Room-and-pillar major-diameter longhole inverted-step-like segmented lateral caving subsequent filling mining method

A filling mining method and large-diameter technology, which can be used in surface mining, underground mining, special mining, etc., and can solve problems such as increased large block rate, uneven ore wall of ore pillars, and increased workload of secondary blasting in the stope, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific use cases for the proposed mining method of the present invention are:

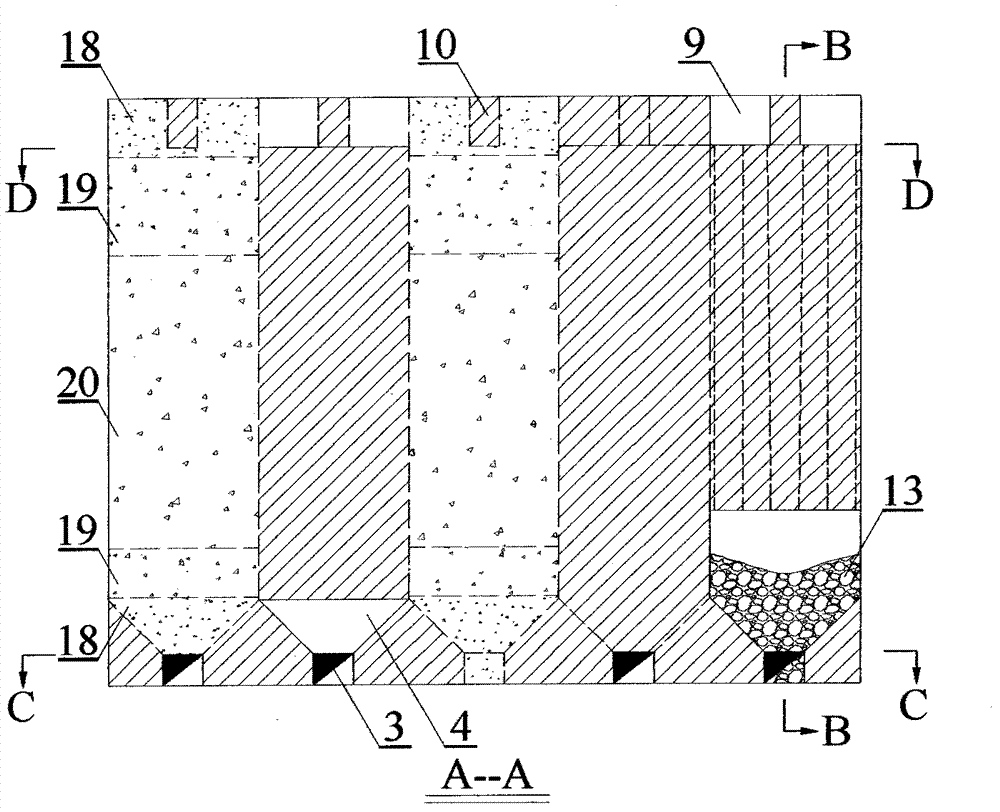

[0028] ① Divide the ore body seamless pillars into panel areas, and divide continuous mining units in the panel area, implement the mining sequence of "one mining at a time", that is, mining room first and then mining pillars. The width of the stope is 15m, and the length is the thickness of the ore body. The height is 60m;

