Hanging wall crushing gentle-inclined thick and large ore body filling mining method

A filling mining method and a technology of thick and large ore bodies, which are applied in the direction of filling, ground mining, mining equipment, etc., and can solve problems such as low safety, inability of large machinery and equipment to enter the stope, and low production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

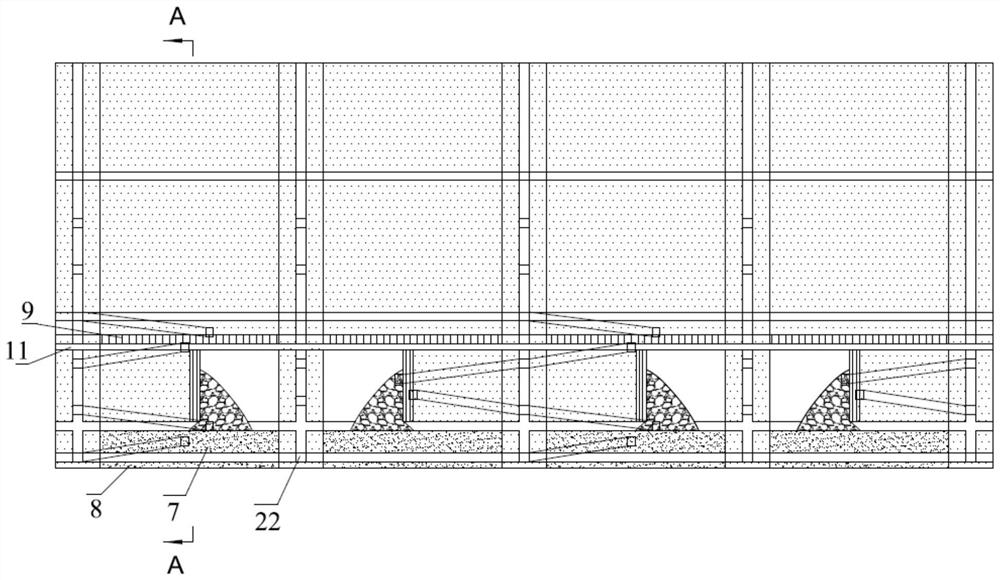

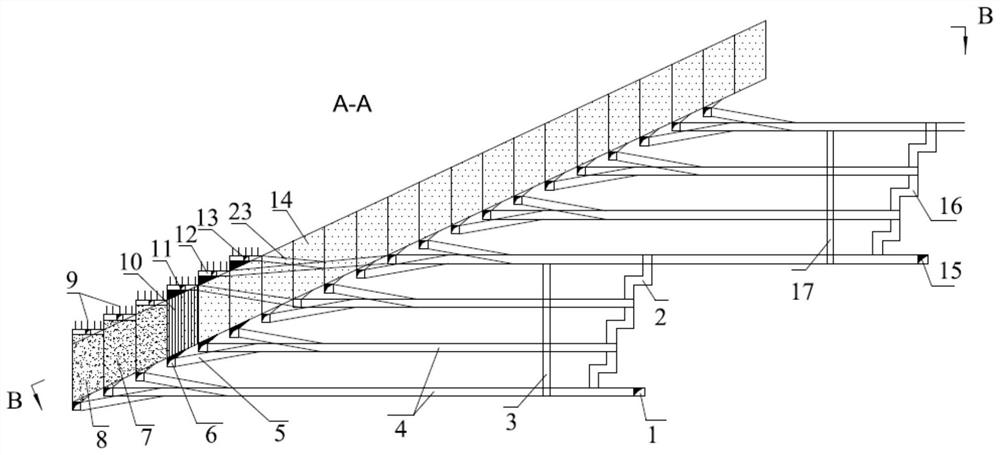

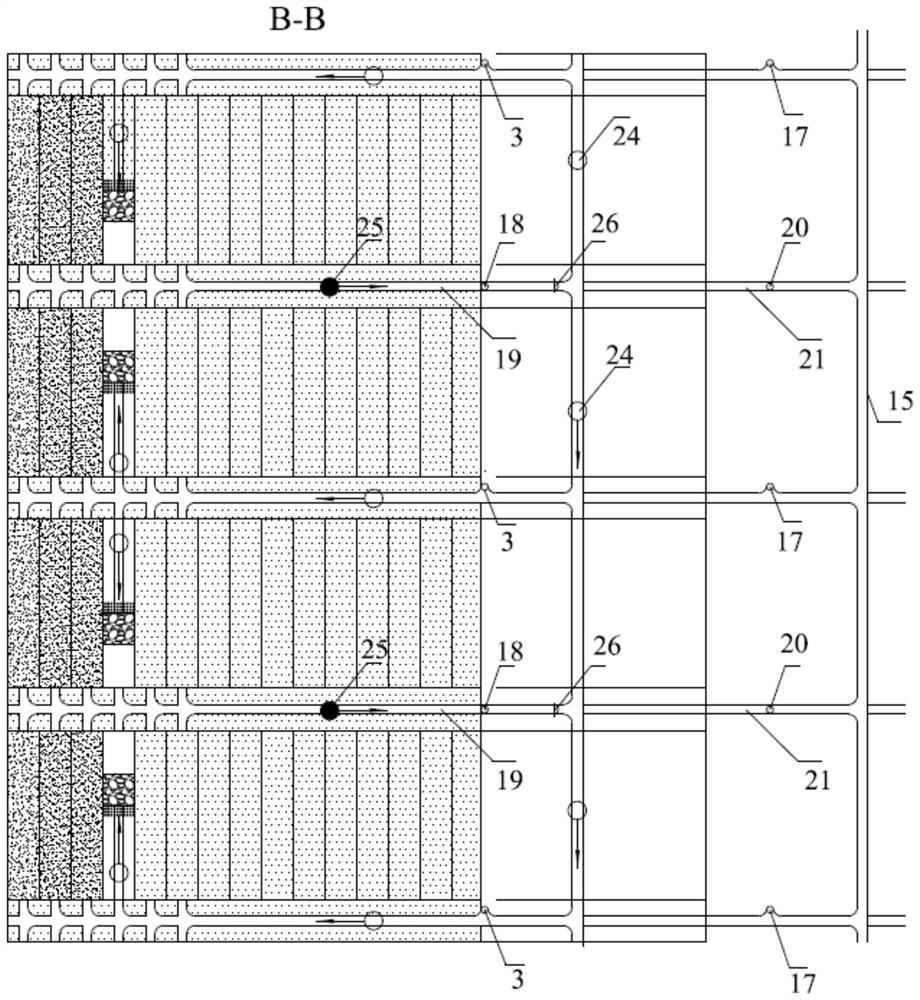

[0036]Such asfigure 1 ,figure 2 withimage 3As shown, the upper plate of the present invention is reduced to incline the thickness of the large mineral filling mining method, including the following steps:

[0037]Step 1) Turn along the ore body 14, 200m is divided into one panel, divided by the two acquisitions within each panel, and the length of the harvest area is 80m, and the column 22 is replaced between the two acquired regions in the panel. The urging inter-block 22 width is 20m, and there is a housing 22 between each of the disk regions, and the interlayer column 22 is 20m;

[0038]Step 2) Segment the ore body 14 in the vertical direction, divided into segments from the vertical direction, respectively, a divided segment, two mining segments, ..., N-taking subtragraph, stage height of 60m The segment height is 20m; three mine blocks are arranged in each segment, as a separate return unit, the mine block width is about 15m, and the length of the mine block is 80m;

[0039]Step 3) Arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com