Patents

Literature

32 results about "Gallium doping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

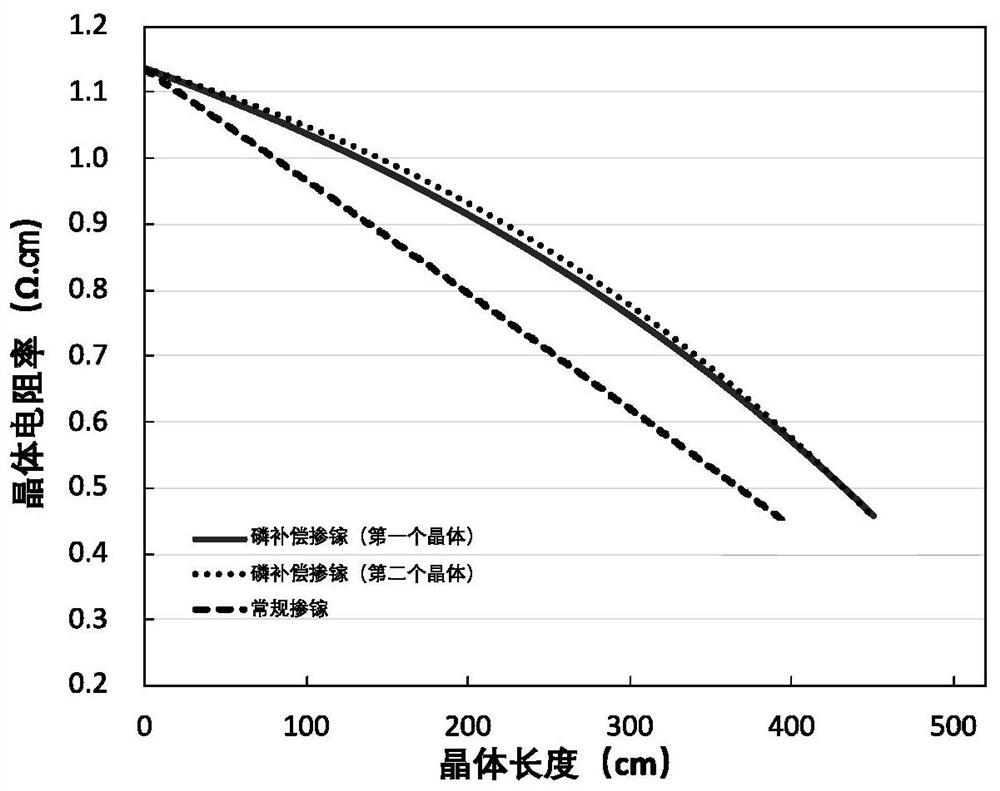

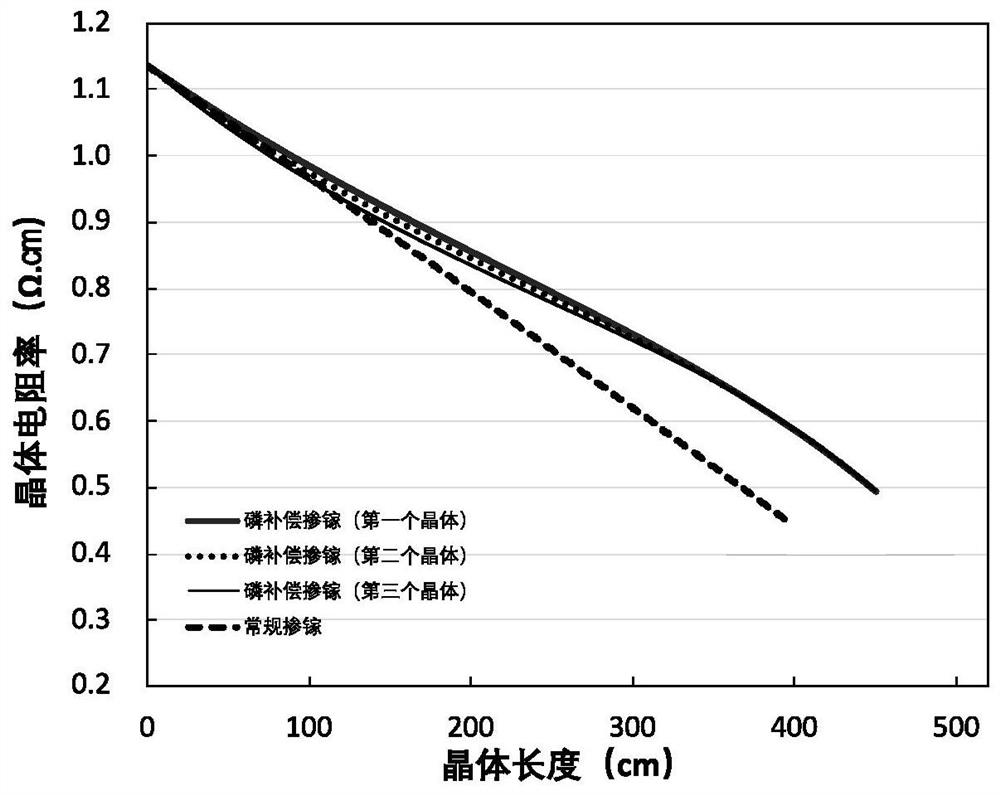

Method for controlling specific resistance of gallium-doped Czochralski silicon in crystal growth process

InactiveCN101654804AIncrease profitReduce manufacturing costBy pulling from meltDopantPhotovoltaic industry

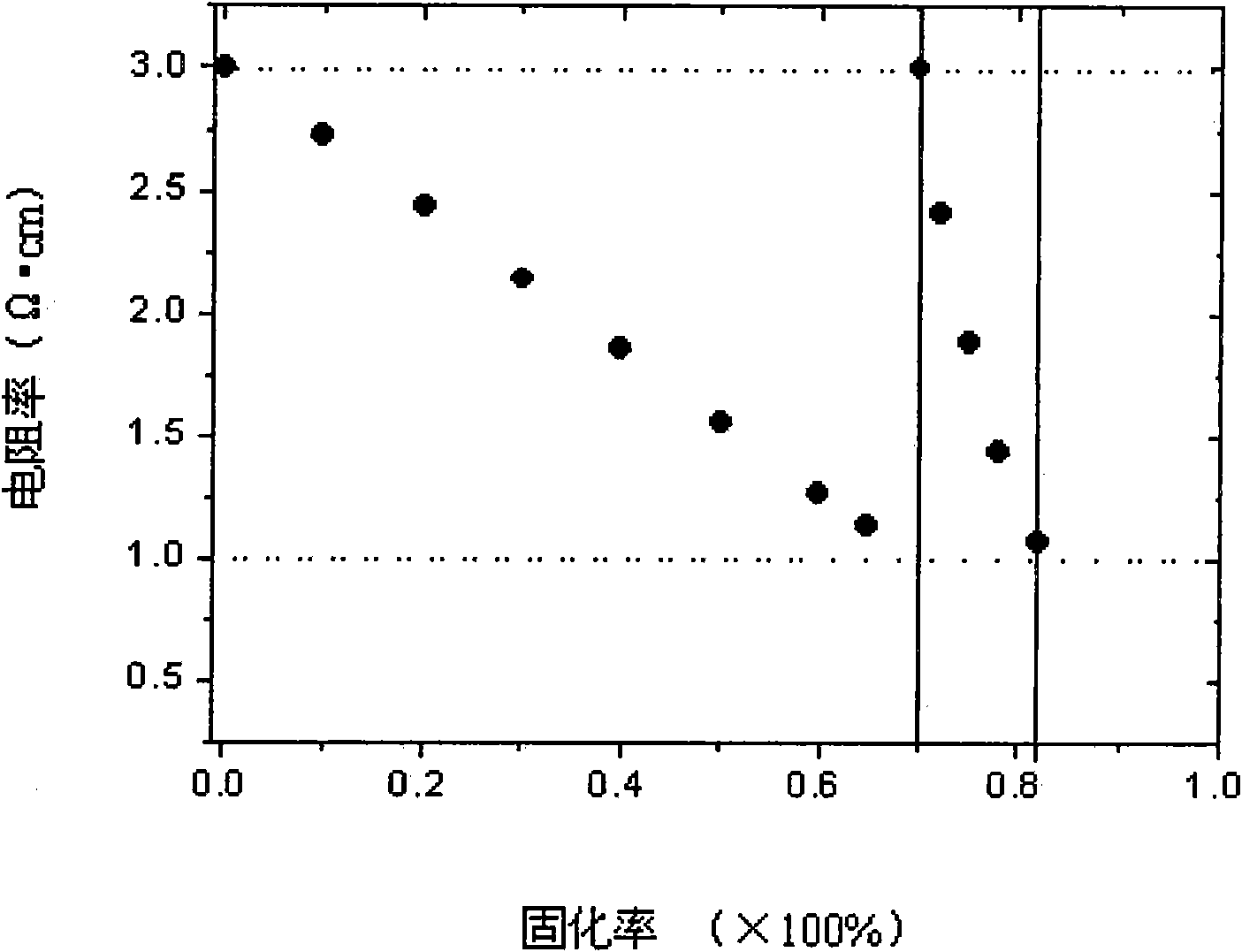

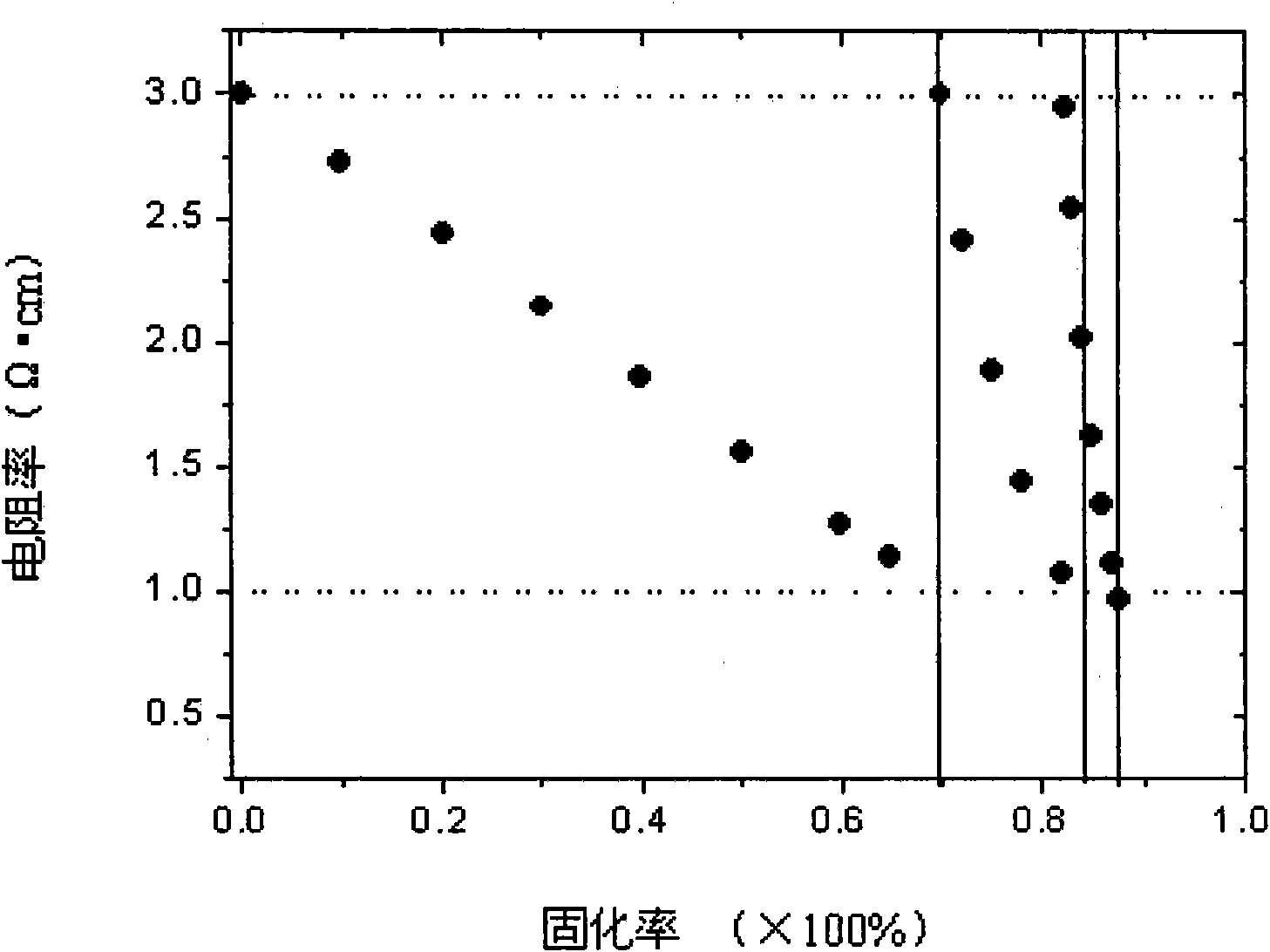

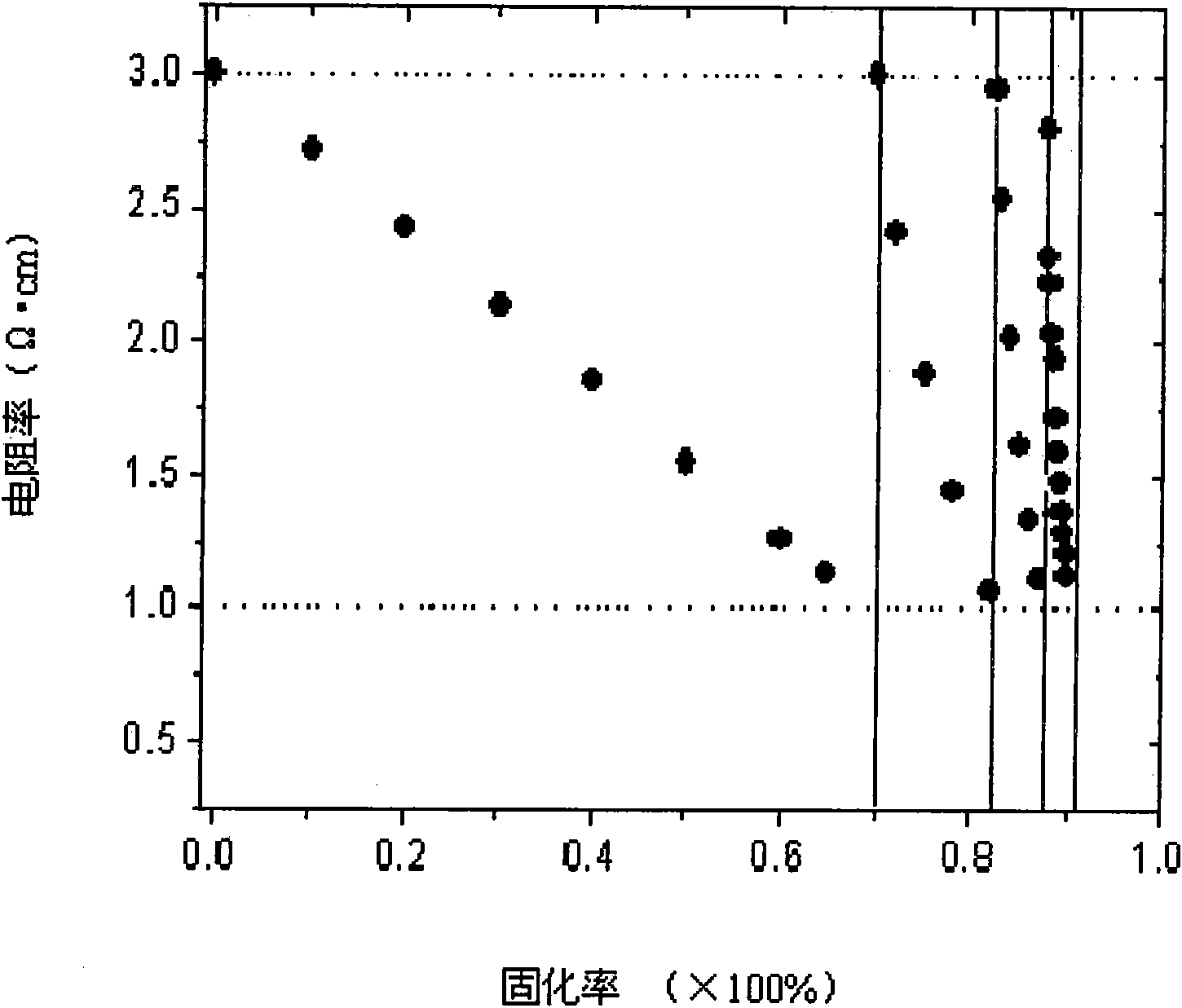

The invention discloses a method for controlling the specific resistance of gallium-doping Czochralski silicon in the crystal growth process, which comprises the following steps: melting multi-crystalsilicon in vacuum or under the protection of argon, melting gallium in the silicon solution to form a gallium-doping silicon solution, and growing the single crystal of the Czochralski silicon; in the crystal growth process, when the specific resistance of the crystal is 1.2-1.0 omega cm, doping the n type dopant-phosphorus with certain concentration in the residual gallium-doping silicon solution to form a phosphorus and gallium-doped silicon solution for continuously growing, and enabling the specific resistance of the crystal to be regulated to 3.0 omega cm again; and when the curing ratioof the crystal reaches 80-90%, stopping the growth. The phosphorus doping process in the residual gallium-doped silicon solution can be carried out many times. The invention can control the specificresistance of the back half part of the single crystal of the gallium-doped Czochralski silicon in the range of 1-3 omega cm to be favorable for increasing the utilization ratio of silicon materials in the process of preparing high-efficiency solar batteries, thus the manufacturing cost of the high-efficiency batteries is greatly reduced, and the method has simple operation and can be easily applied to the photovoltaic industry in a large scale.

