Cooling jacket for electric machines

A technology for cooling enclosures and cooling covers, which is applied in the direction of cooling/ventilation devices, casings/covers/supports, electromechanical devices, etc., and can solve problems such as cost and heat transfer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

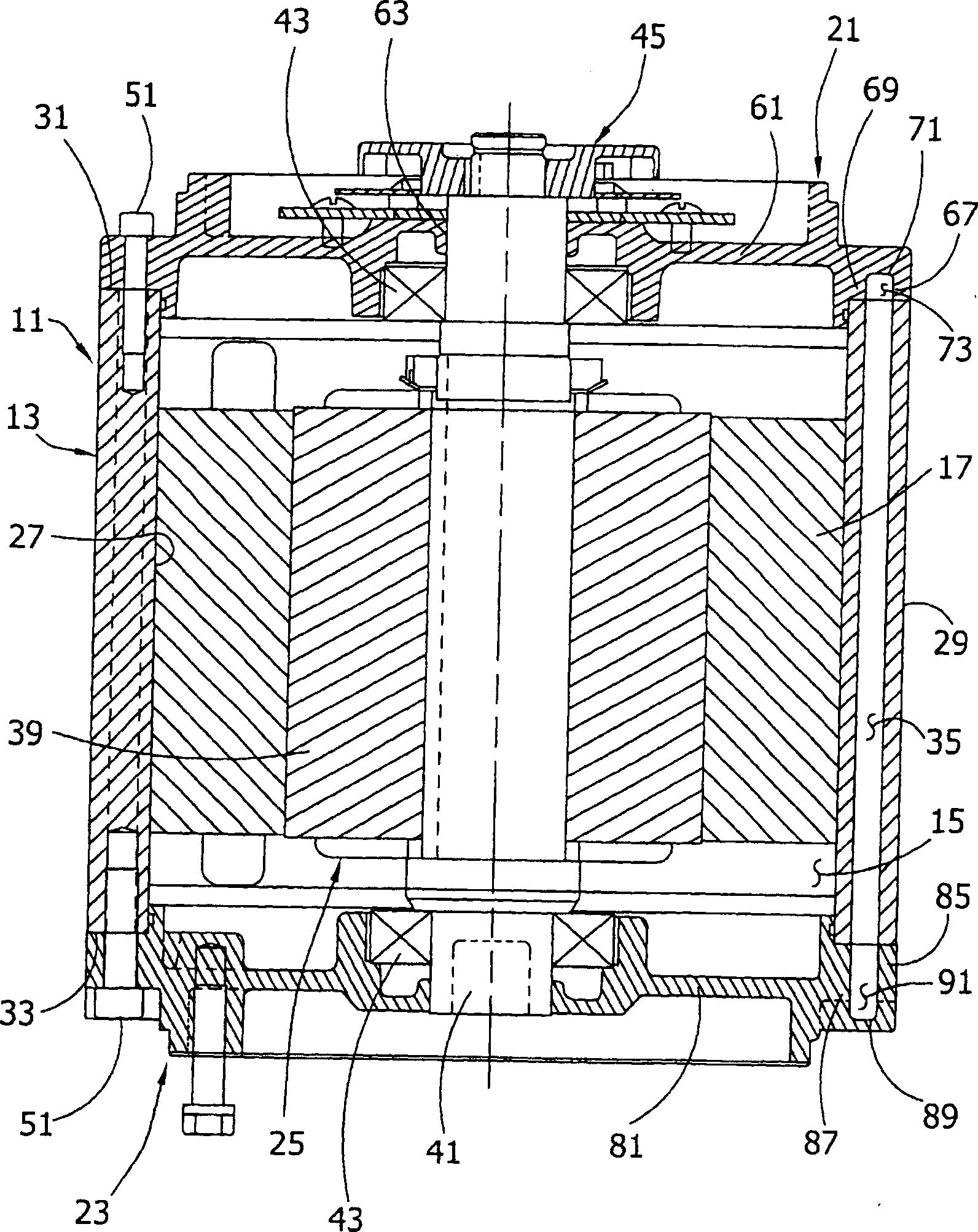

[0023] Referring now to the accompanying drawings in particular figure 1 , a cooling enclosure of the present invention is indicated by reference numeral 11 as a whole. The casing includes a casing body portion 13 defining a cavity 15 for receiving a stator 17 of an electric motor, and first and second body portions generally indicated by 21 and 23 respectively and connected to opposite ends of the body portion. end cap. (The term "motor" as used herein refers to a machine that works as an electric motor or generator.) As an example, the cooling enclosure 11 may be used to cool an electric motor of an electric vehicle, where heat transfer efficiency and weight are important factors. A conventional rotor and shaft assembly, indicated generally at 25 , is rotatable within stator 17 .

