A locking bar floating installation mechanism and installation method

A technology of installation mechanism and locking strip, which is applied in the direction of support structure installation, clamping/extracting device, etc., can solve the problem of easy locking of locking strip, and achieve the problems of wedge locking, convenient use and avoiding locking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is further described below in conjunction with accompanying drawing:

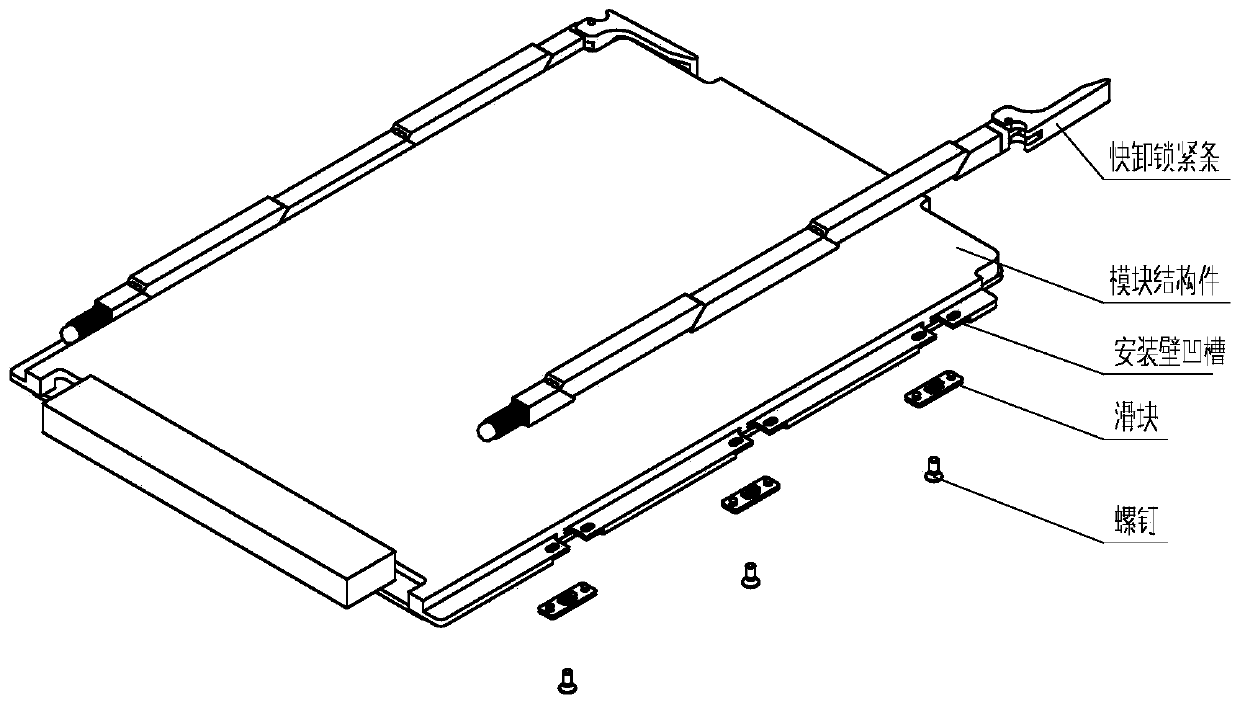

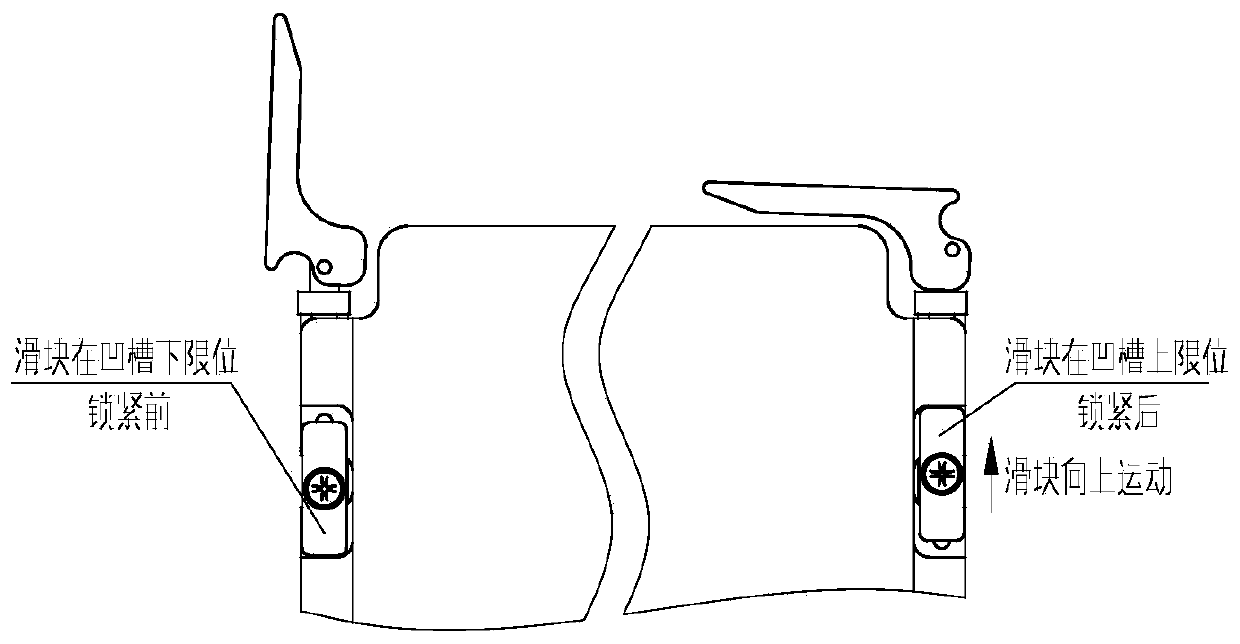

[0016] like figure 1 As shown, a locking bar floating installation mechanism includes a quick-release locking bar and screws, and the quick-release locking bar is fixed to the module structure through