Owner:ZHEJIANG UNIV

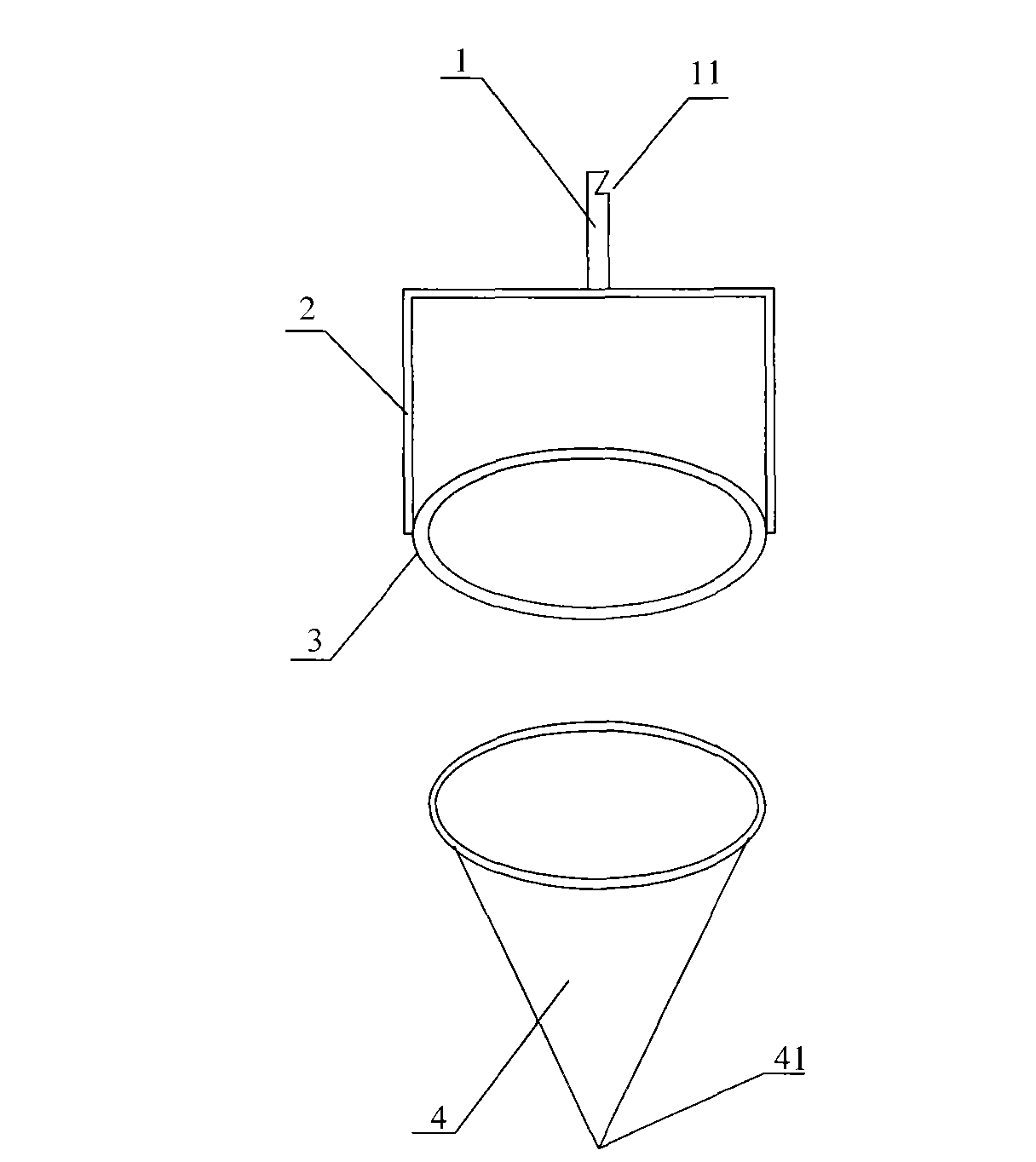

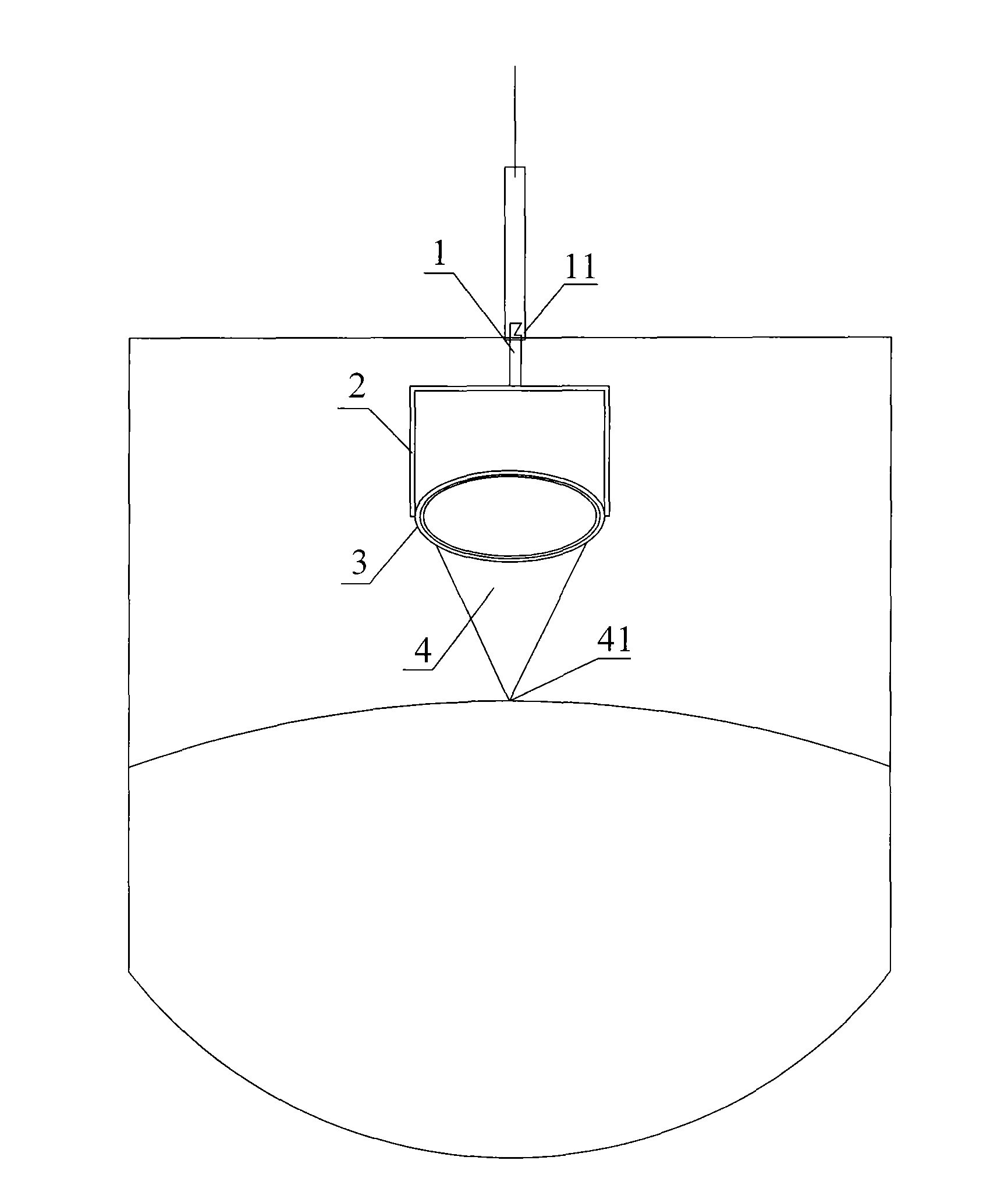

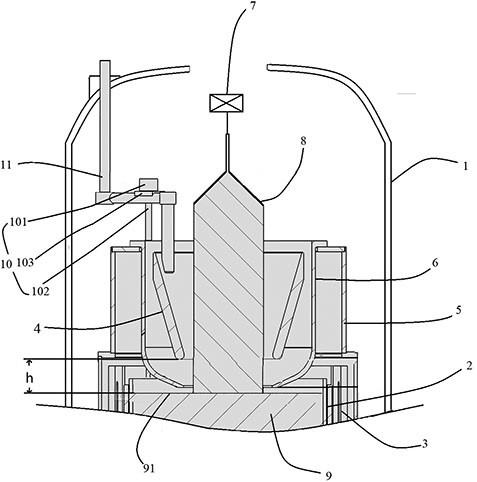

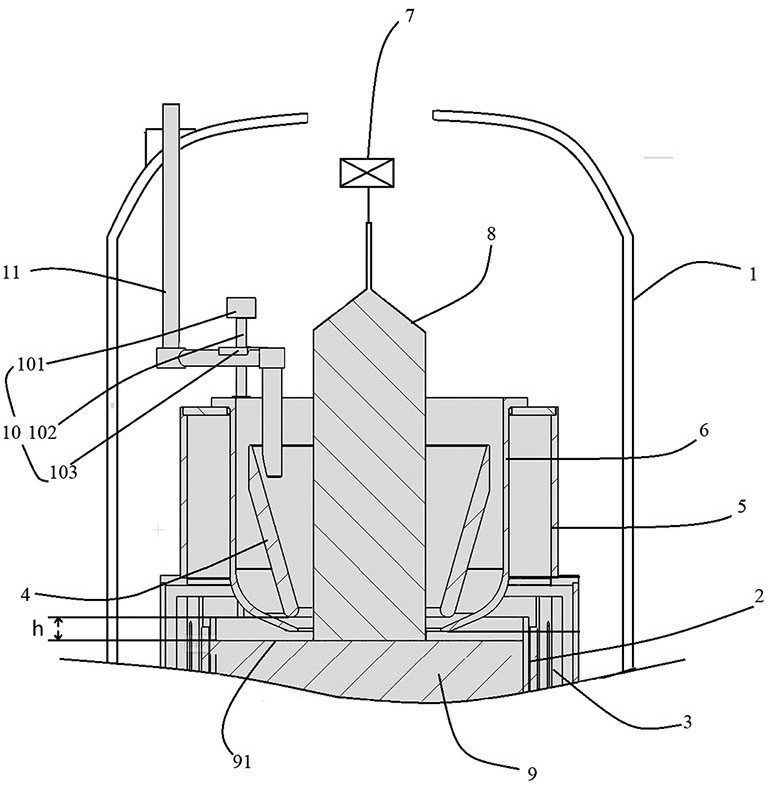

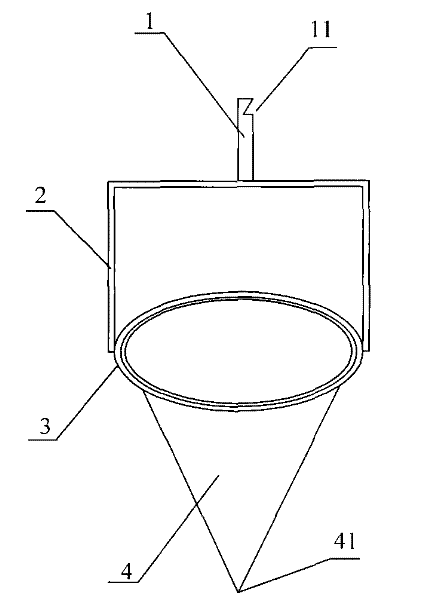

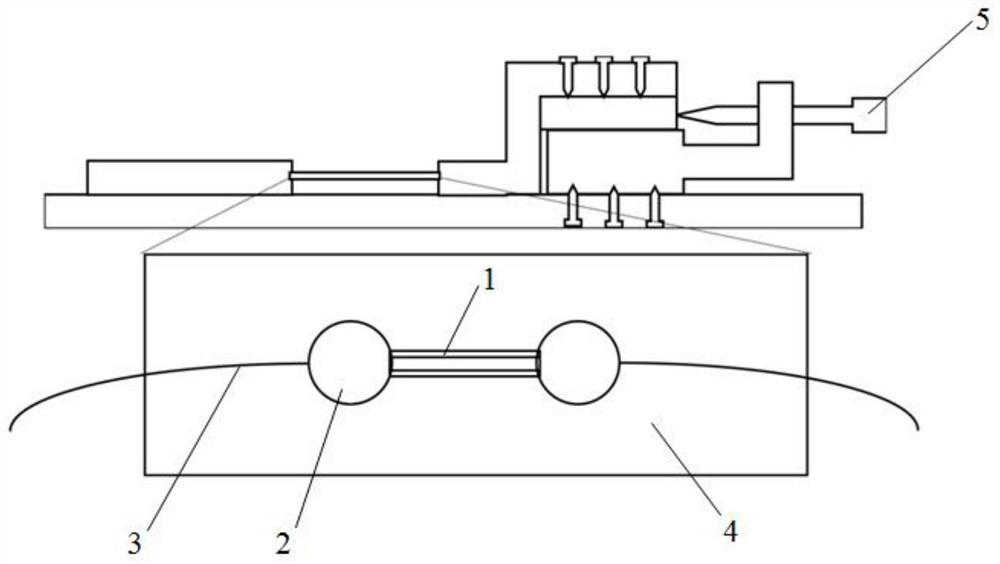

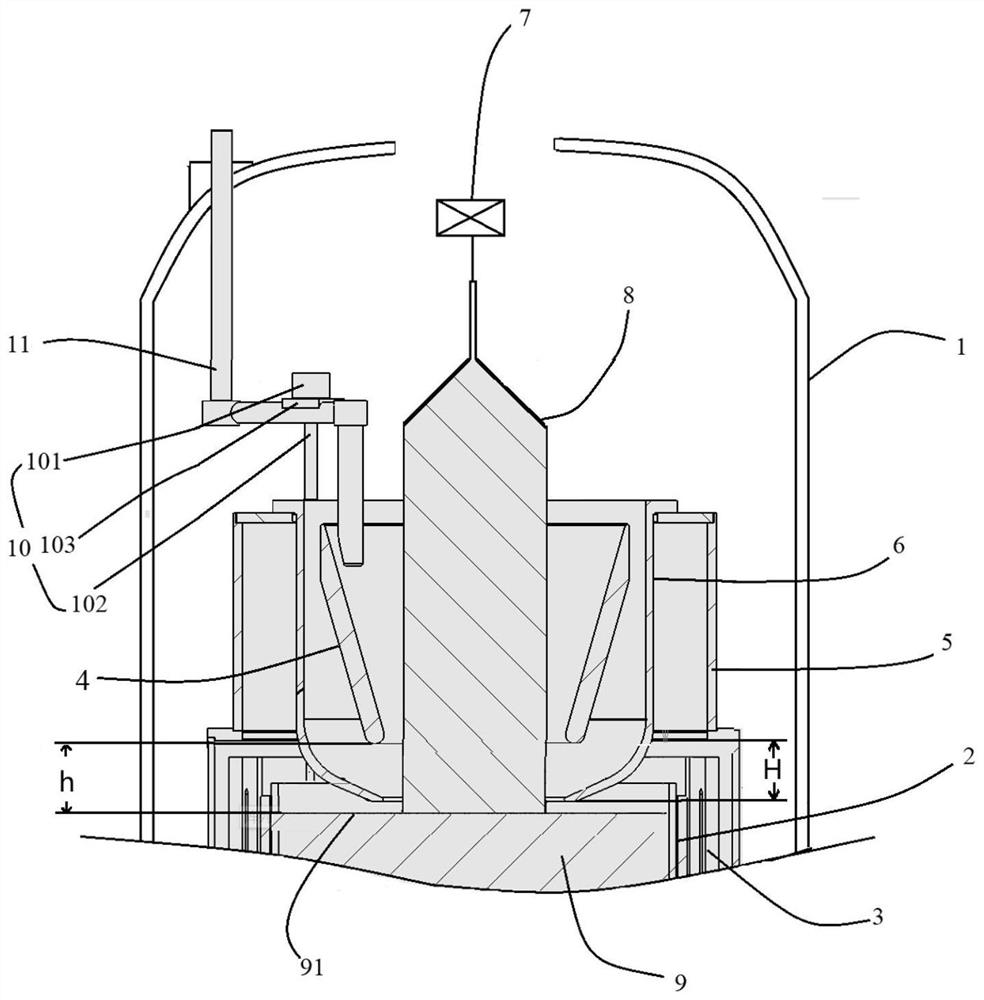

Gallium doping method of Czochralski silicon monocrystalline and doping device thereof

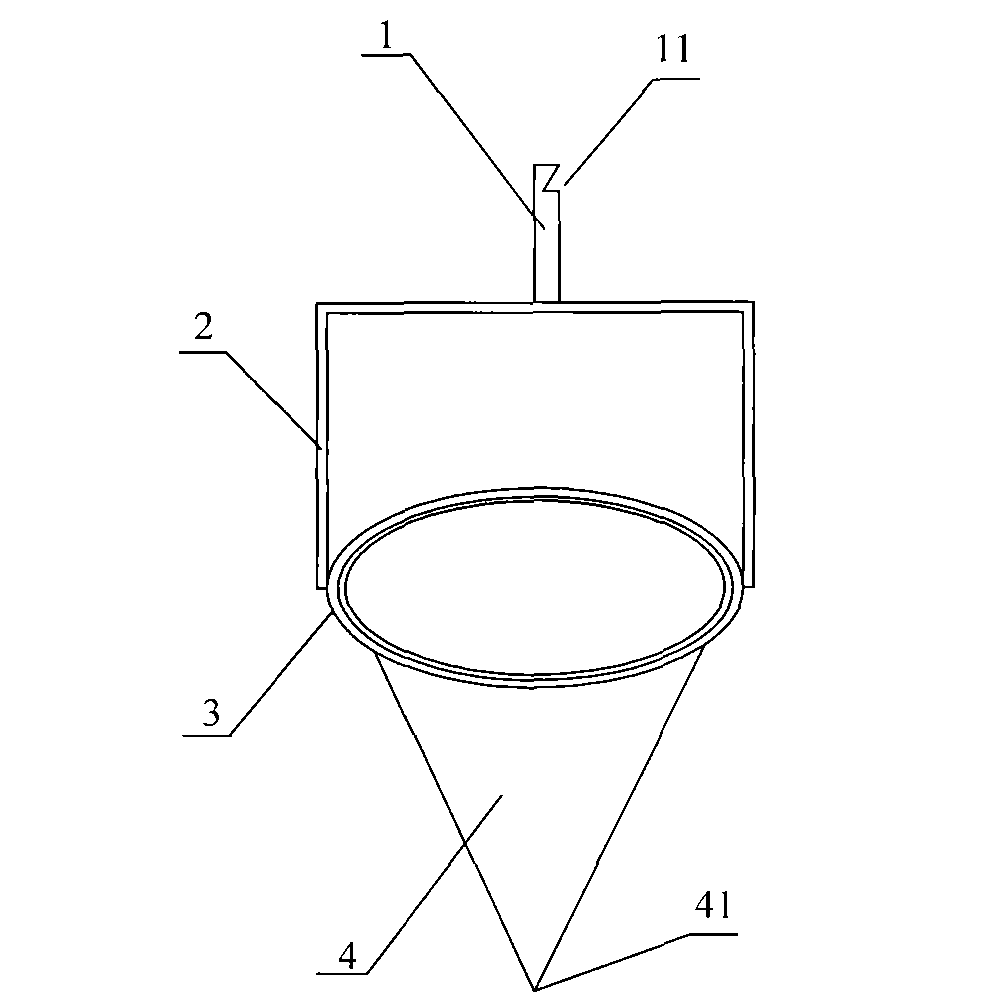

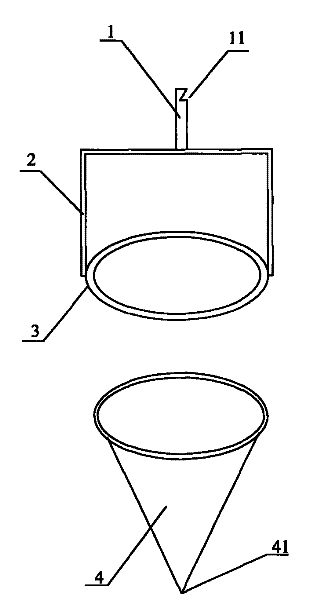

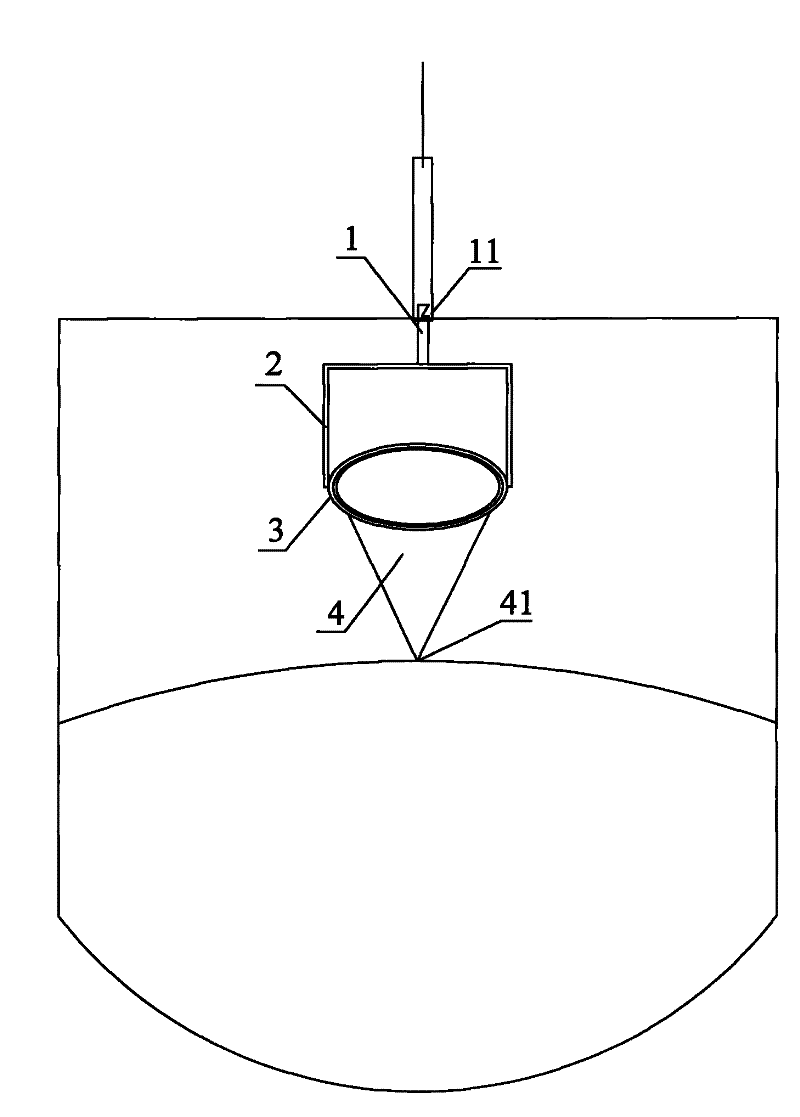

The invention discloses a gallium doping device, comprising a flying ring (2), a ring-shaped fixed sleeve (3) and a hollow cone (4), wherein the flying ring (2) is made of high-purity quartz, the hollow cone (4) is made of high-purity monocrystalline silicon, the ring-shaped fixed sleeve (3) is connected with the hollow cone (14), one end of the flying ring (2) is connected with the ring-shaped fixed sleeve (3), the other end of the flying ring (2) is connected with a handle part (1), and the handle part (1) is provided with a groove (11) which is matched with a crystal seed chuck on a crystal seed rod. The invention also discloses a doping method of gallium of Czochralski silicon monocrystalline through the gallium doping device. The invention can effectively avoid the poor influence on crystal growing caused by the splash of silicon melt.

Owner:ZHEJIANG HAINA SEMICON CO LTD

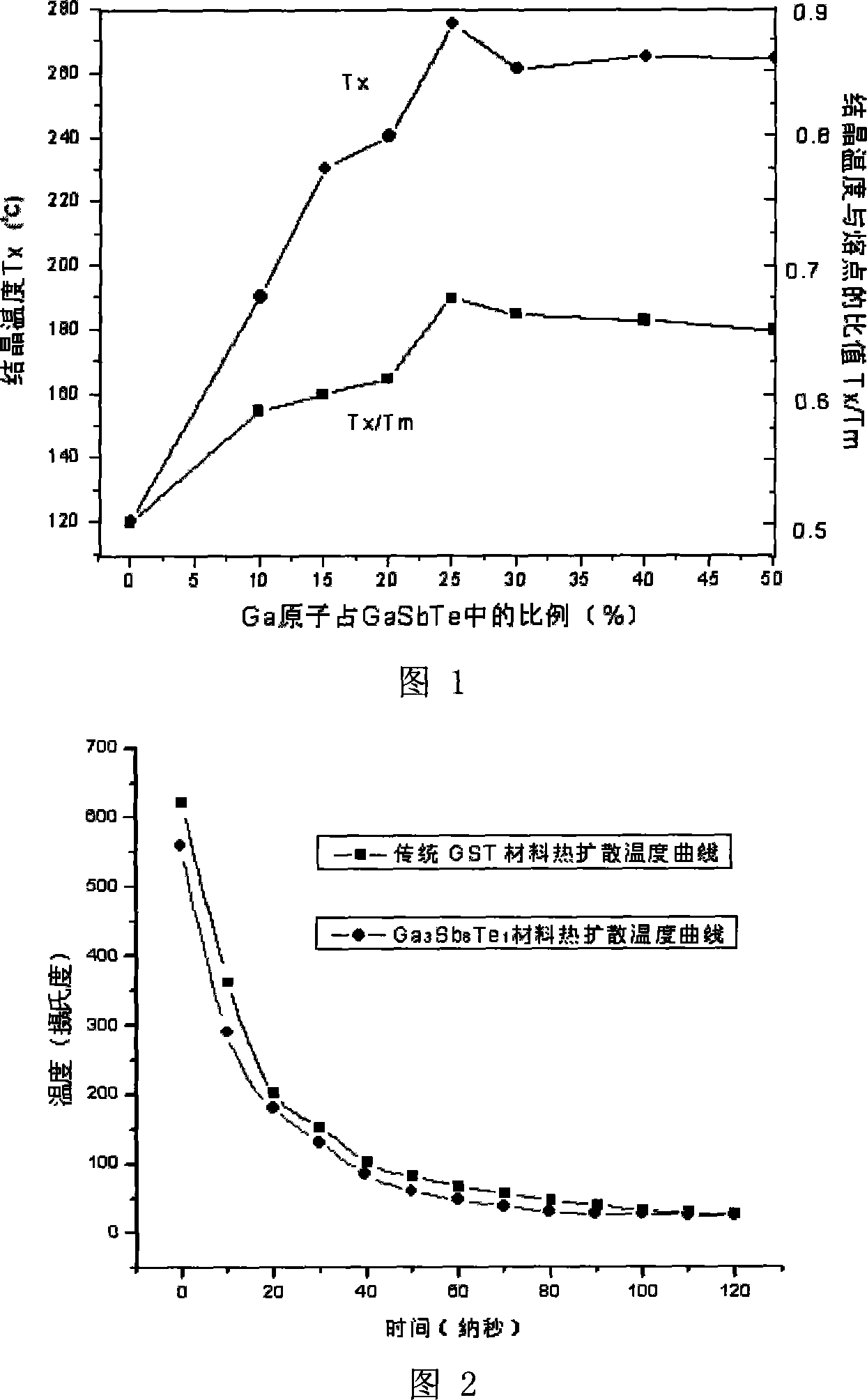

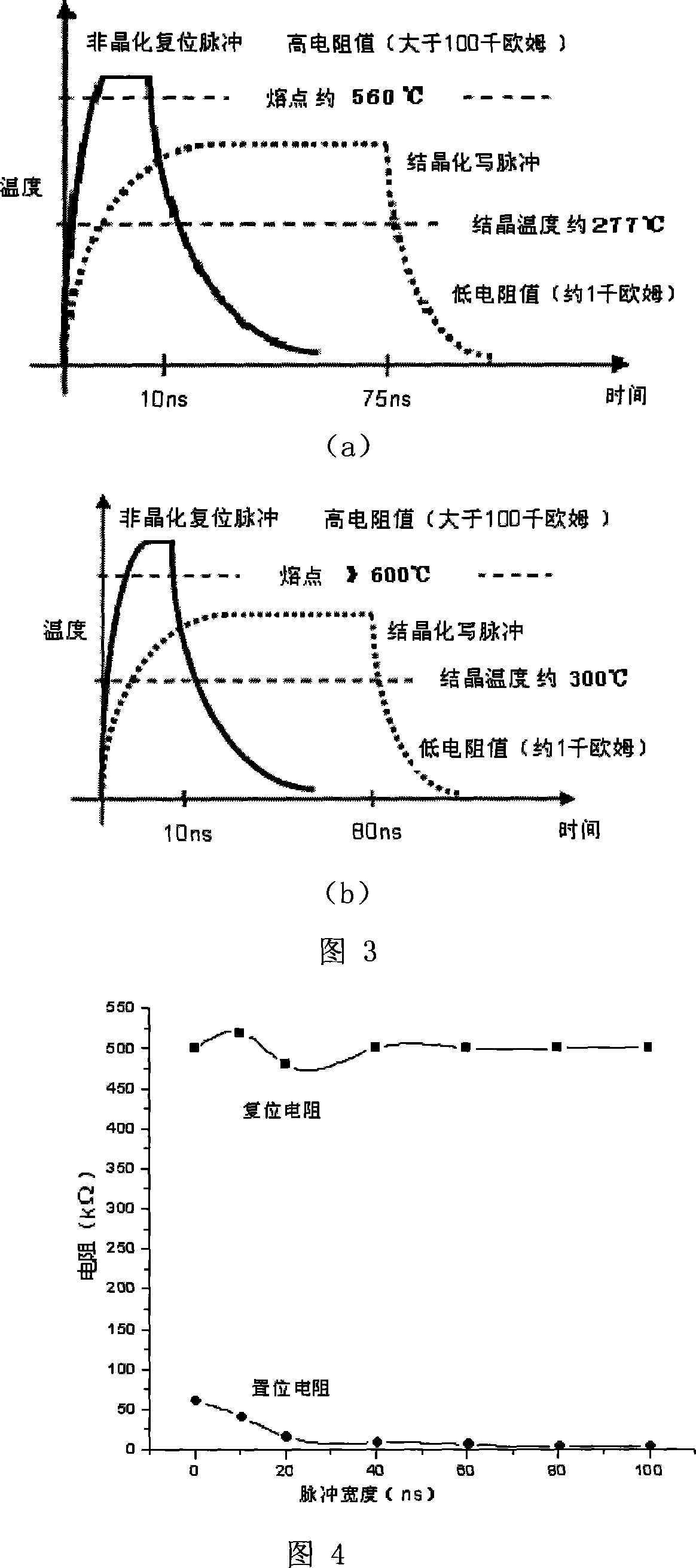

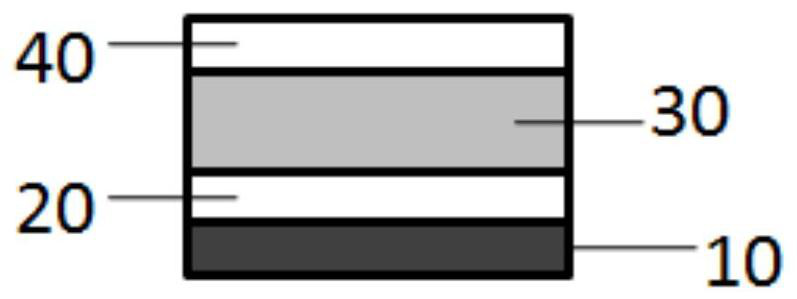

Gallium-adulterated Ga3Sb8Te1 phase change memory unit and its making method

InactiveCN101101962AReset Power ReductionLow melting pointSolid-state devicesDigital storagePhase-change memoryNanoimprint lithography

The invention is concerned with the gallium doping Ga3Sb8Te1 phase change memorizer unit and its making method, belongs to the micro-electronics technique field, it includes: the silicon underlay, the up and down electrode, the heating layer, and the insulating medium layer, the phase change material is the Ga3Sb8Te1, as the sulfur system compound. It is: forming the down electrode by depositing the layer of the down electrode material on the silicon underlay; applying the nanometer coining photolithography and the dry etching technique chisels the small hole on the center of the first insulating medium layer which depositing on the down electrode material; filling up the small hole with the heating layer depositing and conducting the chemical-mechanical polishing; depositing the second insulating medium on the heating layer, then, chiseling the groove on the second insulating medium with same techniques and depositing the layer of Ga3Sb8Te1 phase change material in the groove, conducting the chemical-mechanical polishing; at last, forming the up electrode by depositing the up electrode material. The invention reduces the power consumption of the phase change memorizer unit to 10%.

