Downward concave-convex rib-free inlaying continuous layered filling mining method

A backfill mining method and backfill technology, which are used in underground mining, backfill, surface mining, etc., can solve the problems of high economic value, falling backfill roof, waste of mineral resources, etc., and achieve reasonable process cycle replacement and mining safety. High and economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

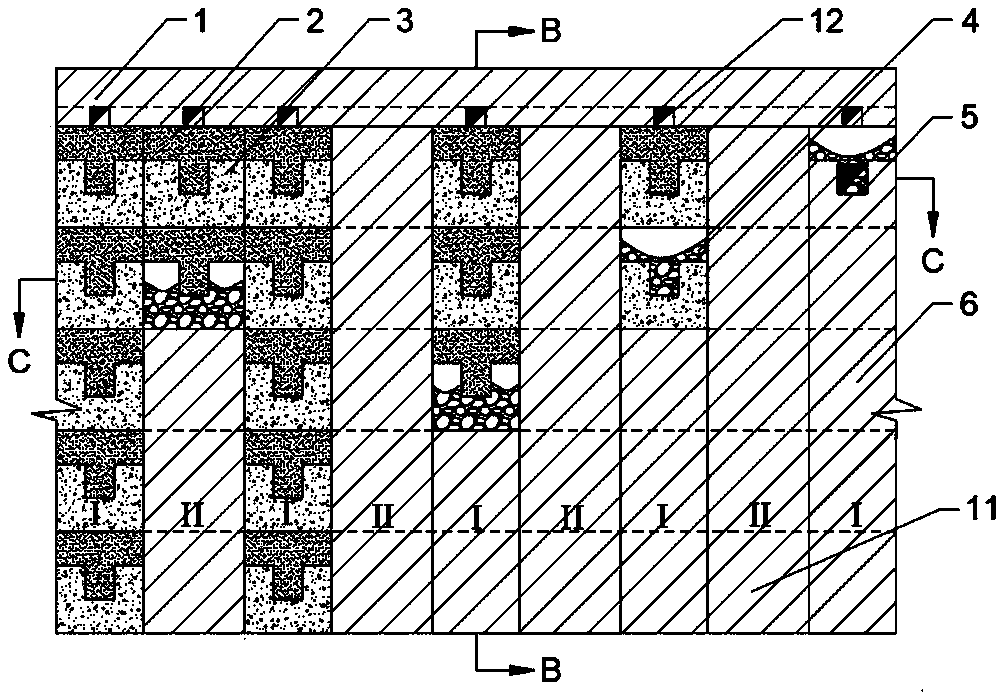

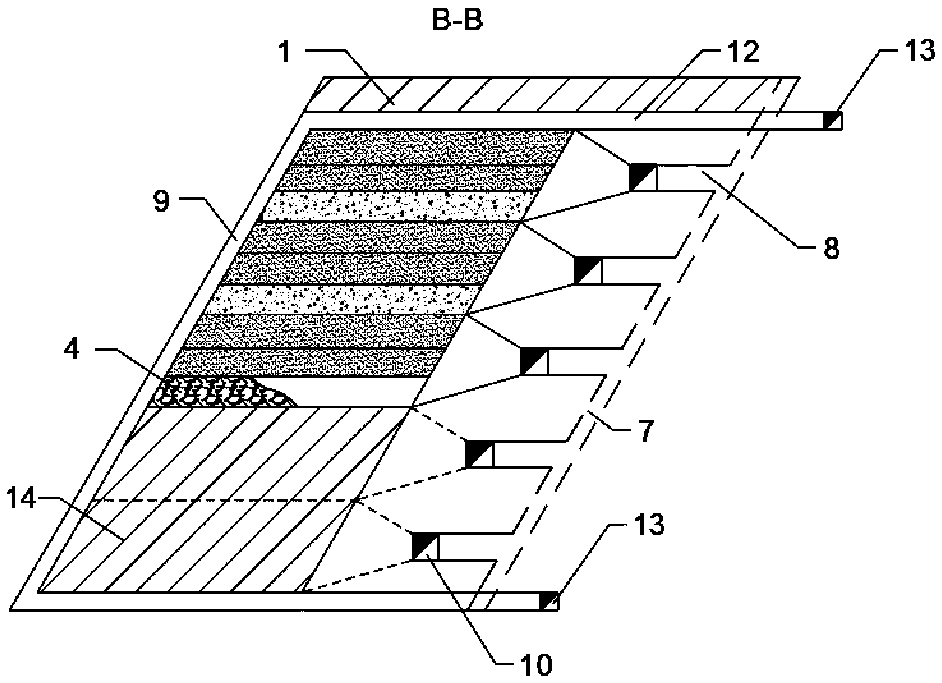

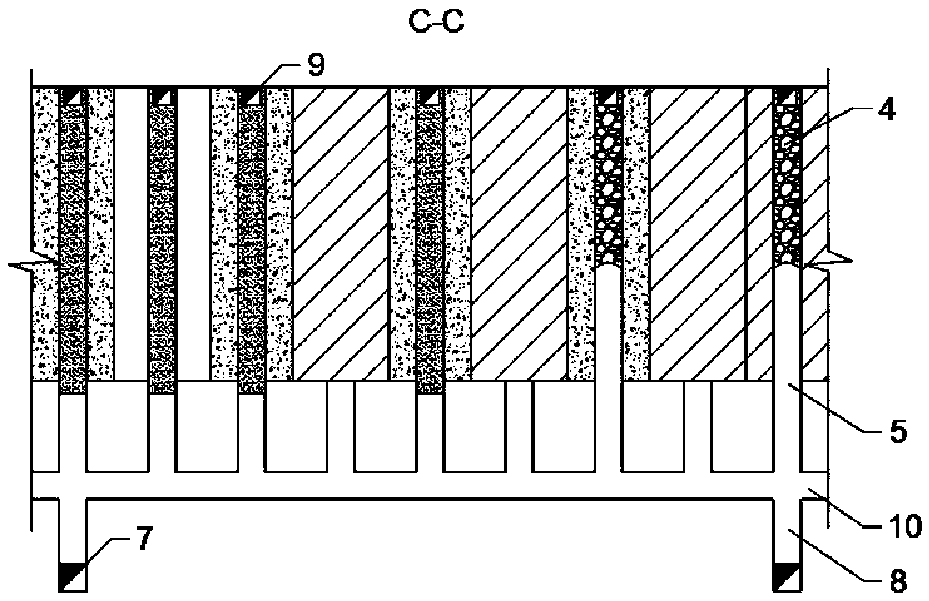

[0017] Such as Figure 1~4 As shown, a downward concave-convex and non-reinforced inlay continuous layered filling mining method includes the following steps: (1) The ore body is divided into stages in the vertical direction, and an inclined top pillar is reserved between the upper and lower adjacent stages. The stage assumes a reserved inclined roof column, and completes the safe mining of the stage ore body under the protection of the inclined roof column. The stage is divided into multi-layer middle sections in the height direction; (2) The stage is divided into intervals arranged along the direction of the ore body. Room and pillar, one-step stope is arranged in the mine room, and two-step stope is arranged in the ore pillar. Every 5~7 room-pillar stope constitutes a panel; (3) The out-of-vein trackless mining system is adopted. Including the stage transportation roadway, the panel chute, the middle section outside the vein transportation roadway and the transfer connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com