Preparation method of gallium-doped silicon ingot, gallium-doped silicon ingot and silicon piece

A technology of silicon ingots and silicon wafers, which is applied in chemical instruments and methods, self-melting liquid pulling method, polycrystalline material growth, etc., can solve the problem of light attenuation rate of polycrystalline gallium-doped silicon wafers, which is not theoretically feasible for chemical reactions fluctuations, resistivity fluctuations of crystalline silicon materials, etc., to achieve the effect of improving photoelectric conversion efficiency, high photoelectric conversion efficiency, and long minority carrier lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of gallium-doped silicon ingot, comprising the following steps:

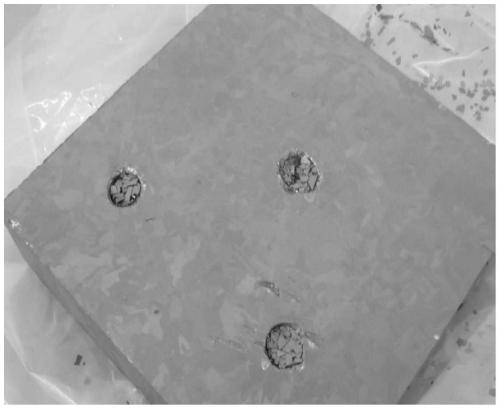

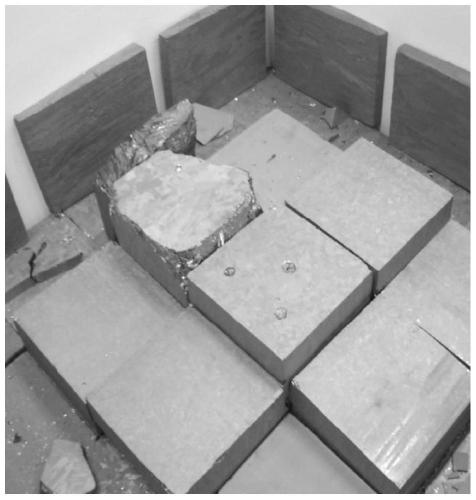

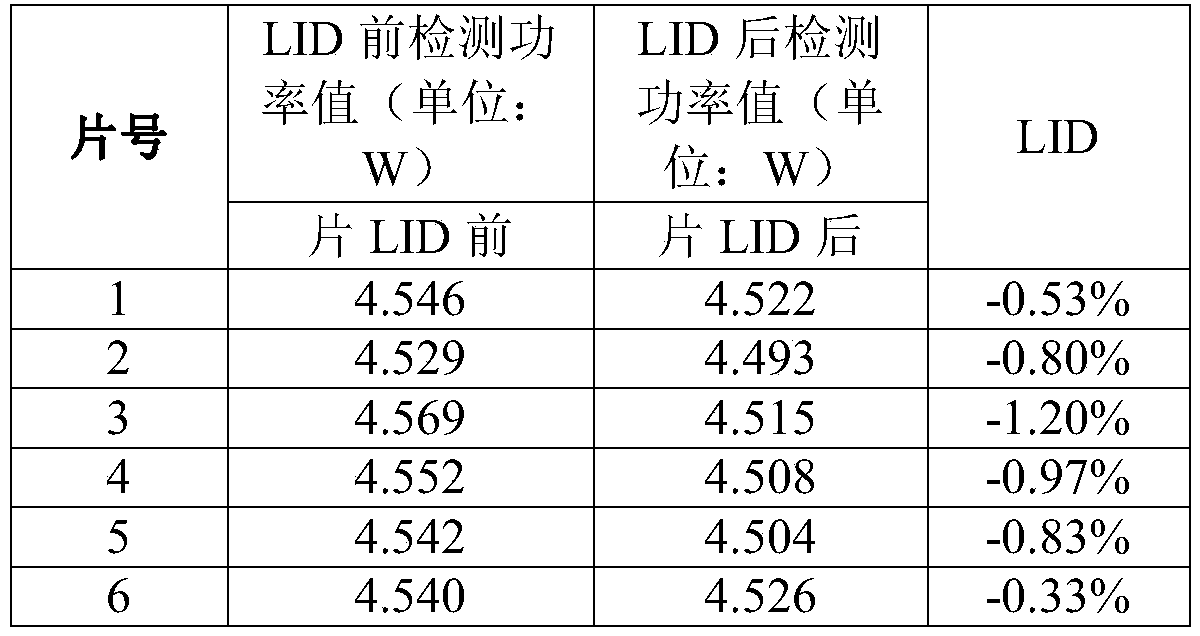

[0030] (1) Use a diamond drill to drill holes in the massive polycrystalline tailings (that is, the silicon material returned to the furnace), and the shape of the holes is cylindrical, and the number is 3, such as figure 1 As shown, wherein the diameter of the circular hole is 10mm and the depth is 30mm. The obtained polycrystalline tailings with holes are cleaned, dried and set aside.

[0031] (2) Use a plastic syringe to inject 4g of liquid metal gallium into the holes of the polycrystalline tailings in step (1), and simultaneously add polycrystalline scraps (being crushed silicon) to the holes to make the crushed silicon and liquid metal The gallium is solidified together to realize the solidification of the liquid gallium metal and the sealing of the circular hole, and obtain the polycrystalline tail material containing the gallium metal, which is the silicon material containing...

Embodiment 2

[0042] A preparation method of gallium-doped silicon ingot, comprising the following steps:

[0043] (1) Get the cylindrical primary polysilicon material (primary silicon material) with bowl-shaped hole, the diameter of its bowl-shaped hole is 40mm, depth is 20mm; With the primary polysilicon material with bowl-shaped hole, clean, dry, spare.

[0044] (2) Use a plastic syringe to inject 2.5g of liquid metal gallium into the bowl-shaped hole of the primary polysilicon material in step (1), and add polycrystalline scrap (silicon scrap) to the bowl-shaped hole at the same time to make the scrap silicon and The liquid metal gallium is solidified together to realize the solidification of the liquid metal gallium and the sealing of the round hole, and obtain the primary polysilicon material filled with metal gallium, that is, the silicon material loaded with metal gallium. The liquid metal gallium used is obtained by melting the metal gallium, specifically: the metal gallium is pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com