Owner:SHANGHAI JIAO TONG UNIV

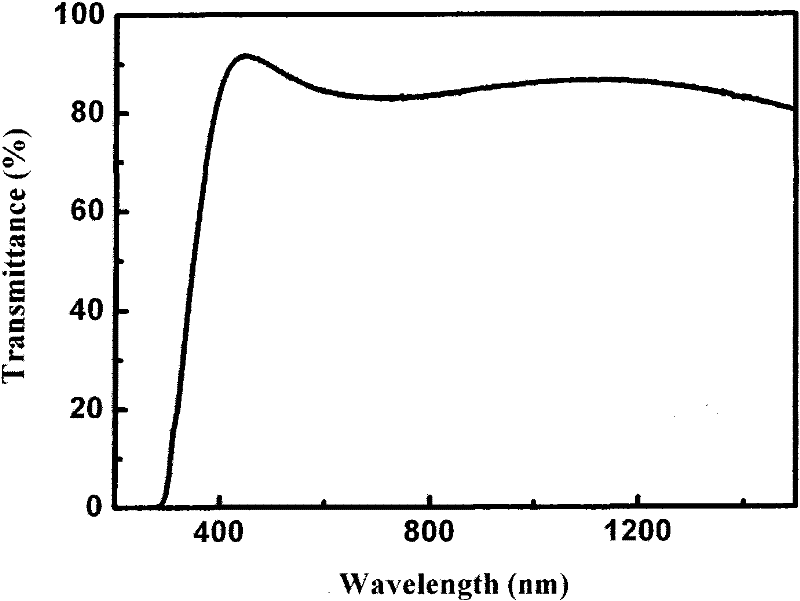

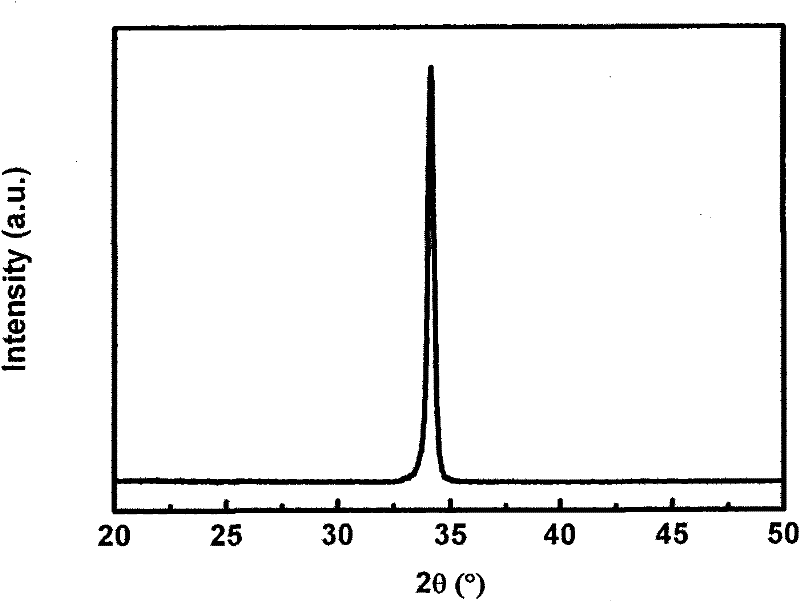

Gallium doped zinc oxide target and preparation method of transparent conductive film thereof

The invention relates to gallium doped zinc oxide target and a preparation method of a transparent conductive film thereof. The target is formed by sintering zinc and gallium oxide powder, wherein the weight content of gallium oxide is 0.5-10%; the purity of the target is no less than 99.9%; and the relative density of the target is no less than 95%, and the maximum is up to 99.5%. The transparent conductive film prepared from the target through the sputtering method has good photoelectric properties; the resistivity can be as low as 1.05*10<-4>Omega cm, the maximum transmissivity is up to 92% in the visible light range (400-800 nm), the average transmissivity is no less than 84%; and the transparent conductive film can be widely used in the fields such as solar cells, light emitting diodes, flat-panel display and liquid crystal display.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

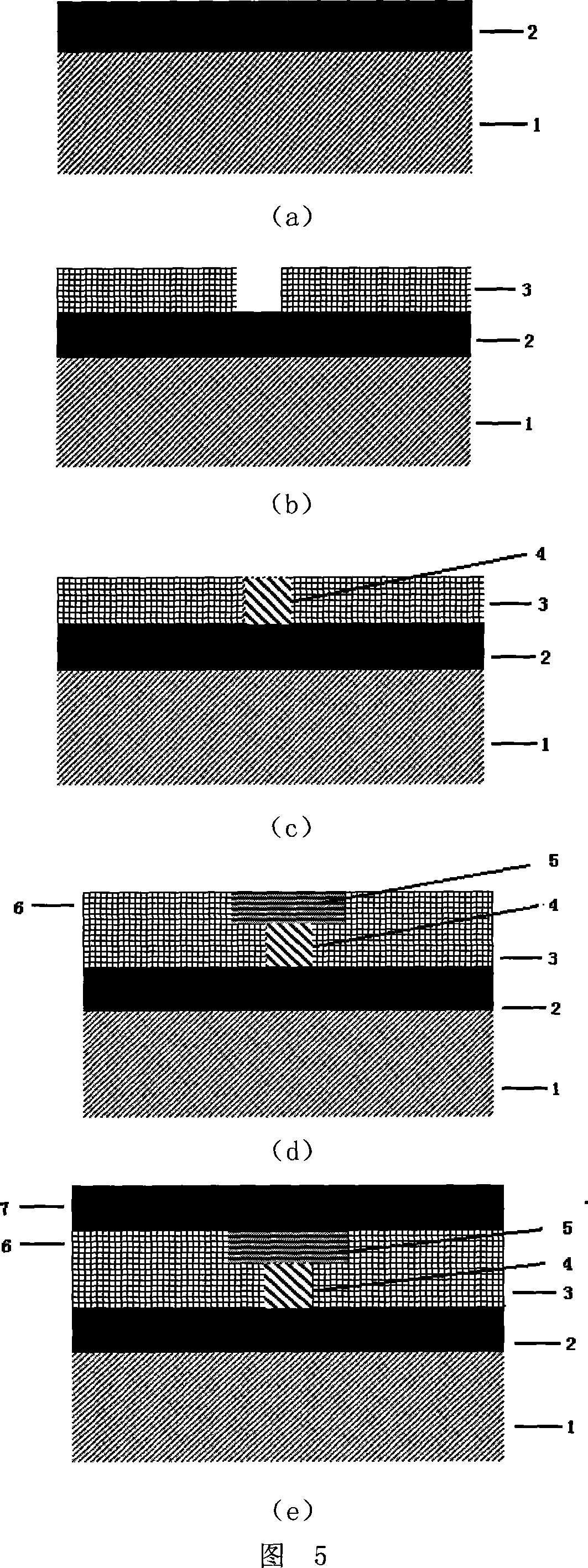

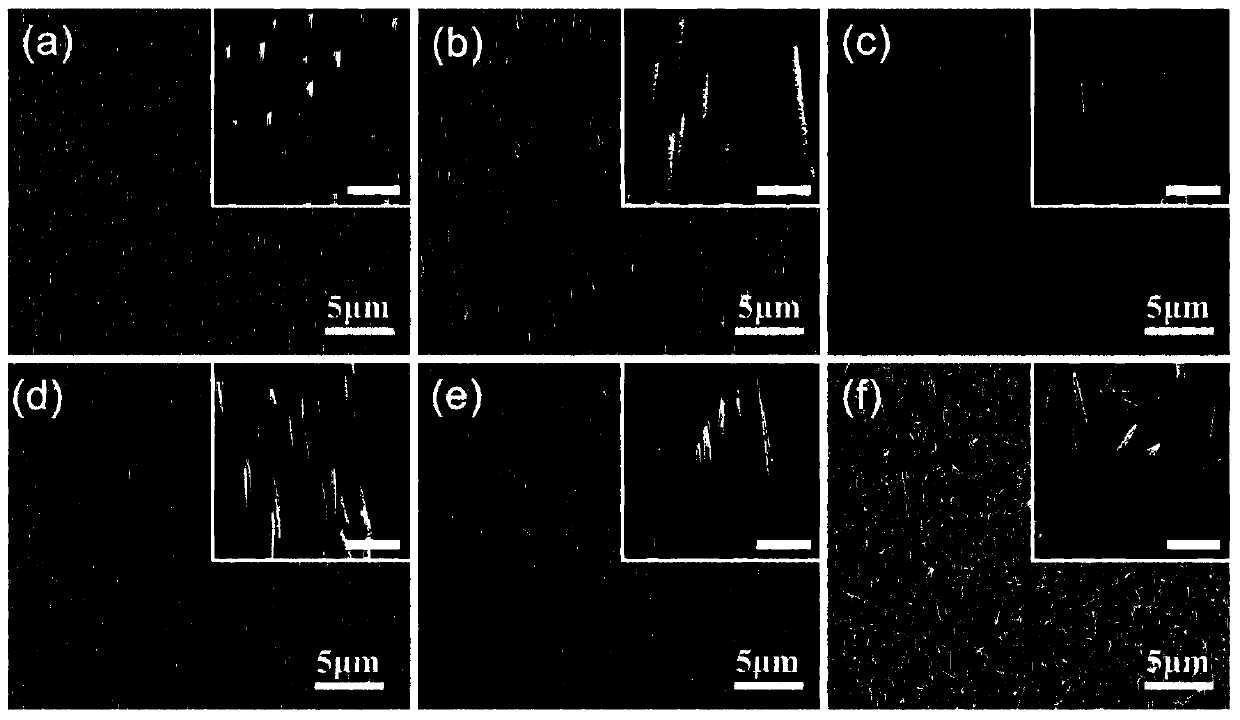

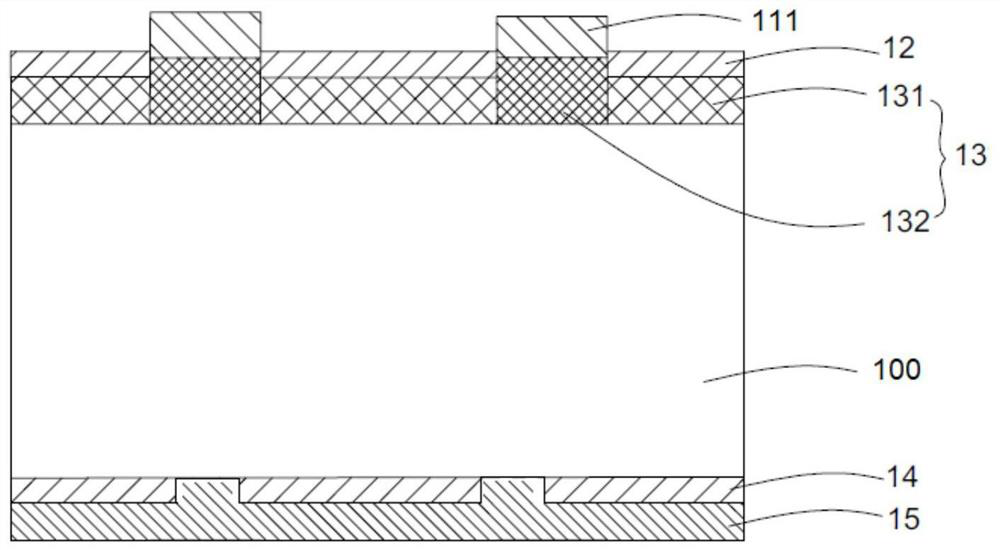

Wave length-adjustable light-emitting diode based on gallium-doped zinc oxide nanowire array and manufacturing method thereof

InactiveCN103746056AImprove propertiesLow costVacuum evaporation coatingSputtering coatingLength waveLight-emitting diode

The invention discloses a wavelength-adjustable light-emitting diode based on a gallium-doped zinc oxide nanowire array and a manufacturing method thereof. The wavelength-adjustable light-emitting diode based on the gallium-doped zinc oxide nanowire array comprises a p-type conducting substrate, a gallium-doped zinc oxide nanowire array, a bottom electrode and a top electrode, wherein the gallium-doped zinc oxide nanowire array and the bottom electrode are positioned on the p-type conducting substrate; the top electrode is positioned on the gallium-doped zinc oxide nanowire array. The manufacturing method of the wavelength-adjustable light-emitting diode based on the gallium-doped zinc oxide nanowire array comprises the following steps: providing a p-type conducting substrate; growing a gallium-doped zinc oxide nanowire array on the p-type conducting substrate by controlling the gallium-doping amount of the gallium-doped zinc oxide nanowire array; rotationally coating the grown gallium-doped zinc oxide nanowire array with a blocking layer; etching and removing the blocking layer coated on the top of the gallium-doped zinc oxide nanowire array; depositing the top electrode on the top of the gallium-doped zinc oxide nanowire array; removing a part of the gallium-doped zinc oxide nanowire array to expose the p-type conducting substrate, and manufacturing the bottom electrode on the exposed p-type conducting substrate.

Owner:HUAZHONG UNIV OF SCI & TECH

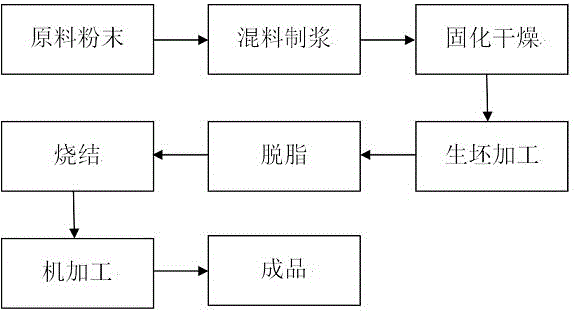

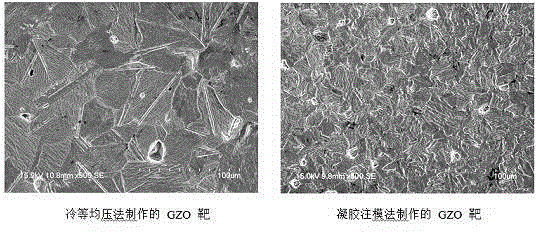

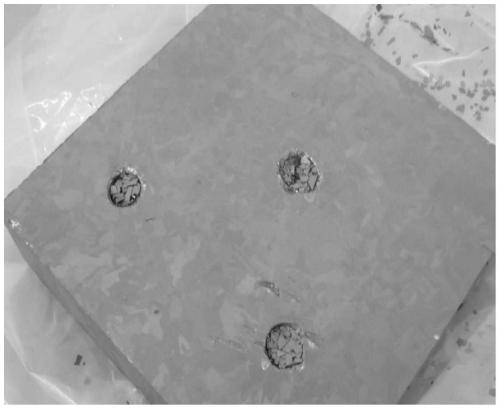

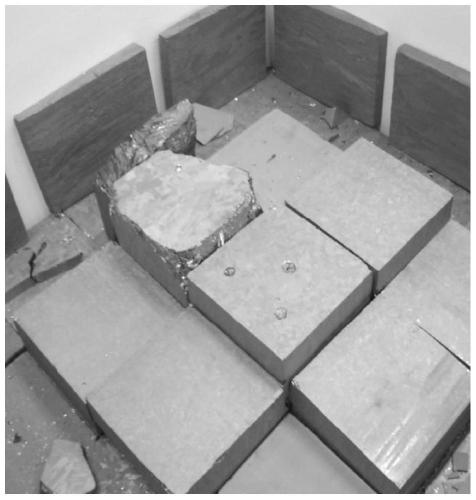

Manufacturing method of gallium doped zinc oxide target material

The invention relates to a manufacturing method of a gallium doped zinc oxide target material. The gel casting technology is used for manufacturing the gallium doped zinc oxide target material. The gallium doped zinc oxide target material with the compactness being 98% is manufactured through the steps of mixing, pulping, curing drying, green body machining, degreasing, sintering, machining and the like. According to the manufacturing method, the vacuum defoamation technology is omitted, so that the existing gel casting technological process is simplified, and the manufacturing cost is lowered.

Owner:HANERGY CO INNO MOBILE ENERGY INVESTMENT CO LTD

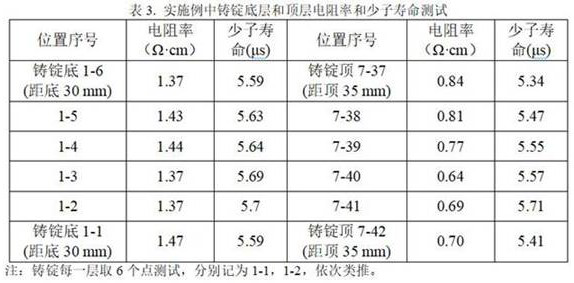

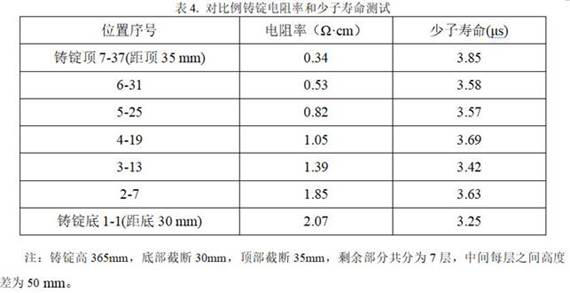

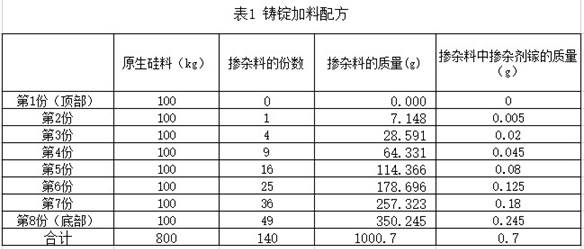

Preparation method of gallium-doped silicon ingot, gallium-doped silicon ingot and silicon piece

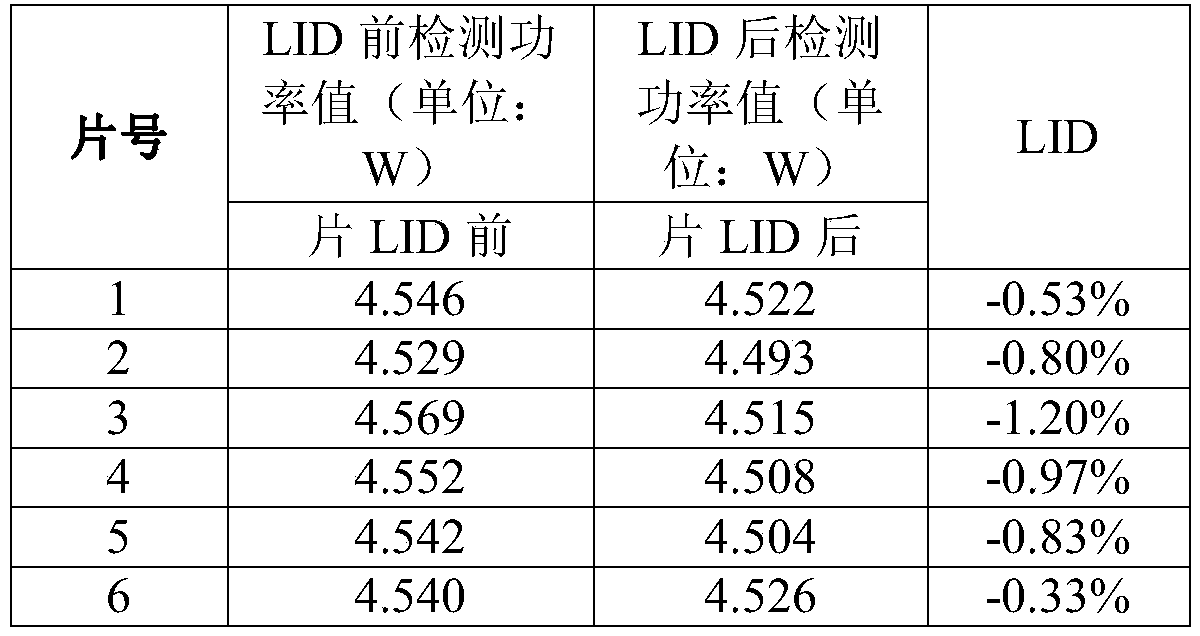

InactiveCN110438565AGood uniformity of longitudinal resistivity distributionImprove life expectancyPolycrystalline material growthBy pulling from meltLiquid metalIngot

The invention discloses a preparation method of a gallium-doped silicon ingot, the gallium-doped silicon ingot and a silicon piece. The preparation method comprises the following steps: injecting a molten metal gallium into pores of a silicon material, curing the molten metal gallium and / or sealing the pores, putting the obtained silicon material with the metal gallium and the rest silicon material into a quartz crucible, and performing melting, recrystallization and annealing cooling so as to obtain gallium-doped silicon ingot. The gallium-doped silicon ingot is prepared by using the preparation method. The silicon piece is prepared from the gallium-doped silicon ingot. By adopting the preparation method, a gallium doping process and effective and precise control on gallium doping amountscan be achieved, the preparation method has the advantages of being convenient in operation, easy in control, high in gallium doping amount precision, and the like, the prepared gallium-doped siliconingot has the advantages of being good in resistance distribution uniformity, long in minority carrier lifetime, and the like, a solar battery prepared from the gallium-doped silicon ingot has high photoelectric efficiency and low light degradation, and great significances can be achieved for wide application of solar batteries.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