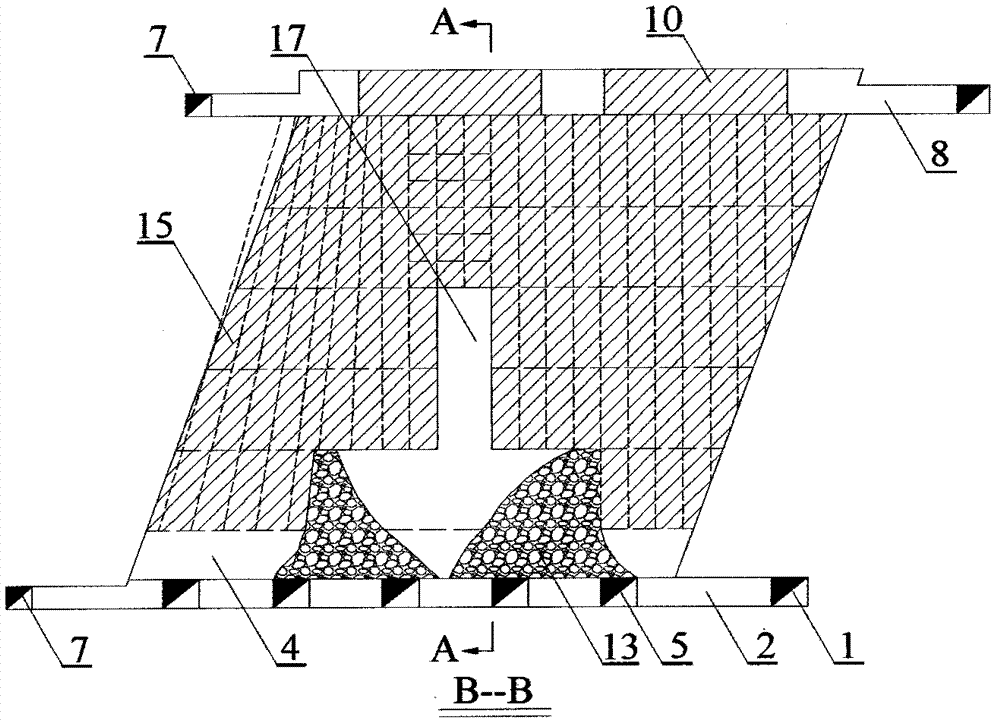

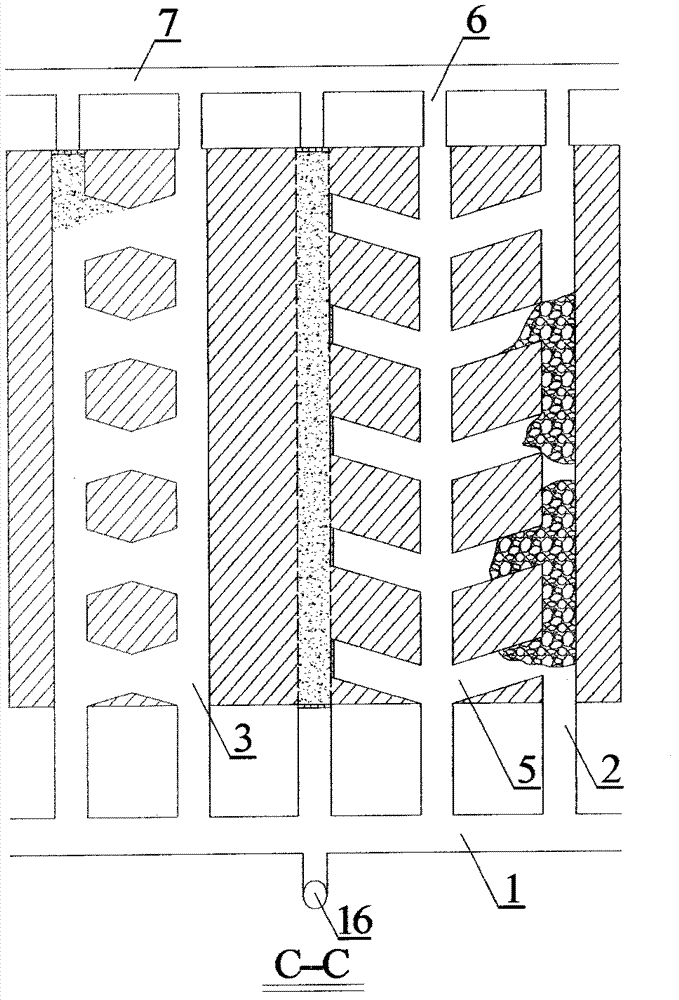

[0029] ② Mining project: the bottom is stage transportation level roadway 1 → ore exit contact roadway 2 → rock drilling and ore collection horizontal roadway 3 → "V" type cutting ditch 4 → mine exit roadway 5 → return air connection roadway 6 → return air level Lane 7; the top is rock drilling chamber connecting road 8→rock drilling chamber 9→return air connecting road 6→return air flat road 7, and the size of the roadway depends on the specifications of the trackless equipment;

[0030] ③Smooth blasting is used to form a rock-drilling chamber with a width of 15m an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com