Method for preparing highly-uniform synthetic quartz glass weight

A technology for synthesizing quartz and glass ingots, which is applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., and can solve the problems of longitudinal distribution of quartz glass ingots, affecting the uniformity of longitudinal structure, and uneven distribution of quartz glass refractive index and density. Uniformity and other issues to reduce or eliminate temperature gradients, uniform temperature distribution, and improve structural uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

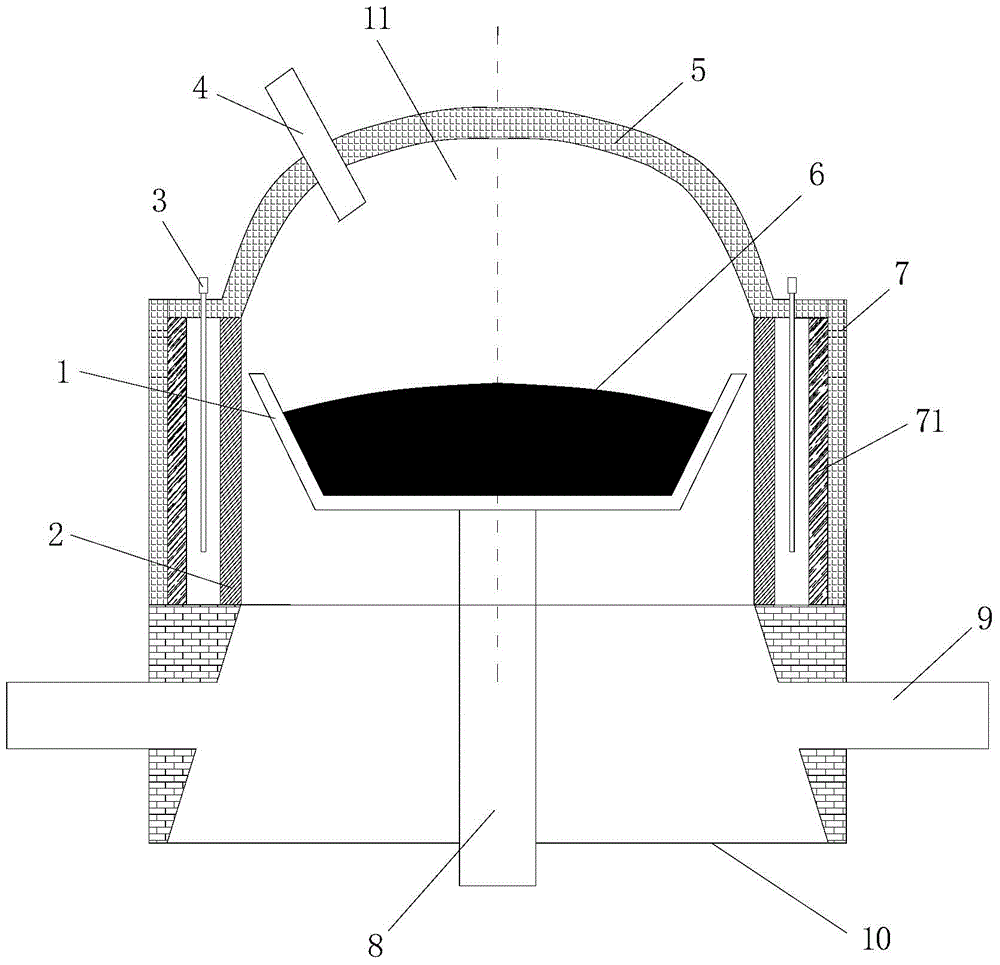

[0025] figure 1 It is a schematic structural diagram of a deposition furnace used in the preparation method of the embodiment of the present invention. Please combine figure 1 , also refer to figure 2 and image 3 .

[0026] The preparation method of highly uniform synthetic quartz glass ingot, the steps are as follows:

[0027] Formation of silicon dioxide particles: the silicon tetrachloride raw material directly enters the silicon tetrachloride evaporation system to generate silicon tetrachloride vapor, and the flow rate of silicon tetrachloride vapor and hydrogen and oxygen entering the burner 4 is adjusted by a mass flow controller , Silicon tetrachloride vapor reacts chemically in the burning hydrogen-oxygen flame to form silicon dioxide particles; the flow rate of each raw material gas can be set by those skilled in the art according to needs, or the flow rate of the prior art can be used. In this embodiment, the silicon tetrachloride vapor flow rate is 20 g / min, ...