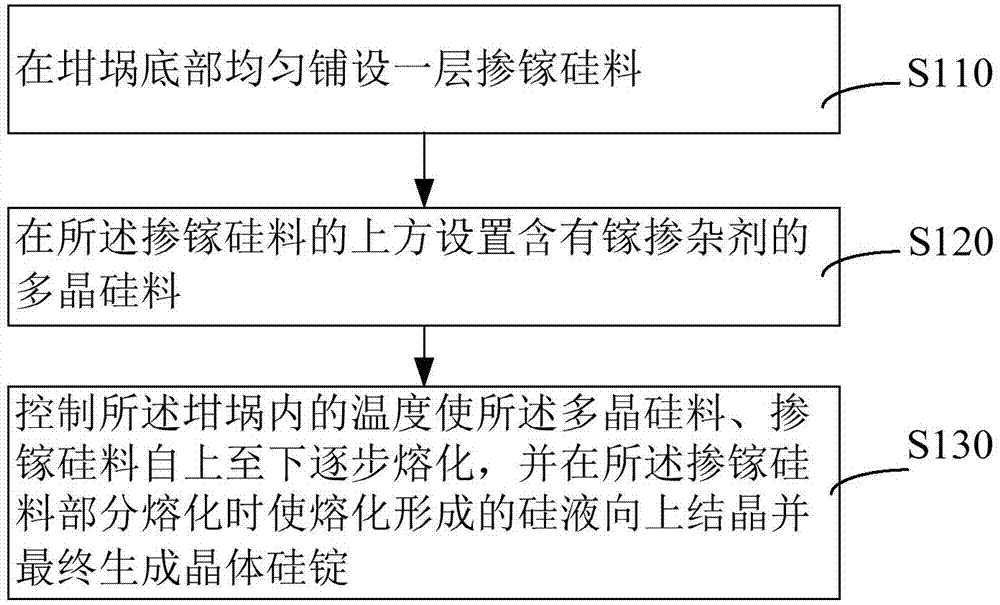

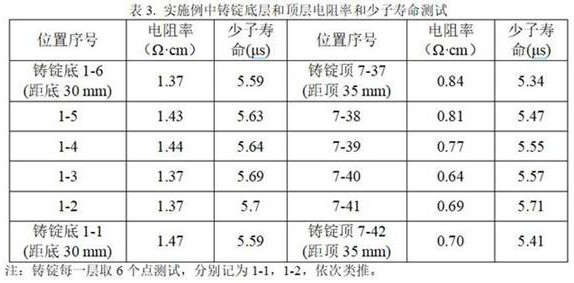

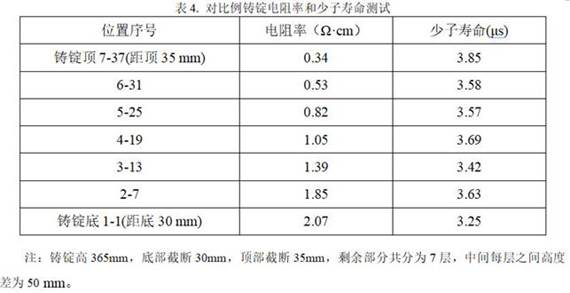

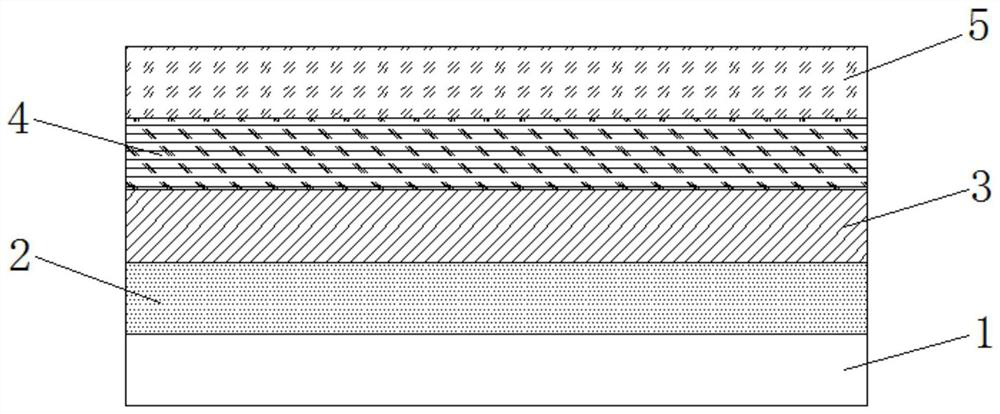

Gallium-doped crystalline silicon with uniformly distributed resistivity and preparation method thereof

The invention relates to a preparation method of gallium-doped crystalline silicon with uniformly distributed resistivity. The preparation method comprises the following steps: uniformly laying a layer of gallium-doped silicon material at the bottom of a crucible; arranging a polycrystalline silicon material containing a gallium doping agent above the gallium-doped silicon material; controlling the temperature in the crucible to gradually melt the polycrystalline silicon material and the gallium-doped silicon material from top to bottom, and upwards crystallizing silicon liquid produced during the melting of the partial gallium-doped silicon material, so as to finally generate crystalline silicon ingots. According to the preparation method, the gallium-doped silicon materials are laid at the bottom of the crucible, so that gallium can be continuously dispersed into crystals at the bottom of the crucible in a bottom crystallization process, the bottom doping concentration of the silicon ingots is improved, the bottom resistance of the silicon ingots can be effectively controlled, the distribution range of the resistivity of the silicon ingots in the vertical direction is reduced, and the proportion of the qualified silicon ingots with the resistivity of 0.8-3 omega.cm is increased. Besides, the invention further discloses the gallium-doped crystalline silicon prepared by virtue of the preparation method.

Owner:JIANGSU XIEXIN SILICON MATERIAL TECH DEV

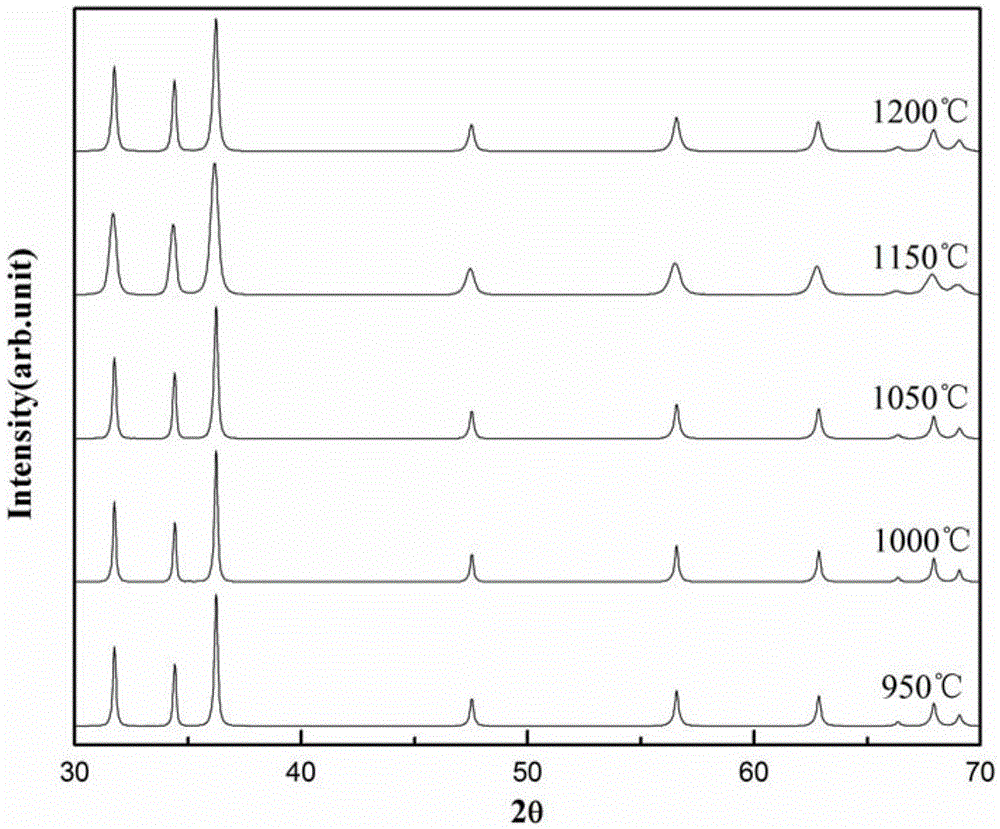

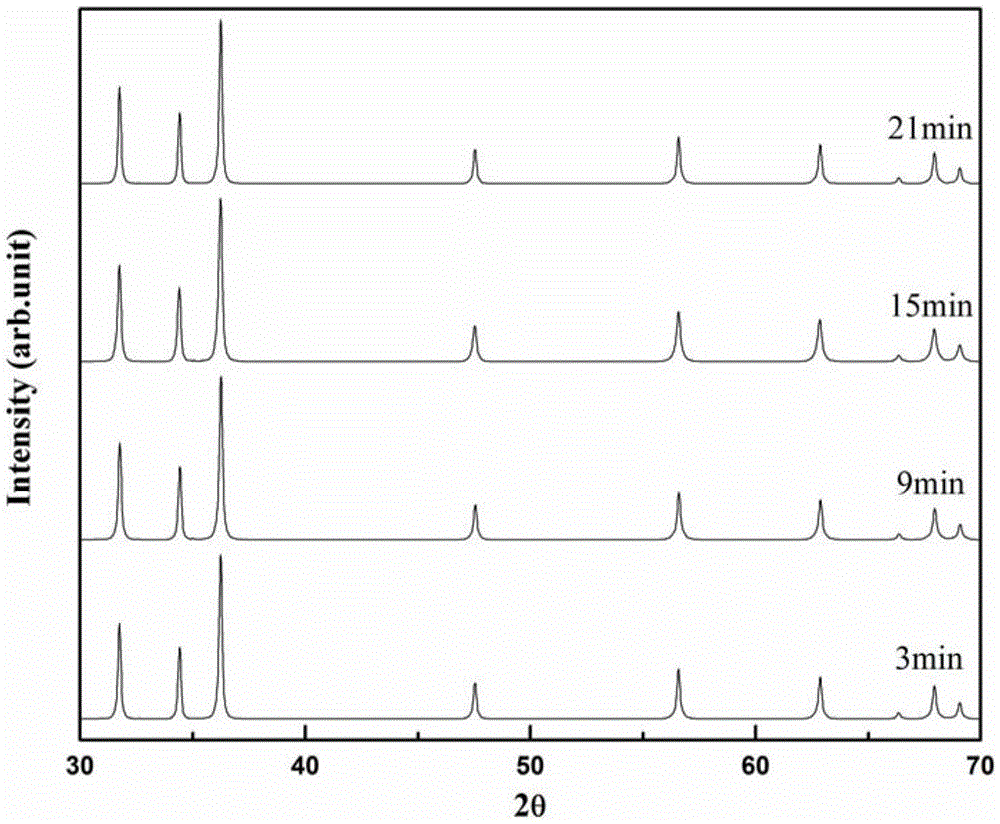

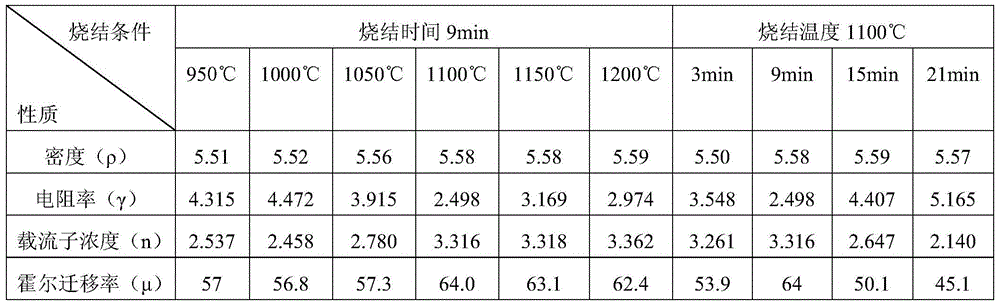

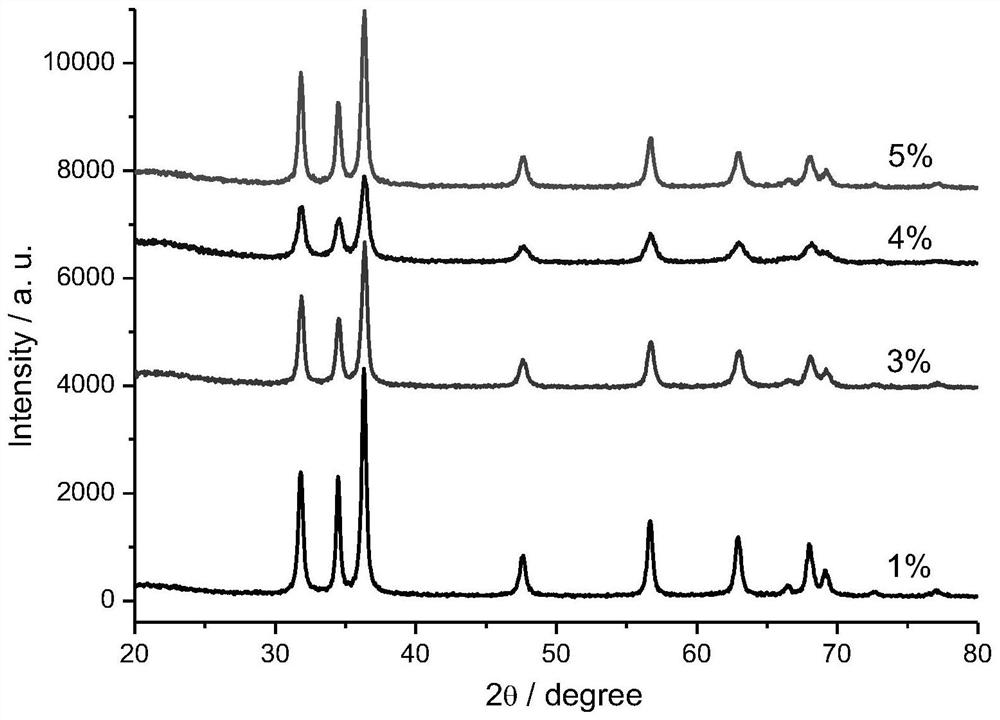

Method for studying optimum sintering process of gallium-doped zinc oxide ceramic by spark plasma sintering

The invention provides a method for studying the optimal sintering process of gallium-doped zinc oxide ceramics by spark plasma sintering. ZnO and Ga 2 o 3 Powder according to Ga 0.00075 Zn 0.99925 After the O ratio is weighed, ball milled, dried and sieved, ZnO, Ga 2 o 3 Powder; the powder is put into the graphite grinding tool, compacted, the graphite grinding tool is placed in the furnace cavity of the spark plasma sintering furnace, vacuumed, and the pre-pressure is 15MPa; it is raised from room temperature to 600 ° C within 4 minutes, and then Raise the temperature at a rate of 10°C / min. When the maximum peak value appears on the displacement curve, increase the pressure to 60MPa, then increase the temperature at a rate of 10°C / min to 1100°C, keep the temperature for 9 minutes, and reduce the pressure to the minimum after cooling down. Once sintered into porcelain. This process greatly improves the preparation efficiency; it also has the characteristics of one-time sintering into porcelain, low energy consumption, and is convenient for industrial production; it greatly reduces the resistivity of GZO ceramics and improves its electrical properties.

Owner:BEIJING UNIV OF TECH

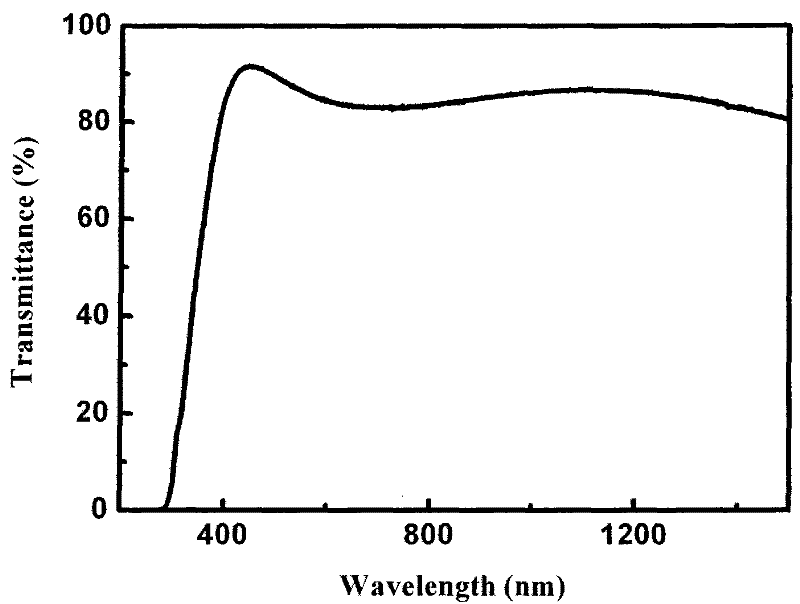

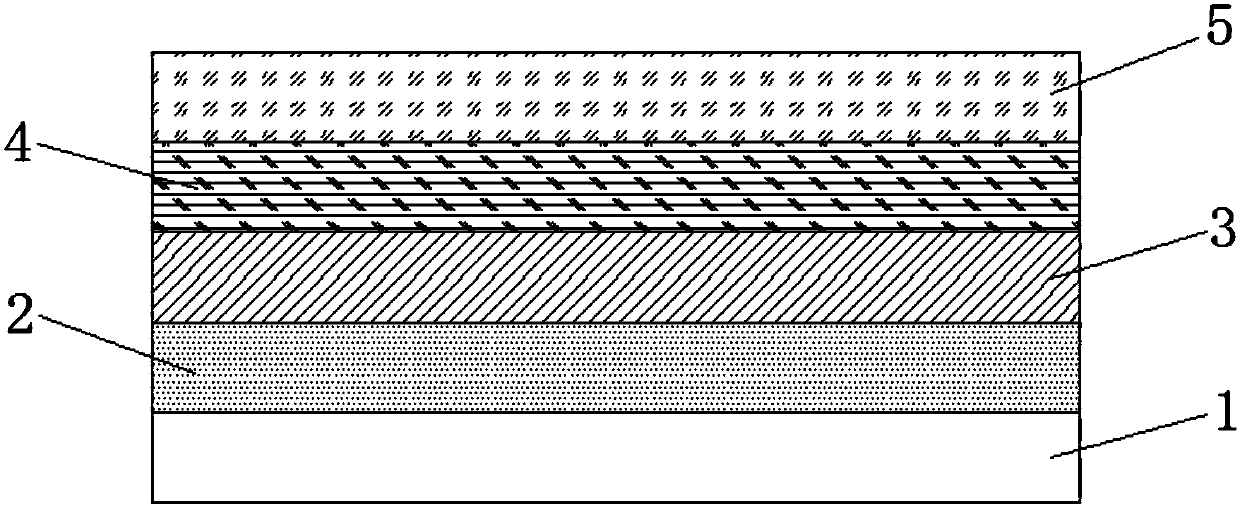

High-efficiency planar perovskite solar cell and fabrication method thereof

ActiveCN107799654AImprove photoelectric conversion efficiencyFacilitate conductionSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellMetal electrodes

The invention relates to a high-efficiency planar perovskite solar cell. The high-efficiency planar perovskite solar cell comprises a transparent conductive substrate, an electron conduction layer, aperovskite layer, a hole conduction layer and a metal electrode, wherein the electron conduction layer is a gallium-doped titanium dioxide compact layer fabricated by a low-temperature process solution method. The invention also relates to a fabrication method of the high-efficiency planar perovskite solar cell. The gallium-doped titanium dioxide compact layer is obtained by adding gallium nitrateinto the process of fabricating the titanium dioxide layer by hydrolysis of titanium tetrachloride and by low-temperature heat treatment, and the perovskite solar cell is assembled by the gallium-doped titanium dioxide compact layer. In the planar perovskite solar cell, the gallium-doped titanium dioxide compact layer prepared by the low-temperature process solution method is used as the electronconduction layer, collection and conduction of photo-induced electron by the titanium dioxide electron conduction layer are facilitated by gallium doping, so that the planar perovskite solar cell hasthe advantages of high photoelectric conversion efficiency and high battery efficiency and is easy to fabricate.

Owner:SOUTH CHINA NORMAL UNIVERSITY

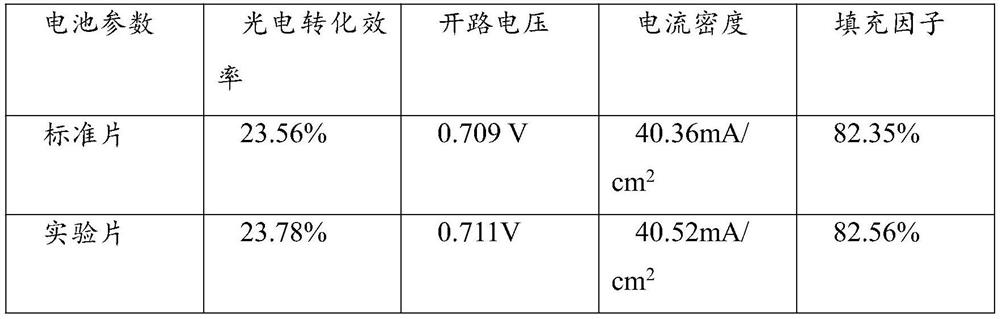

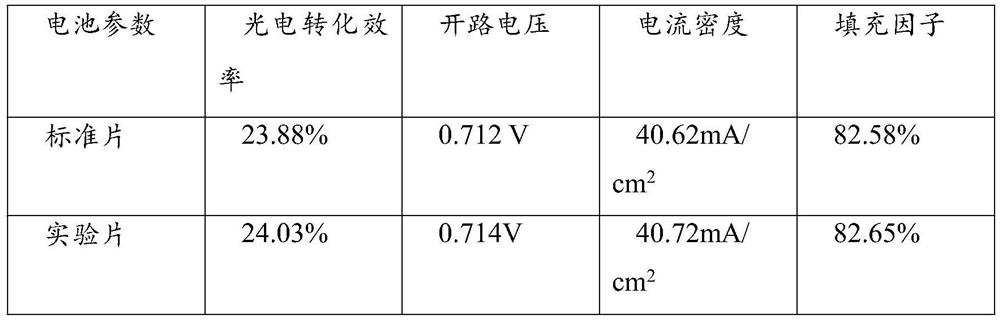

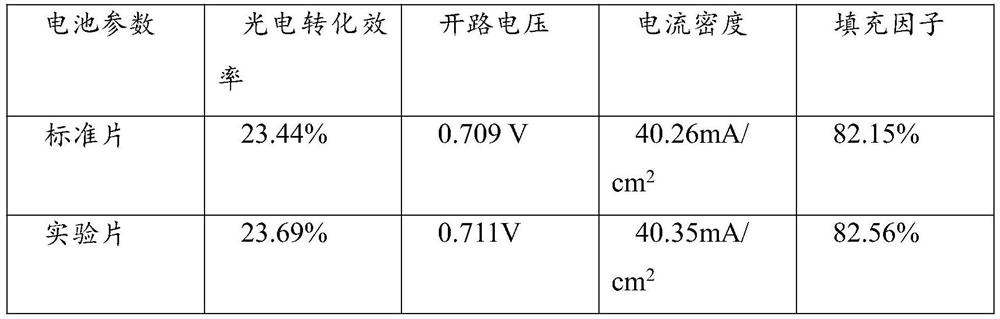

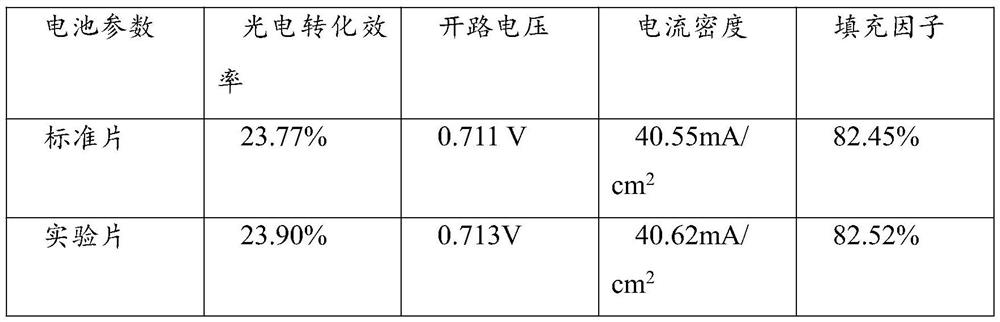

Gallium, hydrogen and nitrogen doped monocrystalline silicon, preparation method thereof and solar cell

ActiveCN111996594AImprove life expectancyImprove qualityPolycrystalline material growthFinal product manufactureSolar cellNitrogen doped

The invention relates to the field of photovoltaics. The invention provides gallium, hydrogen and nitrogen doped monocrystalline silicon, a preparation method thereof and a solar cell. The hydrogen doping concentration in the gallium, hydrogen and nitrogen doped monocrystalline silicon is 1*10 <5>-1*10<16> atoms / cm<3>, the gallium doping concentration is 1*10 <15>-5*10<17> atoms / cm<3>, and the nitrogen doping concentration is 1*10<12>-1*10<16> atoms / cm<3>; and the resistivity of the gallium, hydrogen and nitrogen doped monocrystalline silicon is 0.1-10 ohm.cm. According to the gallium, hydrogen and nitrogen doped monocrystalline silicon, the preparation method thereof and the solar cell, the minority carrier lifetime in the monocrystalline silicon can be effectively prolonged, the passivation effect of the cell is improved, the mechanical strength of a silicon wafer is improved, and the conversion efficiency of the solar cell is improved.

