Propane deasphalting method for paraffin-based vacuum residuum with low needle penetration

A technology of vacuum residue and penetration, which is applied in the direction of selective extraction and processing of tar pitch/petroleum pitch/natural pitch, etc., which can solve the problem of unsmooth discharge of deoiled asphalt, the inability to achieve safe and stable production of the device, and the temperature of the extraction tower. problems such as small gradients, to achieve the effect of being beneficial to extraction and separation, improving mass transfer and separation effect, and improving mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

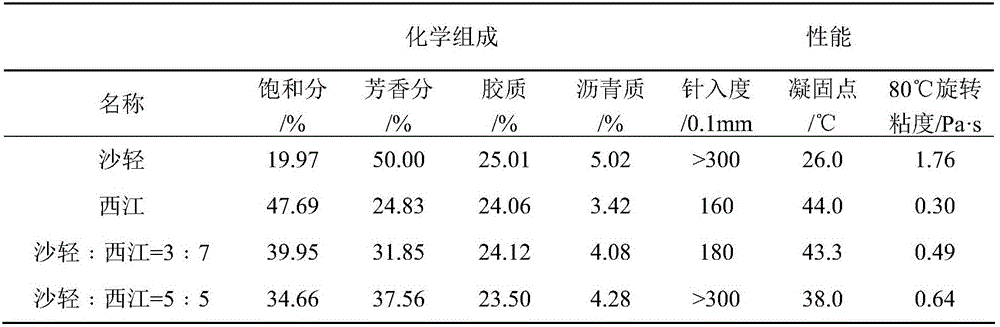

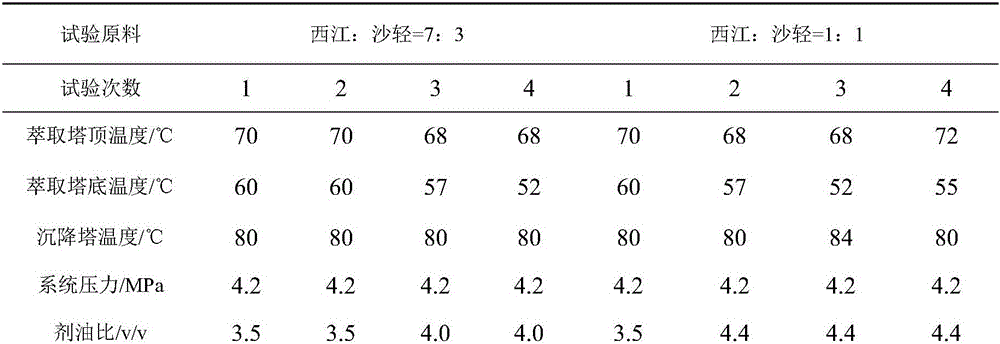

[0026] During the production of Xijiang vacuum residue oil, phase miscibility occurs, and the material is extremely unbalanced. For this reason, Xijiang vacuum residue and Shaqing vacuum residue were blended at a ratio of 7:3 and 1:1 respectively for propane deasphalting. The main properties of Xijiang vacuum residue oil and Shaqing vacuum residue oil blended in different proportions are shown in Table 1. The test conditions and results are shown in Table 2.

[0027] Table 1 Properties of Shaqing-Xijiang blend residue

[0028]

[0029] It can be seen from Table 1 that the properties of the blended vacuum residue have changed significantly. After blending, the penetration increases, the saturated hydrocarbon content decreases, the freezing point decreases, and the rotational viscosity increases. After the penetration is increased, the temperature gradient in the extraction tower can be increased; at the same time, the solvent-oil ratio can be increased, the selectivity of...

Embodiment 2

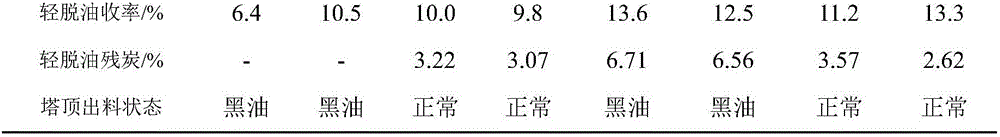

[0035] During the production of Xijiang vacuum residue oil, phase miscibility occurs, and the material is extremely unbalanced. For this purpose, the propane deasphalting was carried out by blending Xijiang vacuum residue and Iran Rawan vacuum residue at a ratio of 1:1. The main properties of Xijiang vacuum residue oil blended with Iran Rawan vacuum residue oil in different proportions are shown in Table 3. The test conditions and results are shown in Table 4.

[0036] Table 3 Properties of Iran Ravan-Xijiang vacuum residue after blending (1:1)

[0037]

[0038] Table 4 Pilot test conditions and results of blended residual oil (Iran Ravan-Xijiang vacuum residual oil = 1:1)

[0039]

[0040] It can be seen from Table 4 that after upgrading, the extraction and separation can be improved by adjusting the temperature gradient and solvent-oil ratio. That is to say, black oil no longer comes out from the top of the tower, and the yield of light deoiling is obviously increas...

Embodiment 3

[0042] The penetration of paraffin-based Huizhou vacuum residue is less than 200 0.1mm. In view of the fact that the yield of deoiled asphalt in the propane pilot test is very low or no output, it is decided to use other residual oil for the pilot test. According to the oil sources processed by the company, oil sources with higher asphalt yields are selected for blending. The yield of intermediate-based Aesop vacuum residue bitumen processed by the propane production unit (abbreviated as Aesop) is as high as 60%, and the yield of light deoiling is as low as 9%. Therefore, it was decided to blend Iraqi heavy Solus vacuum residue oil at a ratio of 1:1. The blended properties of the two vacuum residues are shown in Table 3. It can be seen from Table 3 that after mixing the two vacuum residues at a ratio of 1:1, the penetration, softening point, freezing point and 80°C rotational viscosity of the mixed vacuum residue all changed. The test conditions and results are shown in Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com