Embodiment 2

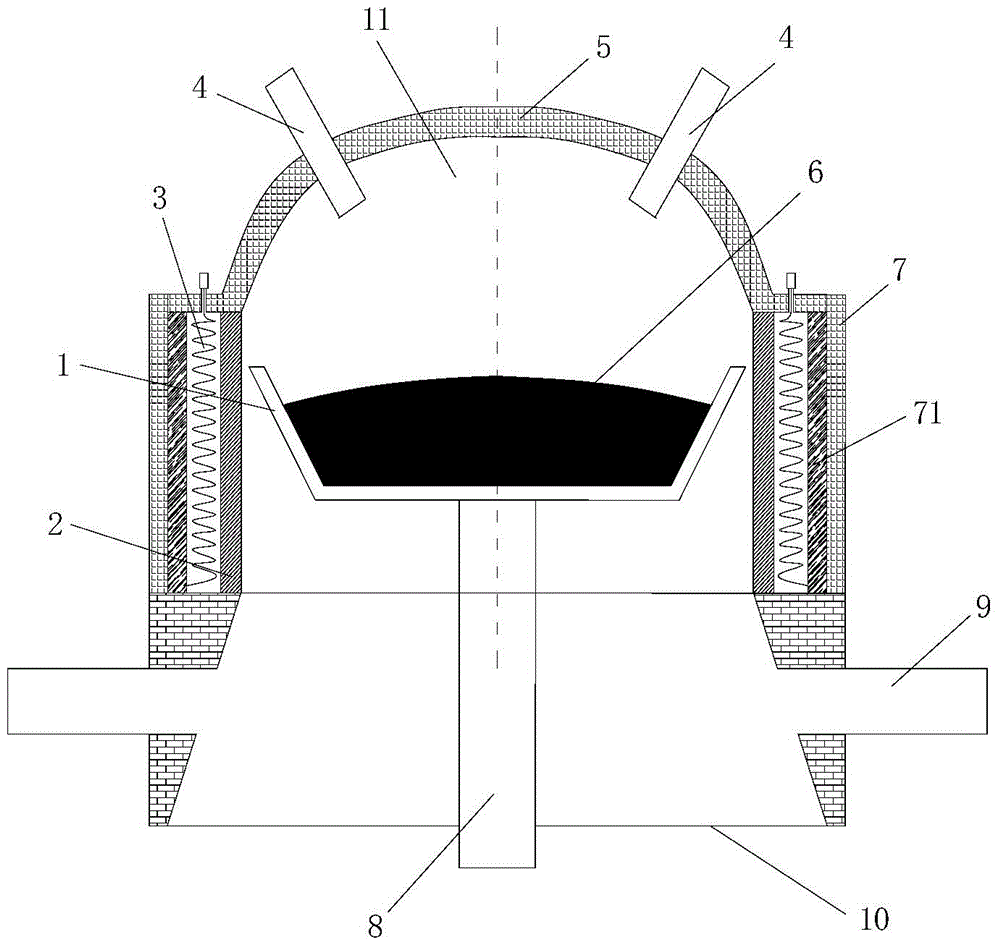

[0032] This embodiment adopts figure 2 Deposition furnace shown. Combine below figure 2 Be explained.

[0033] The preparation method of highly uniform synthetic quartz glass ingot is different from Example 1 as follows:

[0034] Formation of silicon dioxide particles: the silicon tetrachloride raw material directly enters the silicon tetrachloride evaporation system to generate silicon tetrachloride vapor, and the flow rate of the silicon tetrachloride vapor is adjusted to 25g / min by a mass flow controller, and enters the burner 4 Center material pipe, and keep the flow of fuel such as hydrogen and oxygen in the burner 4 to be 380L / min and 205L / min respectively to carry out the burner, and silicon tetrachloride vapor chemically reacts in the burning hydrogen-oxygen flame to form silicon dioxide Particles; there are two burners, symmetrically distributed, and the angle between the burner 4 and the vertical line is 30°.