Owner:JINKO SOLAR CO LTD +1

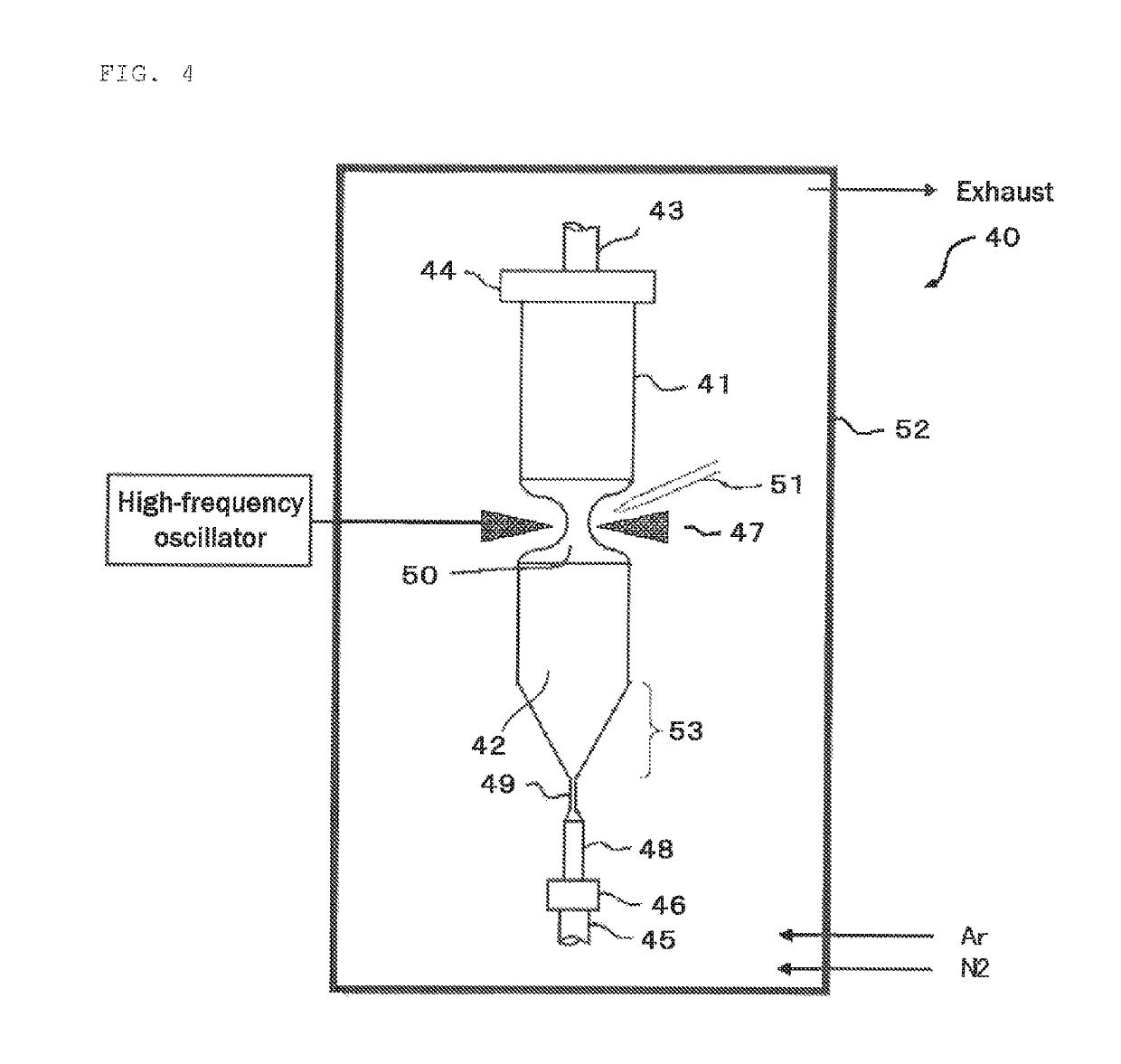

Method for preparing gallium-doped nano silicon particles by utilizing silicon waste

ActiveCN113471422AEnable recyclingIncrease valueFinal product manufactureNegative electrodesSolar batteryNitrogen gas

The invention discloses a method for preparing gallium-doped nano silicon particles by using silicon waste. The method comprises the following steps: selecting silicon micro-powder obtained by purifying the silicon waste after cutting a silicon ingot by a diamond wire as a raw material, preparing a gallium doping agent, mixing the doping agent with the silicon micro-powder, and carrying out ball milling; and pre-diffusing a gallium element to the surfaces of silicon particles through an instantaneous high temperature in a ball milling process, then carrying out vacuum drying on a product after ball milling, placing the dried product in a vacuum furnace, introducing a mixed gas of hydrogen and nitrogen for auxiliary diffusion, and screening and collecting after diffusion is completed to finally obtain the gallium-doped silicon nanoparticles. The gallium-doped silicon nanoparticles are simple in preparation process, low in production cost, suitable for a laser to carry out rapid and efficient local gallium element doping, high in process compatibility with an existing solar battery production line and suitable for industrial production. As the gallium-doped silicon nanoparticles have good conductivity, the gallium-doped silicon nanoparticles can well relieve the volume expansion of silicon and improve the rate capability of the battery as the silicon negative electrode material of the lithium battery.

Owner:YANCHENG INST OF TECH

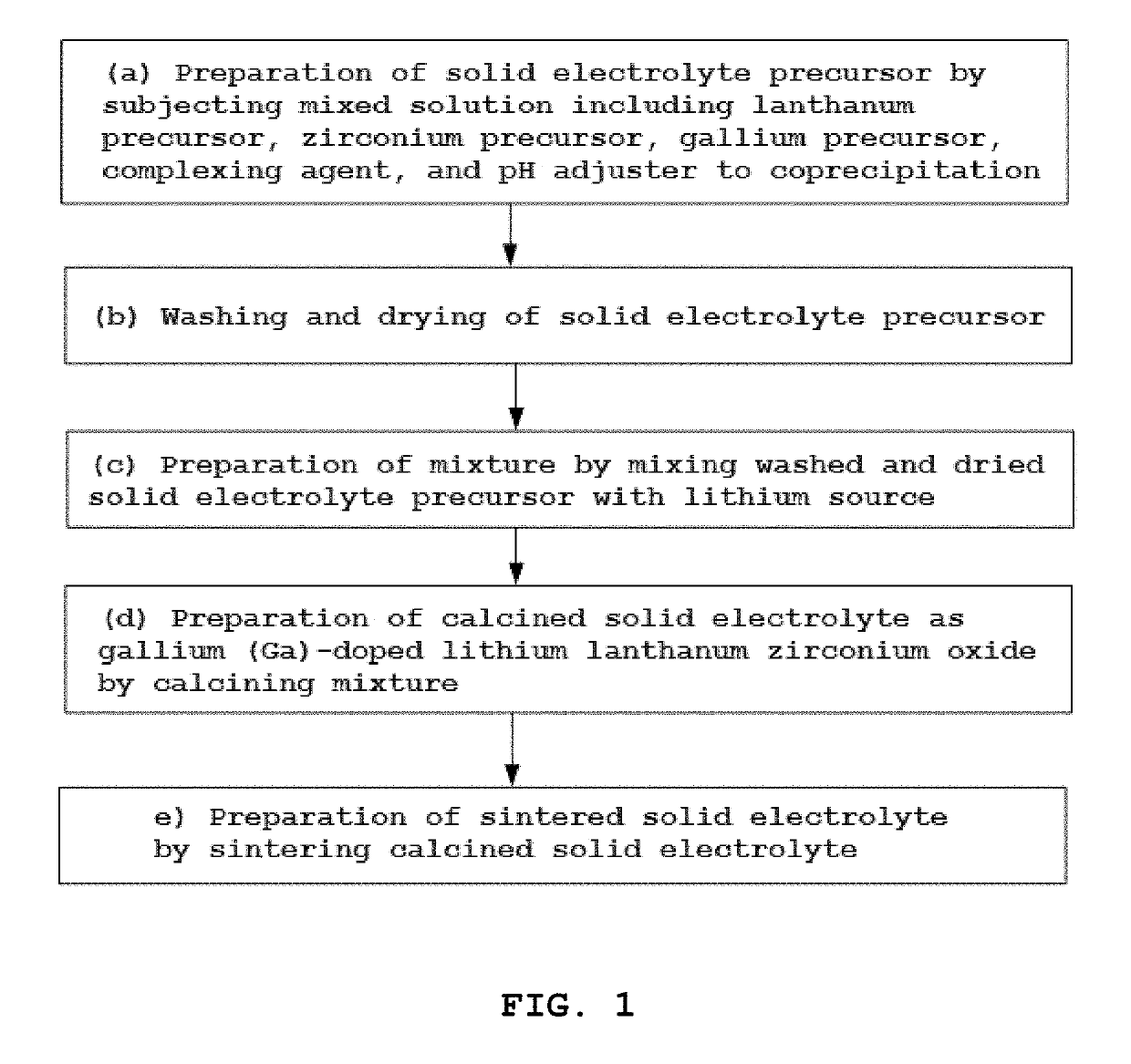

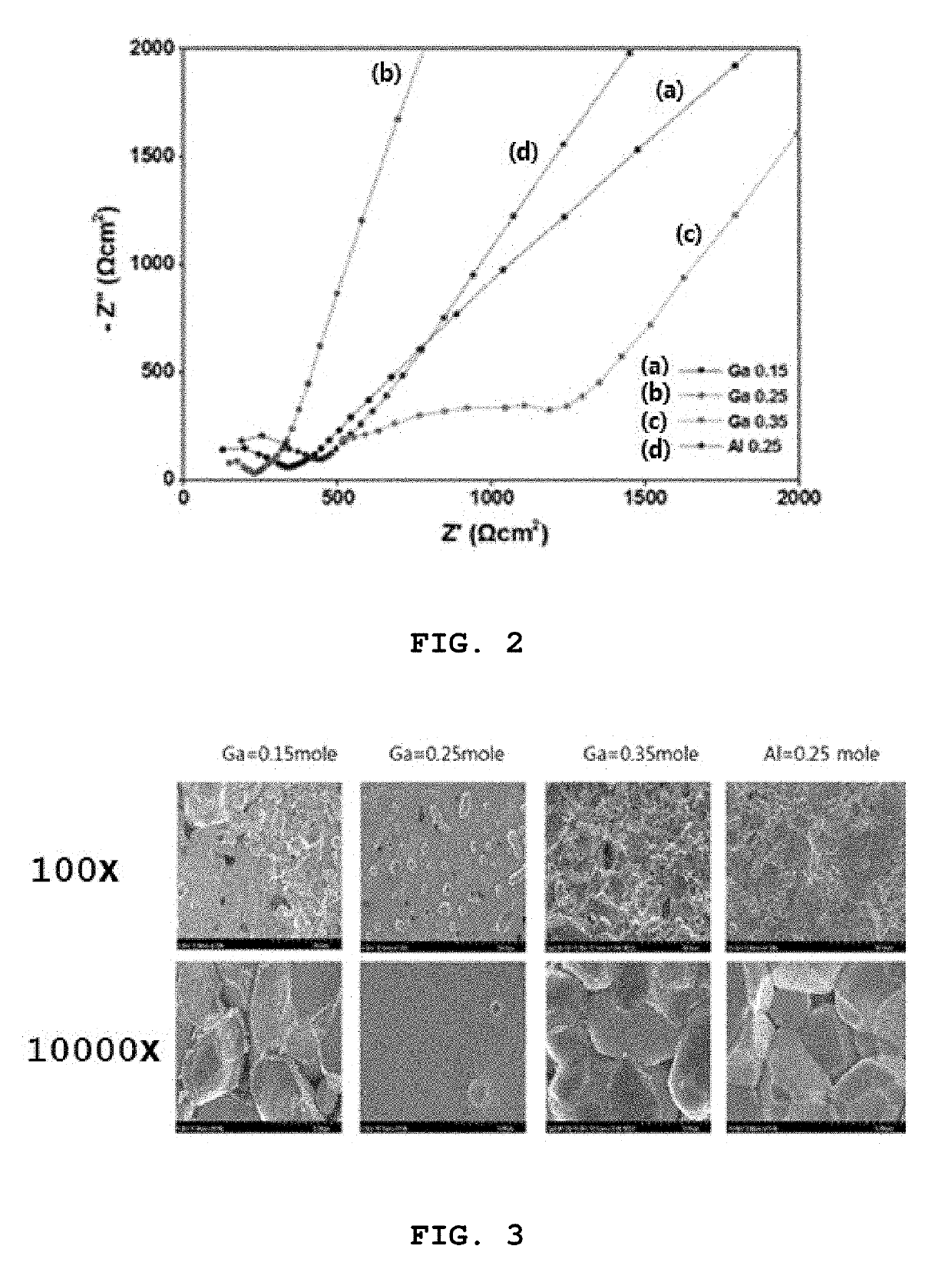

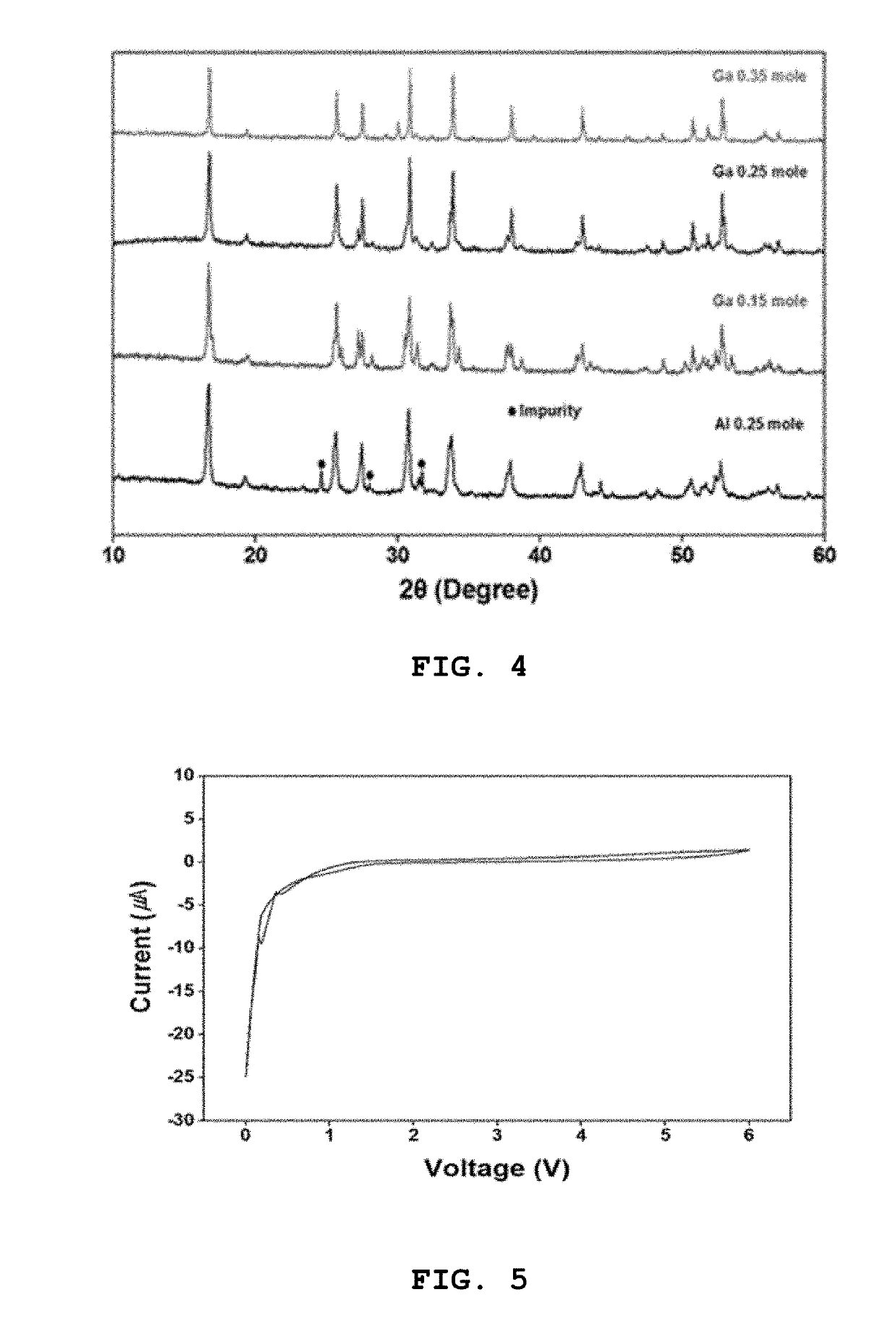

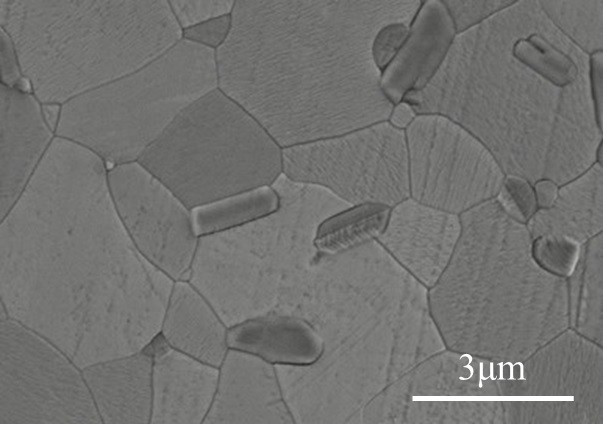

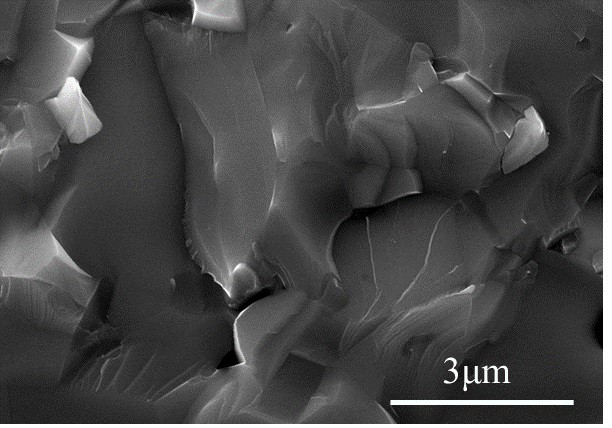

High ion conductive solid electrolyte for all-solid state battery and method for preparing same

ActiveUS20190273283A1Improve ionic conductivityFinal product manufactureElectrolytesAll solid statePhysical chemistry

Disclosed is a method of preparing a solid electrolyte, the method including (a) preparing a solid electrolyte precursor by subjecting a mixed solution composed of a lanthanum precursor, a zirconium precursor, a gallium precursor, a complexing agent, and a pH adjuster to coprecipitation, (b) washing and drying the solid electrolyte precursor, (c) preparing a mixture by mixing the washed and dried solid electrolyte precursor with a lithium source, and (d) calcining the mixture to give a calcined solid electrolyte, which is a gallium (Ga)-doped lithium lanthanum zirconium oxide (LLZO), as represented by Chemical Formula 1. A solid electrolyte having increased ionic conductivity and an improved potential window can be provided using the method of preparing the solid electrolyte.

Owner:KOREA INST OF IND TECH

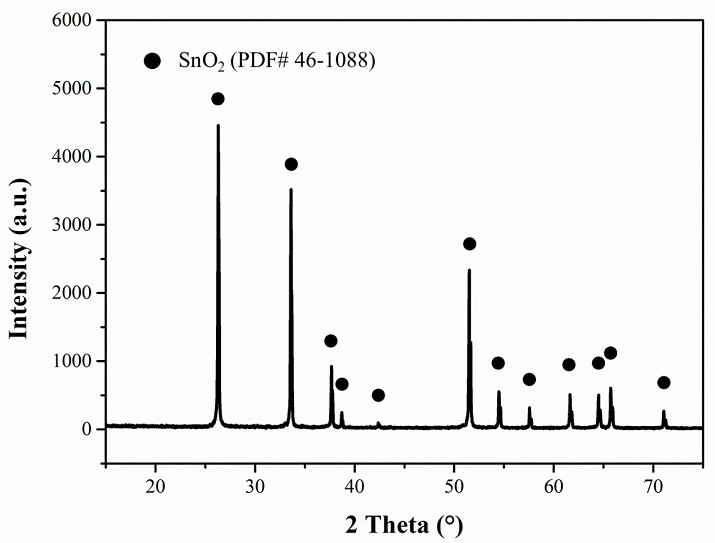

Gallium oxide doped tin oxide ceramic target material and preparation method thereof

The invention provides a gallium oxide doped tin oxide ceramic target material and a preparation method thereof. The gallium oxide doped tin oxide ceramic target material comprises the following raw materials in percentage by mass: 2-10% of gallium oxide and 90-98% of tin oxide high-purity nano powder. The preparation method comprises the following steps: weighing and mixing the powder, adding ammonium polyacrylate, polyvinyl alcohol and pure water, carrying out ball milling on the mixed slurry, granulating, drying to obtain mixed powder, sequentially carrying out compression molding by using an oil press and an isostatic press, and preparing the gallium oxide-doped tin oxide ceramic target material at different sintering temperatures by using a degreasing multi-step sintering integrated sintering technology. According to the doped gallium oxide, the sintering performance of the tin oxide ceramic is effectively improved, the density of the tin oxide ceramic target material is remarkably improved, and meanwhile the gallium oxide doped tin oxide target material which is uniform in structure and fine in grain is obtained through effective control over the preparation process.

Owner:ZHENGZHOU UNIV

Manufacturing process of solar P-type polycrystalline silicon wafer

ActiveCN112359415AReduce dosageGuaranteed consistent stabilityPolycrystalline material growthFine working devicesDopantIngot casting

The invention discloses a manufacturing process of a solar P-type polycrystalline silicon wafer. The manufacturing process comprises the following steps: (1) preparing raw materials; (2) preparing a P-type silicon ingot; (3) cutting and squaring the silicon ingot; and (4) cutting and cleaning the silicon wafer, wherein the used raw materials comprise a primary silicon material with the purity of 6N, a circulating silicon material and a doping agent gallium, the circulating silicon material comprises a circulating silicon plate, a circulating silicon block, a circulating silicon sheet and circulating silicon powder, the circulating silicon material needs to be subjected to impurity removal and purification treatment before being used, the edge of a crucible is filled with the circulating silicon material during ingot casting, the center of the crucible is filled with the primary silicon material doped with gallium, the doping concentration of gallium in the primary silicon material is gradually reduced from the bottom of the crucible to the top of the crucible, the concentration of gallium at the top is zero, the crucible filled with the silicon material is put into a microwave sintering furnace, and the material is discharged out of the furnace after heating, heat preservation and cooling under the protection of argon to obtain the P-type silicon ingot uniformly doped with gallium. According to the method, the circulating silicon material is fully utilized, and the prepared silicon wafer is stable in quality.

