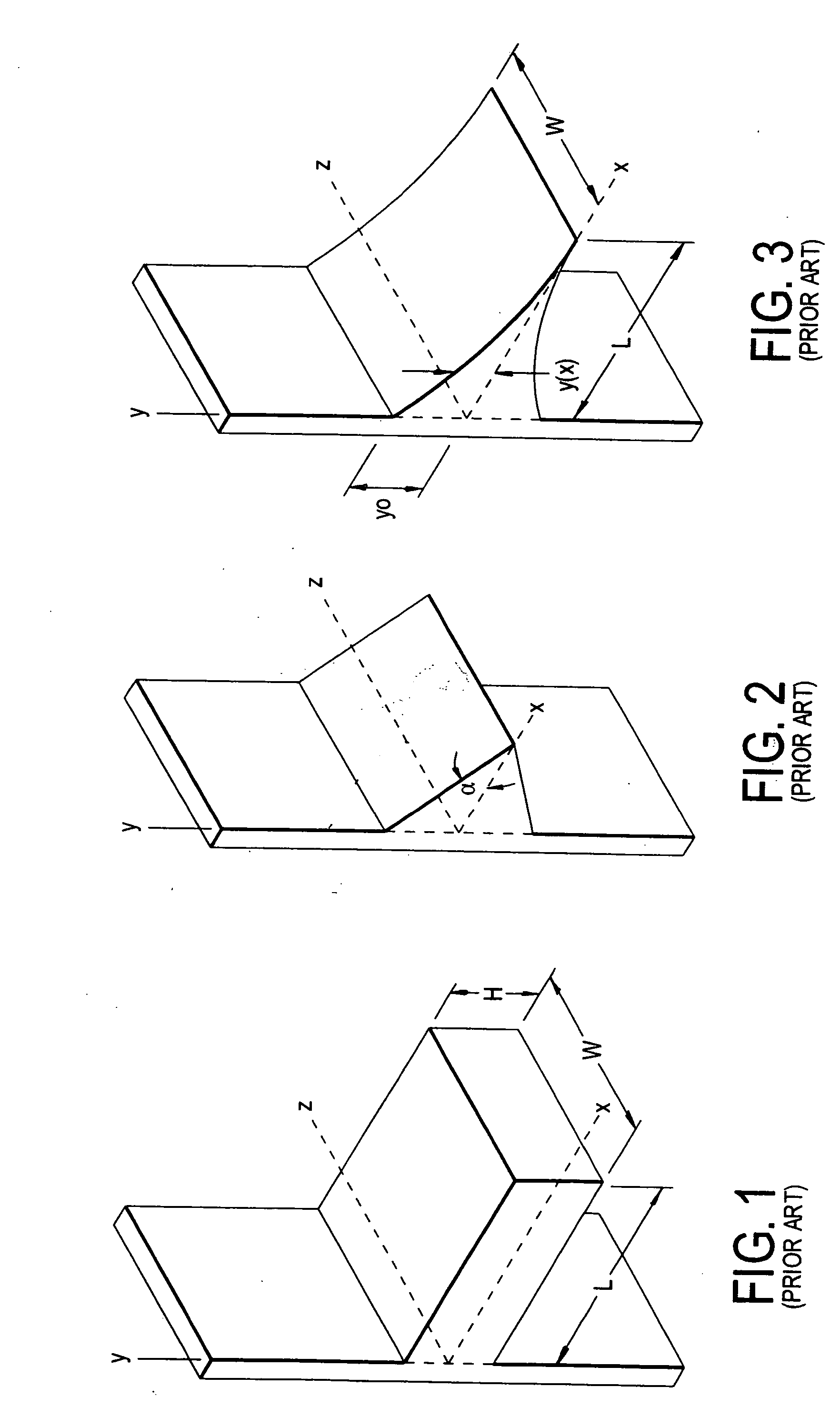

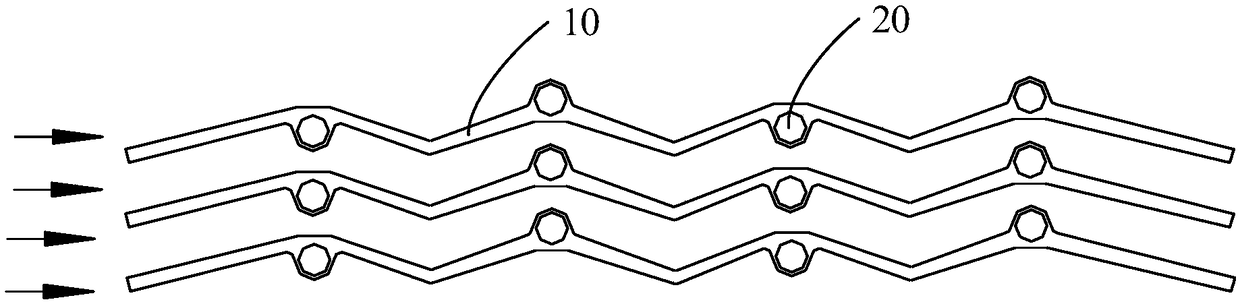

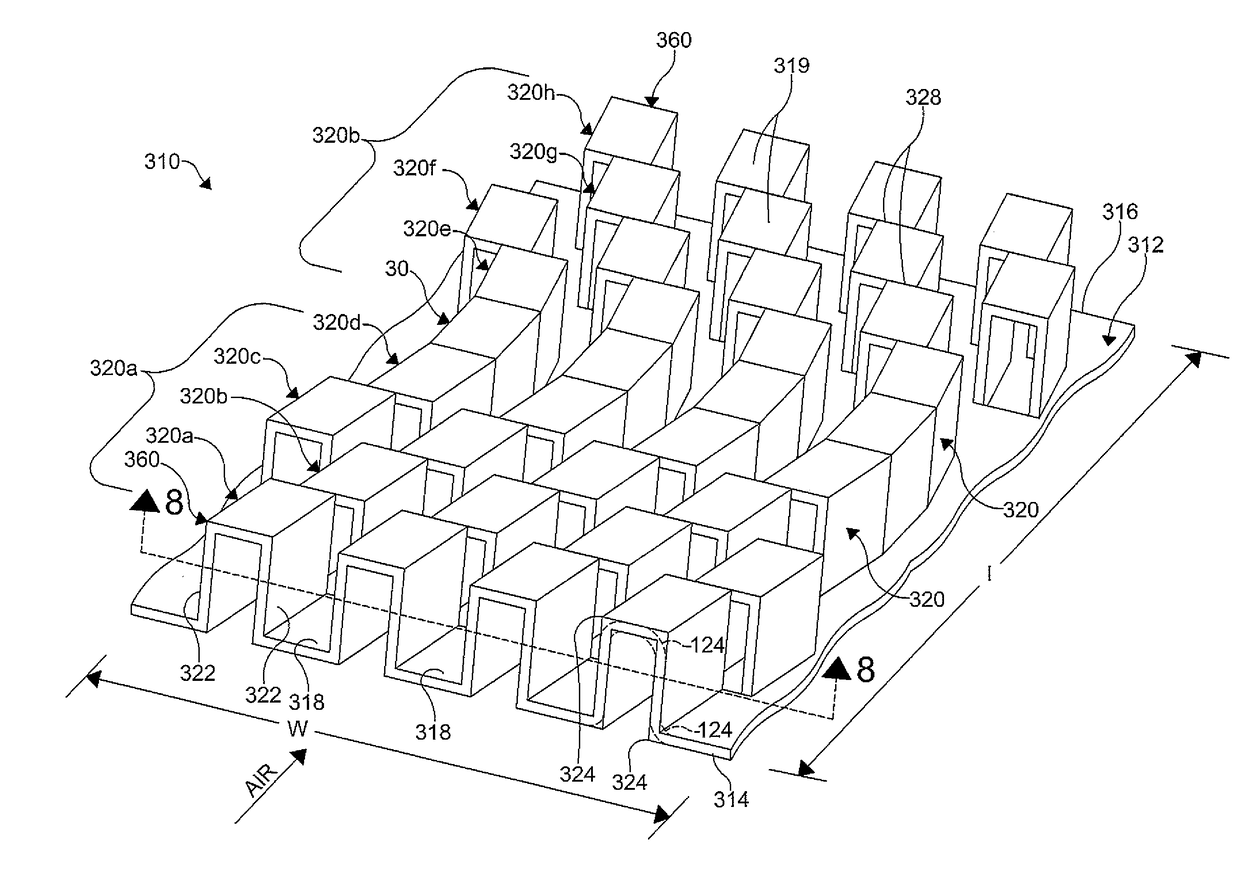

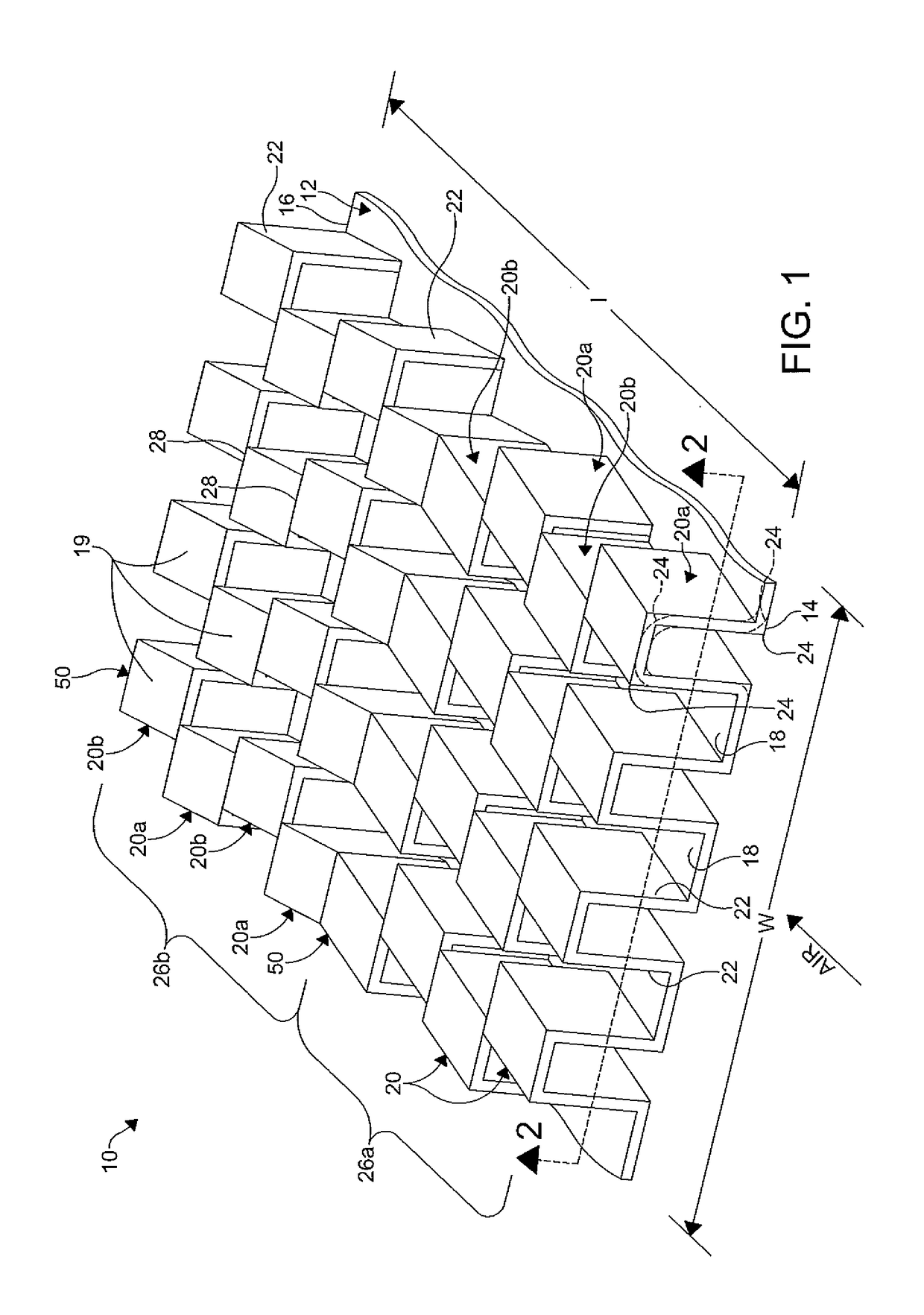

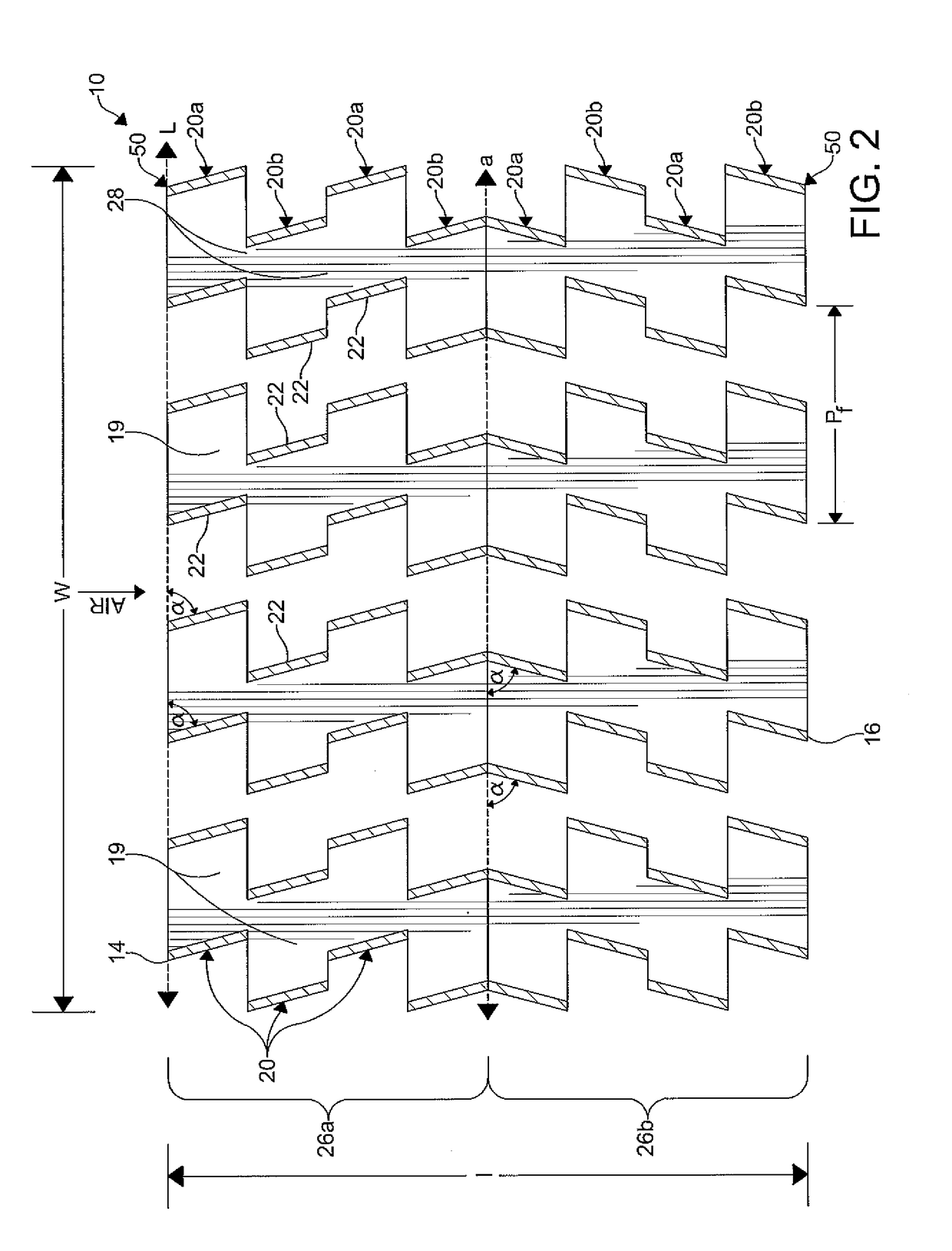

Fin for heat exchanger

ActiveUS20170198983A1Maximize heat transfer efficiencyMaintain structural integrityLaminated elementsTubular elementsEngineeringMechanical engineering

A fin for a heat exchanger includes a member and a first row formed in the member. The first row having a plurality of valley sections alternating with a plurality of crest sections. A plurality of walls is interposed between and integrally joins the plurality of valley sections and the plurality of crest sections. At least one of the plurality of walls of the first row is angled with respect to a lateral axis of the member. A second row is formed in the member, the second row having a plurality of valley sections alternating with a plurality of crest sections and a plurality of walls interposed between and integrally joining the plurality of valley sections to the plurality of crest sections.

Owner:HANON SYST

Feed-back control system for heat exchanger with natural shedding frequency

InactiveUS7293605B2Maximize heat transfer efficiencyForce measurement by measuring frquency variationsAir-treating devicesResonanceControl system

The invention relates with the feed-back control system of a heat exchanger by use of the flow resonance phenomenon which maximizes the heat transfer efficiency by generating the flow disturbances of a heat transfer medium. If a heat transfer medium is periodically stimulated at the characteristic frequency of a heat exchanger, the flow resonance frequency, which is dependent upon the flow conditions of heat transfer medium and the geometries of a heat exchanger, the disturbances of heat transfer medium is increased to the extent that heat transfer is dramatically high. This system is composed of the detecting part for the detection of flow characteristics, the processing part for the determination of flow resonance frequency, and the stimulating part which excites a heat transfer medium at the calculated flow resonance frequency.

Owner:BSTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com