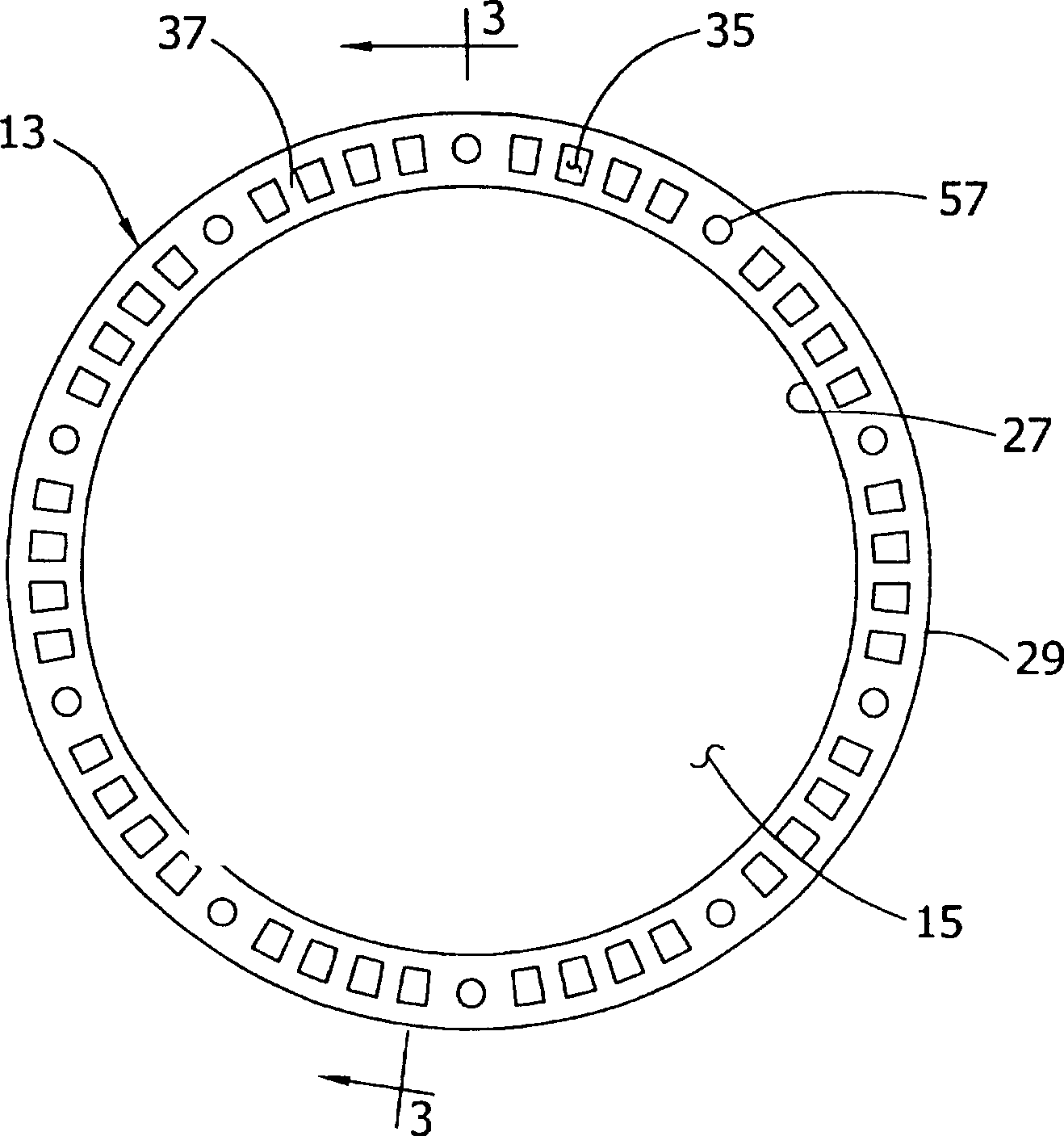

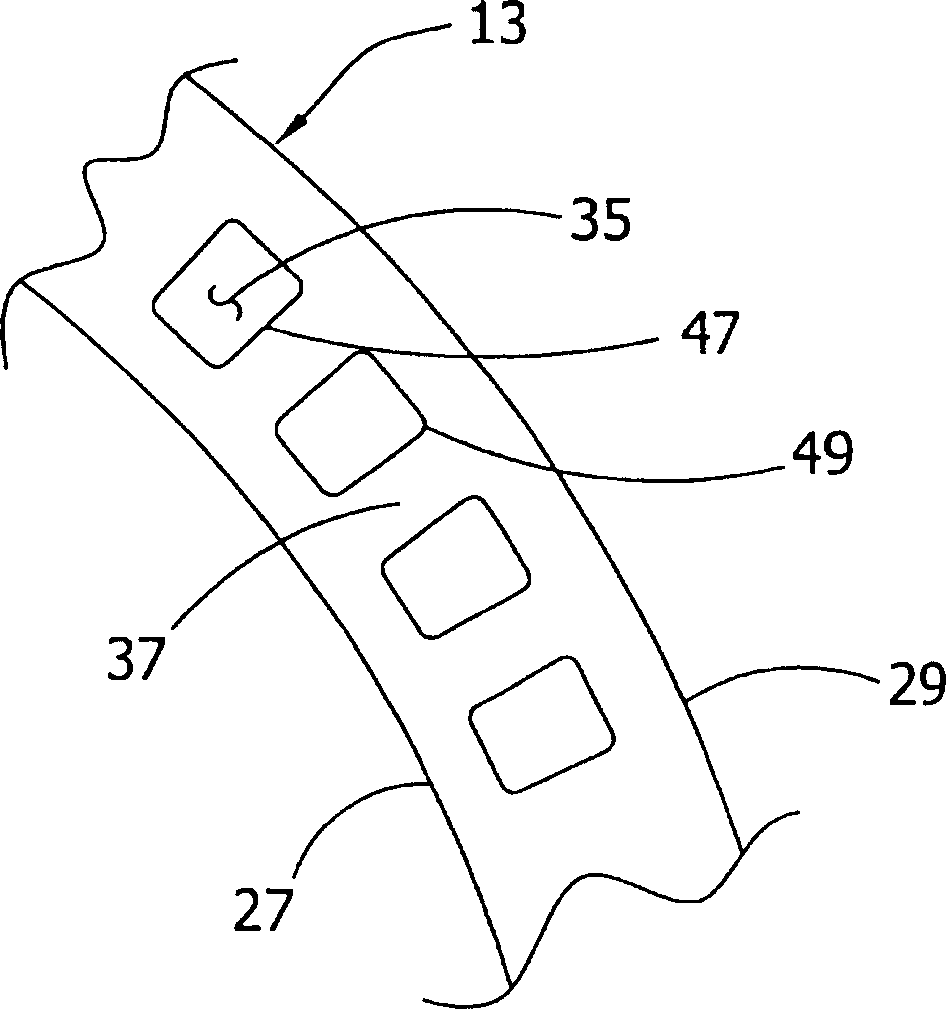

[0024] refer to figure 1 To 3, the housing body portion 13 is made of a thermally conductive material and has coaxial inner and outer surfaces 27, 29, and annular end faces 31 and 33 at opposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com