Owner:ANYANG INST OF TECH

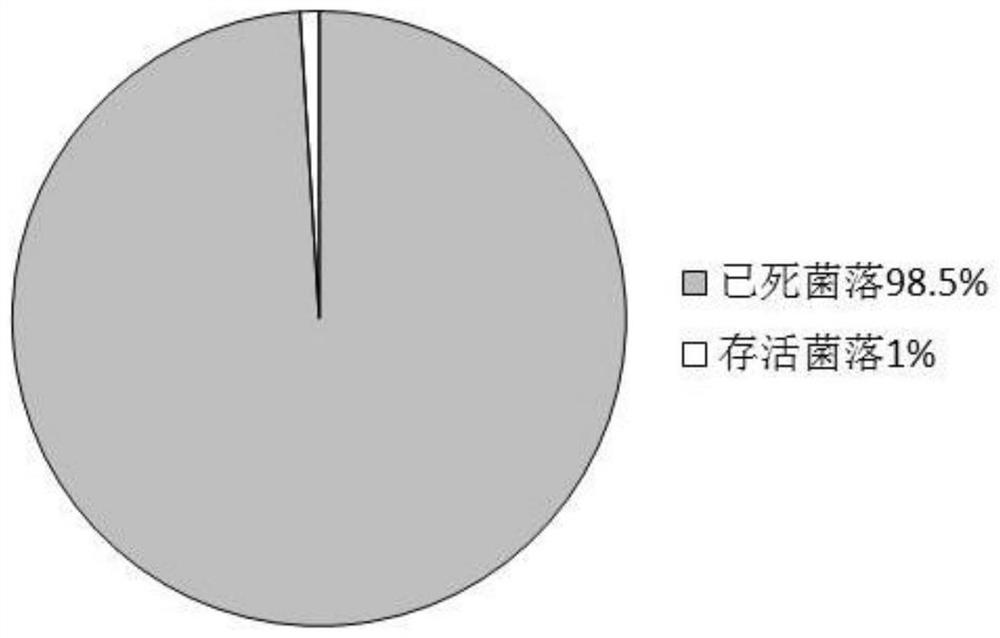

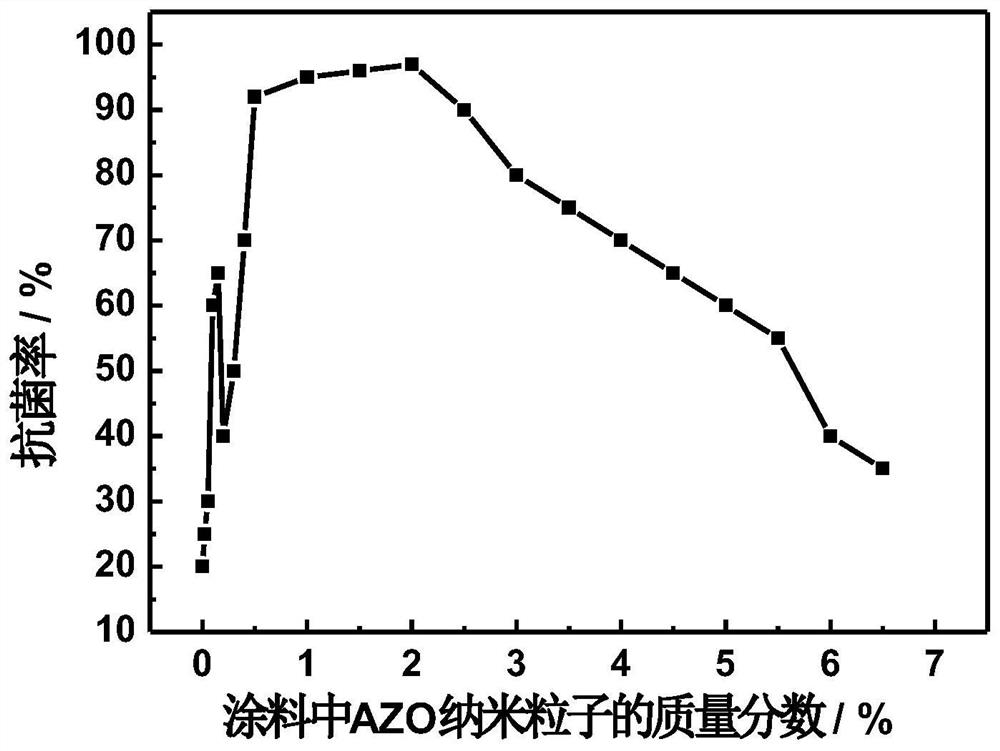

A near- and mid-infrared plasmon resonance nanomaterial, its preparation method and its application in antibacterial and antifungal aspects

ActiveCN108946793BLow costEasy to manufactureAntifouling/underwater paintsZinc oxides/hydroxidesIndiumLight energy

A near- and mid-infrared plasmon resonance nanomaterial, a preparation method and its application in antibacterial and antifungal aspects belong to the technical field of nanomaterials and applications. It specifically relates to aluminum-doped zinc oxide, tin-doped indium oxide, gallium-doped zinc oxide, indium-doped cadmium oxide, indium-doped zinc oxide, antimony-doped tin oxide, fluorine-doped tin oxide, gallium oxide and other nanoparticles. The invention utilizes the quantum effect, small size effect and special structure of nanomaterials to form near- and mid-infrared plasmon resonance phenomena on the surface of nanoparticles, and utilizes the conversion of plasmon resonance energy of near- and mid-infrared light energy to effectively eliminate organic microorganisms. Under the irradiation of sunlight (or ambient light), the surface of these materials produces plasmon resonance absorption, and the energy generated interacts with the protein on the surface of the bacteria to kill the bacteria. At the same time, this type of nanomaterial has a large specific surface area, which makes it easier to have a large area of contact with the surface of bacteria, and is also conducive to the digestion of bacteria.

Owner:JILIN UNIV

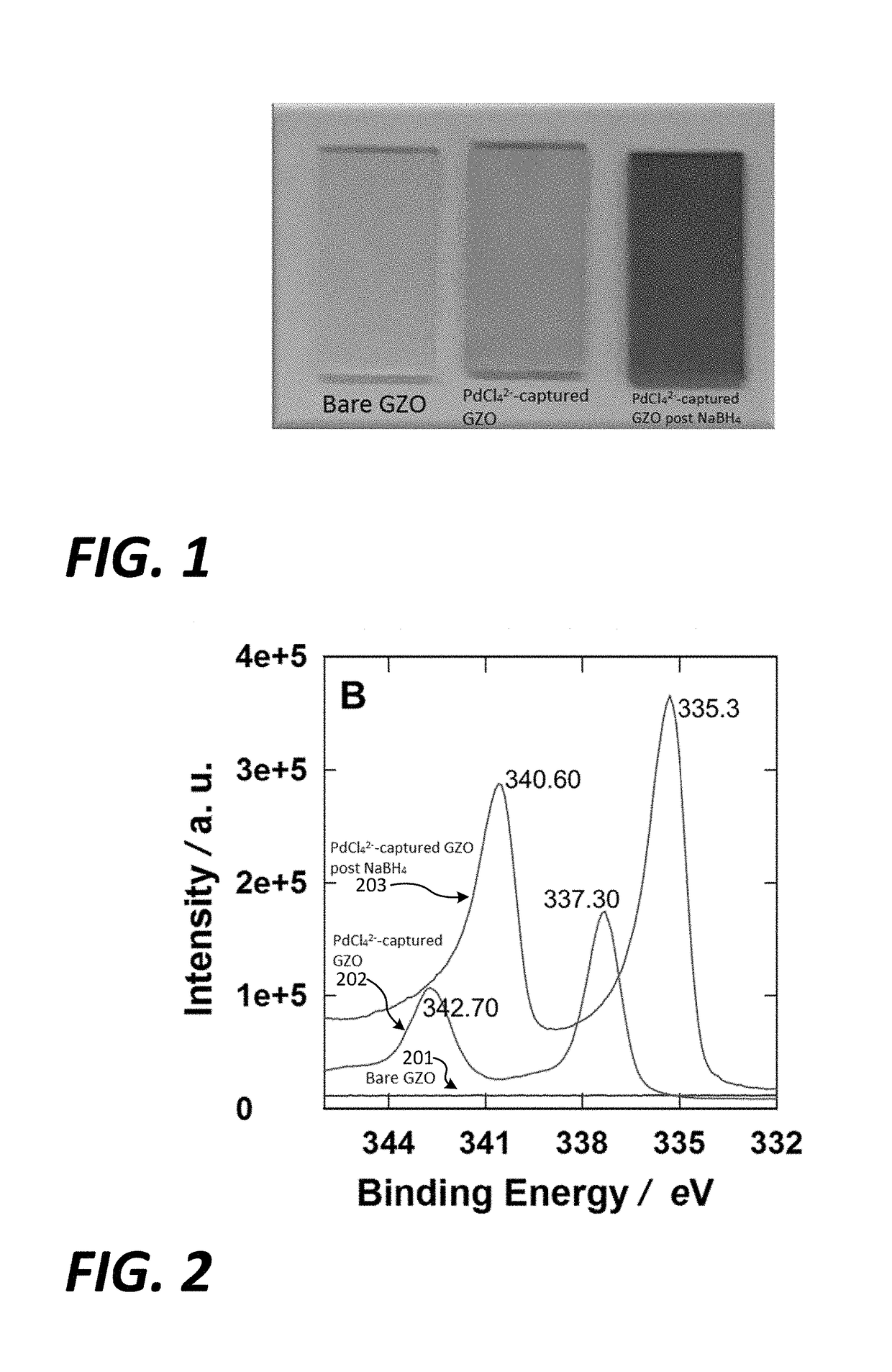

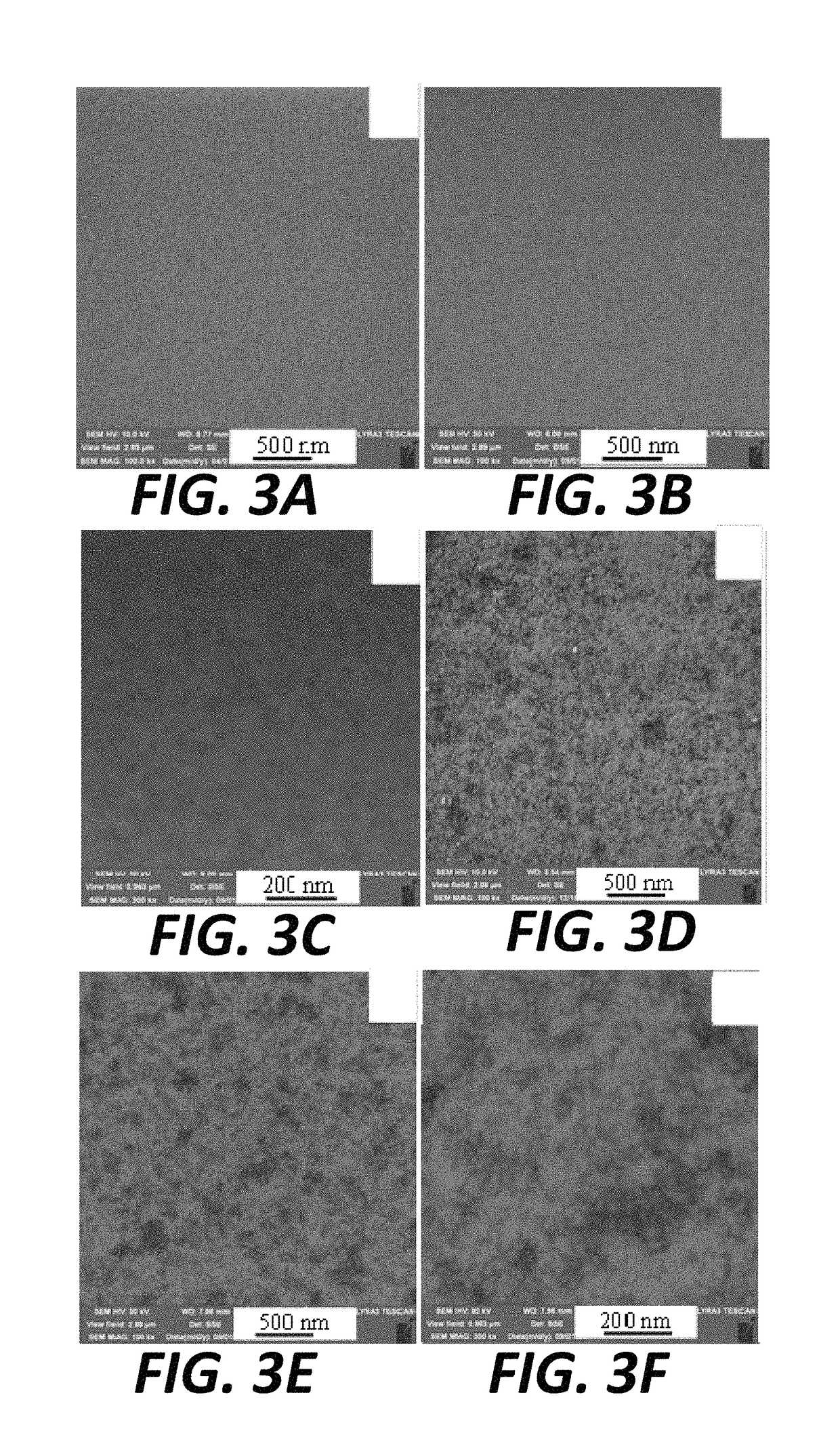

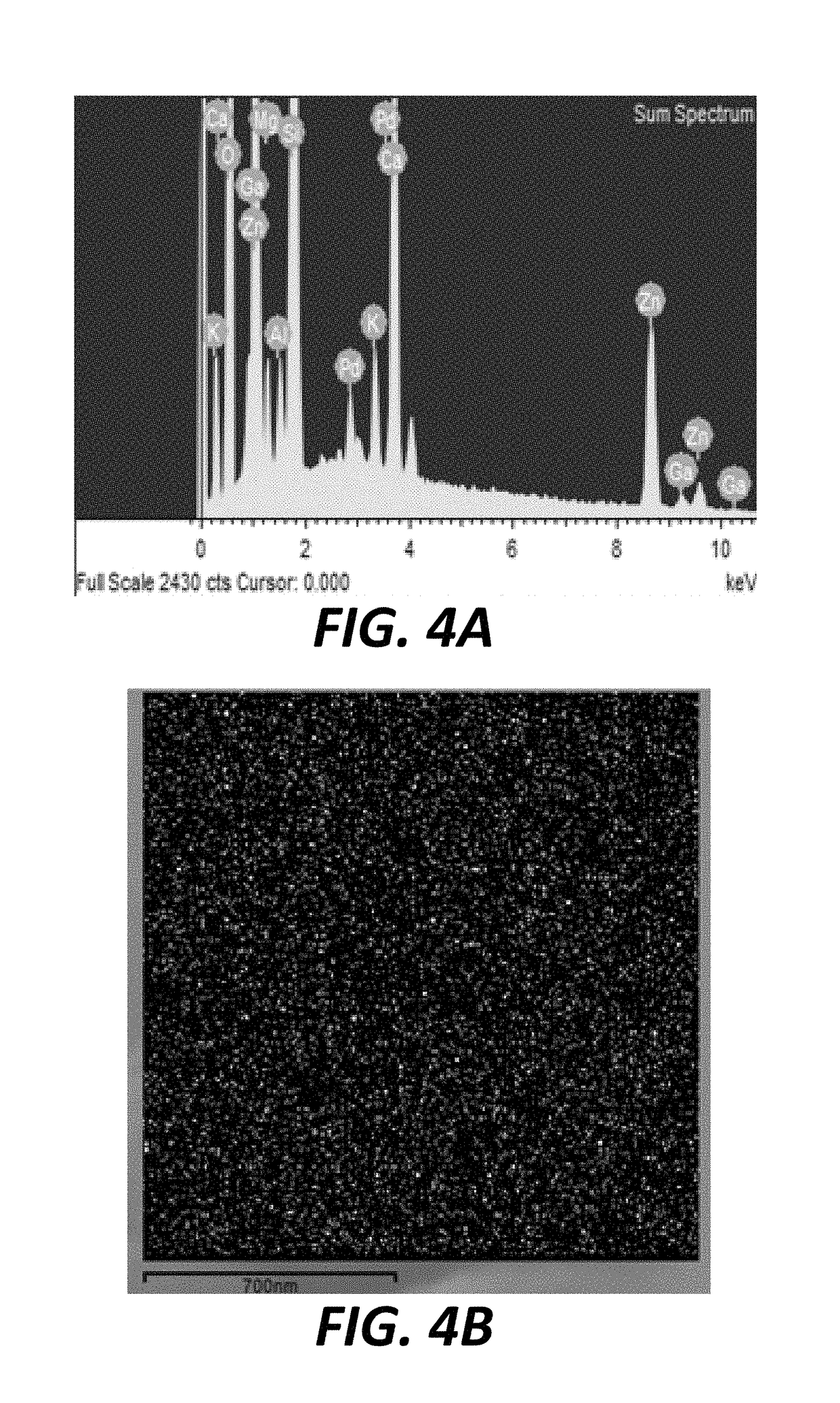

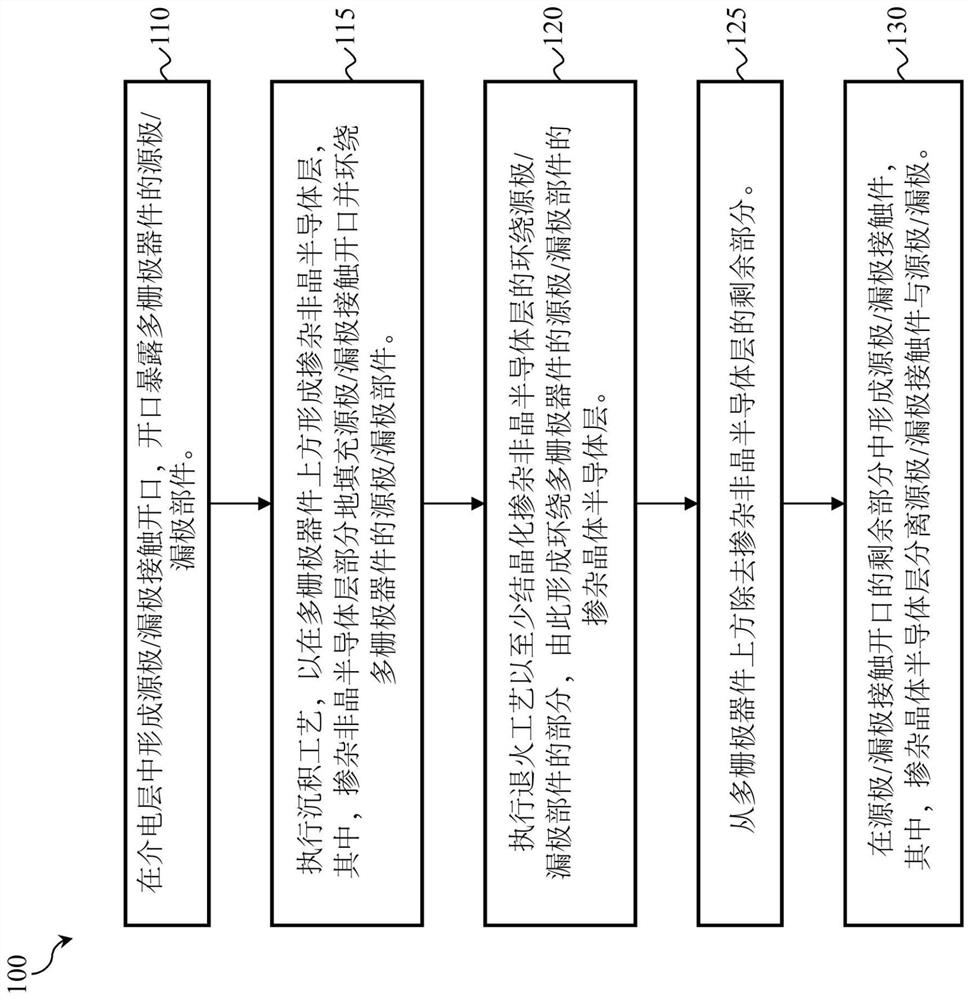

Method for preparing a gallium-doped zinc oxide electrode decorated with densely gathered palladium nanoparticles

A method for manufacturing a palladium coated doped metal oxide conducting electrode including immersing a metal oxide conducting electrode into an aqueous solution having a palladium precursor salt to form the metal oxide conducting electrode having at least one surface coated with palladium precursor. To form a layer of palladium nanoparticles on the metal oxide conducting electrode the palladium precursor on the metal oxide conducting is reduced with a borohydride compound. The palladium nanoparticles on the metal oxide conducting electrode have an average diameter of 8 nm to 22 nm and are present on the surface of the metal oxide conducting electrode at a density from 1.5×10−3 Pd·nm−2 to 3.5×10−3 Pd·nm−2.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

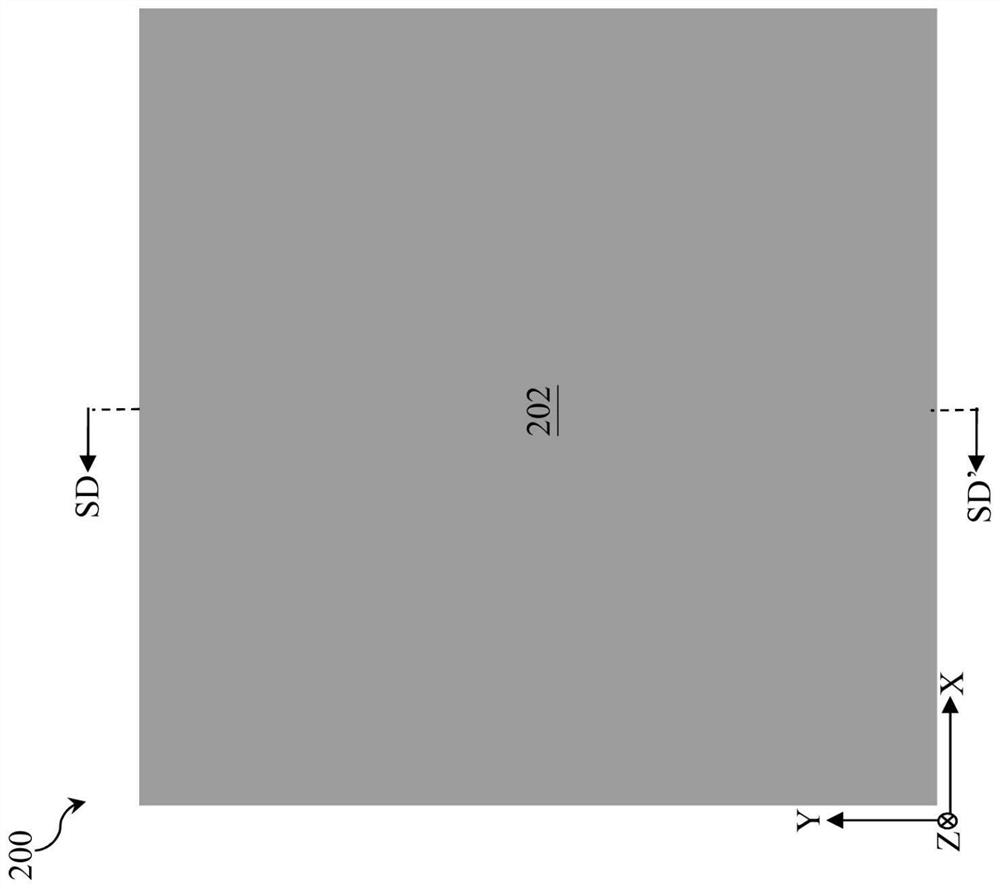

Multi-gate device and forming method thereof

PendingCN113394216AReduce contact resistivityTransistorSolid-state devicesGallium dopingCondensed matter physics

The invention relates to a multi-gate device and a method of forming the same. An exemplary device includes a channel layer, a first epitaxial source / drain feature, and a second epitaxial source / drain feature disposed over a substrate. The channel layer is disposed between the first epitaxial source / drain feature and the second epitaxial source / drain feature. A metal gate is disposed between the first epitaxial source / drain feature and the second epitaxial source / drain feature. The metal gate is disposed over and in physical contact with at least two sides of the channel layer. A source / drain contact is disposed over the first epitaxial source / drain feature. A doped crystalline semiconductor layer, such as a gallium doped crystalline germanium layer, is disposed between the first epitaxial source / drain feature and the source / drain contact. The doped crystalline semiconductor layer is disposed over and in physical contact with at least two sides of the first epitaxial source / drain feature. In some embodiments, the doped crystalline semiconductor layer has a contact resistivity of less than about 1 * 10 <-9 > [Omega]-cm < 2 >.

