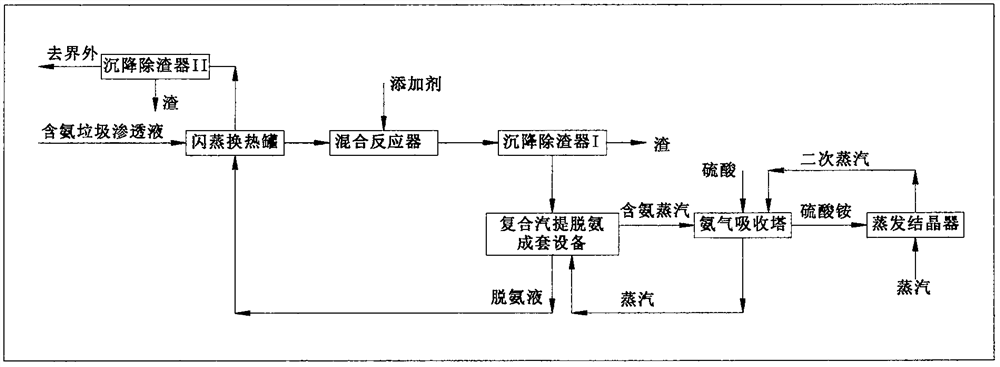

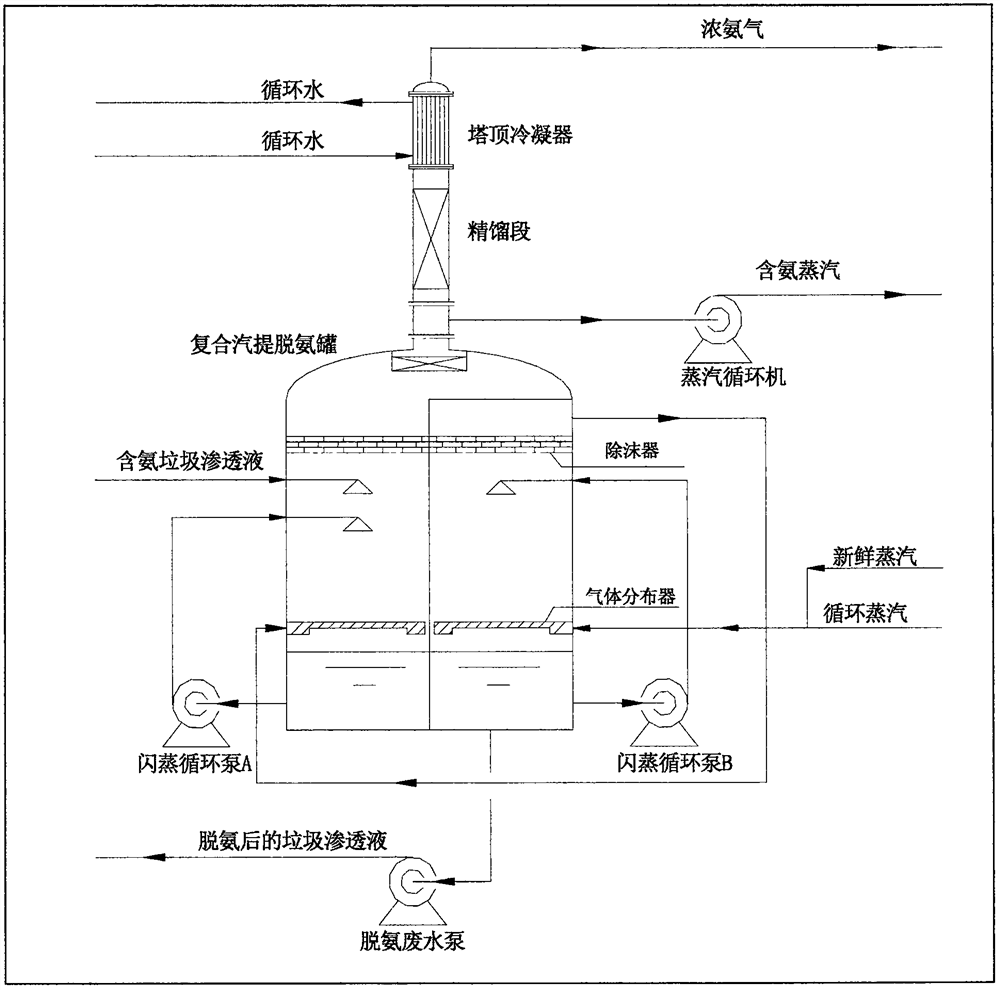

A kind of process method for removing ammonia and chromium from garbage permeate

A technology of waste permeate liquid and process method, which is applied in the field of deamination and chromium removal of waste permeate liquid, can solve the problems of affecting the mass transfer efficiency of the tower, easy blocking of the tower, consumption of precipitant, etc., so as to improve the sedimentation and chromium removal effect and work. Conditions are safe, the effect of reducing the time required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

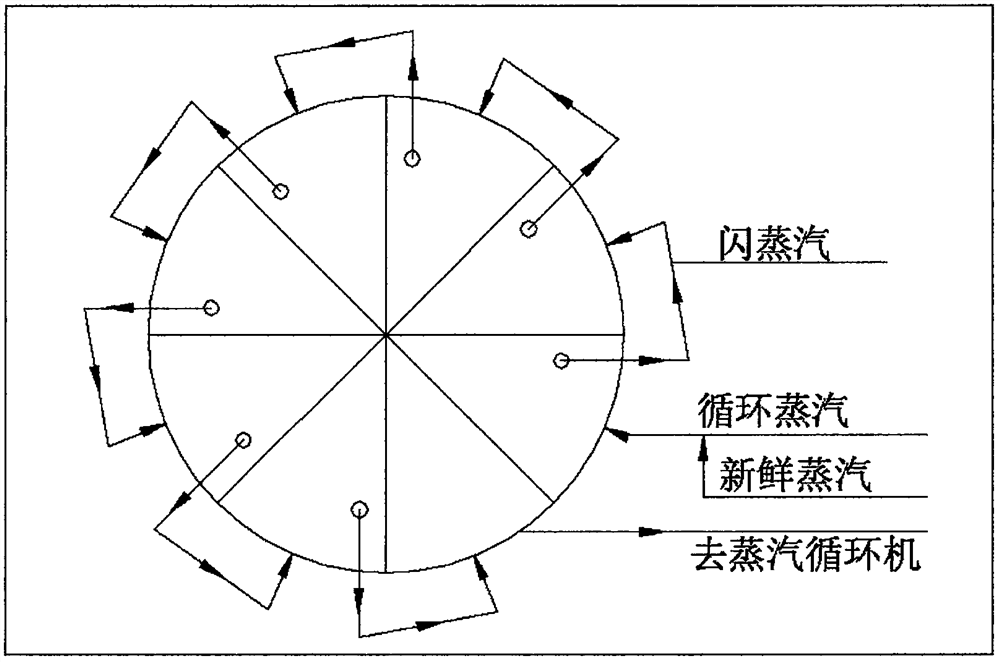

Method used

Image

Examples

Embodiment 1

[0043] The garbage permeate of a factory has a daily treatment capacity of 120t, the ammonia nitrogen content is about 7000mg / L, and the chromium content is 3.2mg / L. The process of the present invention is used to remove ammonia and chromium, and the steam consumption per ton of garbage permeate wastewater treatment is about 50kg, the outlet temperature of the deamination solution is 55°C, the ammonia nitrogen content is 37mg / L, and the chromium content is 0.003mg / L.

Embodiment 2

[0045] The garbage permeate of a factory has a daily processing capacity of 1400t, ammonia nitrogen content of about 3000mg / L, and chromium content of 1.2mg / L. The process of the present invention is used to remove ammonia and chromium, and the steam consumption per ton of garbage permeate wastewater treatment is about 60kg, the outlet temperature of the deammonization solution is 57°C, the ammonia nitrogen content is 12 mg / L, and the chromium content is not detected.

Embodiment 3

[0047] The garbage permeate of a factory has a daily processing capacity of 2200t, ammonia nitrogen content of about 4000mg / L, and chromium content of 1.1mg / L. The process of the present invention is used to remove ammonia and chromium, and the steam consumption per ton of garbage permeate wastewater treatment is about 57kg, the outlet temperature of the deammonization solution was 58°C, the ammonia nitrogen content was 28 mg / L, and the chromium content was not detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com