Double-pipe blowing slurry preparation and density detection equipment and density detection method

A technology of density detection and gas distribution, applied in the direction of determining the specific gravity by measuring the pressure difference, and displaying the liquid level indicator by the pressure measurement. Large, precise density and volume control, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

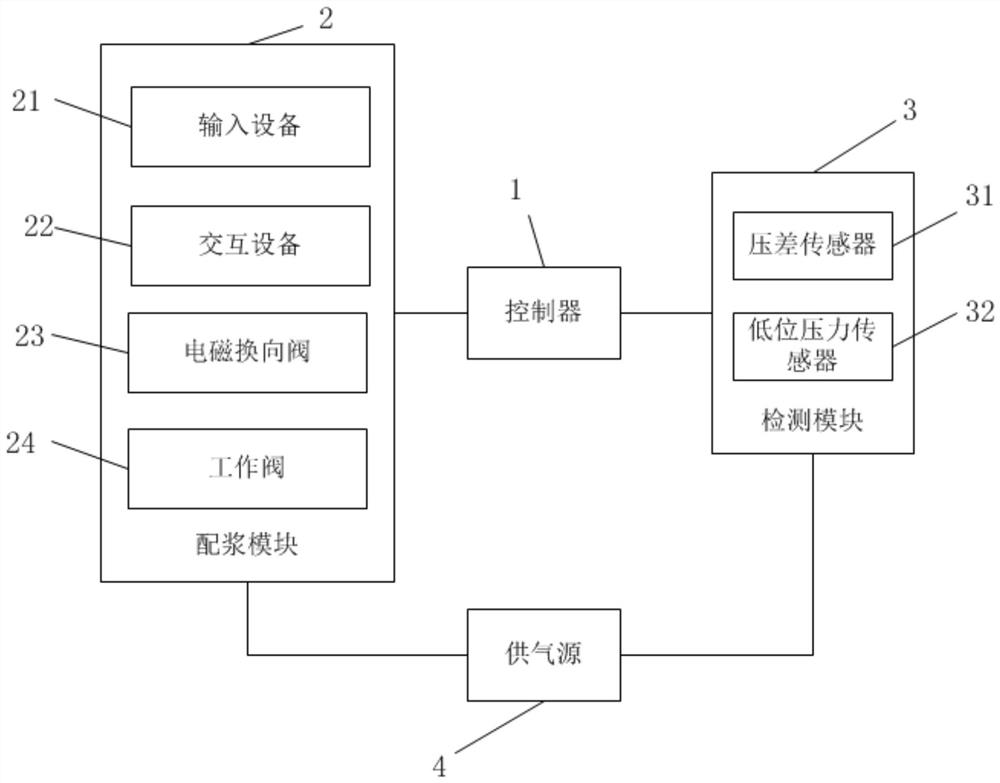

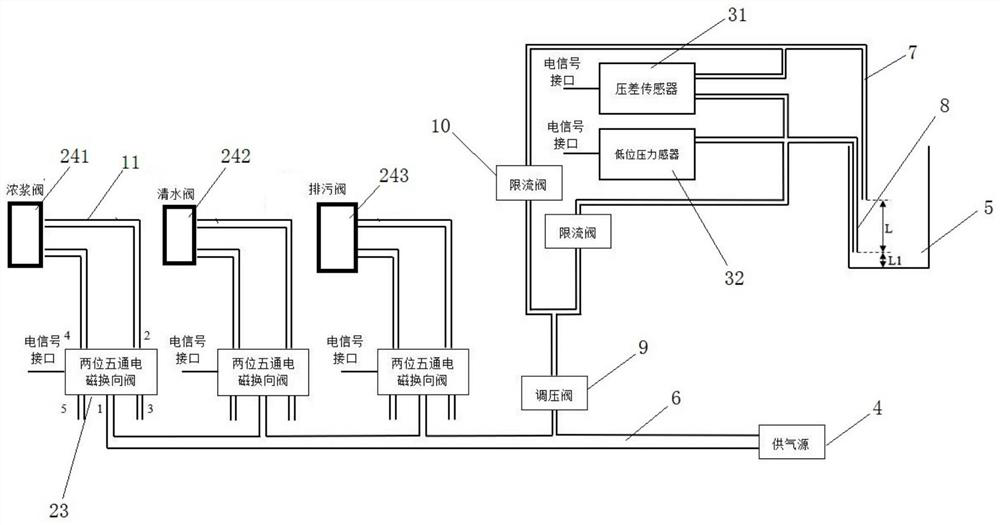

[0035] A dual pipe and blowing with pulp density detecting device, such as a figure 1 and figure 2 Shown, comprising: a controller 1, 2 with pulp module, the detection module 3, and the gas supply source 4 barrel 5 with pulp, pulp module 2 and with the detection module 3 are respectively connected to the controller 1, and the gas supply source 4 with slurry 5 are connected to the tub 2 with pulp module and a detection module 3; 2 module with pulp slurry and for priming with slurry water to the tub 5, and then real-time detection by the detection module 3 and the ratio of the density level, and when the density level of compliance after the stop with slurry; when the time required with pulp, pulp with 2 modules also may be sewage, the tub 5 with the residual slurry discharging the slurry; gas supply source 4 for pulp with a detection module 2 and module 3 gas, and with pulp in order to achieve the detection of the double tube blowing.