screws. It is characterized in that the quick-release locking bar is fixedly connected to the installation wall of the module structure A slider is added at the place to cooperate with the groove of the installation wall of the module structure to form a relatively sliding installation mechanism.

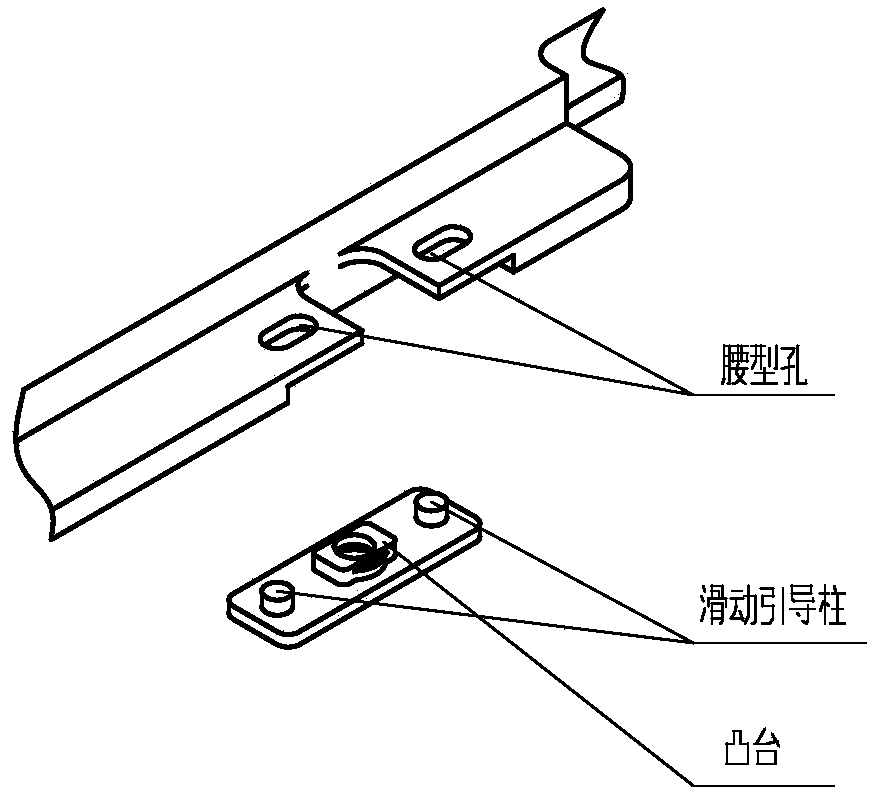

[0017] like figure 2 As shown, the slider is a sheet structure, with screw mounting holes and bosses in the middle, and sliding guide columns on both sides, which cooperate with the waist-shaped holes at both ends of the groove of the module structure installation wall. The height of the boss must be greater than the wall thickness of the joint of the module structure. The height of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com