Anti-corrosion light high-efficiency finned type heat exchanger

A heat exchanger and high-efficiency technology, applied in the field of heat exchangers, can solve the problems of equipment requiring welding and welding processes, constraints, etc., and achieve the effects of low manufacturing cost, high product cost performance and good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

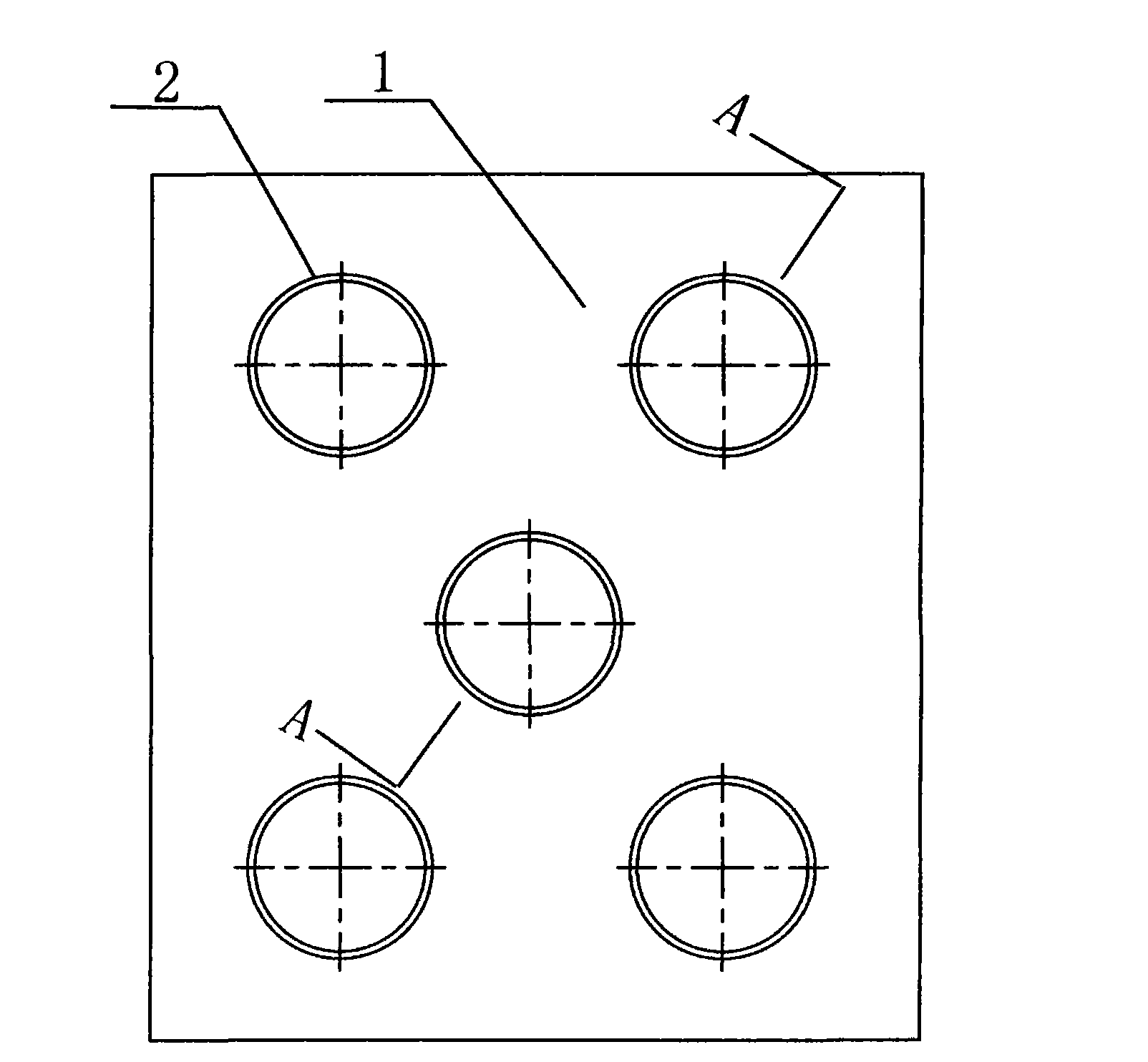

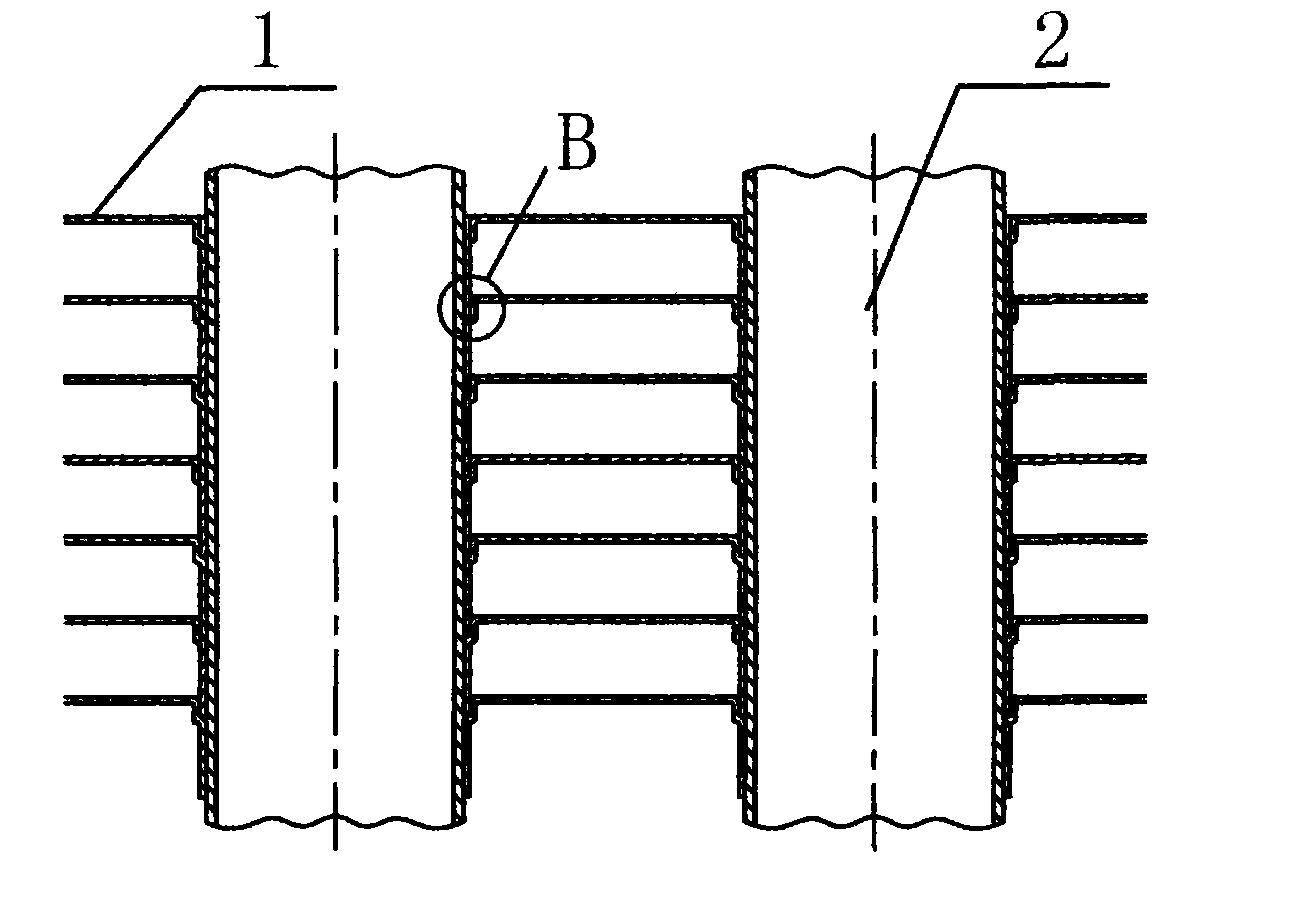

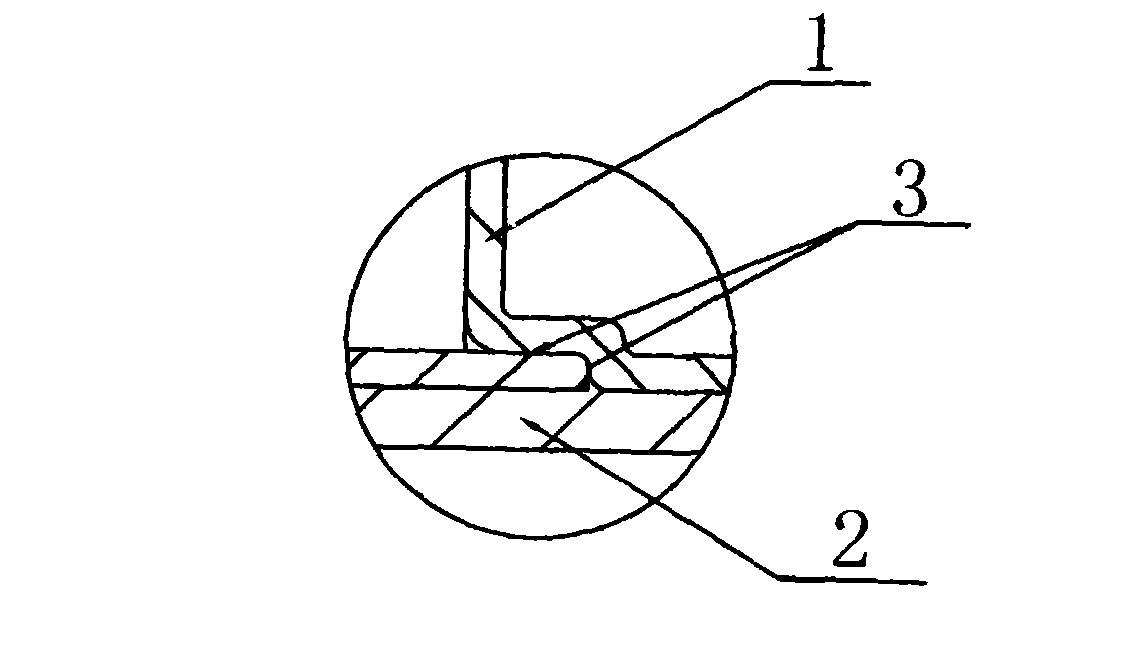

[0018] like Figure 1-3 As shown, the anti-corrosion light-weight and high-efficiency finned heat exchanger includes several laminated fins 1, and several inner tubes 2 are installed on the fins 1, and there is a The slot 3 is used to connect two adjacent fins 1 through the slot 3 .

[0019] In order to ensure the service life of the heat exchanger in the corrosive environment and improve the corrosion resistance, ceramicization and sealing treatment are performed on the surface of the heat exchanger fin 1 to form a strong and dense anti-corrosion film to prevent acid and alkali corrosion and oxidation.

[0020] Due to the adoption of ceramic treatment technology, conditions are created for the use of light metals with poor corrosion resistance. The invention makes it possible to manufacture anti-corrosion heat exchangers using materials such as aluminum and aluminum alloys, magnesium and magnesium alloys, titanium and titanium alloys. .

[0021] The invention adopts a new d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com