Gas-insulated switch cabinet, switch cabinet gas box and heat transfer system of gas box

A technology of heat transfer system and cabinet air box, which is applied in the field of heat transfer system, can solve the problems of heavy overall weight, low heat dissipation efficiency, and limited size of heat dissipation, and achieve the effect of ensuring sealing performance and avoiding insulation failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

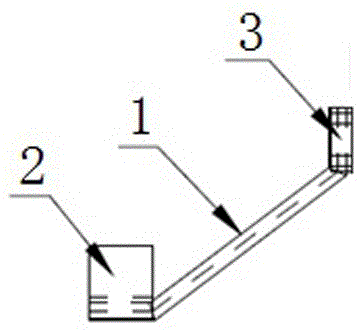

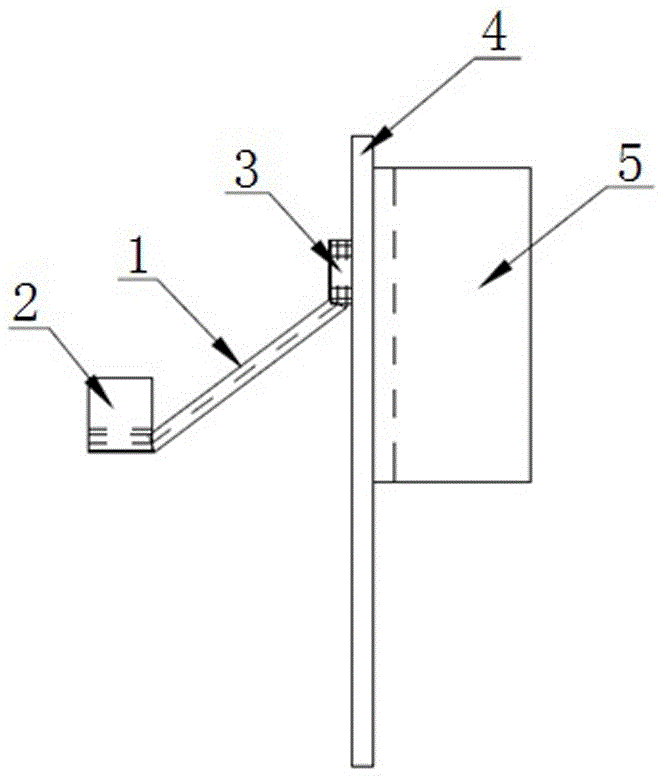

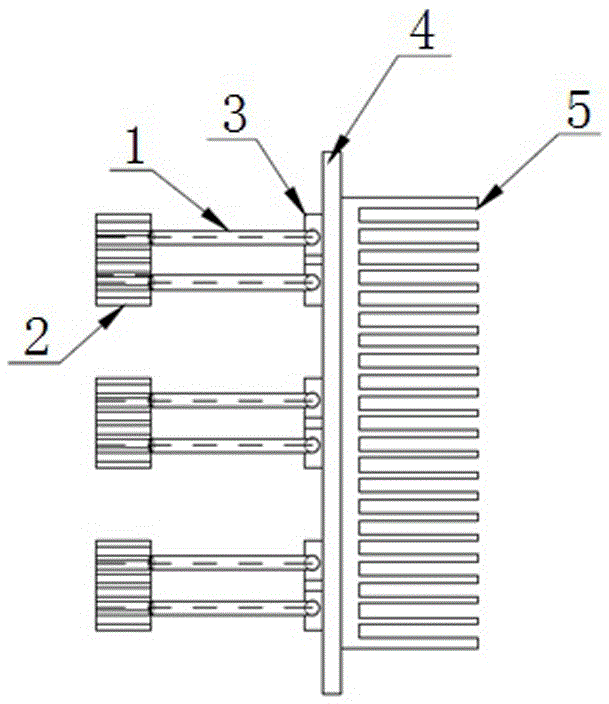

[0013] The specific embodiment of the heat transfer system of the gas box of the present invention, such as Figure 1 to Figure 3 As shown, wherein, 1 is a heat pipe, 2 is a heat sink, 3 is a fixed block, 4 is a sealed aluminum plate, and 5 is a radiator.

[0014] The left end of the heat pipe 1 shown in the figure is the hot end of the heat pipe, the heat absorber 2 is installed on the hot end, and the other end is the cold end of the heat pipe. When in use, under the premise of satisfying the insulation distance, the heat absorber 2 should be as close as possible to the electrical components in the gas box of the gas insulated switchgear, so that the heat absorber 2 can quickly absorb the heat generated by the electrical components and the heat released by the electrical components Release as little as possible into the airbox. There are multiple hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com