Disc shape self-cleaning waste-water thermal energy recoverer

A heat recovery device and disc-type technology, applied in the direction of moving pipe heat exchangers, heat exchanger types, indirect heat exchangers, etc., can solve the problems of difficult removal, increased use costs, and reduced heat exchange efficiency of heat exchangers And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

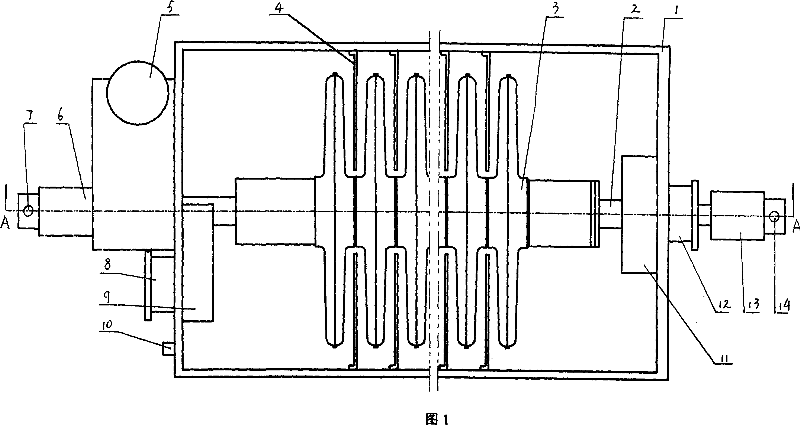

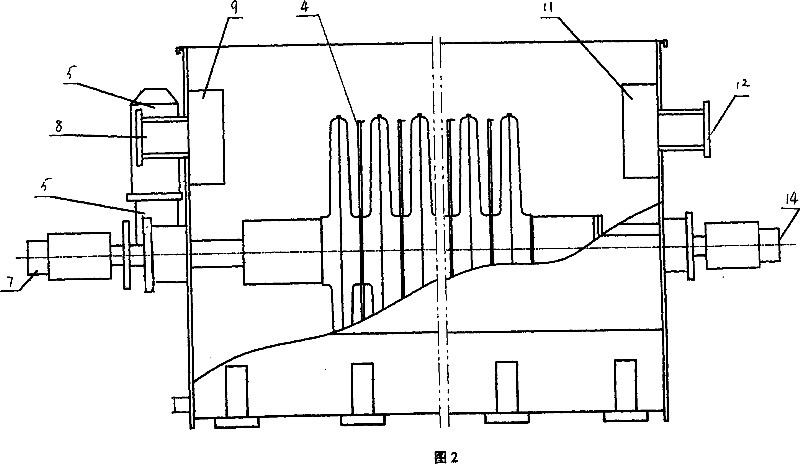

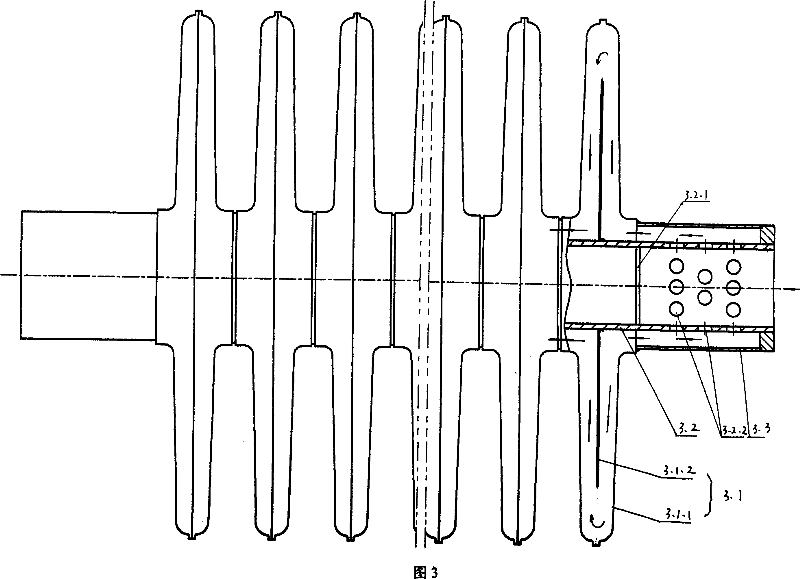

[0015] Referring to Figures 1-2, the disc-type self-cleaning waste water heat recovery device of the present invention is mainly composed of a box body 1, a main shaft 2, a heat exchange plate assembly 3, a deflector plate 4, a power unit 5 and a rotary joint 6.

[0016] The left wall of the box 1 is provided with a waste water inlet 12, and the right side of the waste water inlet 12 is provided with a liquid baffle 11, and the liquid baffle 11 is connected with the inner wall of the left wall of the box 1 to prevent direct impact of waste water The heat exchange plate assembly 3 in the box; the right wall panel of the box body 1 is provided with a waste water outlet 8, and the left side of the waste water outlet 8 is provided with a liquid level control panel 9, and the liquid level control panel 9 is connected with the right wall panel of the box body 1 The inner walls are connected to control the liquid level of the waste water in the tank; the inside of the front and rear w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com