Method for safely and efficiently recovering panel pillars by using sublevel open-stope subsequent filling method

An efficient and safe technology, applied in the direction of filling, safety devices, earthwork drilling, etc., can solve the problems of large amount of mining engineering, difficulty in ensuring safety, long mining cycle, etc., and achieve high mechanization, large production capacity, and improved recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

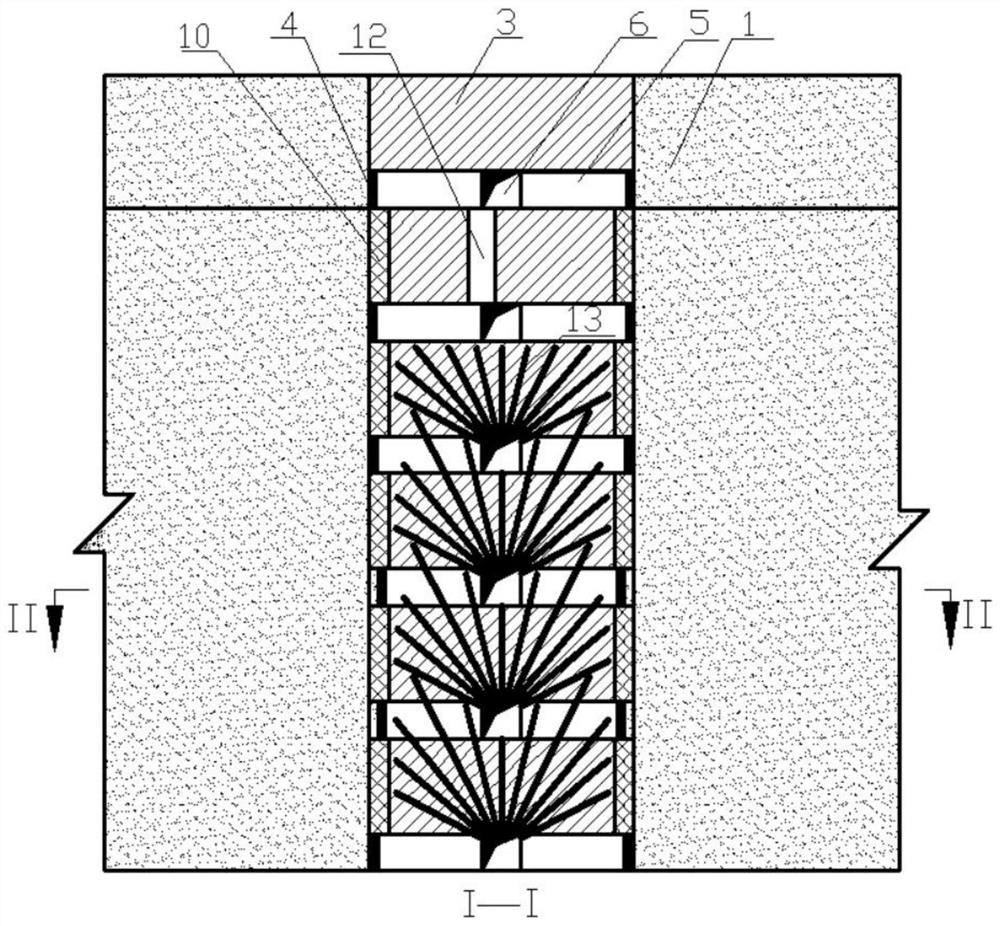

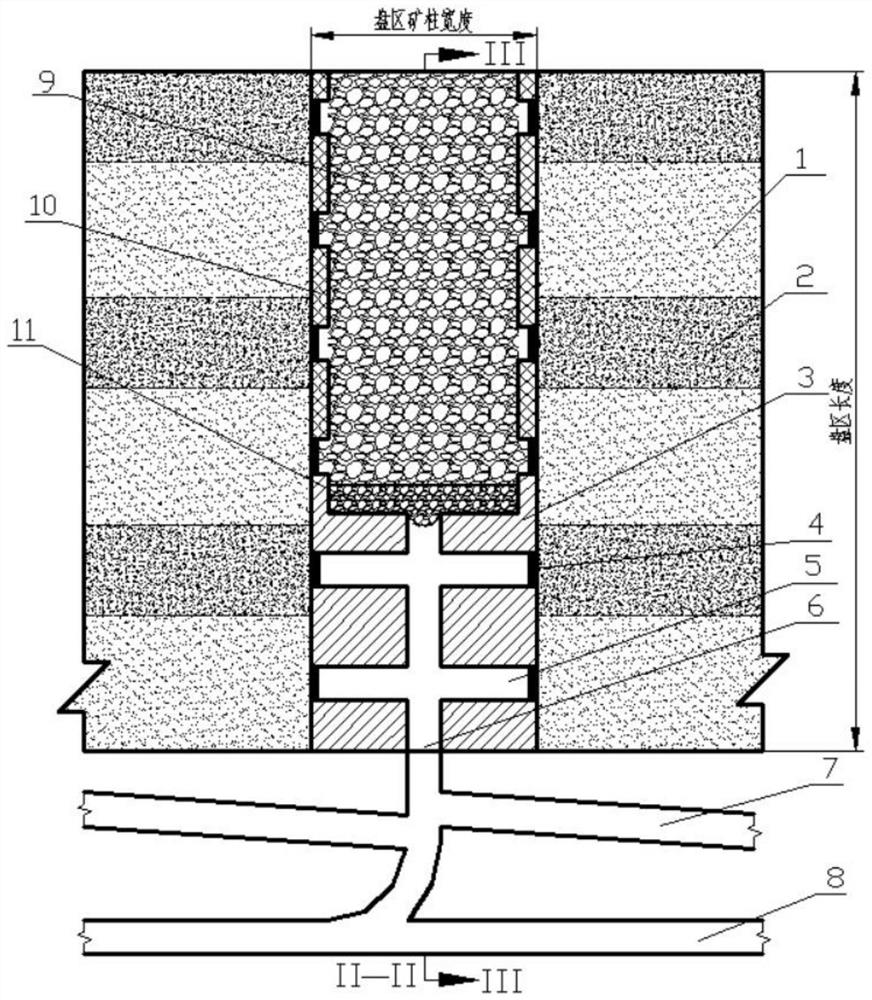

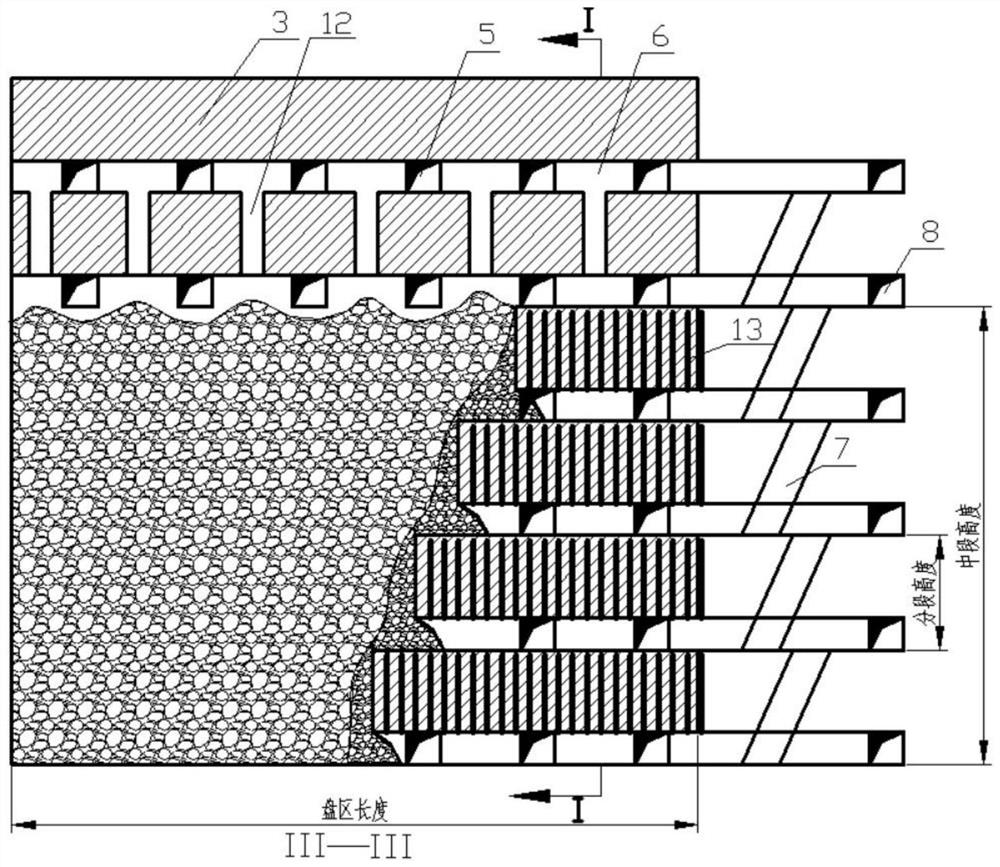

[0030] In order to better describe the present invention, a method for safely and efficiently recovering the inter-panel columns of the sectioned empty field and subsequent filling method of the present invention will be further described in detail in conjunction with the accompanying drawings.

[0031] The present invention is a method for safely and efficiently recovering the inter-panel inter-panel column of the segmented empty field and subsequent filling method. The two sides of the inter-panel inter-panel column 3 are composed of a non-cemented filling body 1 filled with waste rocks and a cemented filling body 2 filled with tailings. In the already mined stope, there are segmental rock drilling roadways 5 and segmental connecting roads 6 in the panel interval column 3, the segmental rock drilling roadway 5 is provided with filling retaining walls 4, and there is a stope slope outside the panel surrounding rock Road 7 is connected to each segment, segmental connecting road...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com