A mining method for medium-thick ore body

A mining method and technology of thick ore body, applied in surface mining, underground mining, special mining, etc., can solve the problems of long horizontal conveying distance, affecting mine production, large filling line, etc. The effect of ore dilution rate and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

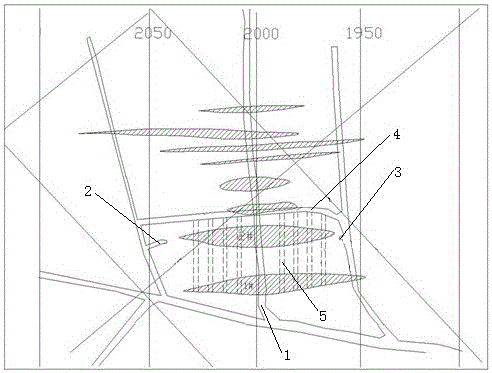

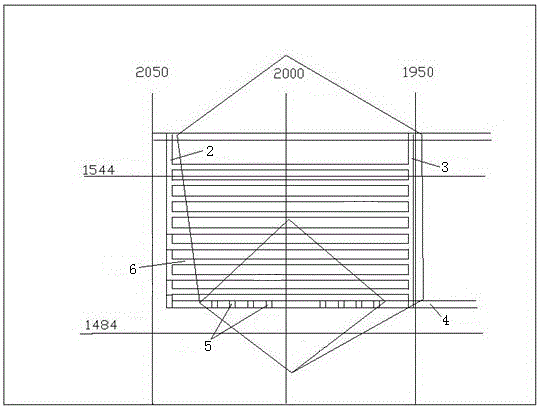

[0027] Such as Figure 1-2 As shown, Xiaotieshan Mine of Baiyin Nonferrous Metals Group Co., Ltd. arranges exploration lines 1950 lines, 2000 lines, and 2050 lines at a certain distance in the direction perpendicular to the length of the 2# ore body at the level of elevation line 1484 (seventh middle section) Excavate the prospecting roadway 1 along the exploration line until the entire 1# ore body and 2# ore body are broken down; from the level of 1484 above sea level (seventh middle section) and near the prospecting roadway 1 of the 2050 line, a 2×2m From the patio to the altitude line 1544 level (sixth middle section), it is used as a channel for ventilation, pedestrians and materials to go up and down, which is called the West Mixed Well 2; from the altitude line 1484 level, near the 1950 line prospecting roadway 1, a 2×2m well is excavated. From the patio to the elevation line 1544 level (sixth middle section), it is used as a channel for ventilation, pedestrians and mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com