Method for segregation and purification of high-purity aluminum

A segregation, high-purity technology, applied in the field of foundry metallurgy, which can solve problems such as operational errors, increased labor intensity, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

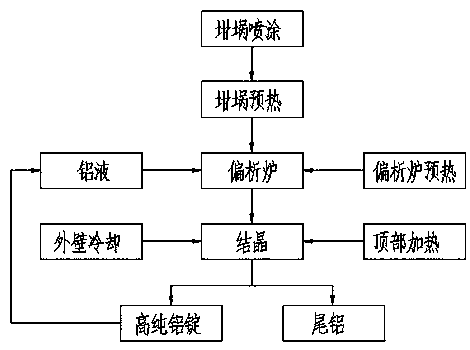

Method used

Image

Examples

Embodiment 1

[0037] Example 1: The preheating temperature of the segregation furnace is 500°C, the preheating temperature of the crucible is 450°C, the electrolytic aluminum liquid is 99.85Al, the temperature of the aluminum liquid is 800°C, the closing temperature of the segregation furnace is 700°C, the initial temperature of the segregation furnace is set at 700°C, and stirring The frequency is 20Hz, the crystallization time is 4h, the aluminum crystal growth thickness is 15cm, and the purity of the high-purity aluminum ingot can reach 99.95Al.

Embodiment 2

[0038] Example 2: The preheating temperature of the segregation furnace is 500°C, the preheating temperature of the crucible is 500°C, the molten aluminum is 99.95Al, the temperature of the molten aluminum is 800°C, the closing temperature of the segregation furnace is 700°C, the initial temperature of the segregation furnace is set to 700°C, and the stirring frequency 22Hz, crystallization time 4h, aluminum crystal growth thickness is 15cm, and the purity of high-purity aluminum ingot can reach 99.98Al.

Embodiment 3

[0039] Example 3: The preheating temperature of the segregation furnace is 500°C, the preheating temperature of the crucible is 450°C, the molten aluminum is 99.98Al, the temperature of the aluminum liquid is 800°C, the temperature of the segregation furnace cover is 700°C, the initial temperature of the segregation furnace is set to 700°C, and the stirring frequency 20Hz, crystallization time 3h, aluminum crystal growth thickness 13cm, high-purity aluminum ingot purity can reach 99.993Al.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com