Integrated brake caliper

A brake caliper, integrated technology, applied in the direction of brake type, brake actuator, brake components, etc., can solve the problems of unreasonable structural design, reduced braking performance, low market competitiveness, etc., to improve braking effect, increased friction coefficient, good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following examples are combined with the appended figure 1 to attach Figure 9 The technical solutions provided by the present invention are described in detail, but the following content is not intended as a limitation of the present invention.

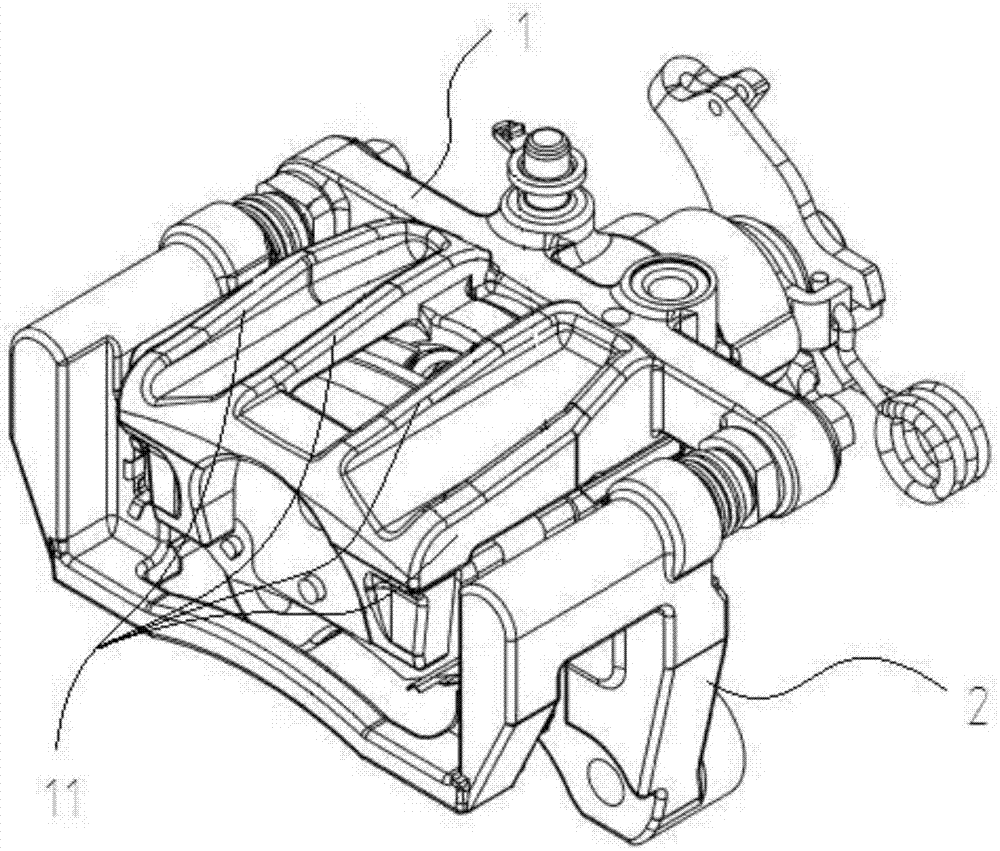

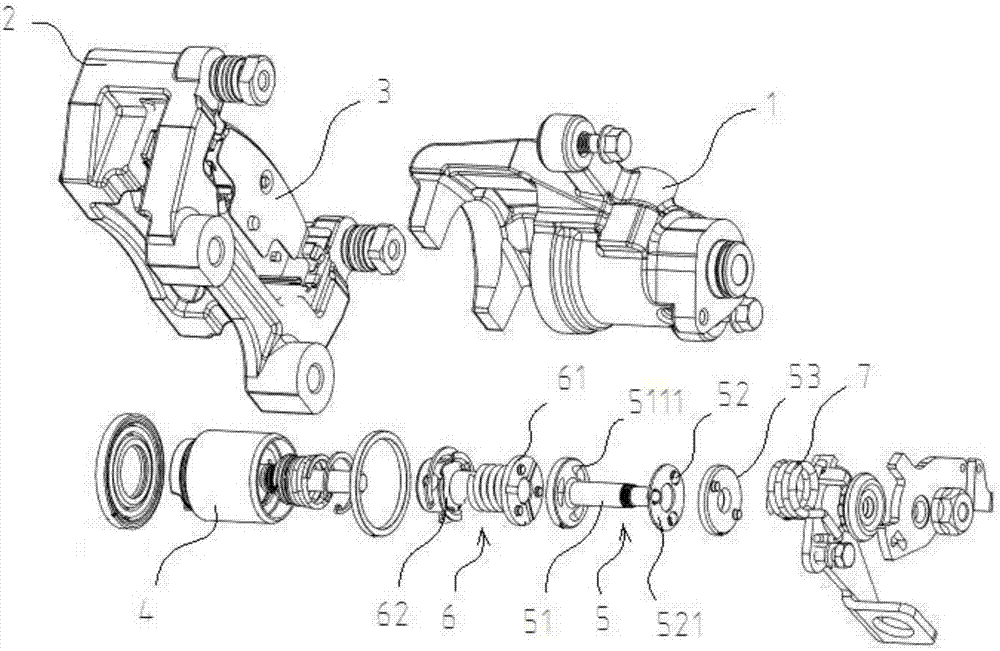