Owner:TAIWAN SEMICON MFG CO LTD

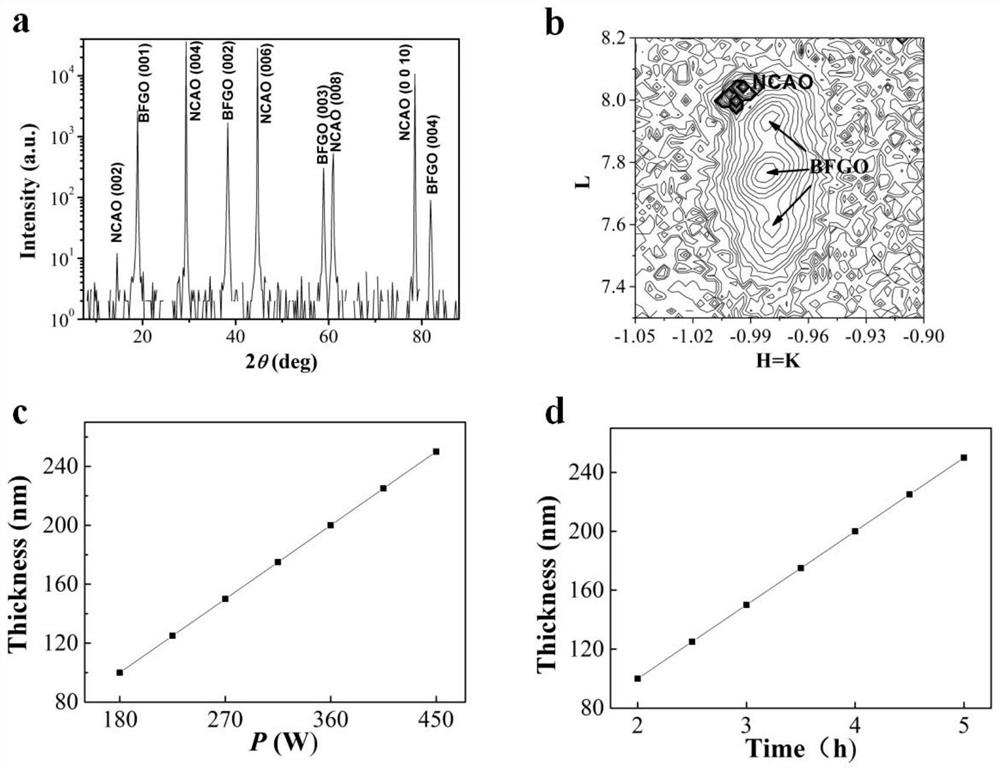

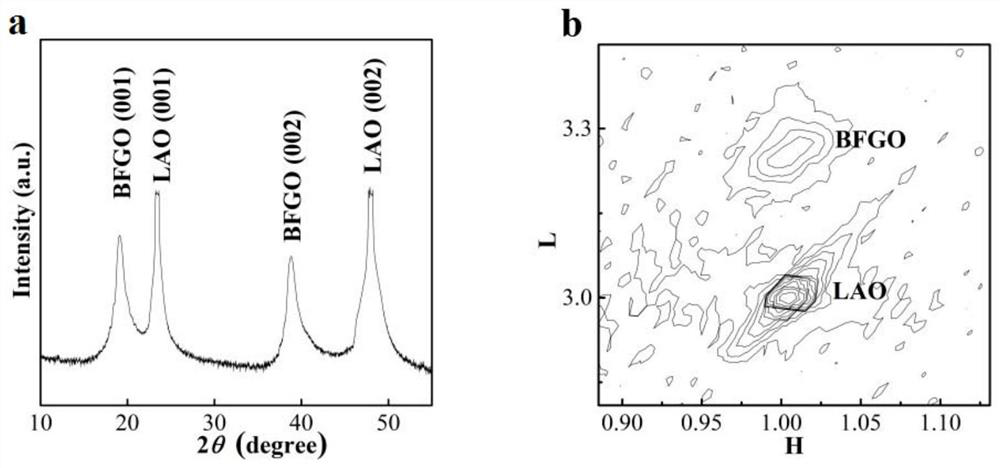

Gallium-doped bismuth ferrite hypertetragonal phase epitaxial thin film and its preparation method and application

ActiveCN109161847BPolycrystalline material growthVacuum evaporation coatingCrystallographyThin membrane

The invention provides a Ga-doped BiFeO3 ultra-tetragonal-phase epitaxial thin film as well as a preparation method and an application thereof. The preparation method of the Ga-doped BiFeO3 ultra-tetragonal-phase epitaxial thin film comprises steps as follows: S1: Bi2O3, Fe2O3 and Ga2O3 are mixed, and then a Ga-doped BiFeO3 block is formed through sintering and pressing; and S2: Ga-doped BiFeO3 isdeposited on a substrate, and the Ga-doped BiFeO3 ultra-tetragonal-phase epitaxial thin film is obtained. The Ga-doped BiFeO3 ultra-tetragonal-phase epitaxial thin film can be used for manufacturingof capacitors. According to the thin film, the preparation method and the application, BiFeO3 is doped with Ga, Ga atoms replace Fe atoms, the distortion degree of the oxygen octahedron is increased,one oxygen atom in the c-axis direction gets close to the central Ga atom, another oxygen atom gets far away from the central Ga atom, the oxygen octahedron is transformed into the oxygen tetrahedralcone, thus the length in the c-axis direction is increased, the ultra-tetragonal phase is stabilized, and the BiFeO3 ultra-tetragonal-phase epitaxial thin film is not limited by factors such as the thickness of the thin film, the strain of the substrate, the buffer layer and the like.

Owner:SOUTH CHINA NORMAL UNIVERSITY

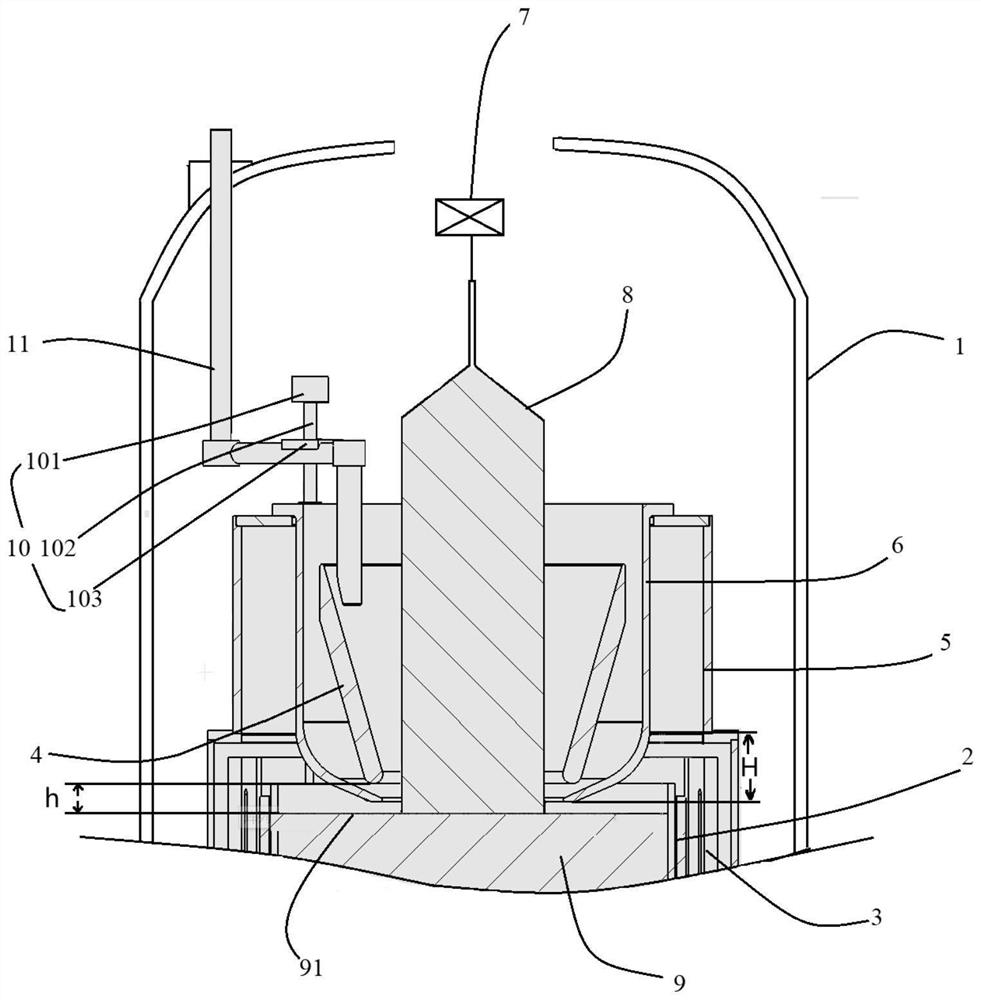

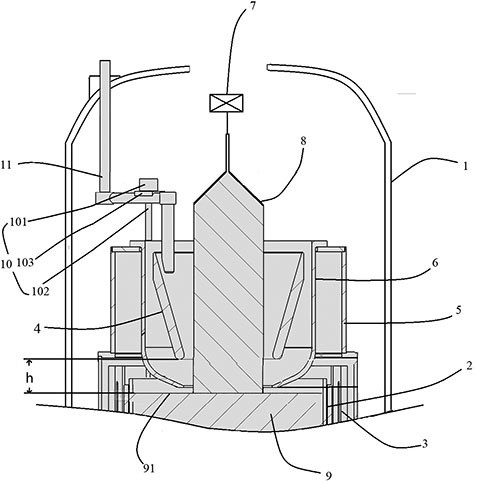

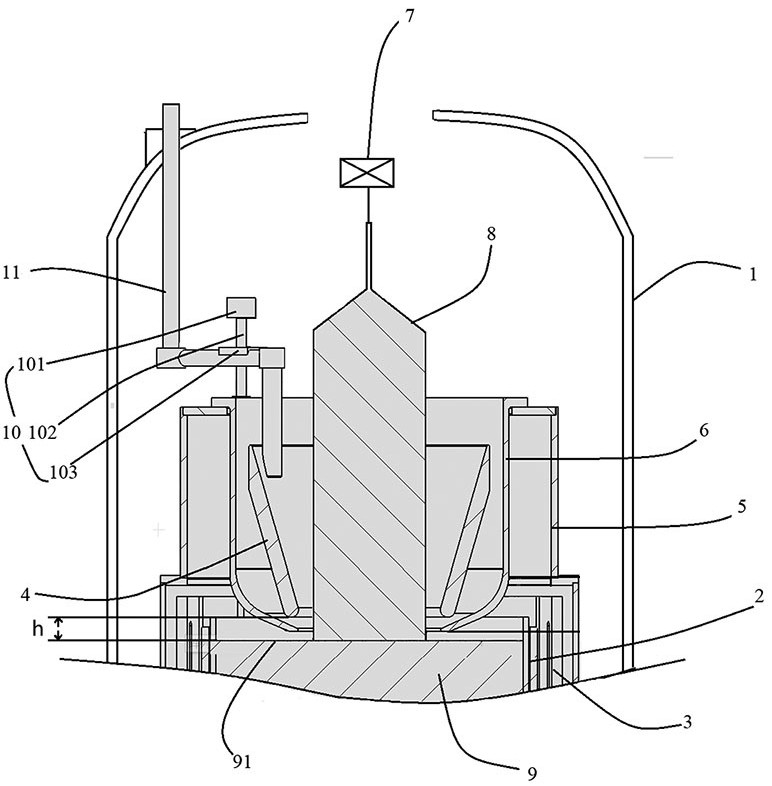

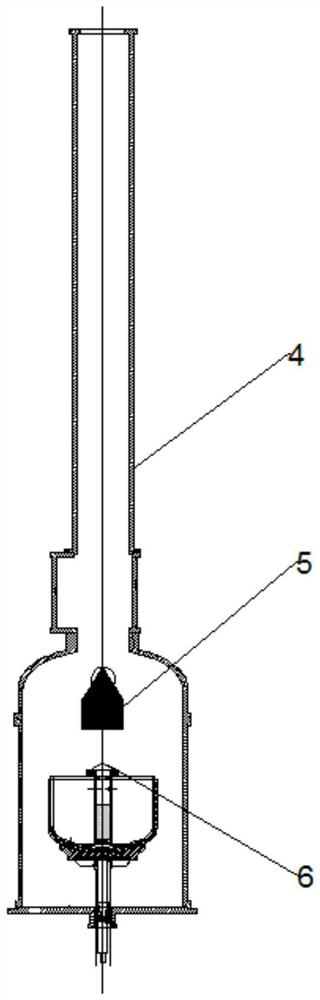

Gallium doping method of Czochralski silicon monocrystalline and doping device thereof

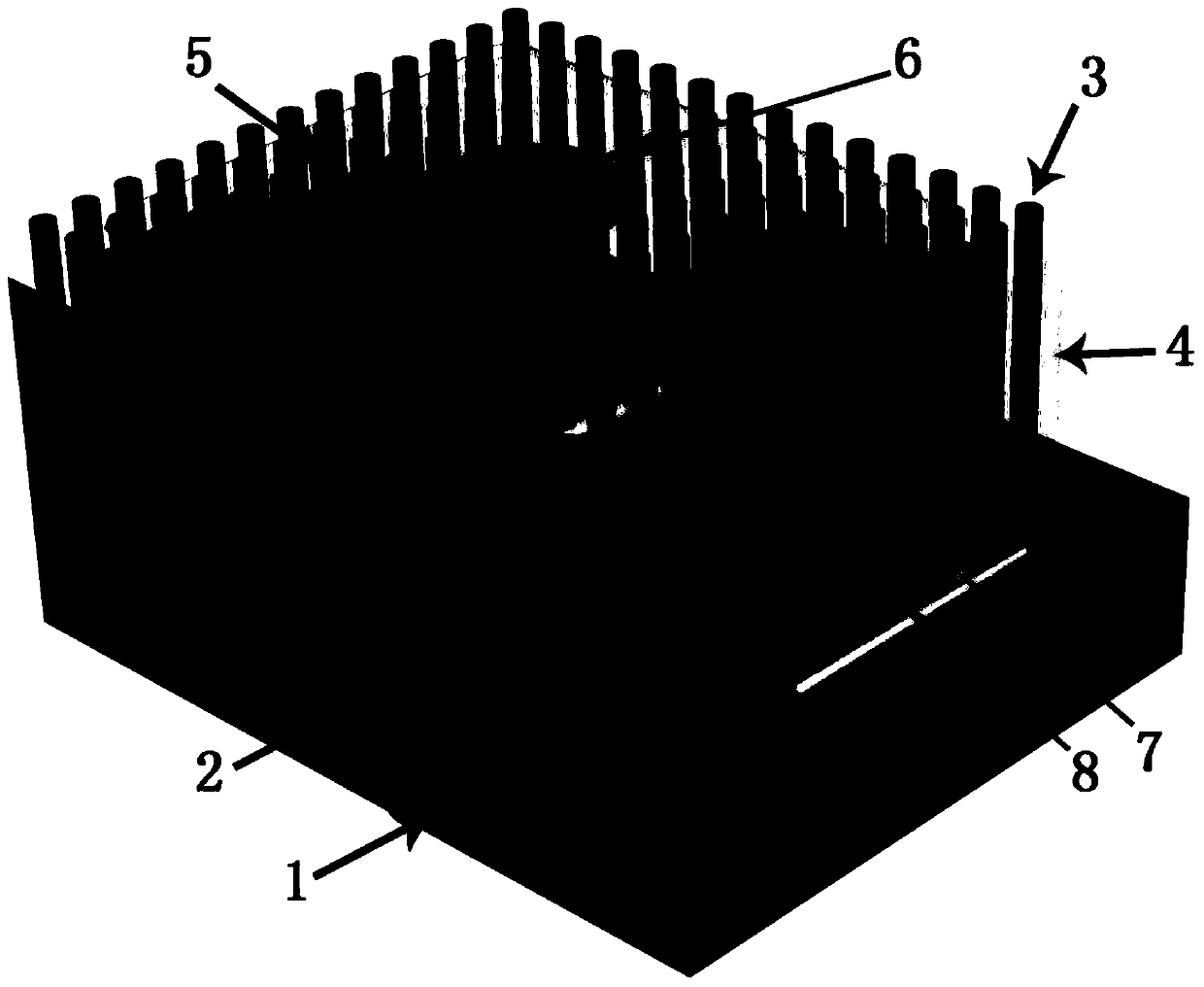

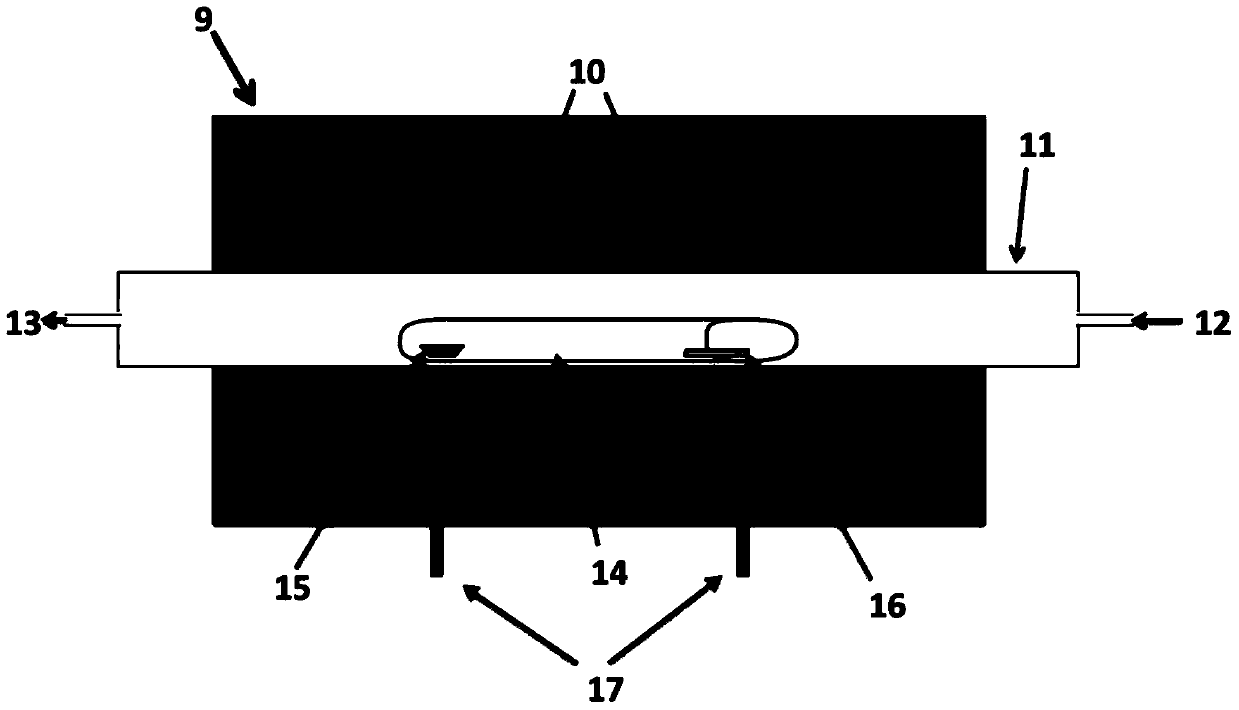

ActiveCN101787566BAvoid spillingReduced risk of poor growthDiffusion/dopingSingle crystalGallium doping

The invention discloses a gallium doping device, comprising a flying ring (2), a ring-shaped fixed sleeve (3) and a hollow cone (4), wherein the flying ring (2) is made of high-purity quartz, the hollow cone (4) is made of high-purity monocrystalline silicon, the ring-shaped fixed sleeve (3) is connected with the hollow cone (14), one end of the flying ring (2) is connected with the ring-shaped fixed sleeve (3), the other end of the flying ring (2) is connected with a handle part (1), and the handle part (1) is provided with a groove (11) which is matched with a crystal seed chuck on a crystal seed rod. The invention also discloses a doping method of gallium of Czochralski silicon monocrystalline through the gallium doping device. The invention can effectively avoid the poor influence on crystal growing caused by the splash of silicon melt.

Owner:ZHEJIANG HAINA SEMICON CO LTD

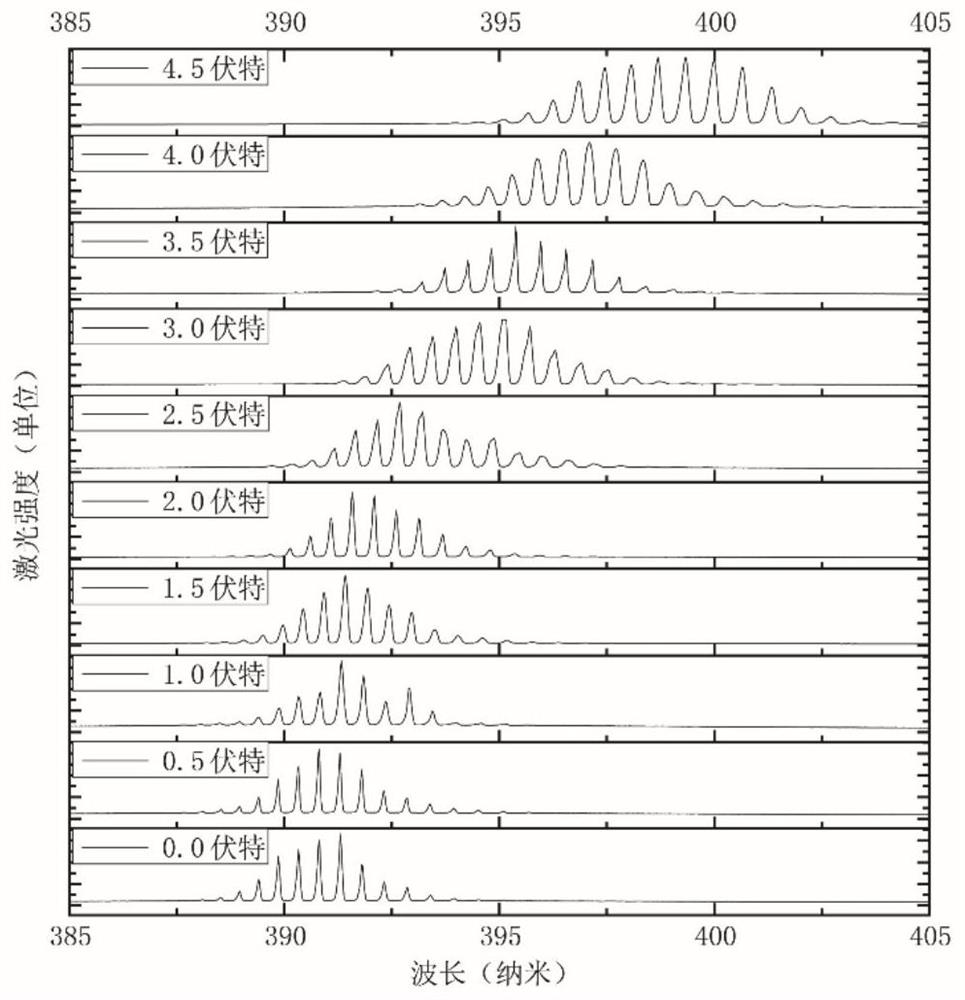

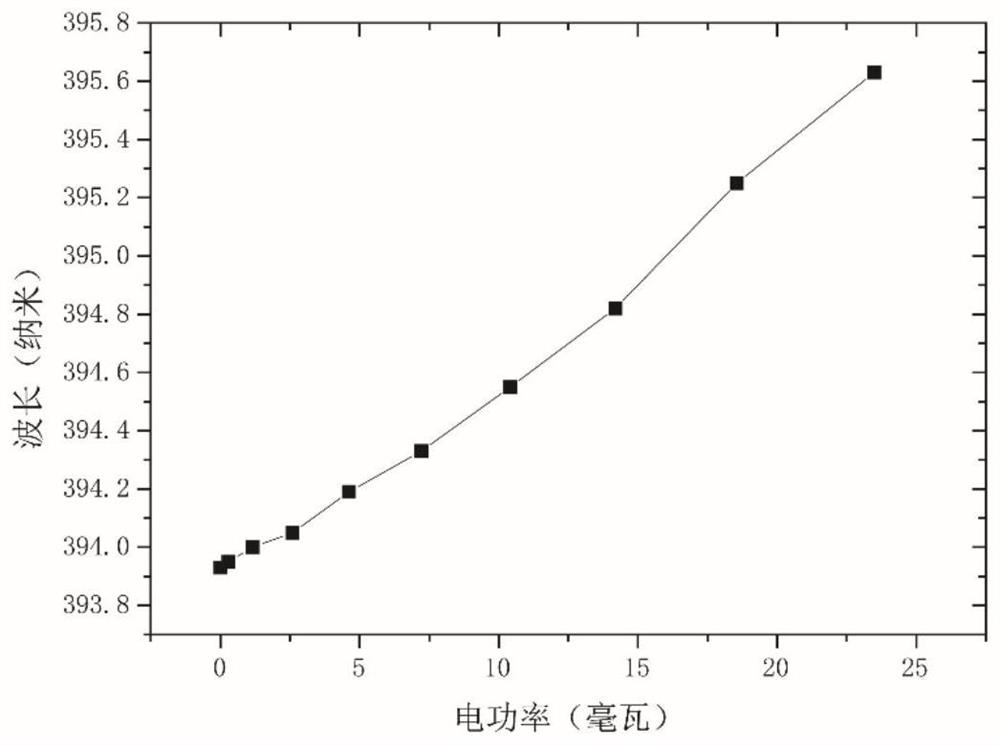

Method for dynamically regulating and controlling laser mode based on thermo-optic effect

