Method for preparing thermoelectric device and thermoelectric device

A technology of thermoelectric components and components, which is applied in the manufacture/processing of thermoelectric devices, and the material of the junction lead wires of thermoelectric devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] The hollow structural block was prepared by spark plasma sintering (SPS) according to the following steps:

[0100] The skutterudite material CeFe was prepared by melting and heat treatment 4 Sb 12 . Put 20g of powder into a specially designed graphite mold with a hollow structure. Then, the powder is sintered into a block by SPS process, the heating rate is 40K / min, the sintering temperature is 843K, the holding time is 30min, and the sintering pressure is 60MPa. After cooling in the furnace, the sample with a hollow structure is taken out of the mold, and then, the sample is refined by wire cutting to obtain a sample of predetermined size. Finally, wire cutting or laser cutting is used to cut the block of the hollow structure into thin slices of specified thickness.

Embodiment 2

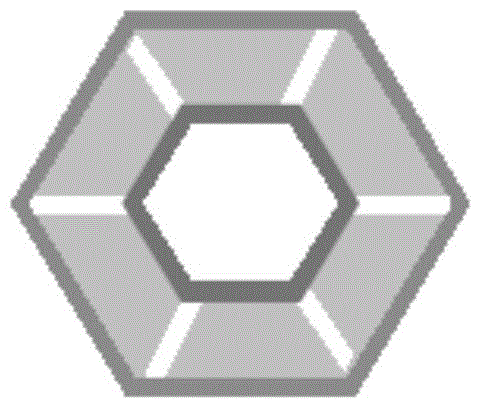

[0102] According to the following steps, the hexagonal hollow block is prepared by spark plasma sintering method:

[0103] The composition is ZrNiSn prepared by solid state reaction or arc melting heat treatment. 0.99 Sb 0.01 s material. 20 g of powdered material was put into a graphite mold with a hexagonal structure. Then, the powder is sintered into a block using the SPS process. The heating rate is 30K / min, the sintering temperature is 923K, the holding time is 30min, and the sintering pressure is 50MPa. After the furnace cools, the samples are removed from the molds. Use a drilling machine to drill a 1mm hole axially in the center of the sample, and then use wire cutting to form a hexagonal cavity in the center of the sample. Finally, the hexagonal hollow block is cut into slices of predetermined size and thickness.

Embodiment 3

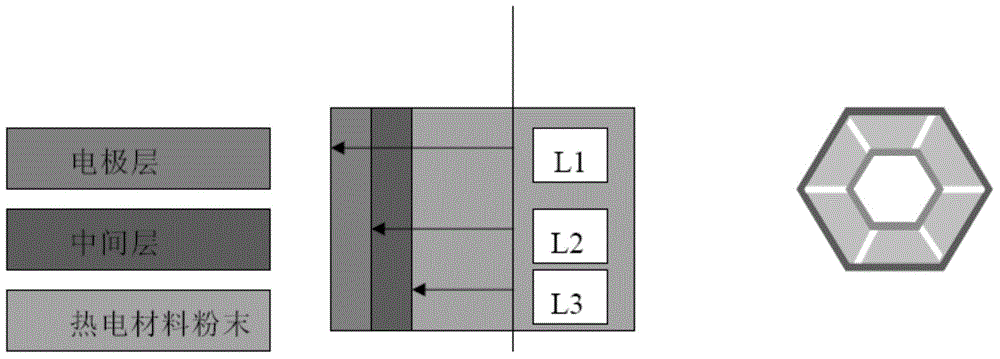

[0105] According to the following steps, the hexagonal hollow block is prepared by hot pressing sintering and assembly method:

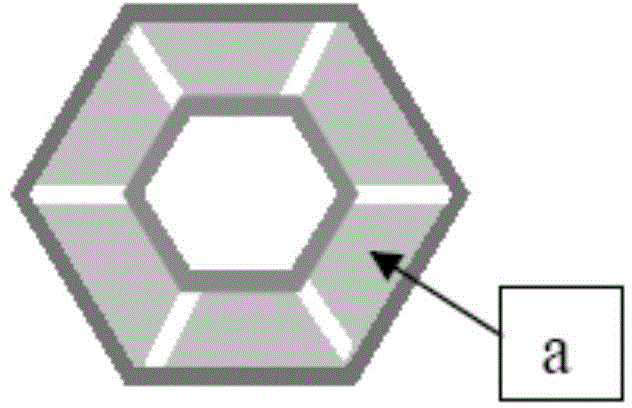

[0106] The skutterudite material Yb was prepared by melting and heat treatment 0.3 CO 4 Sb 12 . Put the electrode sheet, the middle layer sheet and 20g of skutterudite powder into a square graphite mold. Then, the powder is sintered into a block by hot pressing, the heating rate is 40K / min, the sintering temperature is 893K, the holding time is 60min, and the sintering pressure is 30MPa. After cooling in the furnace, the square samples were removed from the molds. The sample is then machined using wire EDM, cut and finished into preset components (see figure 1 In a), the bottom of the trapezoid of the finishing part is the electrode layer (hot end). The cold terminal electrode is formed on the upper bottom of the trapezoidal part by means of electroplating. Finally, assemble the six parts into a complete thermoelectric element with a hexagonal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com