[0035] Deposition of silicon dioxide particles: Th...

Embodiment 3

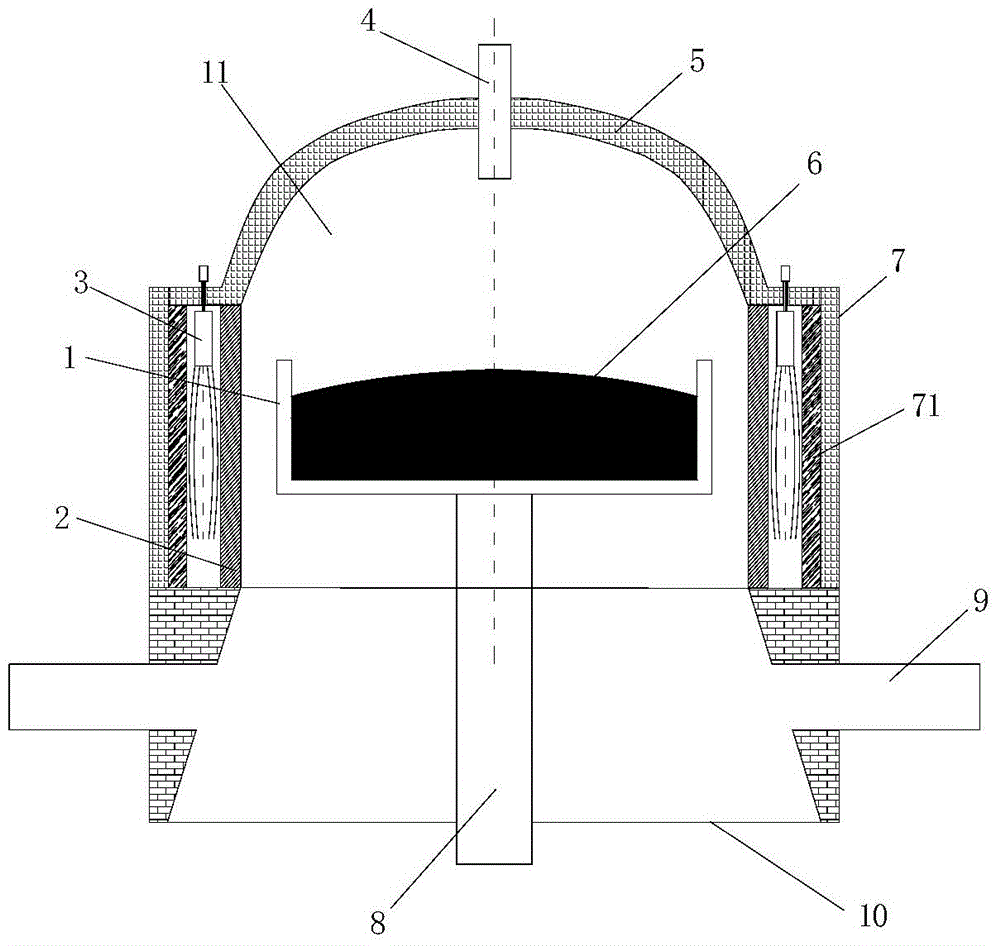

[0039] This embodiment adopts image 3 Deposition furnace shown. Combine below image 3 Be explained.

[0040] The preparation method of highly uniform synthetic quartz glass ingot is different from Example 1 as follows:

[0041] Formation of silicon dioxide particles: the silicon tetrachloride raw material directly enters the silicon tetrachloride evaporation system to generate silicon tetrachloride vapor, adjusts the flow rate of silicon tetrachloride vapor to 15g / min through a mass flow controller, and enters the burner 4 The central material pipe, and keep the flow rate of fuel such as hydrogen and oxygen in the burner 4 to be 330L / min and 150L / min respectively to carry out the burner, and the silicon tetrachloride vapor chemically reacts in the burning hydrogen-oxygen flame to form silicon dioxide Particles: one burner 4, and the burner 4 is vertically arranged on the roof of the deposition furnace.

[0042] Deposition of silicon dioxide particles: The silicon dioxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com