PendingCN113300216ARegulation method dynamicsControl method real-timeLaser optical resonator constructionLaser active region structureElectronic temperatureMaterials science

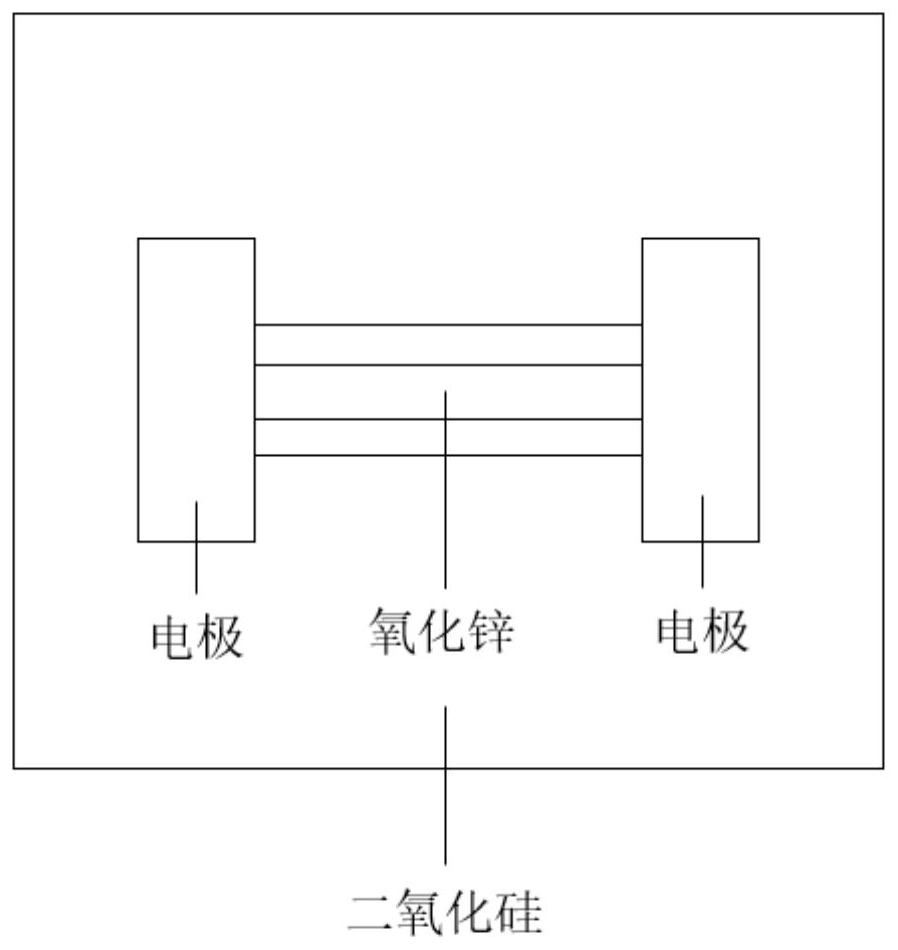

The invention discloses a method for dynamically regulating and controlling a laser mode based on a thermo-optic effect. The method comprises the following steps of placing a gallium-doped zinc oxide microrod on an insulating substrate, and preparing electrodes at the two ends of the gallium-doped zinc oxide microrod; focusing a pump light source on the zinc oxide microrod for optical excitation, and collecting an optical signal of the gallium-doped zinc oxide microrod; applying a voltage to the gallium-doped zinc oxide microrod by using a direct-current power supply, and observing an injection current; meanwhile, carrying out optical pumping, collecting the optical signals after electrification in real time, and comparing and analyzing the spectral signals before and after electrification. According to the invention, Joule heat generated during electric injection is utilized to realize the laser mode dynamic regulation and control of a ZnO microcavity. Compared with a traditional environment thermal control mode, the electric injection mode has the advantages of being more flexible in operation, fast in heating, high in accuracy and the like. The working mode of electronic temperature control lays a solid foundation for the practicability and integration of a tunable laser.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

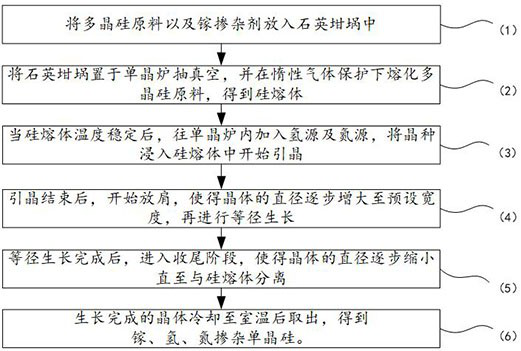

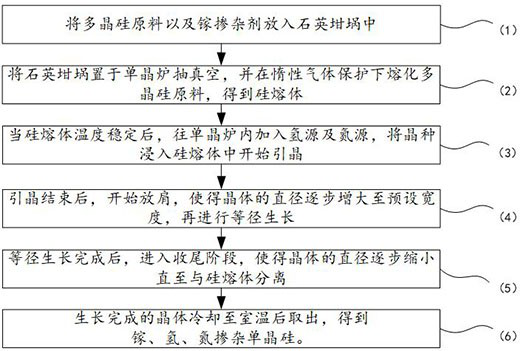

Growth method of gallium-doped Czochralski single crystal silicon, gallium-doped single crystal silicon and its application

ActiveCN112831828BNarrow resistivity distributionReduce manufacturing costPolycrystalline material growthFinal product manufactureDopantPhysical chemistry

The invention discloses a growth method of gallium-doped Czochralski single crystal silicon, gallium-doped single crystal silicon and its application, and relates to the technical field of single crystal silicon. In this growth method, polysilicon raw materials and gallium dopants are heated to the silicon melt, and silicon crystals are grown by Chester Czochralski single crystal method, and gaseous phosphorus dopants or arsenic dopants are introduced during the growth stage of silicon crystals. as a donor dopant. The inventor creatively introduces a gaseous donor dopant, which can significantly increase the solidification ratio, and can grow larger-quality silicon crystals in the same quality silicon melt, thereby significantly improving the crystal production efficiency. The gallium-doped single crystal silicon prepared by the above method has a narrower resistivity distribution and low preparation cost, and can be applied in solar cells.

Owner:杭州晶宝新能源科技有限公司

Electroluminescent device with dynamically adjustable wavelength and adjusting method thereof

InactiveCN112467001AImprove crystal qualityGood optical performanceSemiconductor devicesPoint lightEngineering

The invention discloses an electroluminescent device with dynamically controllable wavelength and a control method thereof. The electroluminescent device comprises a flexible substrate and a gallium-doped zinc oxide microwire arranged on the substrate, wherein two ends of the gallium-doped zinc oxide microwire are fixed on the flexible substrate and connected with electrodes; a single ZnO: Ga micron wire with excellent optical performance is used as a light emitting source, and band gap reforming is induced by applying external mechanical strain, so that dynamic and continuous regulation and control on the electroluminescent wavelength are realized. The invention provides an effective strategy for developing a light-emitting device with dynamically adjustable wavelength, is simple and convenient to operate, and has a huge application prospect in the fields of wavelength tunable point light sources, photoelectric modulators, strain sensing and the like in the future.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A kind of high-efficiency planar perovskite solar cell and its preparation method

ActiveCN107799654BReduce manufacturing costParameter conditions are easy to controlSolid-state devicesSemiconductor/solid-state device manufacturingTitanium chlorideMetal electrodes

Owner:SOUTH CHINA NORMAL UNIVERSITY

A kind of manufacturing process of solar p-type polysilicon wafer

ActiveCN112359415BReduce dosageGuaranteed consistent stabilityPolycrystalline material growthFine working devicesDopantIngot casting

Owner:ANYANG INST OF TECH

Solar cell and preparation method of gallium and hydrogen doped monocrystalline silicon

PendingCN112151628AImprove conversion efficiencyReduced activityPolycrystalline material growthFinal product manufactureSolar batteryGallium doping

The invention provides a solar cell and a preparation method of gallium and hydrogen doped monocrystalline silicon. The solar cell comprises a semiconductor substrate, a doped layer located on the front surface of the semiconductor substrate, a front surface passivation layer and / or anti-reflection layer located on the upper surface of the doped layer, a front surface electrode located on the upper surface of the front surface passivation layer and / or anti-reflection layer, a back surface passivation layer located on the back surface of the semiconductor substrate and a back surface electrodelocated on the back surface of the back surface passivation layer, wherein the semiconductor substrate comprises gallium and hydrogen-doped monocrystalline silicon, the hydrogen doping concentration in the gallium and hydrogen-doped monocrystalline silicon is 1*10<5> to 1*10<16> atoms / cm<3>, the gallium doping concentration is 1*10<15> to 5*10<17> atoms / cm<3>, and the resistivity of the gallium and hydrogen-doped monocrystalline silicon is 0.1-10 [ohm].cm. According to the solar cell, the minority carrier lifetime in monocrystalline silicon can be effectively prolonged, the passivation effectof the cell is improved, and the conversion efficiency of the solar cell is improved.

Owner:四川晶科能源有限公司 +1

Gallium, hydrogen, nitrogen doped single crystal silicon and its preparation method, solar cell

ActiveCN111996594BImprove life expectancyImprove qualityPolycrystalline material growthFinal product manufactureElectrical batterySolar cell

The present application relates to the field of photovoltaics. The present application provides gallium, hydrogen, and nitrogen-doped single crystal silicon and a preparation method thereof, and a solar cell. The hydrogen doping concentration in the gallium, hydrogen, and nitrogen-doped single crystal silicon is 1×10 5 ~1×10 16 atoms / cm 3 , gallium doping concentration is 1×10 15 ~5×10 17 atoms / cm 3 , with a nitrogen doping concentration of 1×10 12 ~1×10 16 atoms / cm 3 ; The resistivity of the gallium, hydrogen, nitrogen doped single crystal silicon is 0.1~10Ω·cm. The gallium, hydrogen, nitrogen-doped single crystal silicon and its preparation method and solar cell of the present application can effectively improve the minority carrier lifetime in single crystal silicon, help to improve the passivation effect of the battery, improve the mechanical strength of the silicon chip, and improve the solar cell. conversion efficiency.

Owner:JINKO SOLAR CO LTD +1

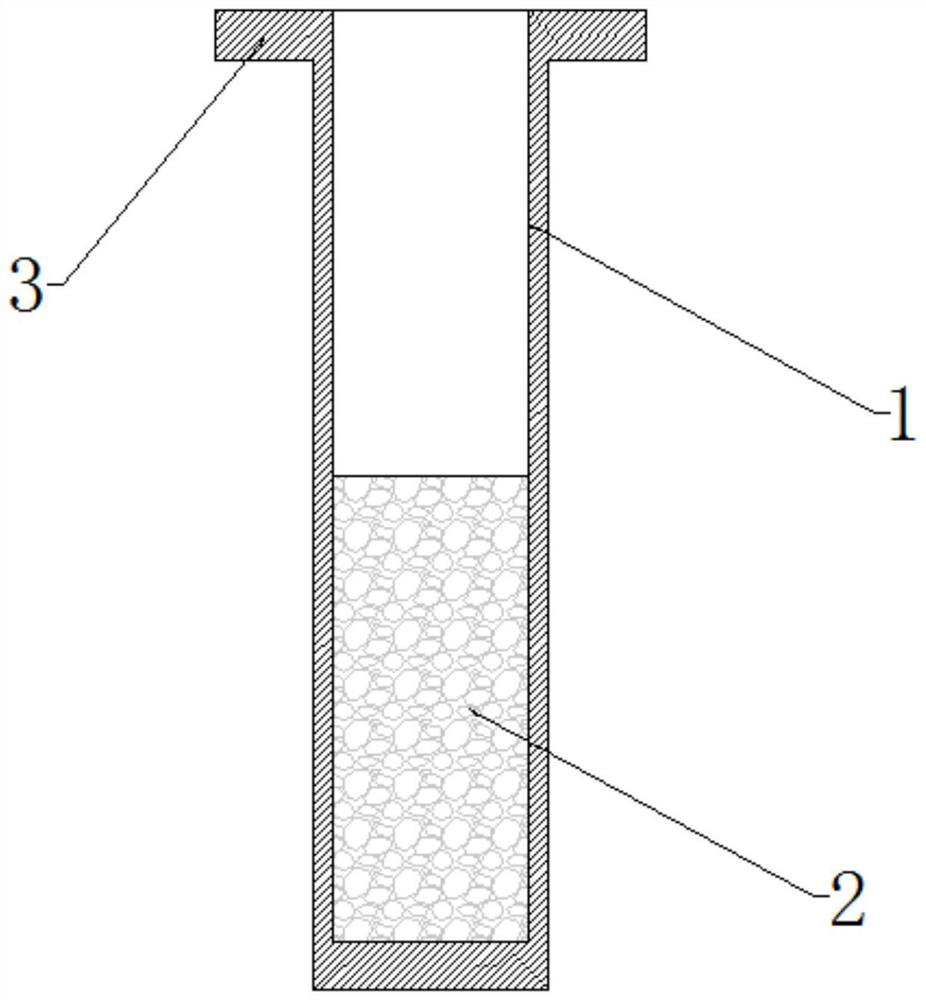

Gallium doping device, gallium doping system and using method

PendingCN113373506ASimple structureEasy to processPolycrystalline material growthBy pulling from meltSingle crystalGallium doping

The invention provides a gallium doping device, which comprises a gallium cylinder main body made of a silicon material and a connecting piece, wherein the gallium cylinder main body is provided with an accommodating cavity for accommodating gallium powder; and the connecting piece is made of a silicon material and is connected with the gallium cylinder main body so as to facilitate the hoisting. The gallium doping device has the advantages that the structure is simple, machining is easy, and the gallium doping process is convenient when the gallium doping device is used for gallium doping; and the gallium doping device is provided with the connecting piece, so that the gallium doping device is conveniently connected with a single crystal furnace heavy hammer through the connecting device, and the gallium doping device descends under the action of the single crystal furnace heavy hammer to perform gallium doping.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

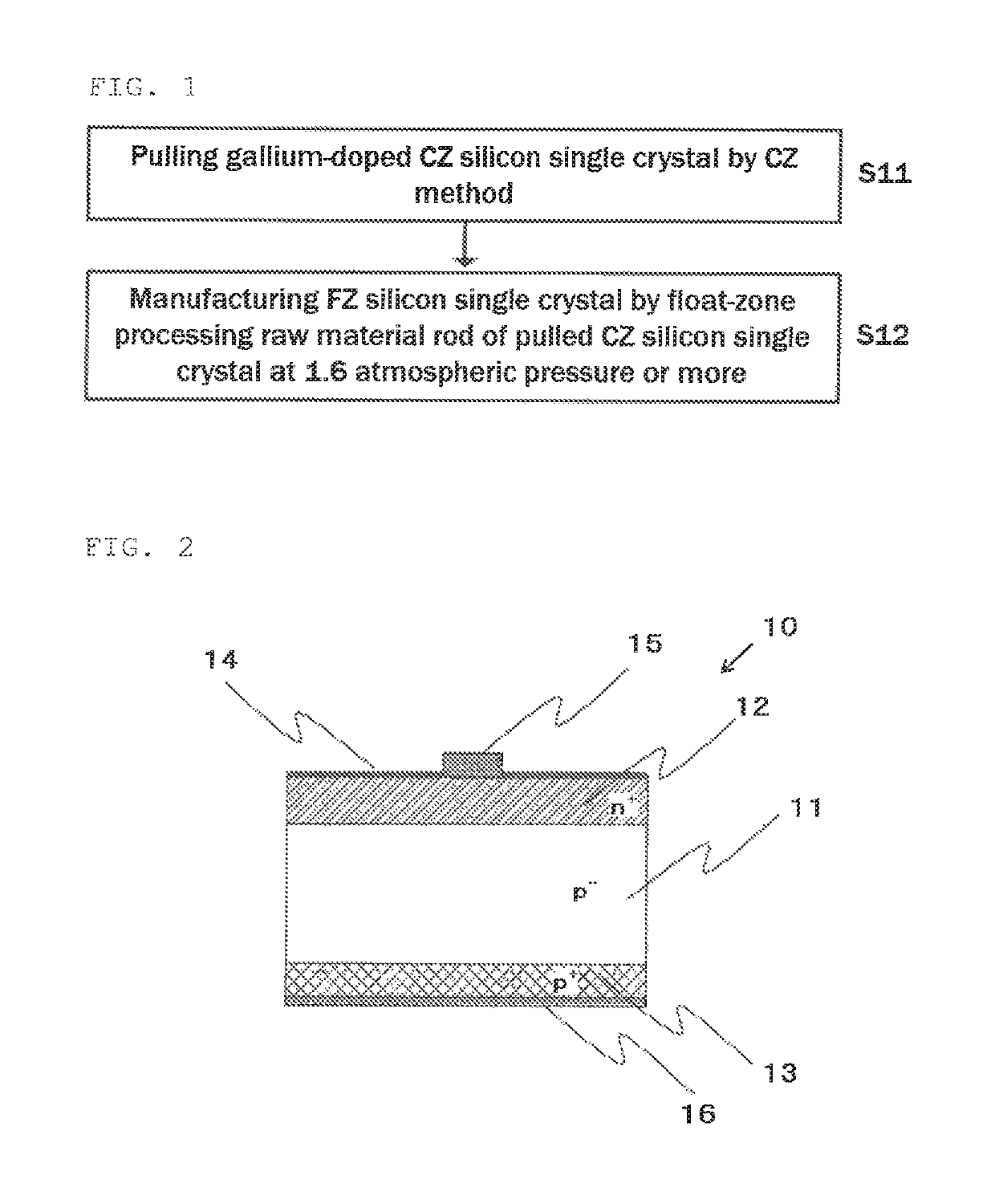

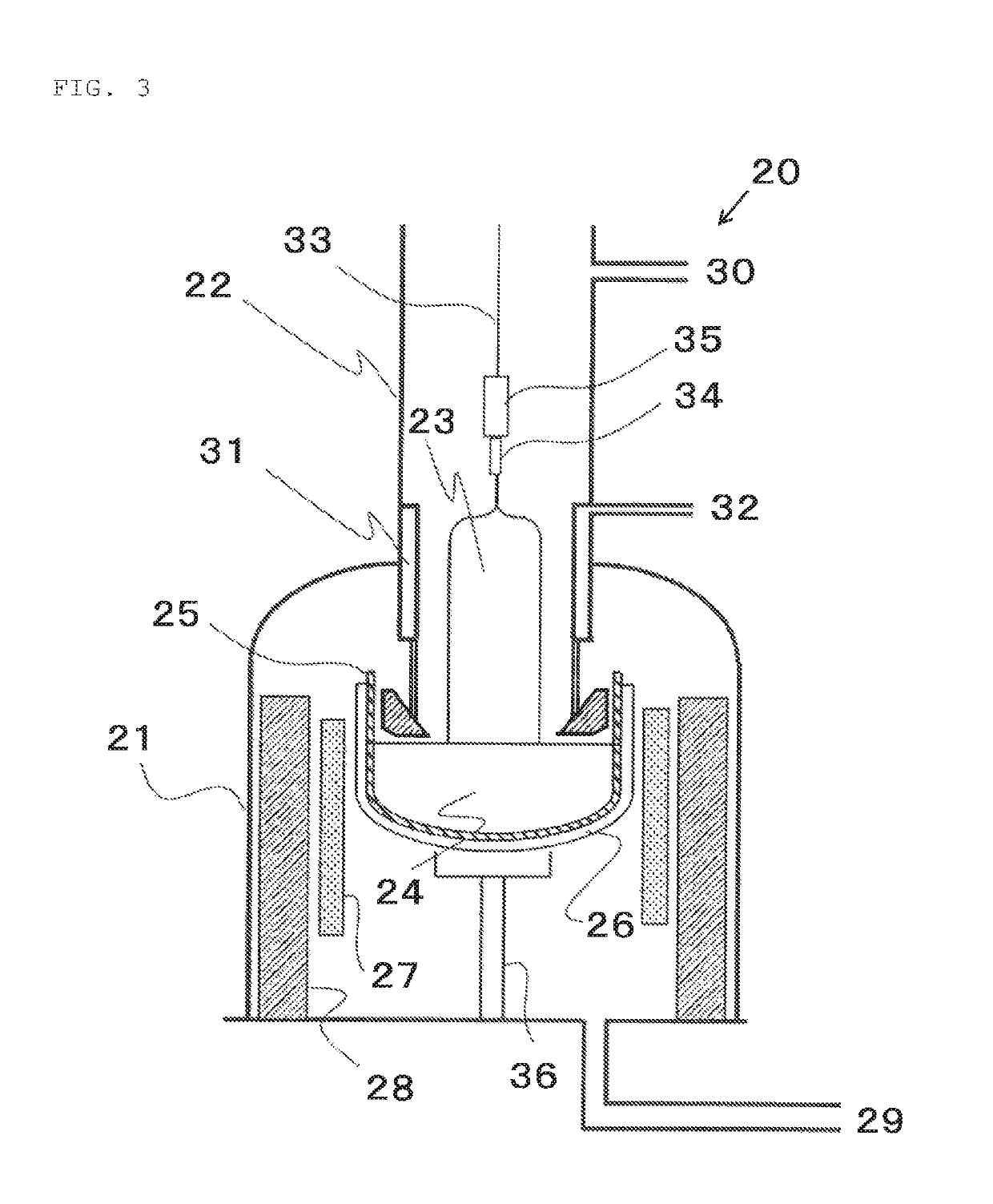

Method for manufacturing a FZ silicon single crystal subject to additional gallium doping for solar cells

ActiveUS10487417B2Reduce the amount requiredImprove the immunityPolycrystalline material growthBy zone-melting liquidsSingle crystalSolar cell

Owner:SHIN ETSU CHEM CO LTD

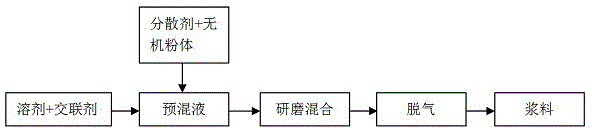

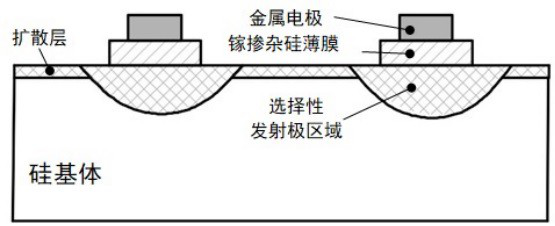

Method for preparing selective emitter by using gallium-doped silicon nano slurry

PendingCN113471314ALow costCan be produced industriallyFinal product manufacturePhotovoltaic energy generationScreen printingPhysical chemistry

The invention discloses a method for preparing a selective emitter by using a gallium-doped silicon nano slurry. The method comprises the following steps of transferring patterns on the front surface of a diffused crystalline silicon solar cell by using a slurry prepared from gallium-doped silicon nano particles as a doping source and adopting silk-screen printing, and drying to form a gallium-doped silicon nano film; and forming a selective diffusion area with local heavily doped gallium on the front surface of the cell by adopting a laser-assisted diffusion process, and then finally obtaining the solar cell with a selective emitter through subsequent solar cell processes such as cleaning of redundant doping sources and overprinting of metal electrodes. The preparation method of the selective emitter can be completely compatible with an existing solar cell production process, new equipment does not need to be added, the production cost is low, and the preparation method is suitable for industrial production.

Owner:YANCHENG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com