[0036] The module 2 with slurry comprising: 2...

Embodiment 2

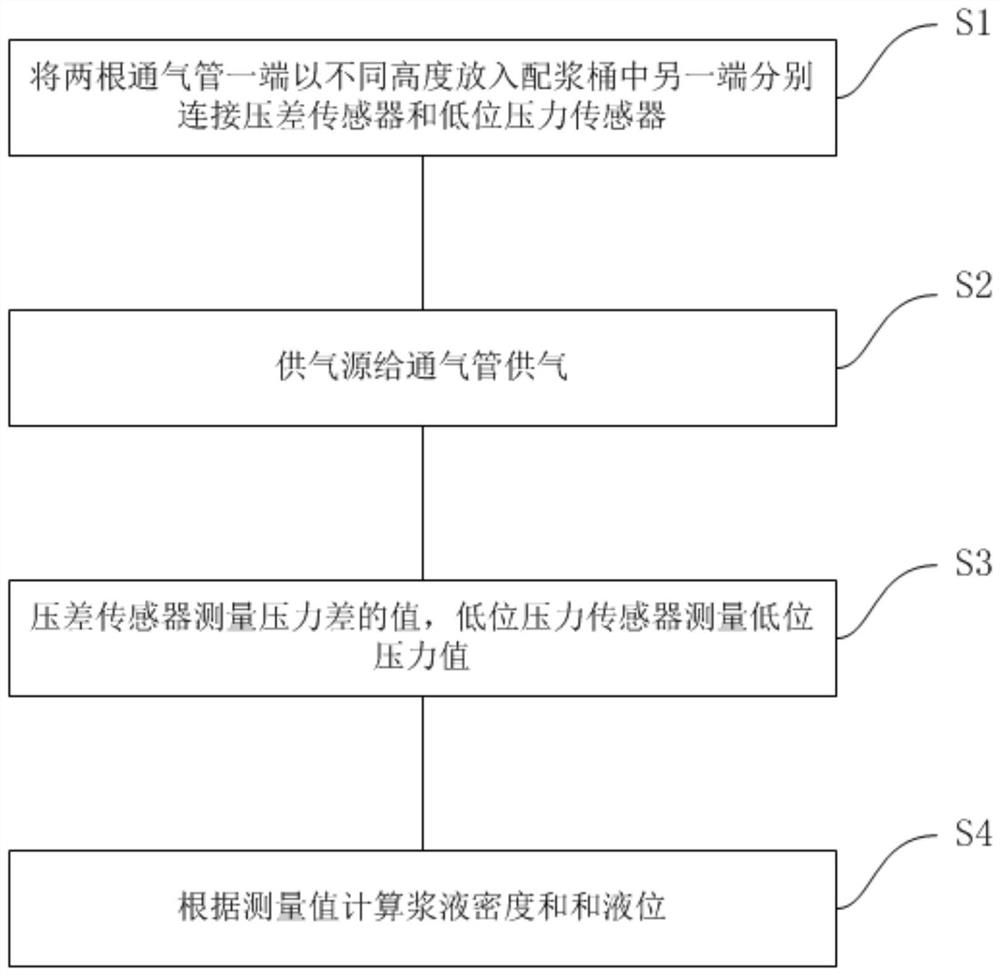

[0042] A method of detecting double pipe blowing with pulp density, such as image 3 As shown, including:

[0043] S1: The breather pipe end two different heights with slurry into the tub and the other end connected differential pressure sensor and a low pressure sensor.

[0044] The above steps, the high differential pressure sensor connected to the breather pipe, the breather pipe is connected to the low differential pressure sensor and the low pressure sensor. Low-pass and high-pass tube height difference between the trachea is L, the lower barrel snorkel and bottom of the barrel with slurry height difference is Ll; embodiment according to the present embodiment, the upper and lower vent tube snorkel with pulp were adherent mounted inside of the barrel .

[0045] S2: the vent gas supply to gas supply.

[0046] In the above step, the gas supply will blow through the trachea, air is conducted to the air tube will be positioned with pulp barrel high and low snorkel through the trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com