Manufacturing method of gallium doped zinc oxide target material

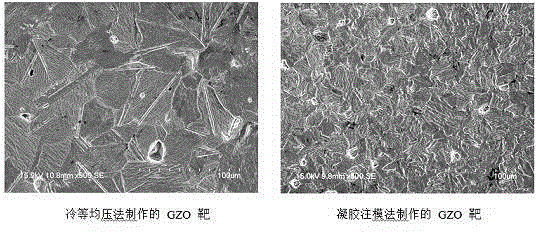

A manufacturing method and technology of zinc oxide, applied in the field of manufacturing gallium-doped zinc oxide targets using gel injection molding technology, can solve the problems of high cost and complicated preparation process, and achieve fast forming speed, low process cost and high density highly controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

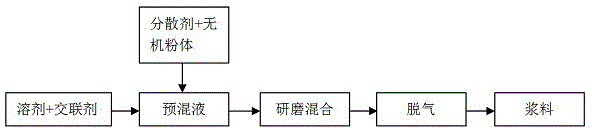

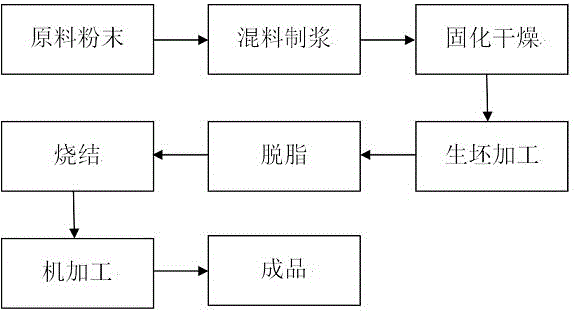

Method used

Image

Examples

Embodiment 1

[0033] In this example, 9900 grams of zinc oxide powder and 100 grams of gallium oxide powder were weighed with a digital electronic balance. The raw material composition was 99 wt % zinc oxide and 1 wt % gallium oxide, the average particle size was 1 μm, and the powder purity was greater than 99.9 %, made into mixed raw material powder.

[0034] Fully dissolve pure water, acrylamide monomer, and N-N' dimethylbisacrylamide in a weight ratio of 100:10:1.5 to form a premix solution of 1975 grams.

[0035] Add 0.1wt% JA-281, which has no residue after sintering, as a dispersant to the premix, and adjust the pH to 9.5.

[0036] Add 60wt% of the raw material into the premix liquid and place it in a ball mill for 30 minutes, then put the remaining 40wt% of the raw material powder into the ball mill and continue ball milling for 24 hours, and use zirconia balls as the ball milling medium for the slurry in the ball mill. Ball milling prepares a slurry with a powder volume content of ...

Embodiment 2

[0044] In this example, 9800 grams of zinc oxide powder and 200 grams of gallium oxide powder were weighed with a digital electronic balance. The raw materials consisted of 98 wt% zinc oxide and 2 wt% gallium oxide, with an average particle size of 1 μm and a powder purity greater than 99.9 %, made into mixed raw material powder.

[0045] Fully dissolve pure water, acrylamide monomer, and N-N' dimethylbisacrylamide in a weight ratio of 100:15:2.5 to form 1975 grams of premix.

[0046] Add 0.1wt% JA-281, which has no residue after sintering, as a dispersant to the premix, and adjust the pH to 9.5.

[0047] Add 60wt% of the raw material into the premix liquid and place it in a ball mill for 30 minutes, then put the remaining 40wt% of the raw material powder into the ball mill and continue ball milling for 24 hours, and use zirconia balls as the ball milling medium for the slurry in the ball mill. Ball milling prepares a slurry with a powder volume content of 50%, that is, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com