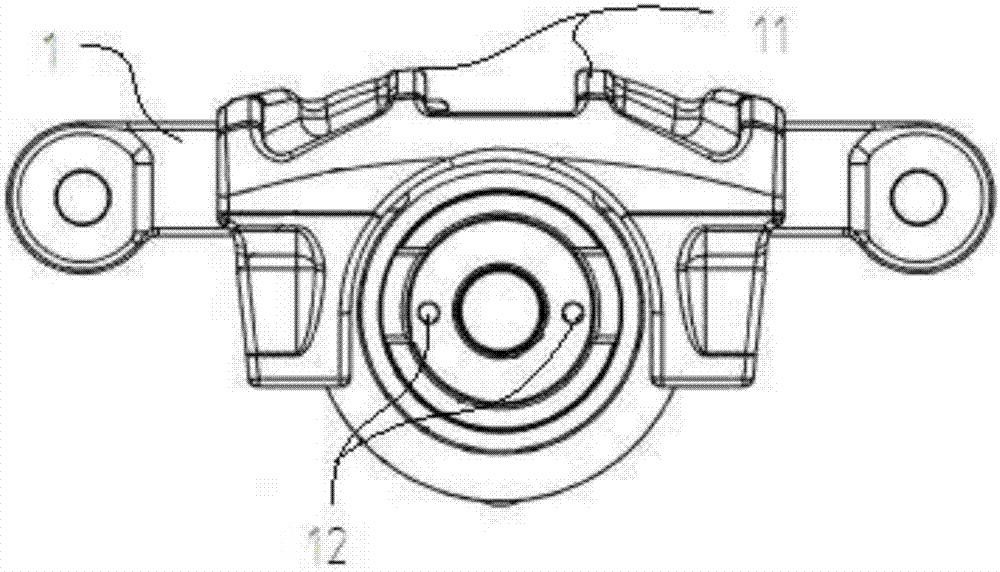

[0032] figure 1 It is a structural diagram of an embodiment of an integrated brake caliper of the present invention; figure 2 It is an exploded view of an integrated brake caliper according to a preferred embodiment of the present invention. Such as figure 1 and figure 2 As shown, the integrated brake caliper provided in this embodiment includes: brake housing 1, reinforcing rib 11, limit groove 12, brake bracket assembly 2, friction plate structure 3, piston 4, thrust assembly 5, Thrust rotating shaft 51, thrust steel ball 52, thrust platform 53, round table 511, rotating shaft 512, cage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com